Convenient well entry device of continuous coal mining equipment assembly of small section mine and well method completed based on same

A technology of equipment components and small sections, which is applied in the directions of earth drilling, transportation and packaging, underground transportation, etc., can solve problems such as low efficiency and poor safety, and achieve the effect of avoiding derailment and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

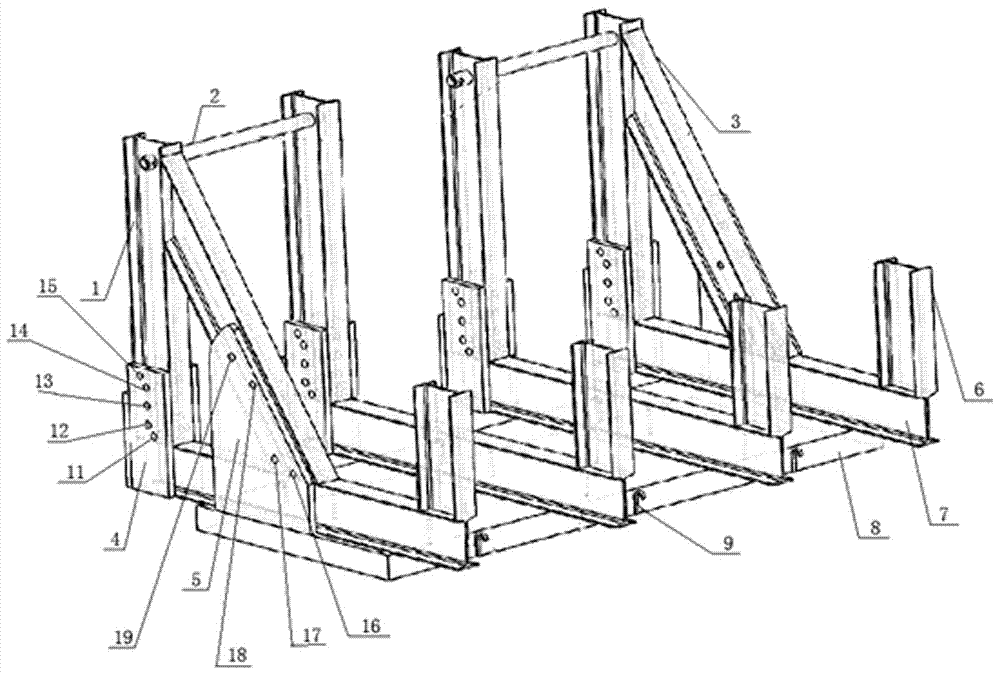

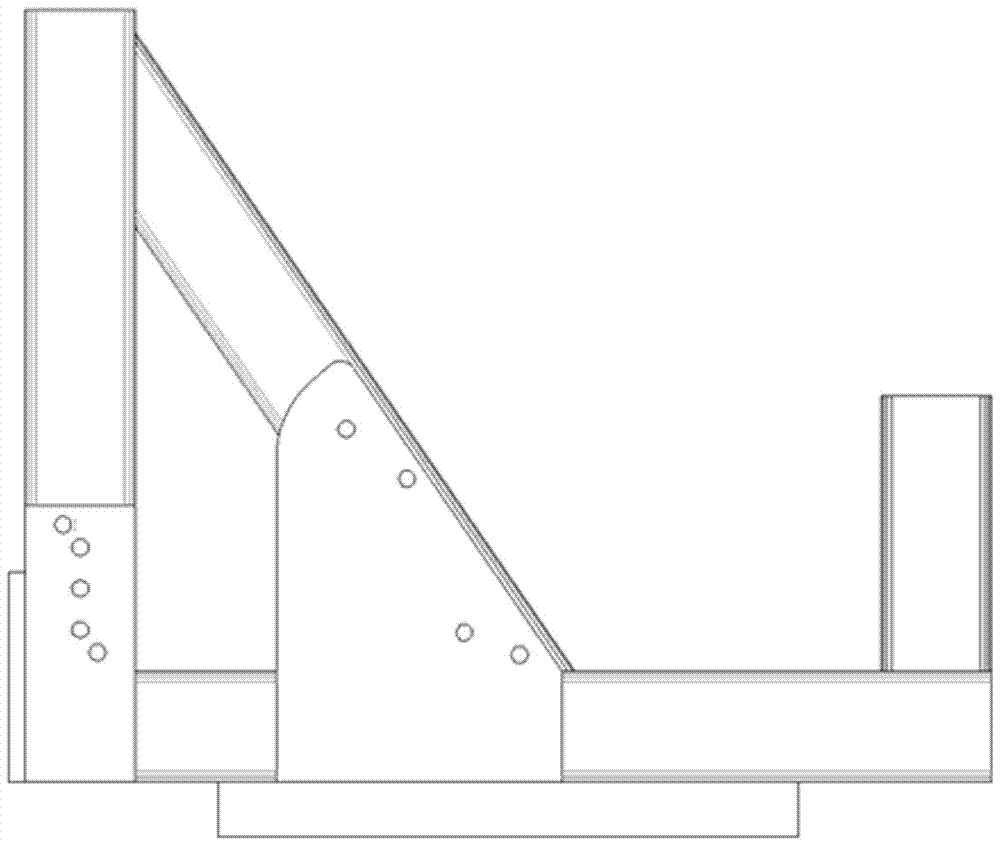

[0036] The device of the present invention will be further described in conjunction with the accompanying drawings.

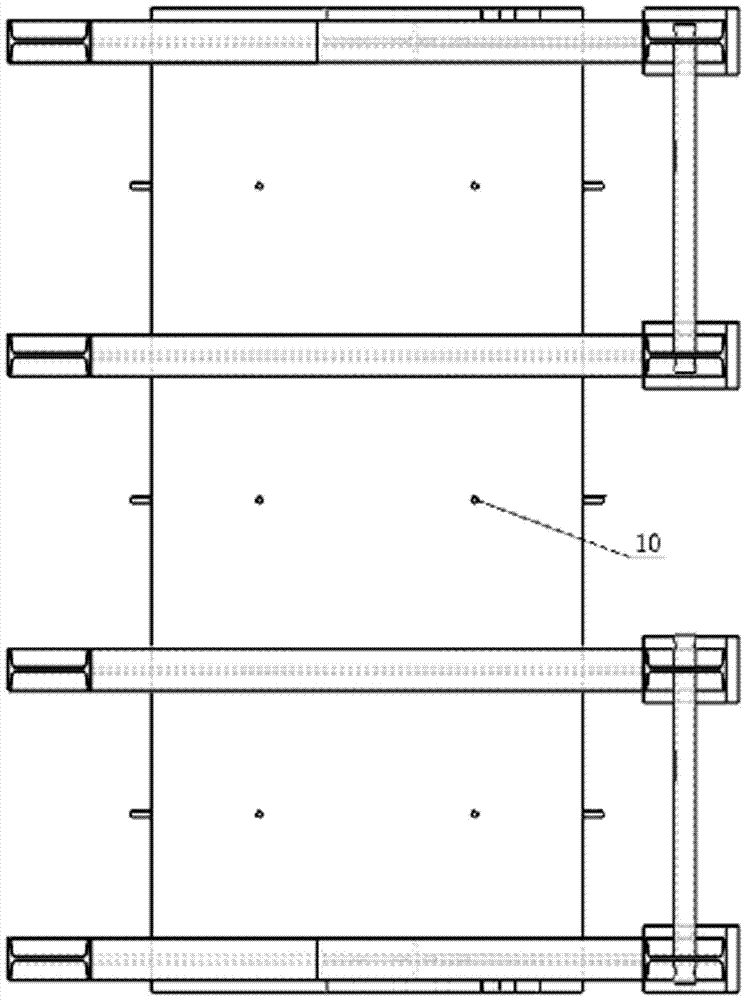

[0037] The present invention relies on the flatbed conveyer 8 for mines with a length of 4 m and a width of 1.05 m, uses four mine connecting beams 7 in the length direction of the flatbed conveyer 8 to divide 3 groove segments, and welds them on the flatbed conveyer 8 , for loading and unloading disassembled parts of different types and sizes, the groove mainly plays the role of facilitating wire rope binding objects and facilitating loading and unloading. In order to realize the transportation of materials with different weights and different sizes, four vertical arms I1 with a height of 1.10~1.20m are installed on one side of the flatbed conveyor 8, and one end of the four vertical arms I1 is connected to four connecting beams welded on the flatbed conveyor 8. 7 Hinged by base I4 and the pin shaft of Φ30mm, adjusting holes are respectively provided on base I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com