Checking method for discharging hopper scale of blast furnace chute

A blast furnace tank and hopper scale technology is applied in the field of blast furnace production, which can solve problems such as poor accuracy and slow speed, and achieve the effects of avoiding uneven space occupation, improving checking speed, and high precision and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

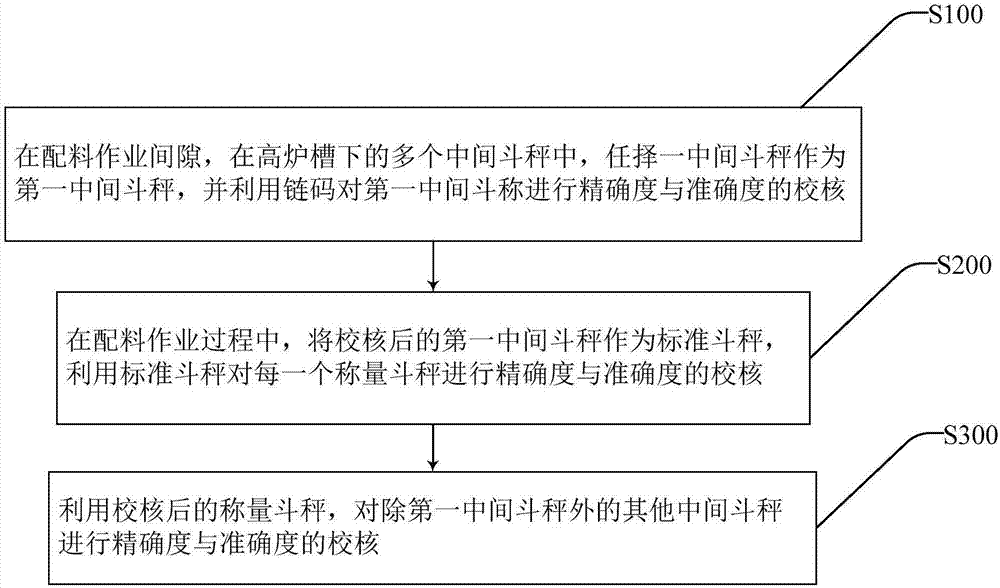

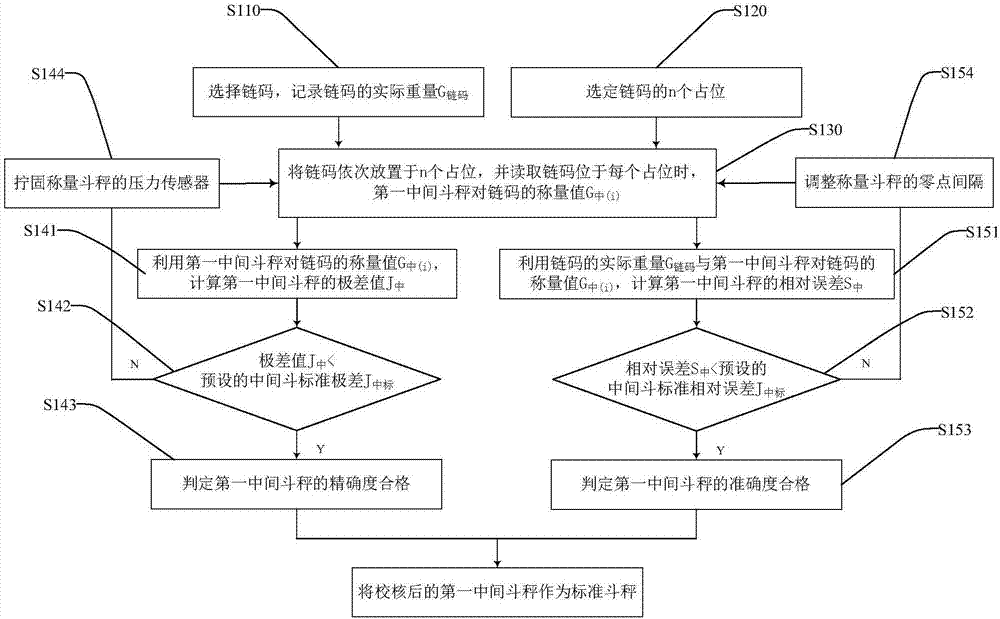

[0049] figure 2 It is a flowchart of a calibration method for a hopper scale under a blast furnace tank provided by the present application. The calibration method is used to check the accuracy and accuracy of a hopper scale under a blast furnace tank, such as figure 2 As shown, the implementation process of the calibration method includes,

[0050] Step S100, during the batching operation interval, among the multiple intermediate bucket scales under the blast furnace tank, select any intermediate bucket scale as the first intermediate bucket scale, and use the chain code to check the accuracy and accuracy of the first intermediate bucket scale checking;

[0051] Step S200, during the batching operation, use the checked first intermediate bucket scale as a standard bucket scale, and use the standard bucket scale to check the accuracy and accuracy of each weighing bucket scale;

[0052] Step S300, using the calibrated weighing bucket scale to check the accuracy and accuracy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com