Paper cigarette filter with broken-line embossed structure and production process thereof

A cigarette filter rod and embossing technology, applied in the field of cigarette filters, can solve problems such as deviation from the research direction, and achieve the effect of stable quality characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

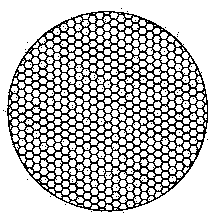

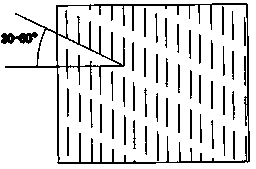

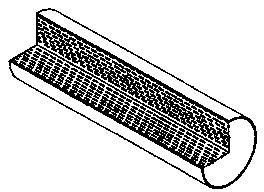

[0044] Such as figure 1 , 2 , 3, and 4, a paper cigarette filter rod with a twill structure, including a filter rod and a molding paper wrapped on the outside of the filter rod, is characterized in that the broken line provided on the longitudinal direction of the filter rod material monomer Column embossing, every two groups of broken line embossings are arranged in inclined steps in the horizontal direction, multiple groups are arranged together to form broken line embossing with inclined angles, and broken line embossing grooves are evenly distributed in the formed filter rod, The distance between two adjacent twill embossings in the transverse direction is 1 mm; the distance between two adjacent twill embossings in the longitudinal direction is 0.8 mm, and the twill embossing is strip-shaped, and the strip-shaped twill The embossing has a length of 10 mm, a width of 0.2 mm, and a depth of 0.6 mm, and the inclination angle formed by the plurality of groups is 30°.

[0045...

Embodiment 2

[0059] Such as figure 1 , 2 , 4, and 5, a paper cigarette filter rod with a twill structure, which is a binary structure, 50% of the filter element from the front end is a broken line embossed groove structure, and the other end is a straight bundle of acetate fibers Tow, the two are wrapped and connected by forming paper, including the filter core rod and the forming paper wrapped on the outside of the filter core rod. The grooves are arranged in inclined steps, and multiple groups are arranged together to form broken line embossing with an inclined angle. After forming, the filter rod is evenly distributed with broken line embossed grooves. The distance between them is 2mm; the distance between two adjacent twill embossings in the longitudinal direction is 1.2mm, and the twill embossing is strip-shaped, the length of the strip-shaped twill embossing is 15mm, and the width is 0.3mm. The depth is 0.8 mm, and the inclination angle formed by the multiple groups is 60°.

[006...

Embodiment 3

[0074] Such as figure 1 , 4 , 6, a paper cigarette filter rod with a twill structure, which is a binary structure, 70% of the filter element from the front end is a broken line embossed groove structure, and the other end is a straight bundle of acetate tow , the two are wrapped and connected by molded paper, including the filter core rod and the molded paper wrapped outside the filter core rod. The intervals are arranged in inclined steps, and multiple groups are arranged together to form broken line embossing with an inclined angle. After forming, there are broken line embossed grooves evenly distributed in the formed filter rod. The distance is 2mm; the distance between two adjacent twill embossments in the longitudinal direction is 1.2mm. The groups are arranged together at an inclination angle of 60°.

[0075] A process for preparing the paper cigarette filter rod of the broken line embossed structure, comprising the following steps:

[0076] a. Substrate treatment

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com