Sealed anti-knock storage battery and preparation method thereof

A battery and battery shell technology, applied in the field of sealed anti-seismic batteries and their preparation, can solve the problems of affecting the input and output of the battery, breaking the plate, shortening the service life, etc., achieving simple production and manufacturing, shortening the sealing and anti-seismic performance, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

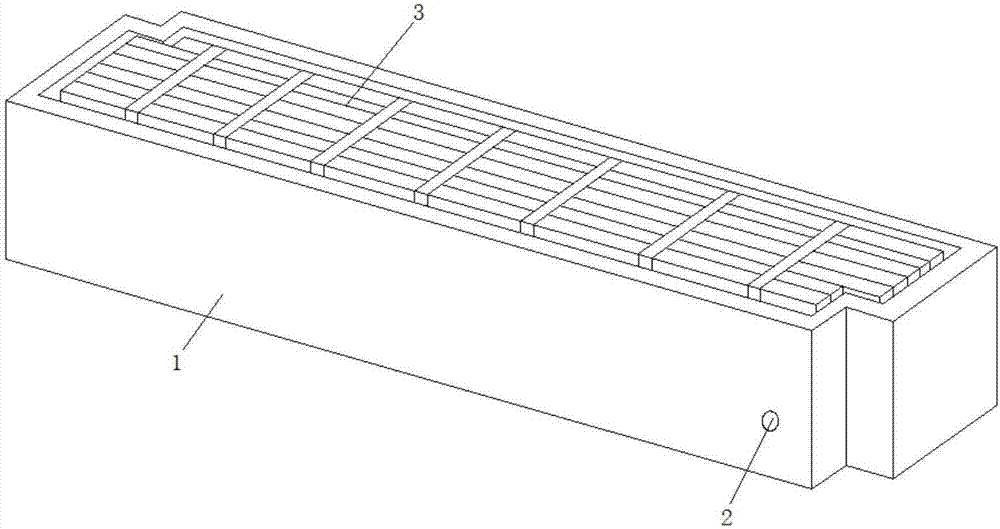

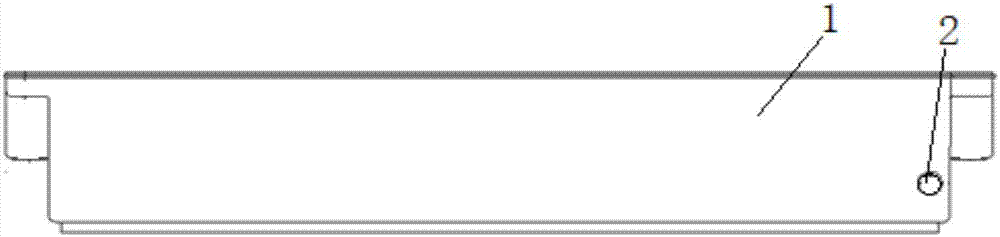

[0032] Such as Figure 1 to Figure 4 As shown, a sealed anti-vibration battery includes a battery case 1, a pressure box 3 and a plate pressing block;

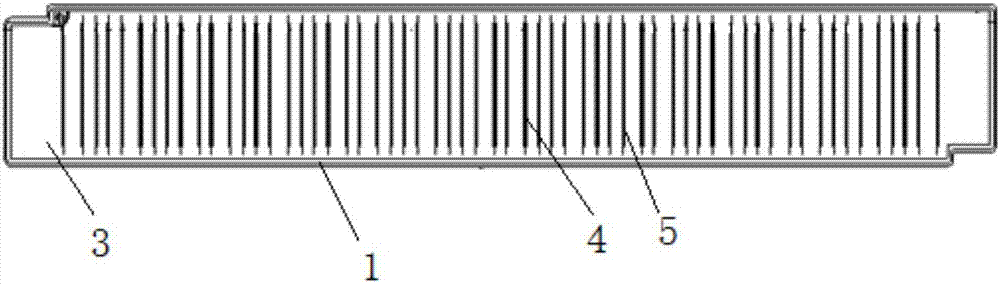

[0033] The pole plate pressing block includes several pole plates 7 that are overlapped and pressed together, and a diaphragm 8 is arranged between adjacent pole plates 7, and electrolyte is adsorbed on the diaphragm 8;

[0034] The side wall of the pressure box 3 has a number of mesh holes, the top of the pressure box 3 is open, and a gland is arranged corresponding to the top opening, and a plurality of plates are arranged side by side in the pressure box 3, and are covered by the gland. combine;

[0035] The top of the battery case 1 is open, and an upper cover 4 is provided corresponding to the top opening. The pressure box 3 is located in the battery case 1 and is covered by the upper cover 4. The upper cover 4 is provided with a number of exhaust holes 6 and overflow The orifice 5, the gap between the pressure box 3 an...

Embodiment 2

[0049] Such as Figure 1 to Figure 4 As shown, a sealed anti-vibration battery includes a battery case 1, a pressure box 3 and a plate pressing block;

[0050] The pole plate pressing block includes several pole plates 7 that are overlapped and pressed together, and a diaphragm 8 is arranged between adjacent pole plates 7, and electrolyte is adsorbed on the diaphragm 8;

[0051] The side wall of the pressure box 3 has a number of mesh holes, the top of the pressure box 3 is open, and a gland is arranged corresponding to the top opening, and a plurality of plates are arranged side by side in the pressure box 3, and are covered by the gland. combine;

[0052] The top of the battery case 1 is open, and an upper cover 4 is provided corresponding to the top opening. The pressure box 3 is located in the battery case 1 and is covered by the upper cover 4. The upper cover 4 is provided with a number of exhaust holes 6 and overflow The orifice 5, the gap between the pressure box 3 an...

Embodiment 3

[0066] Such as Figure 1 to Figure 4 As shown, a sealed anti-vibration battery includes a battery case 1, a pressure box 3 and a plate pressing block;

[0067] The pole plate pressing block includes several pole plates 7 that are overlapped and pressed together, and a diaphragm 8 is arranged between adjacent pole plates 7, and electrolyte is adsorbed on the diaphragm 8;

[0068] The side wall of the pressure box 3 has a number of mesh holes, the top of the pressure box 3 is open, and a gland is arranged corresponding to the top opening, and a plurality of plates are arranged side by side in the pressure box 3, and are covered by the gland. combine;

[0069] The top of the battery case 1 is open, and an upper cover 4 is provided corresponding to the top opening. The pressure box 3 is located in the battery case 1 and is covered by the upper cover 4. The upper cover 4 is provided with a number of exhaust holes 6 and overflow The orifice 5, the gap between the pressure box 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com