Mineral rapid smashing device for chemical engineering

A crushing device and ore technology, which is applied in the direction of grain processing, etc., can solve the problems of waste of energy, low efficiency, and large time consumption, and achieve the effect of rapid crushing, convenient use, and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

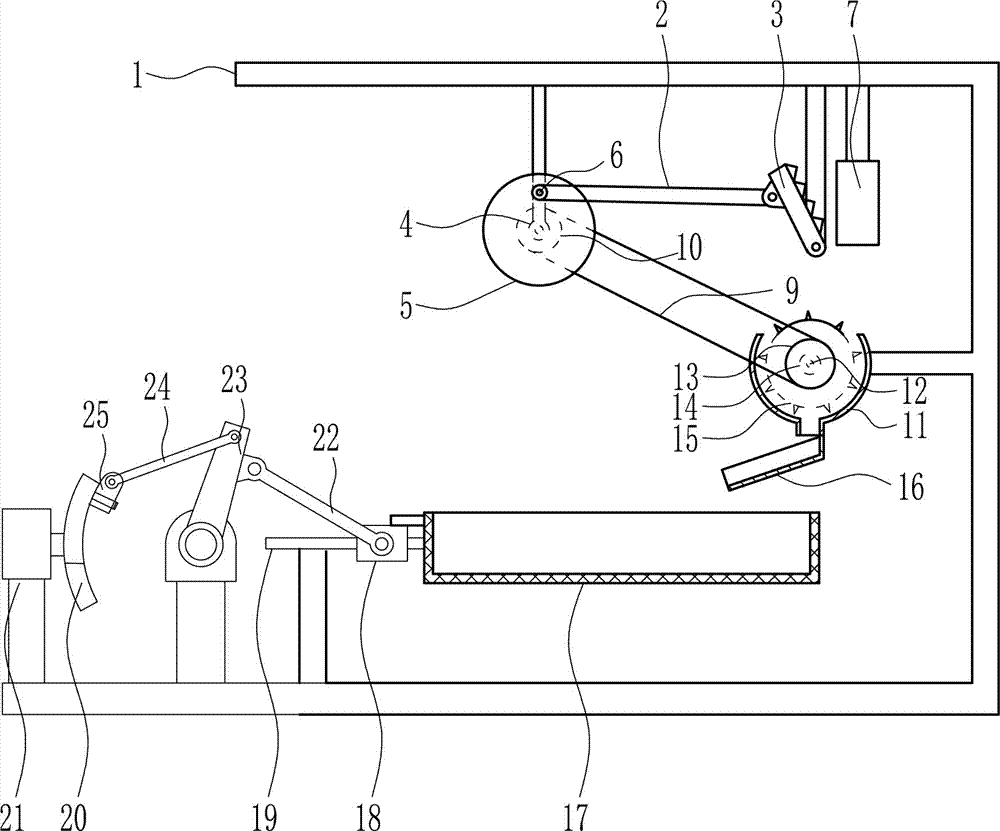

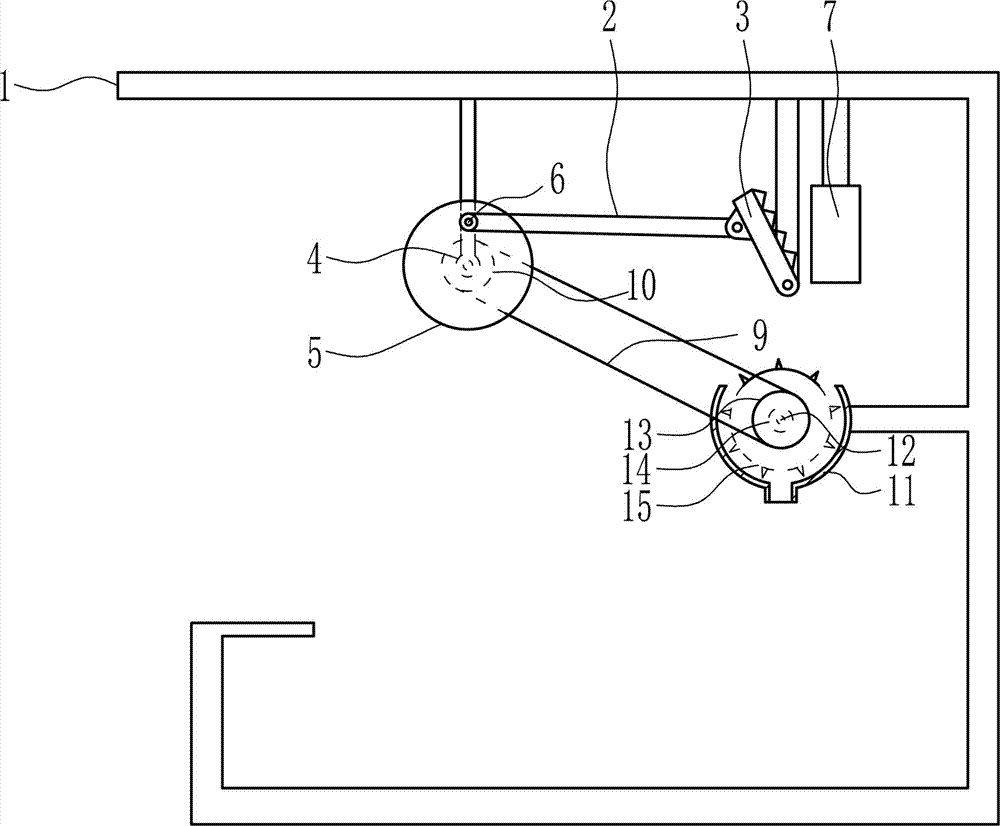

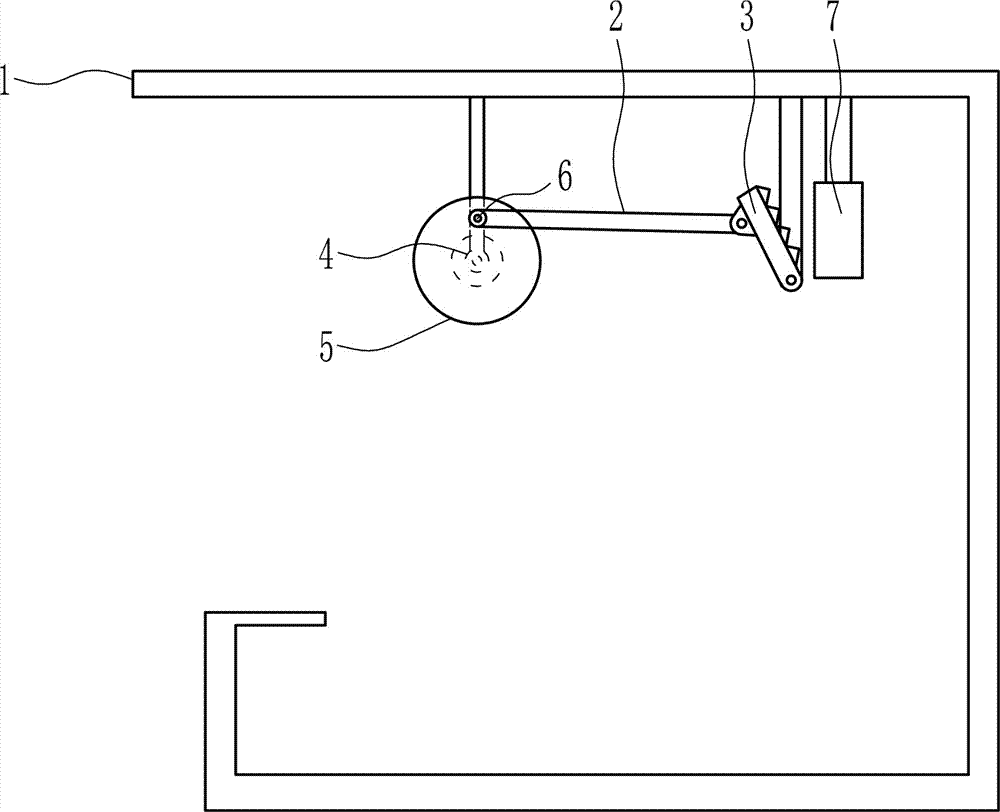

[0029] A chemical ore rapid crushing device, such as Figure 1-5 As shown, it includes a fixed frame 1, a first connecting rod 2, a crushing plate 3, a first motor 4, a turntable 5, a roller 6 and a baffle 7, and the fixed frame 1 is provided with a second bearing seat in sequence from left to right , the first motor 4, the crushing plate 3 and the baffle plate 7, the first motor 4 is provided with a turntable 5, the turntable 5 is provided with a roller 6, the roller 6 is provided with a first connecting rod 2, the first connecting rod 2 The right end is provided with a crushing plate 3 through a hinged connection.

Embodiment 2

[0031] A chemical ore rapid crushing device, such as Figure 1-5 As shown, it includes a fixed frame 1, a first connecting rod 2, a crushing plate 3, a first motor 4, a turntable 5, a roller 6 and a baffle 7, and the fixed frame 1 is provided with a second bearing seat in sequence from left to right , the first motor 4, the crushing plate 3 and the baffle plate 7, the first motor 4 is provided with a turntable 5, the turntable 5 is provided with a roller 6, the roller 6 is provided with a first connecting rod 2, the first connecting rod 2 The right end is provided with a crushing plate 3 through a hinged connection.

[0032] Also include connecting belt 9, first pulley 10, grinding tank body 11, first rotating shaft 12, second pulley 13, first bearing seat 14 and grinding disc 15, fixed frame 1 right is provided with grinding tank body 11, grinding The tank body 11 is provided with a first bearing seat 14, the first motor 4 is provided with a first pulley 10, the crushing tan...

Embodiment 3

[0034] A chemical ore rapid crushing device, such as Figure 1-5 As shown, it includes a fixed frame 1, a first connecting rod 2, a crushing plate 3, a first motor 4, a turntable 5, a roller 6 and a baffle 7, and the fixed frame 1 is provided with a second bearing seat in sequence from left to right , the first motor 4, the crushing plate 3 and the baffle plate 7, the first motor 4 is provided with a turntable 5, the turntable 5 is provided with a roller 6, the roller 6 is provided with a first connecting rod 2, the first connecting rod 2 The right end is provided with a crushing plate 3 through a hinged connection.

[0035] Also include connecting belt 9, first pulley 10, grinding tank body 11, first rotating shaft 12, second pulley 13, first bearing seat 14 and grinding disc 15, fixed frame 1 right is provided with grinding tank body 11, grinding The tank body 11 is provided with a first bearing seat 14, the first motor 4 is provided with a first pulley 10, the crushing tan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap