Ladle nozzle sand tank filling device

A technology for material tanks and ladles, which is applied in the field of sand tank filling equipment at the ladle nozzle, and can solve the problems of sand material waste, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

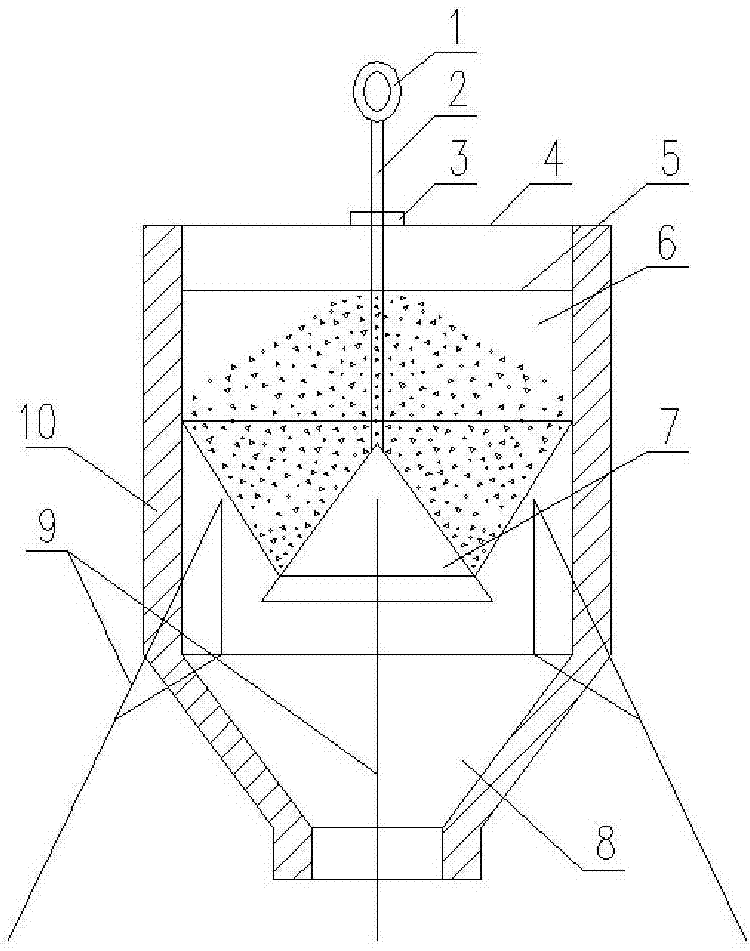

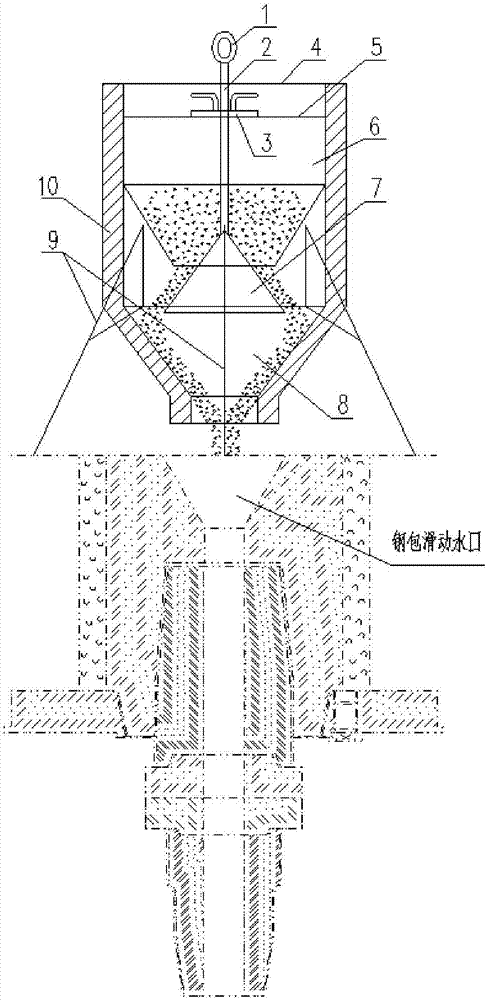

[0025] The utility model relates to a ladle nozzle sand filling tank device, which can fill a ladle with nozzle sand at any suitable place in the ladle thermal turnover process. After determining the sand filling site, and setting a jib crane and an observation platform here (also can utilize the existing suitable platform), the sand filling operation can be carried out by using this ladle nozzle sand filling tank device. Jib cranes need to be equipped with high temperature resistant steel wire ropes sprayed with refractory materials.

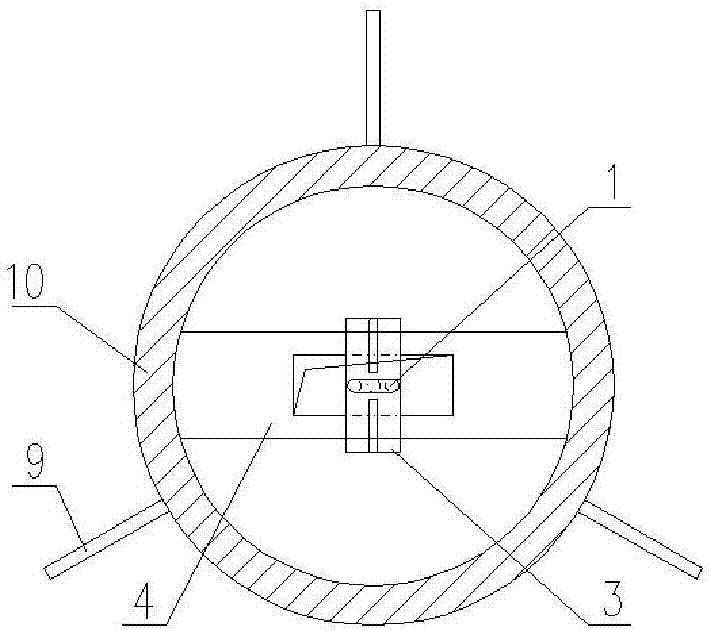

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0027] The lifting ring 1 is welded with the connecting rod 2 with external thread, and the locking device 3 is screwed on the connecting rod 2; the baffle plate 5 and the locking plate 4 are welded on the prepared material tank 6 in sequence, and the above-mentioned manufactured lifting ring , connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com