Transmission rotating nut spanner

A technology of rotating nut and driving nut, applied in the field of wrench, can solve the problems of inconvenient use, inconvenient disassembly, time-consuming and labor-intensive, etc., and achieve the effect of convenient disassembly and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

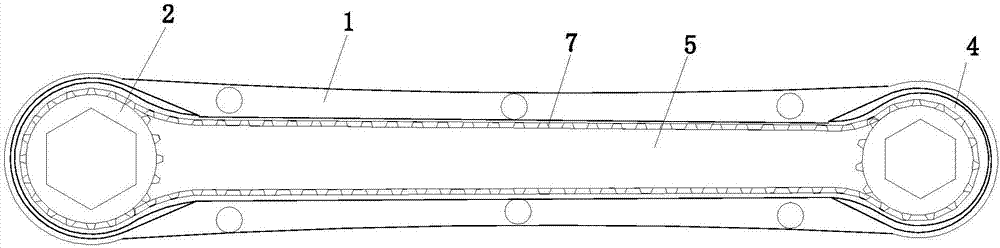

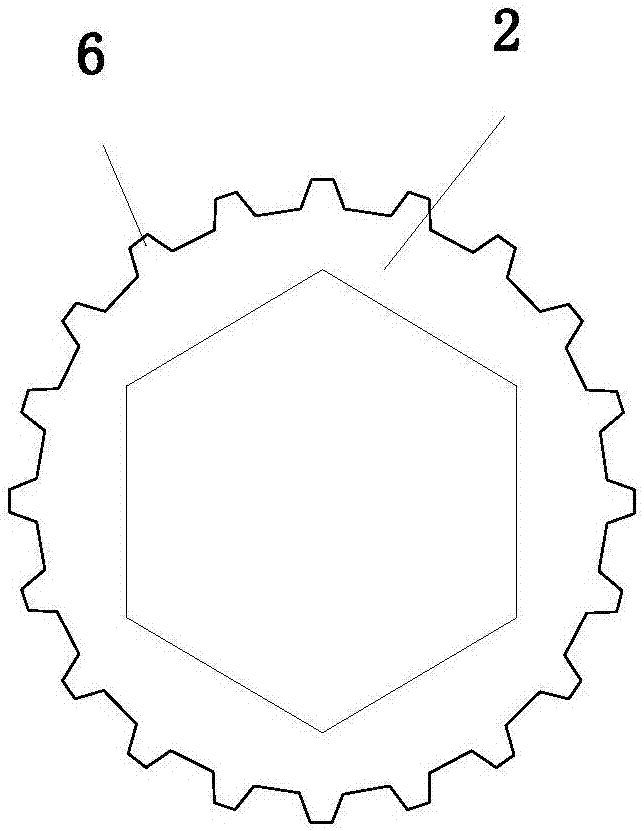

[0026] refer to figure 1 , 2 , 3, 4, 5, 6 and 10 shown in a transmission rotary nut wrench, including a housing 1 and a double-nut transmission mechanism arranged in the inner cavity of the housing 1, the double-nut transmission mechanism includes two transmission nuts 2 , two drive nuts 2 are respectively arranged at both ends of the inner cavity of the housing 1, and a transmission device for connecting the two drive nuts 2 is arranged between the two drive nuts 2, and the inner rings of the two drive nuts 2 The projected shape in its own axial direction is a regular hexagon, and the two ends of the housing 1 respectively correspond to the position of the drive nut 2. There is a circular through hole 3 penetrating through the housing 1, and the two circular through holes 3 are located on the The corresponding drive nuts 2 are coaxial.

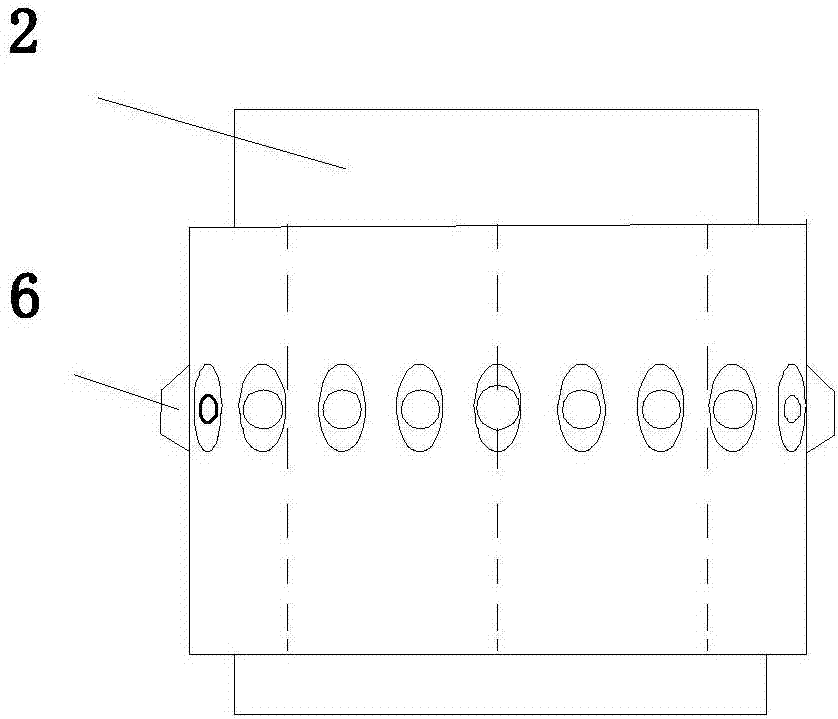

[0027] Both ends of the housing 1 are provided with a nut accommodation chamber 4 for accommodating the transmission nut 2, and the two nu...

specific Embodiment 2

[0032] refer to Figure 7 , 8 A kind of transmission rotating nut wrench shown in , 9 and 10, comprises housing 1 and the double-nut transmission mechanism that is arranged on housing 1 cavity, and described double-nut transmission mechanism comprises two drive nuts 2, two drive nuts 2 They are respectively arranged at both ends of the inner cavity of the housing 1, and a transmission device for connecting the two transmission nuts 2 is arranged between the two transmission nuts 2, and the inner rings of the two transmission nuts 2 are arranged in the The projection shapes are all regular hexagons, and the two ends of the housing 1 respectively correspond to the positions of the transmission nuts 2. A circular via hole 3 penetrating through the housing 1 is provided. axis.

[0033] Both ends of the housing 1 are provided with a nut accommodation chamber 4 for accommodating the transmission nut 2, and the two nut accommodation chambers 4 are connected through a transmission c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com