Patents

Literature

31results about How to "Time-saving and labor-saving effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

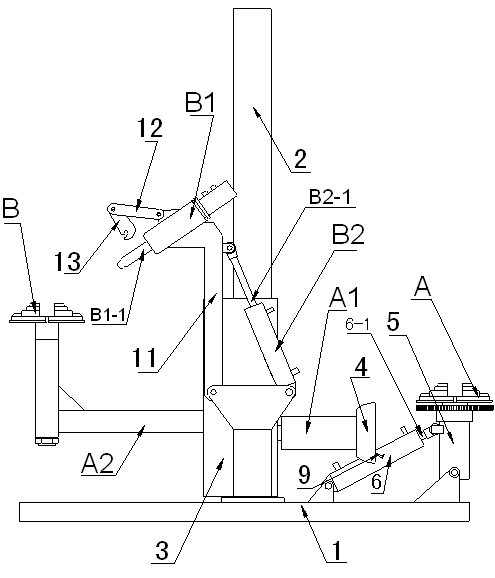

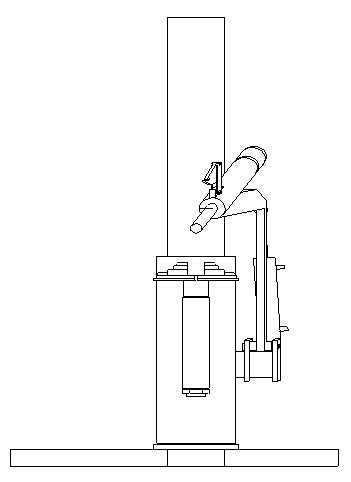

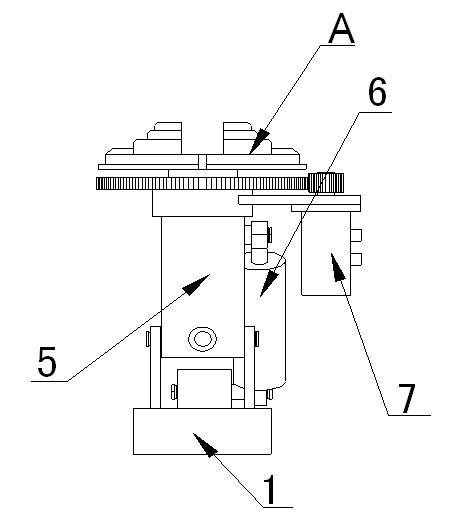

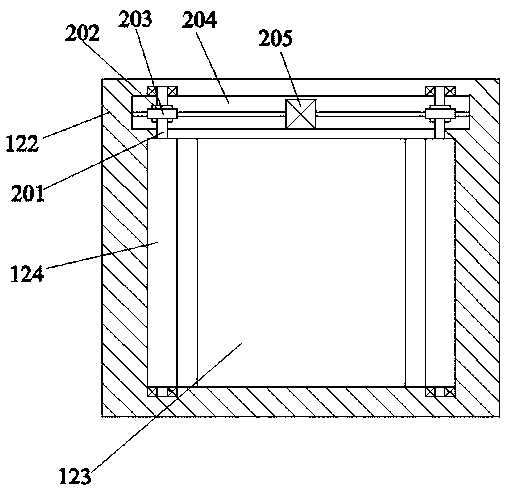

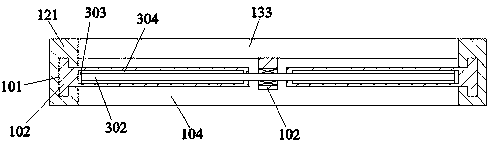

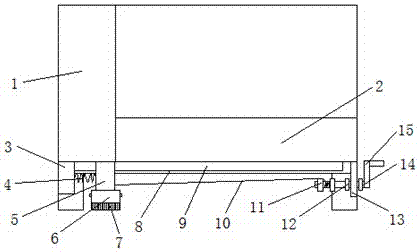

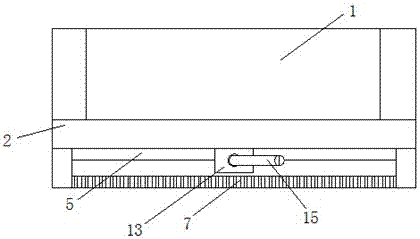

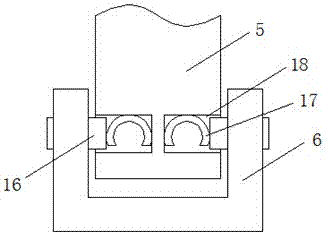

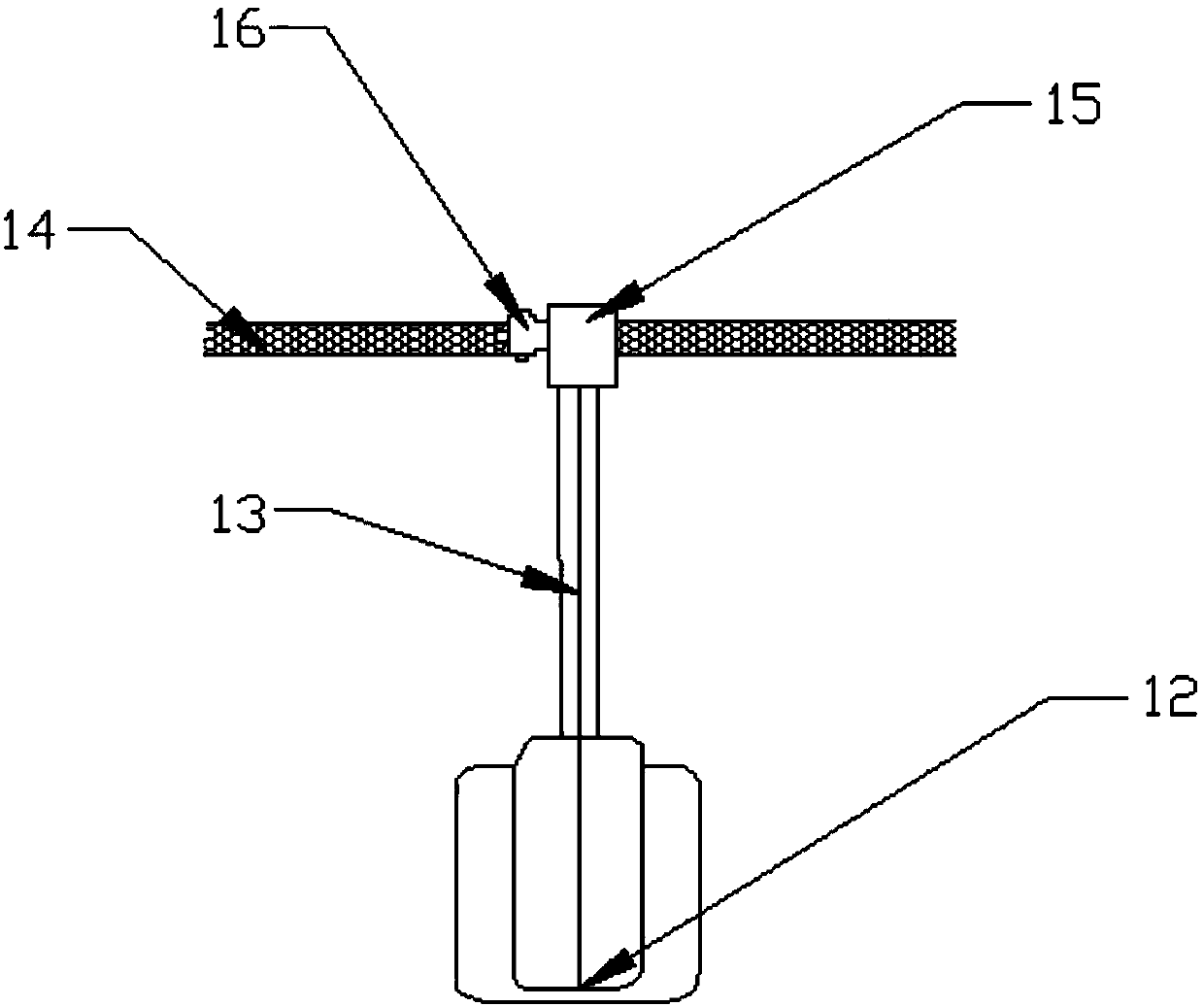

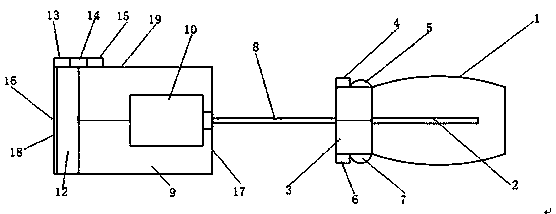

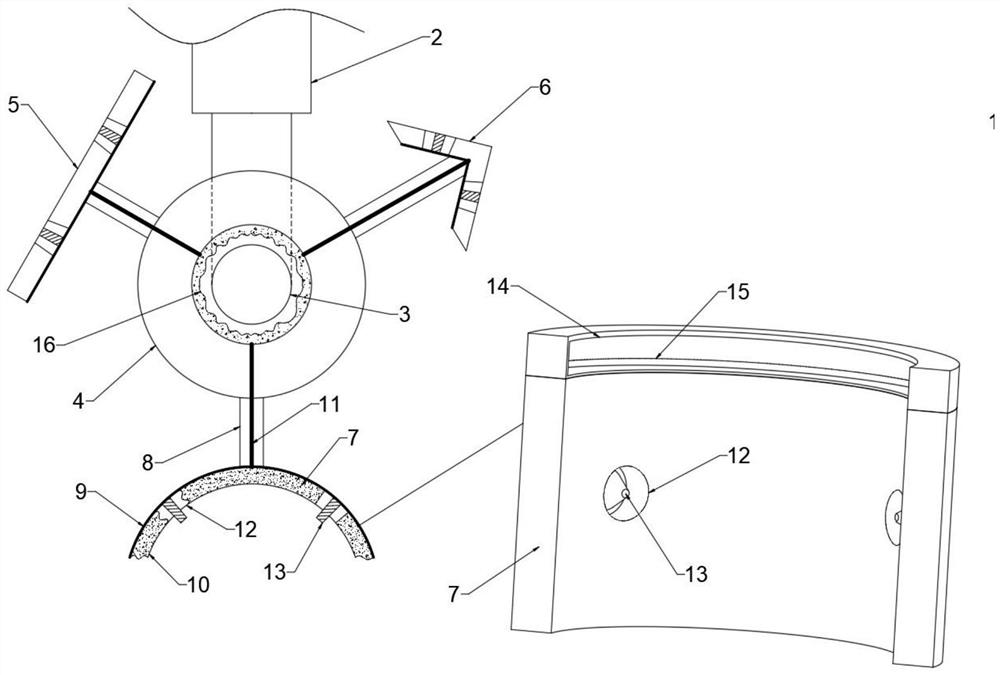

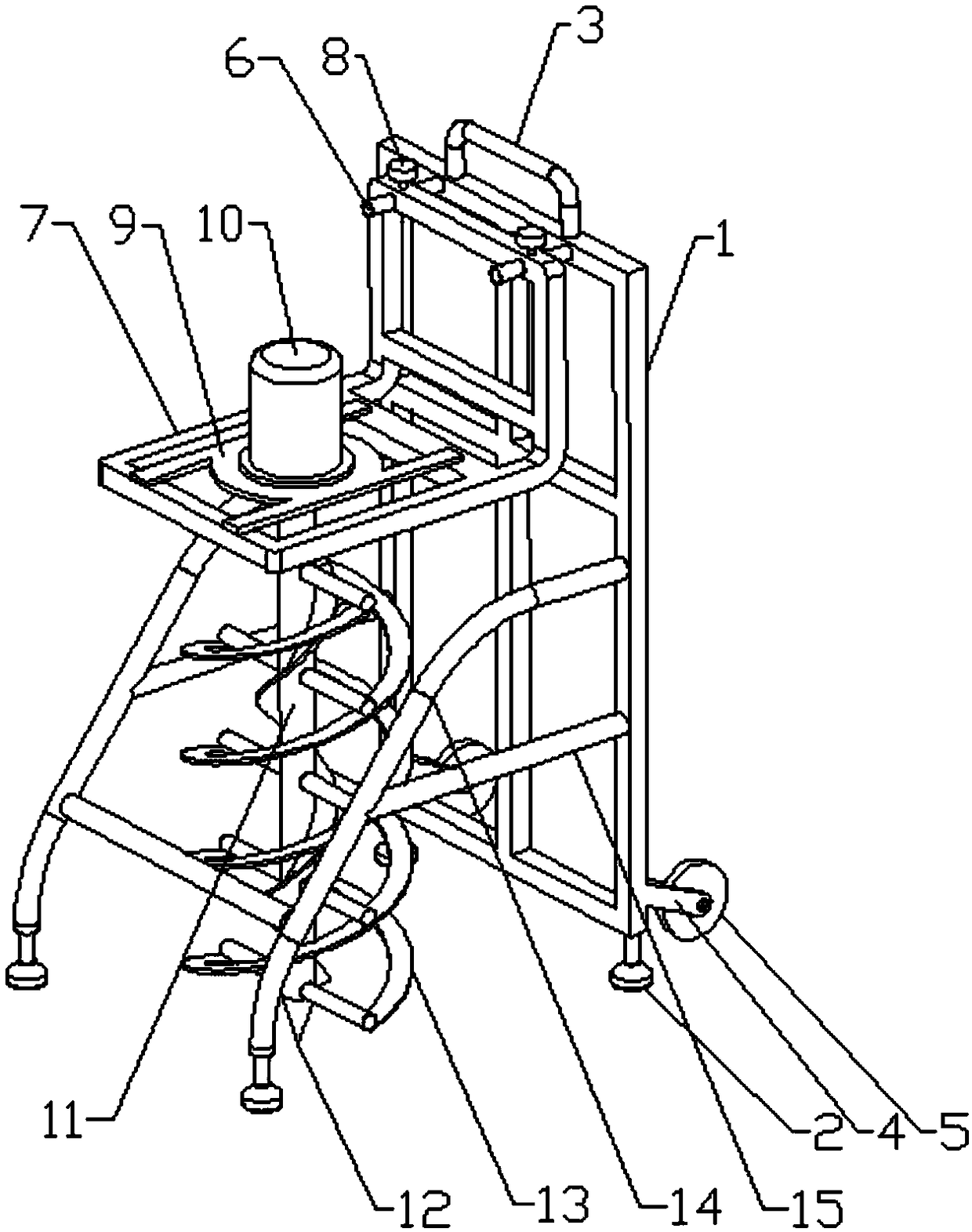

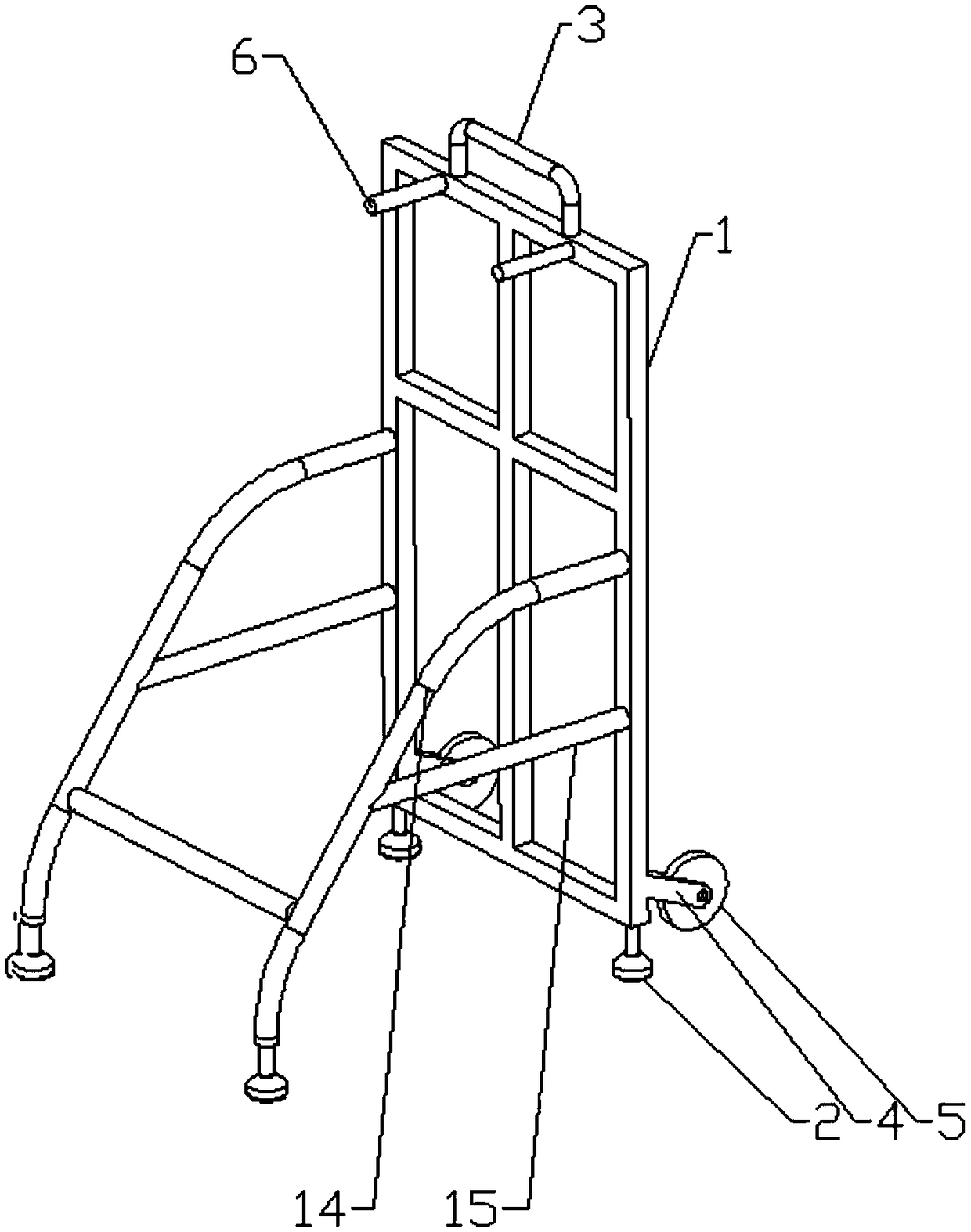

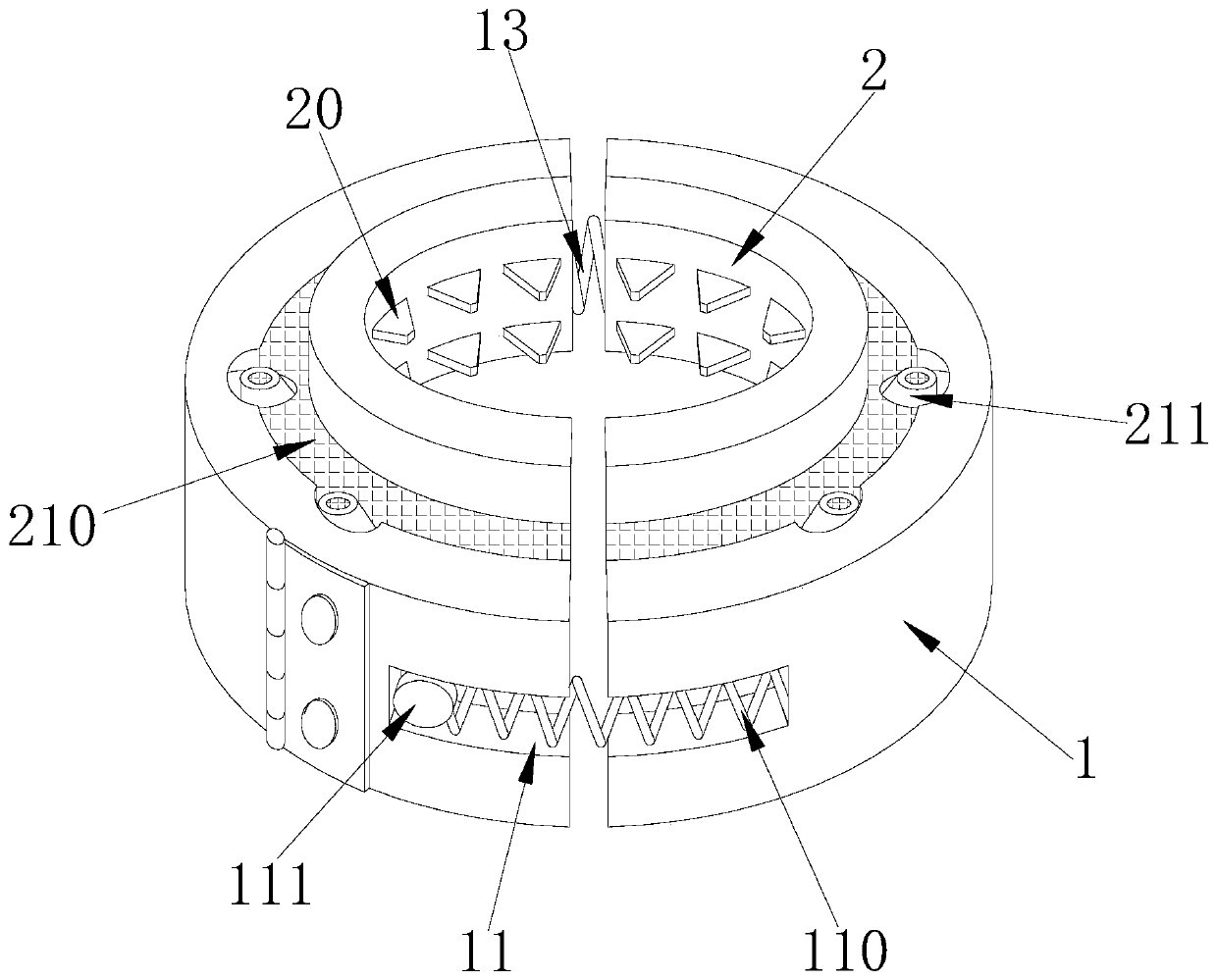

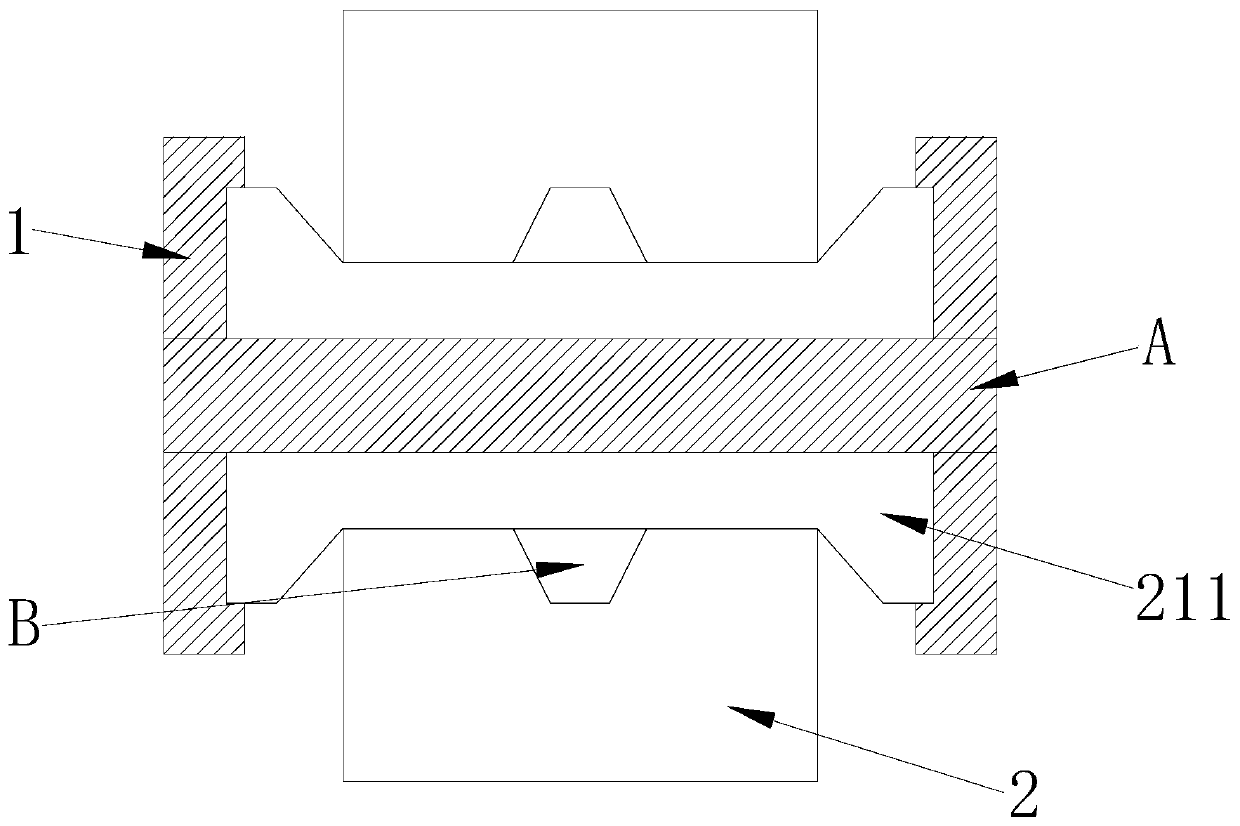

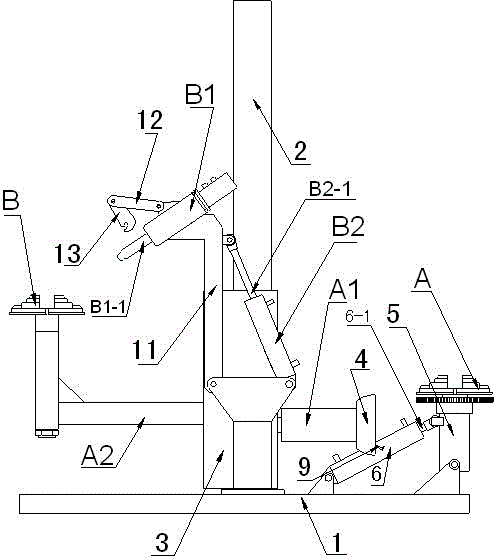

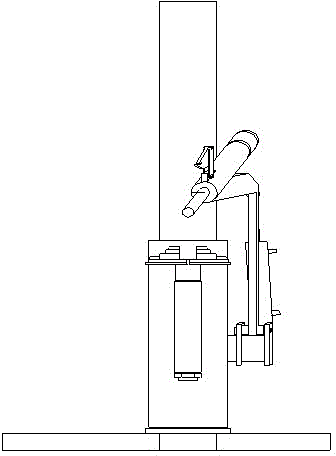

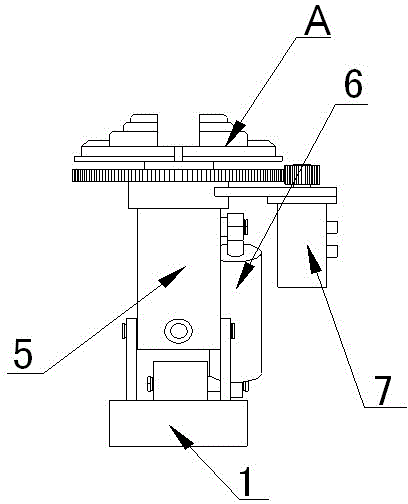

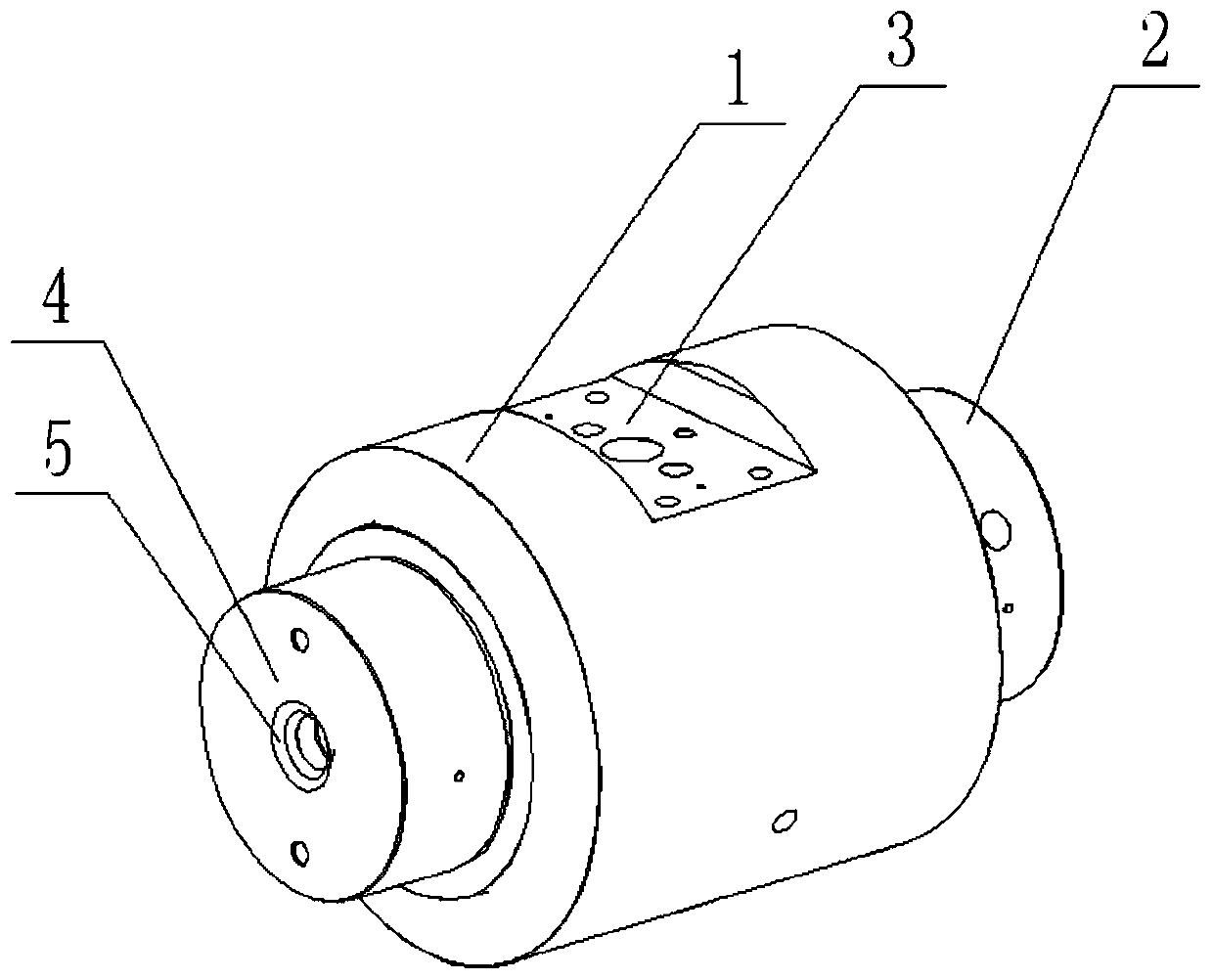

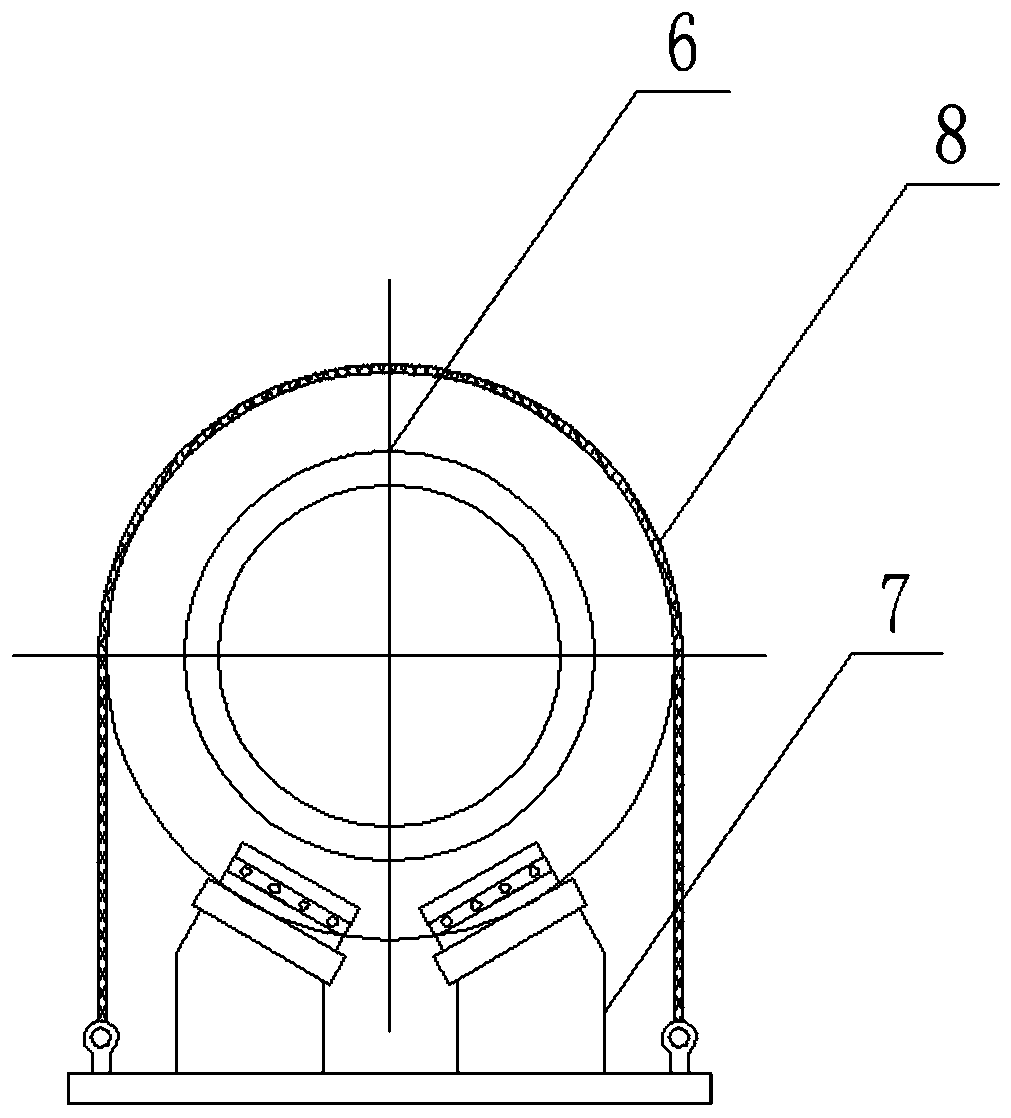

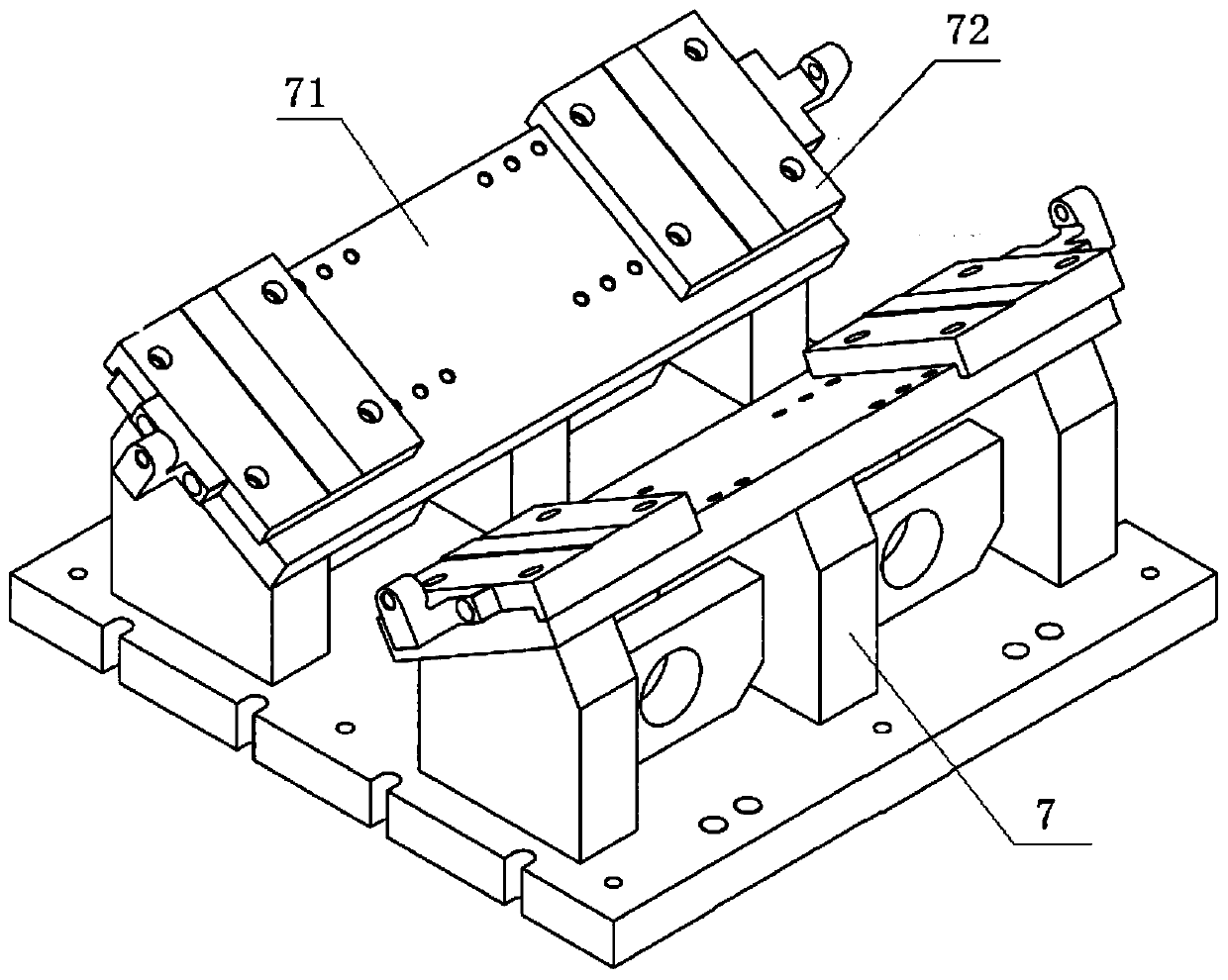

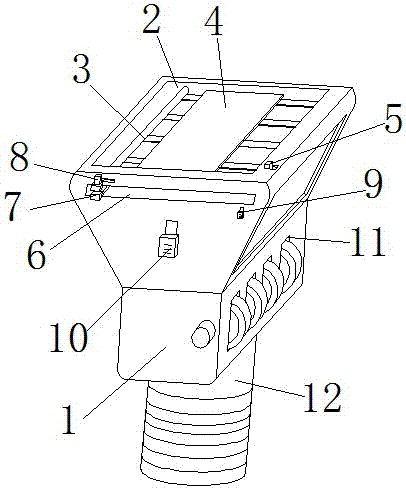

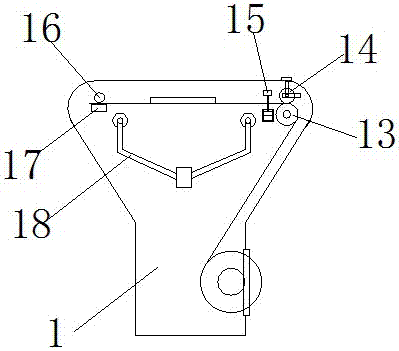

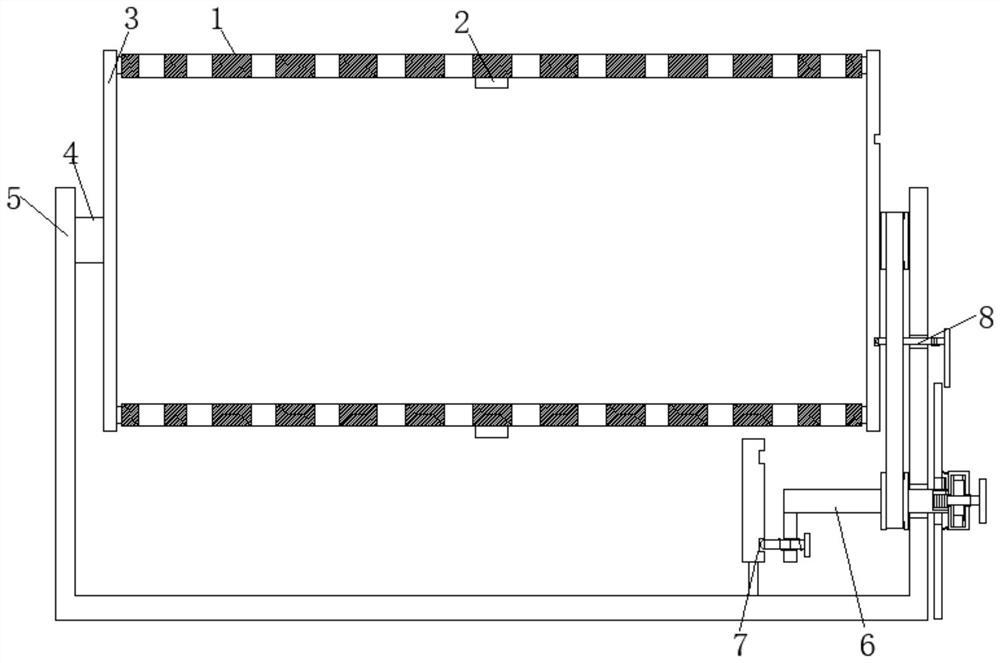

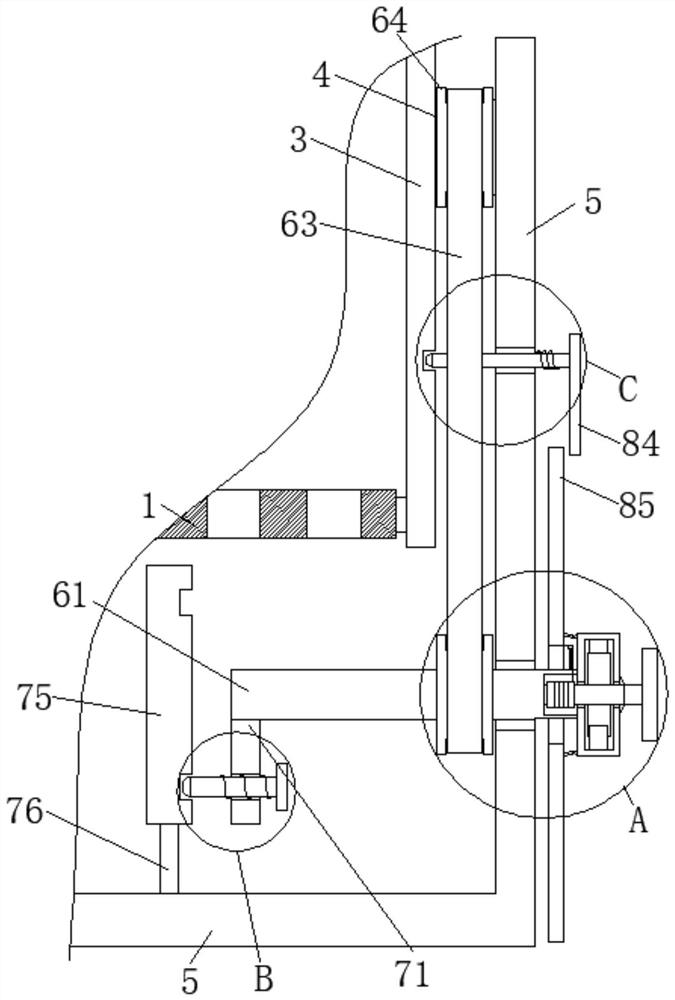

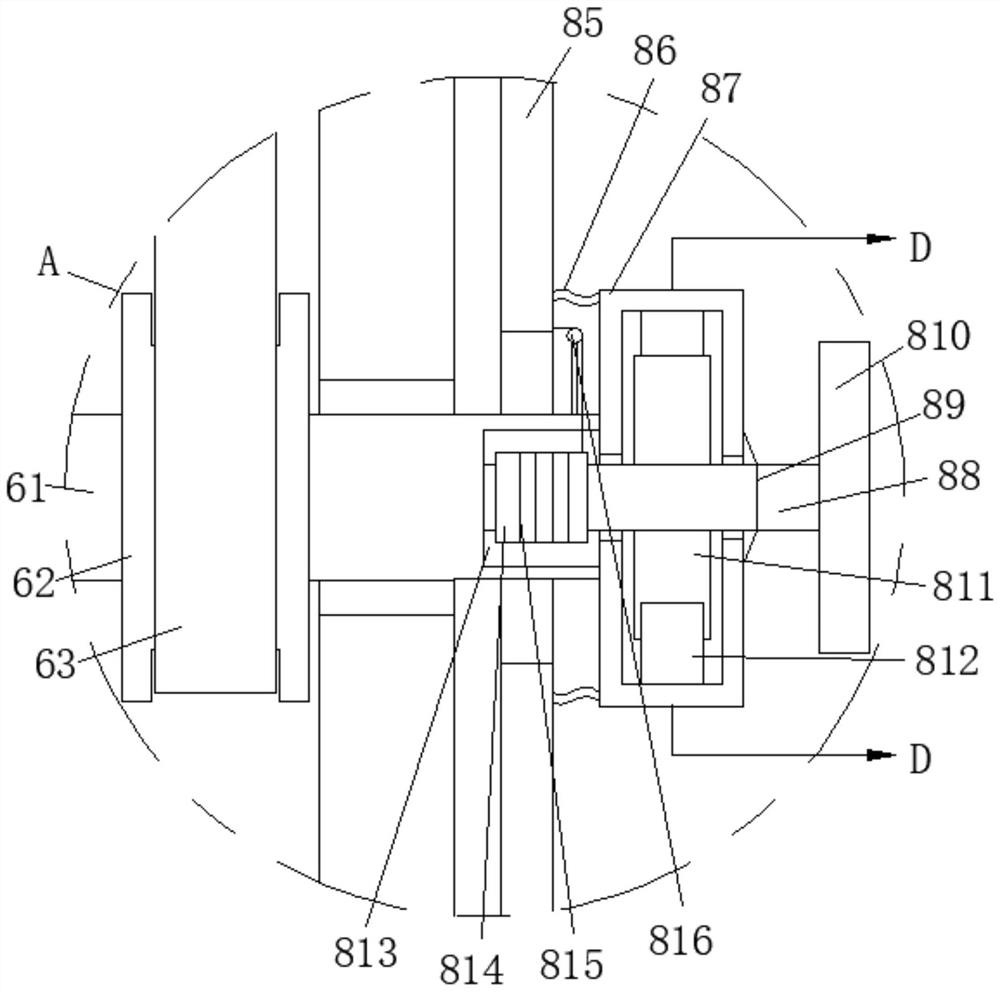

Tire mounting and dismounting device

InactiveCN102019822AReduce workloadSimple structure designTyre repairingHydraulic cylinderEngineering

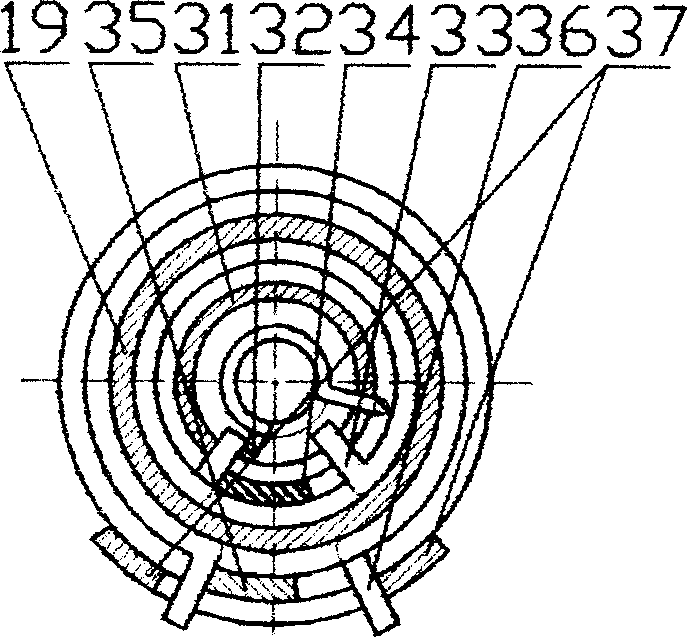

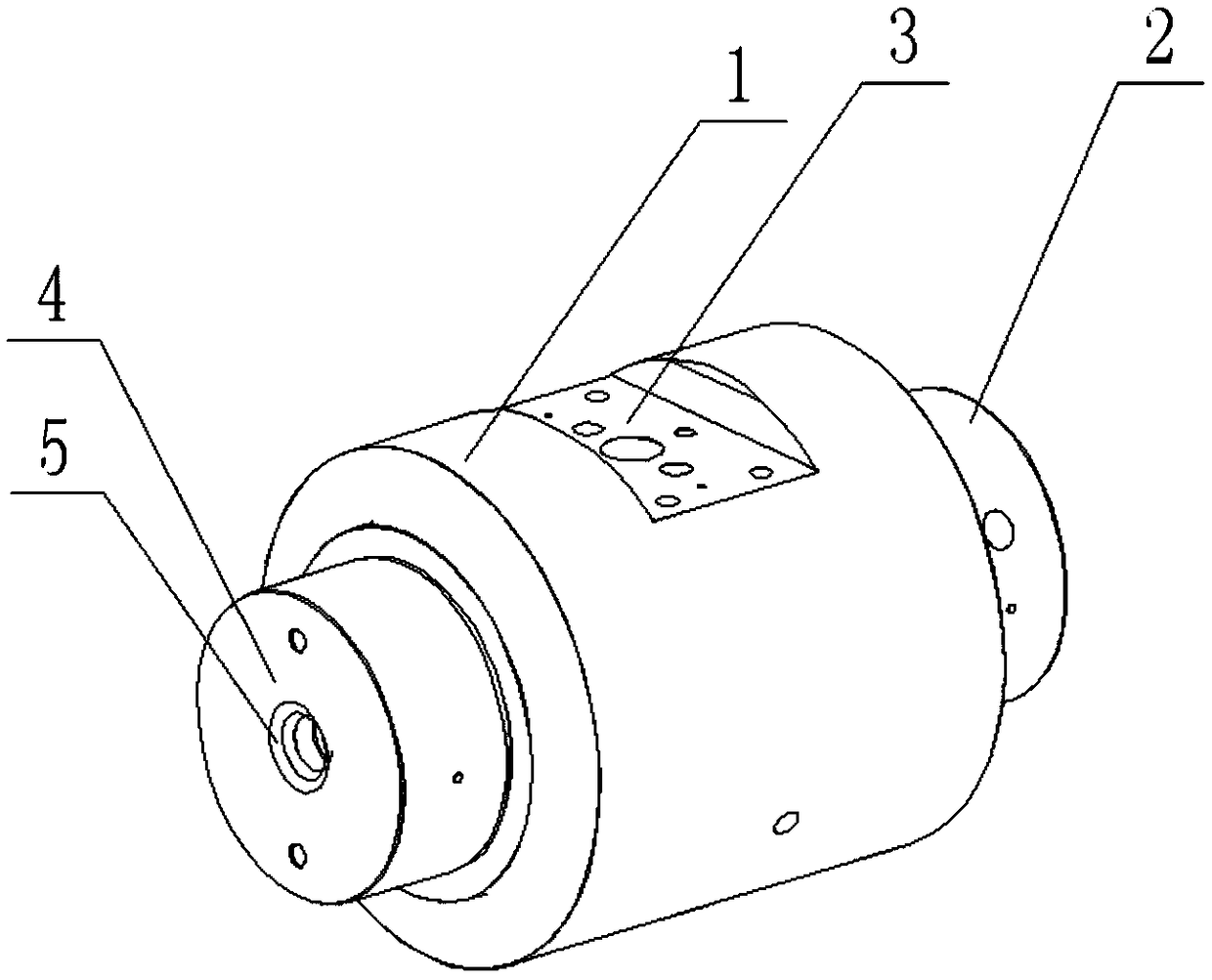

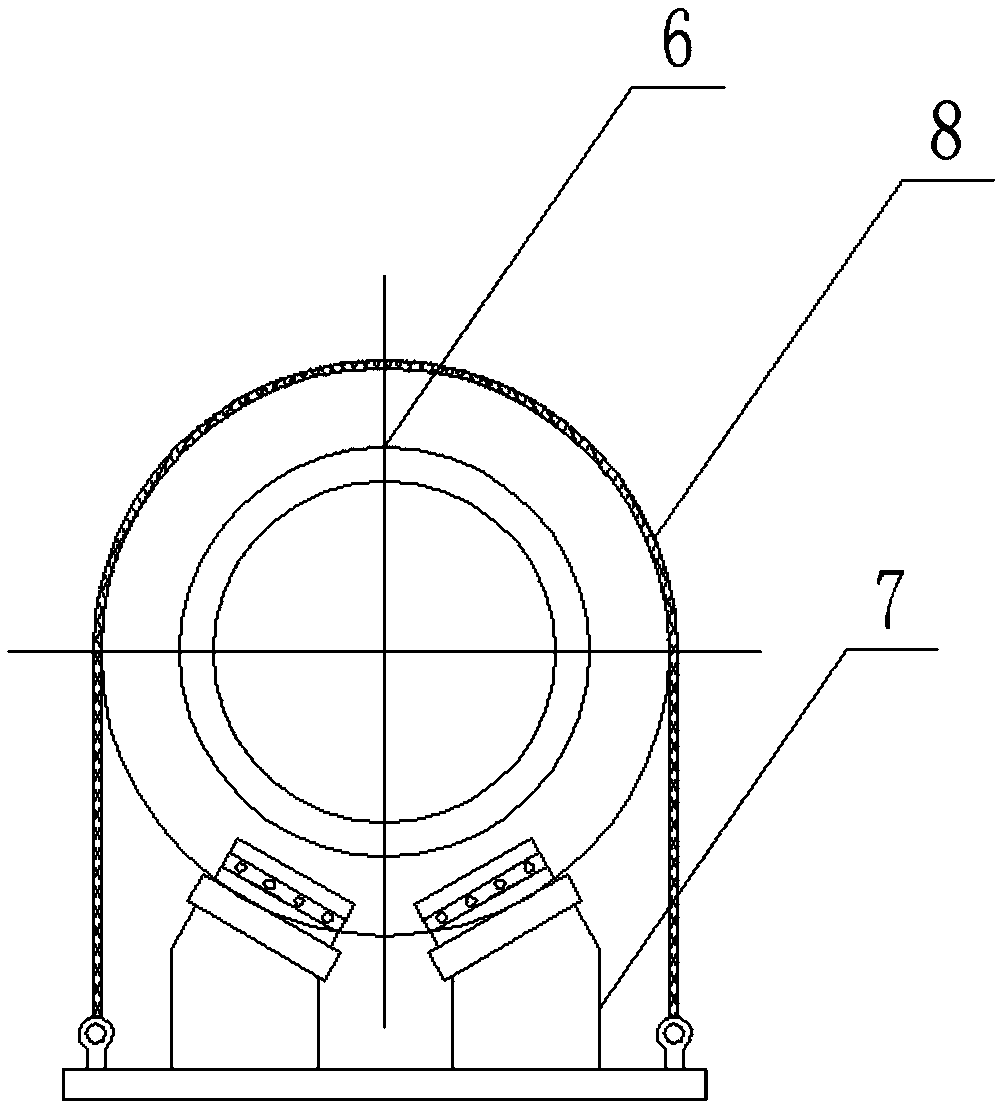

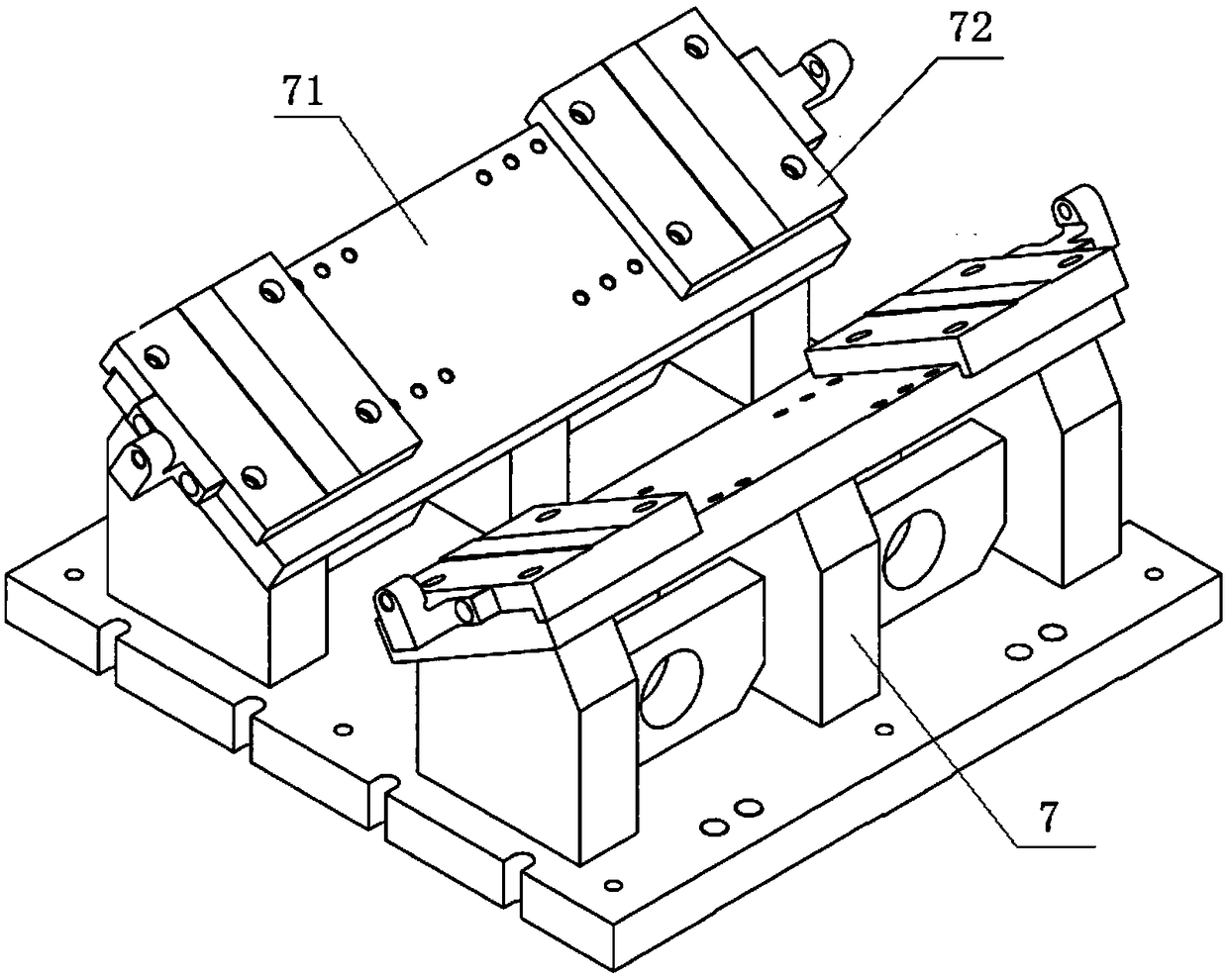

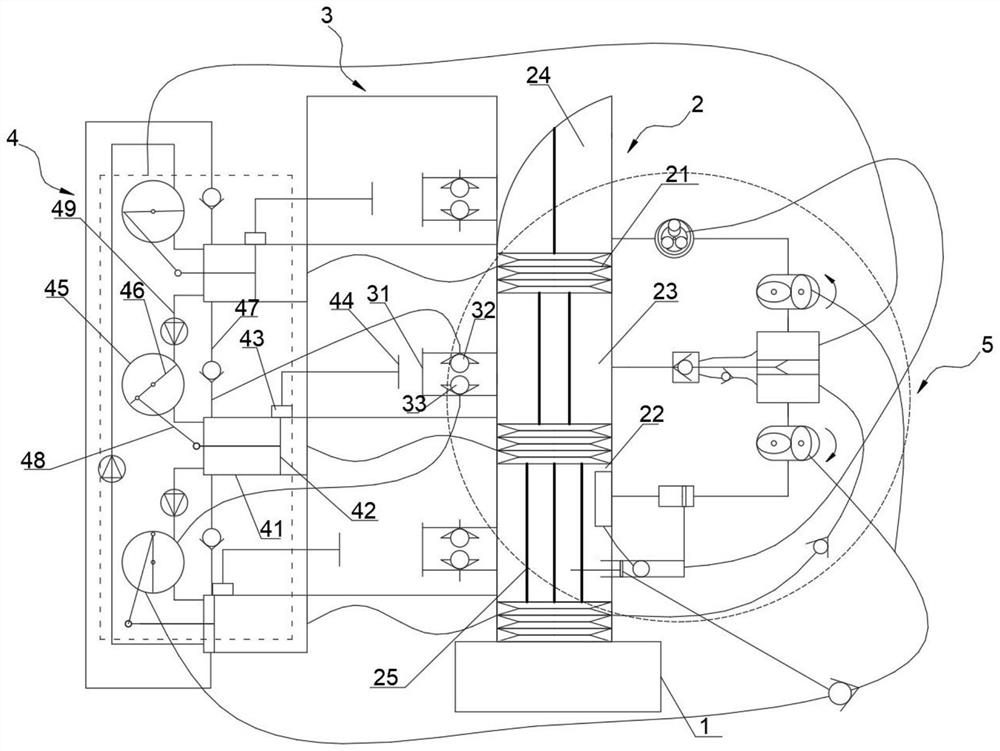

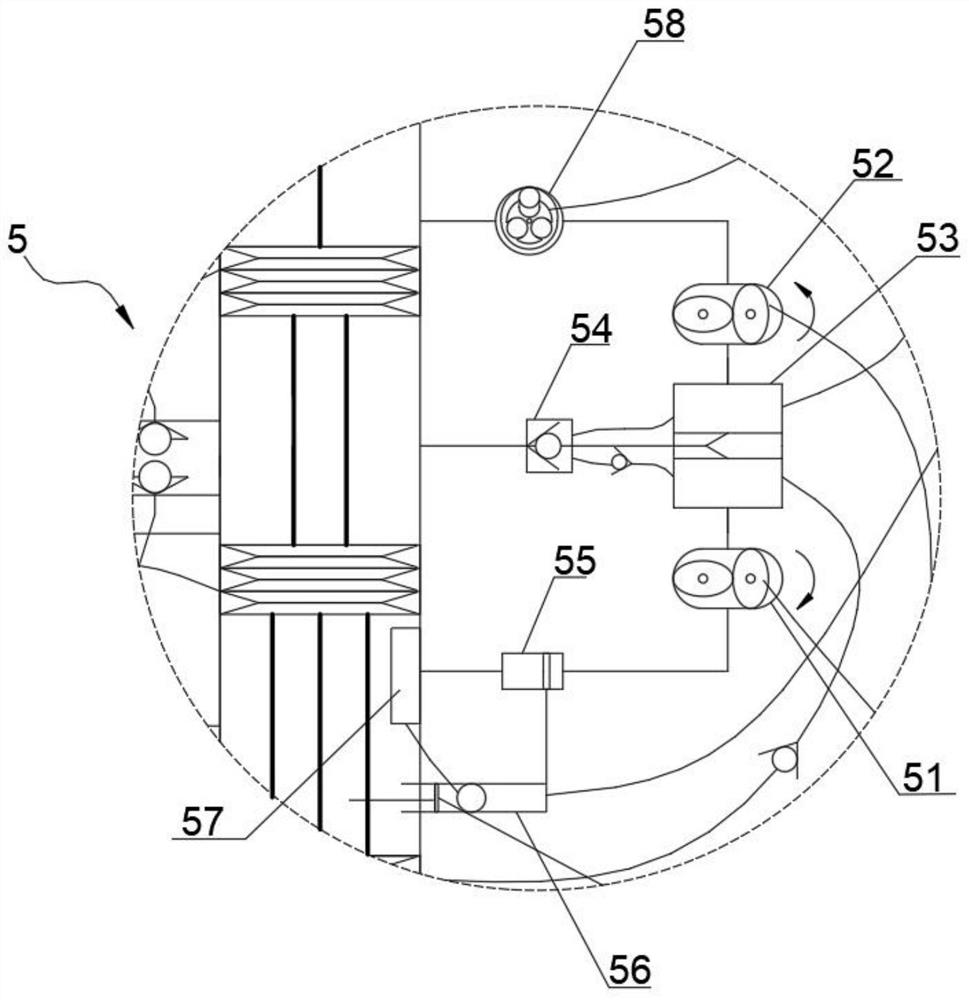

The invention relates to a tire mounting and dismounting device which comprises a base and a frame connected with the base. The invention is characterized in that one lateral side of the base is vertically provided with a wheel rim positioning mechanism A for supporting the tire; the frame is provided with an elevating mechanism; the corresponding lateral side of the elevating mechanism is provided with a rotating drum A1; the corresponding extending end of the rotating drum A1 is connected with a conical sleeve for pressing against the inner circle of the side face of the tire; the wheel rim positioning mechanism A is hinged with the base through the lower end part of a longitudinal support rod which is connected to the lower end part of the wheel rim positioning mechanism A; the upper end of the longitudinal support rod is hinged with a hydraulic cylinder push rod so that the wheel rim positioning mechanism A can swing; the bottom end of the hydraulic cylinder is hinged with the base so that the hydraulic cylinder is positioned on the swing plane of the longitudinal support rod of the wheel rim positioning mechanism A; the center of the rotating drum A1 is provided with a retractable rod; and the end part of the retractable rod is connected with an L-shaped draw hook through a chain. The invention can be used for conveniently mounting and dismounting a tire.

Owner:池学建

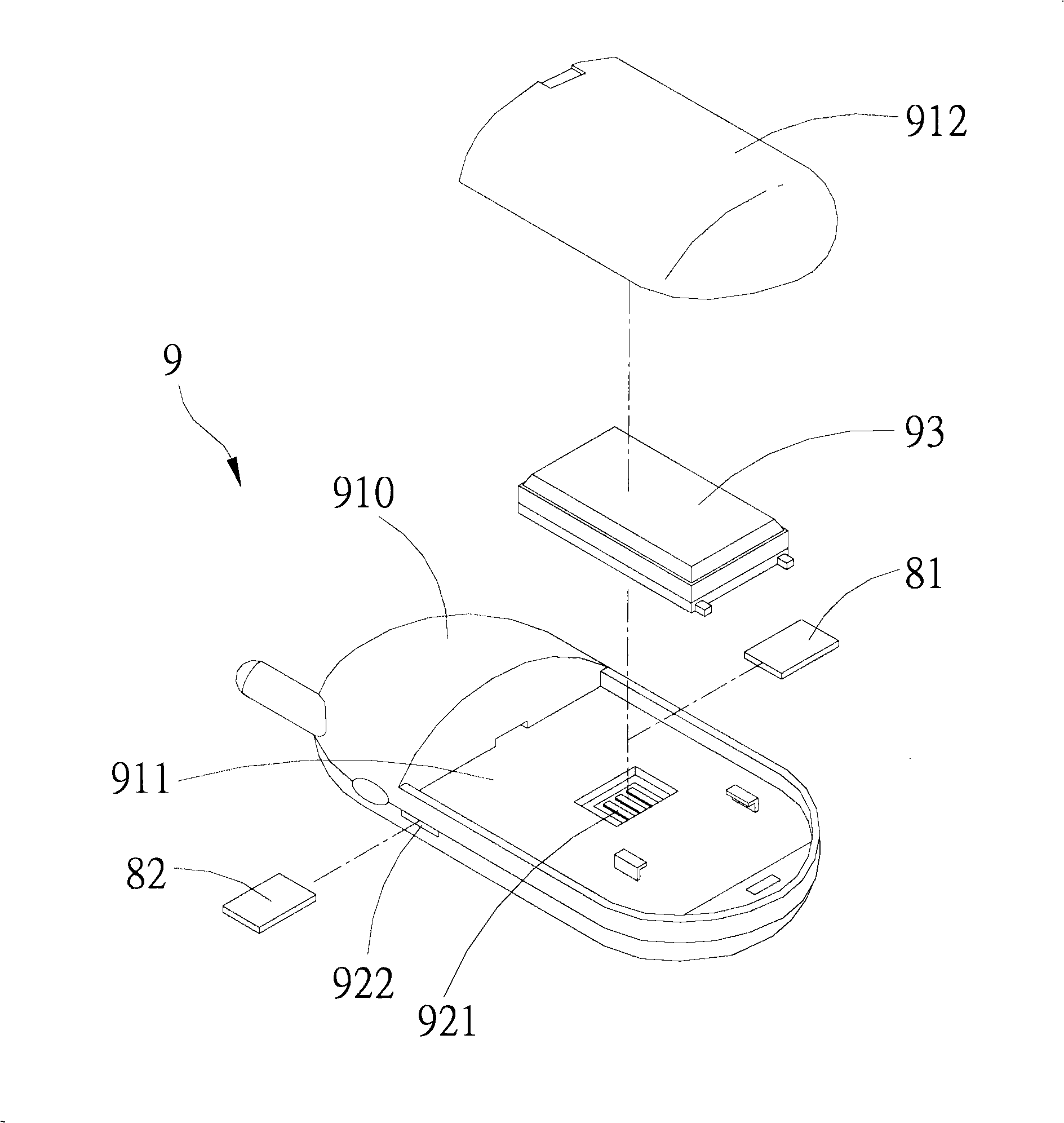

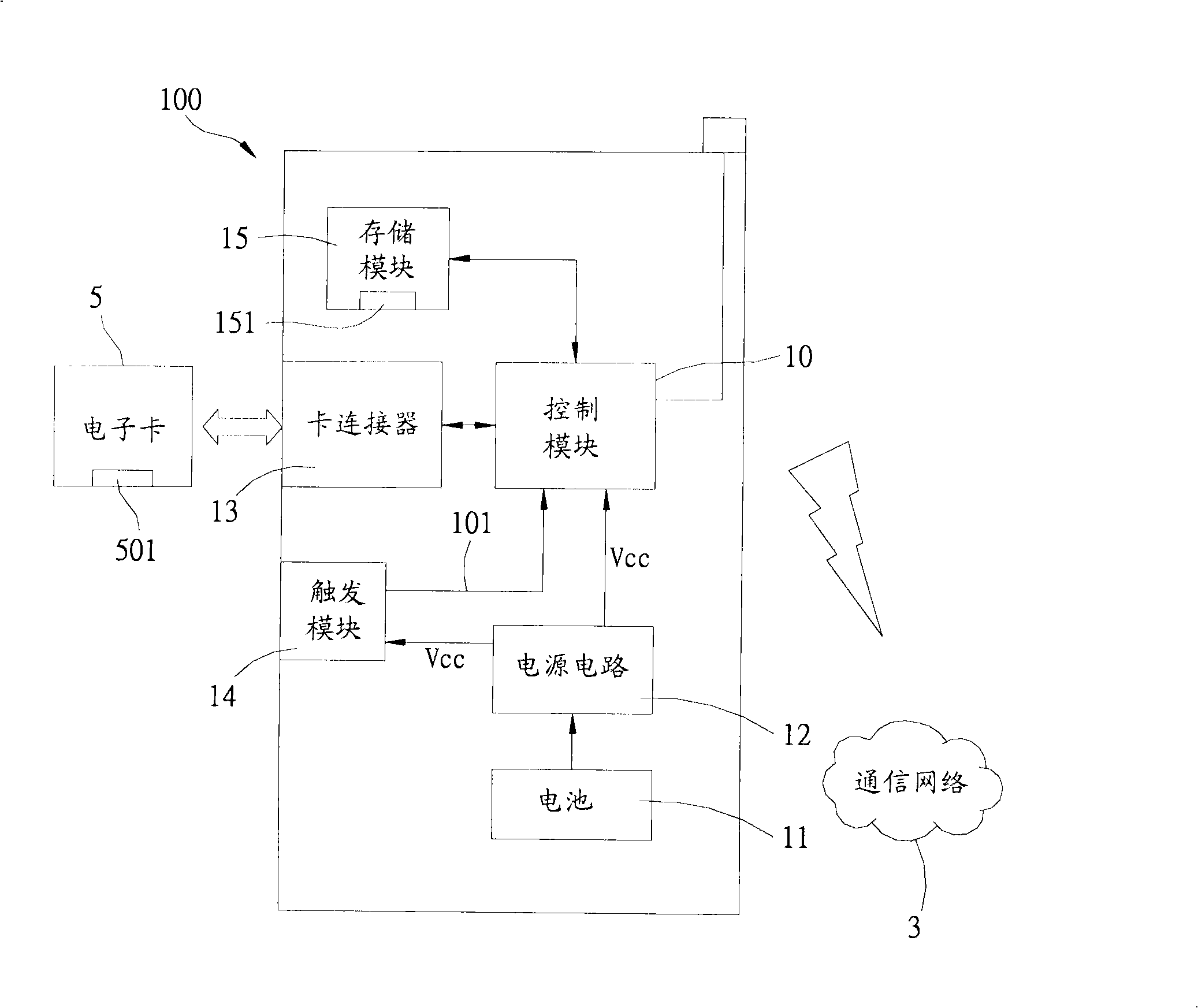

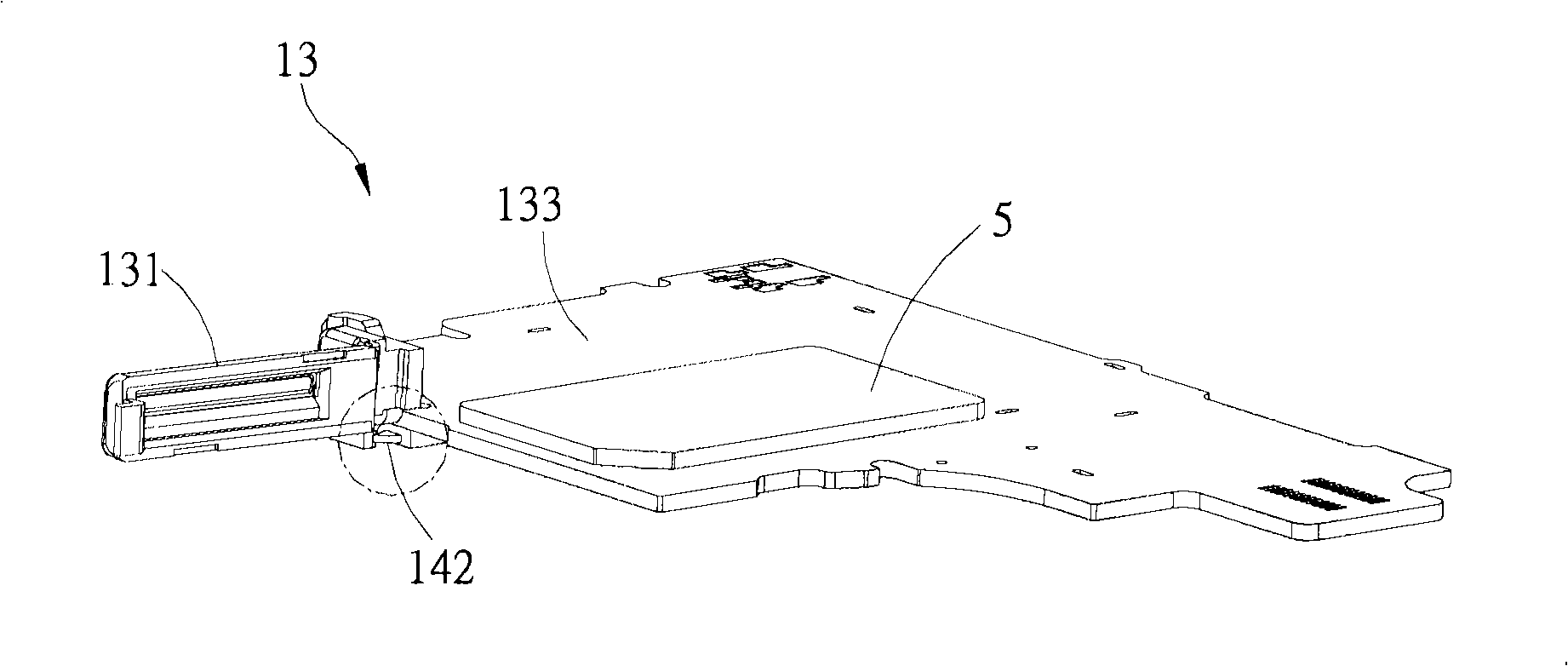

Method for replacing electronic card without closedown and communication apparatus

InactiveCN101494924AEasy to operateTime-saving and labor-saving effectWireless communicationComputer hardwareElectricity

The invention relates to a method for displacing electronic card without powering off and communication apparatus thereof. The communication apparatus comprises a control module, a card connector for plugging the electronic card and a triggering module. The method comprises the following steps: (a) the triggering module is triggered to generate a triggering signal to the control module while the communication apparatus is in power on state; (b) the control module receives the triggering signal, if detecting out that the electric connection of the card connector and the electronic card occurs from nothing, judges as a card inserting-in mode; and (c) when the control module judges as the card inserting-in mode, supplies power to the electronic card in the card connector.

Owner:WISTRON NEWEB

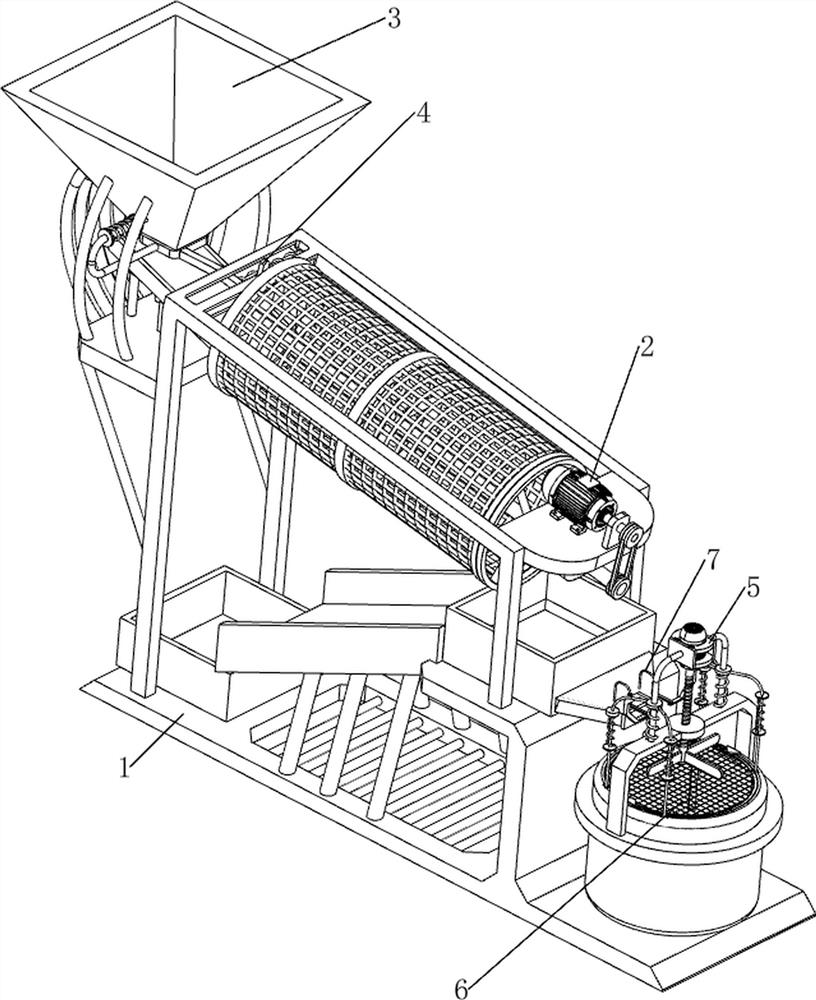

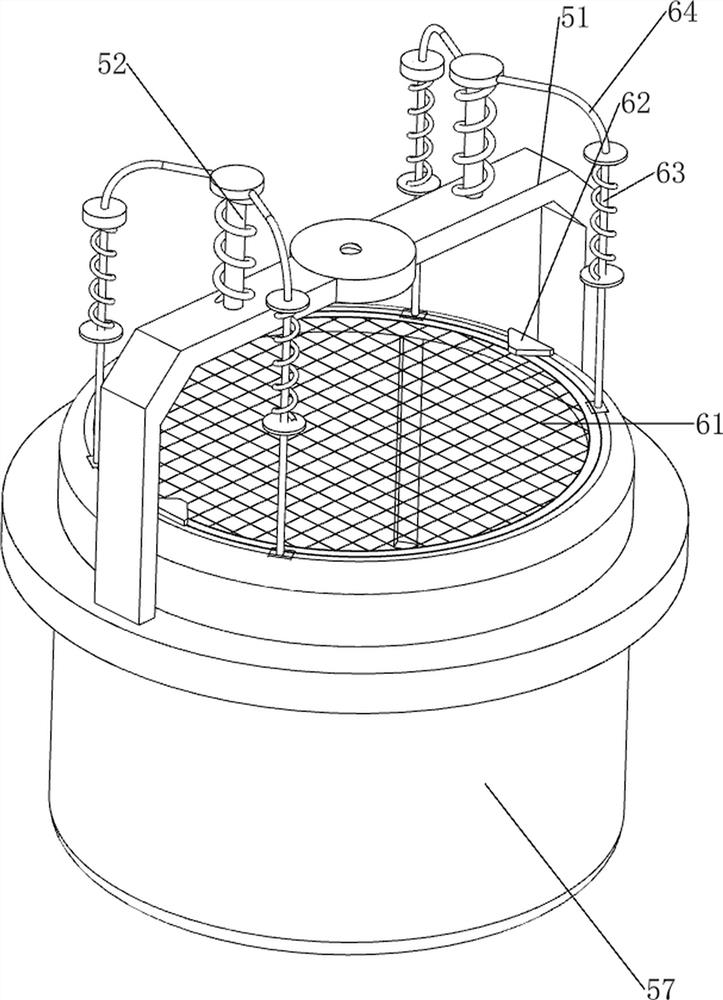

Agricultural red date collecting and screening equipment

PendingCN113333266ARealize automatic cleaningEasy to take outSievingScreeningAgricultural scienceAgricultural engineering

Owner:陈晓东

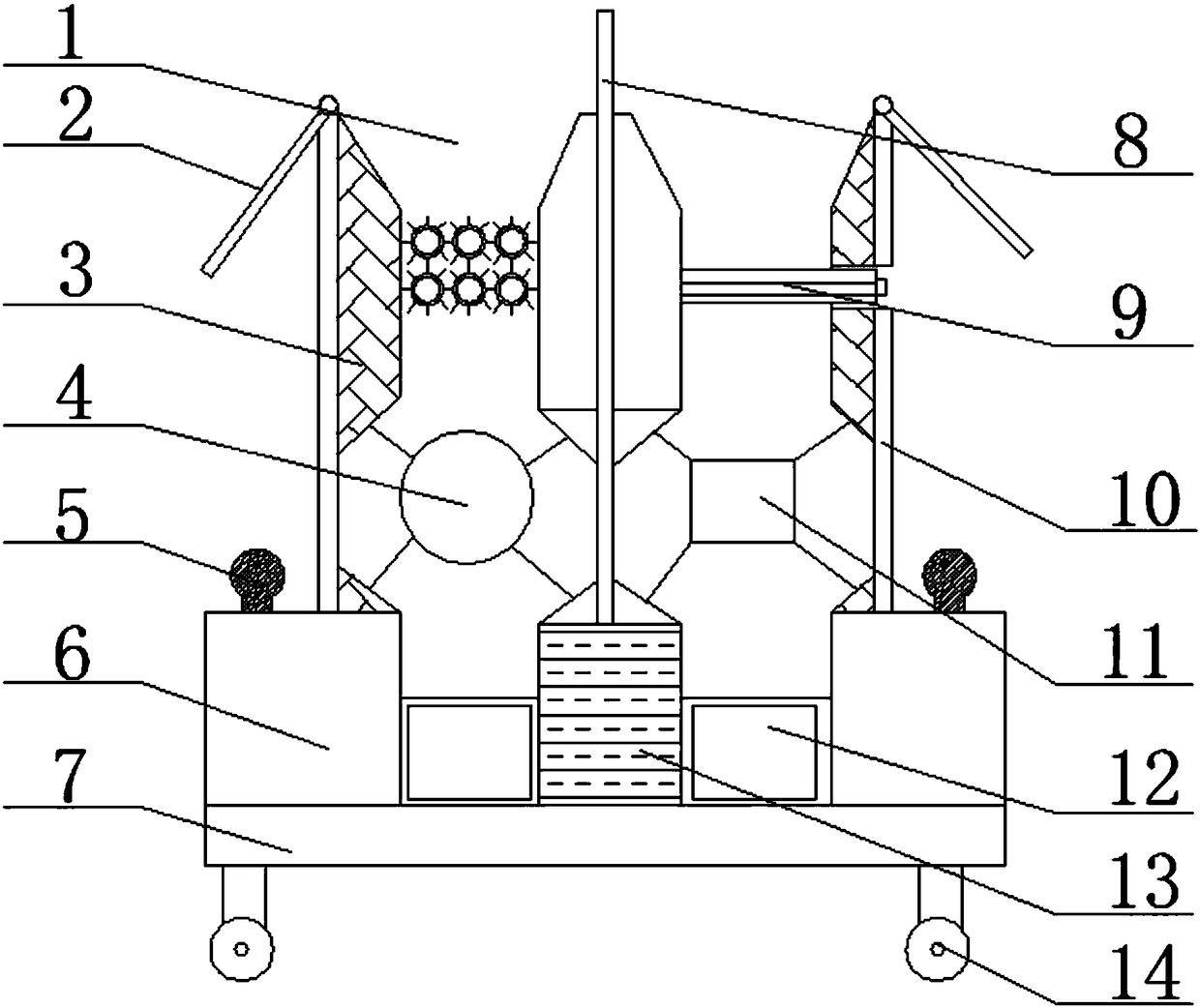

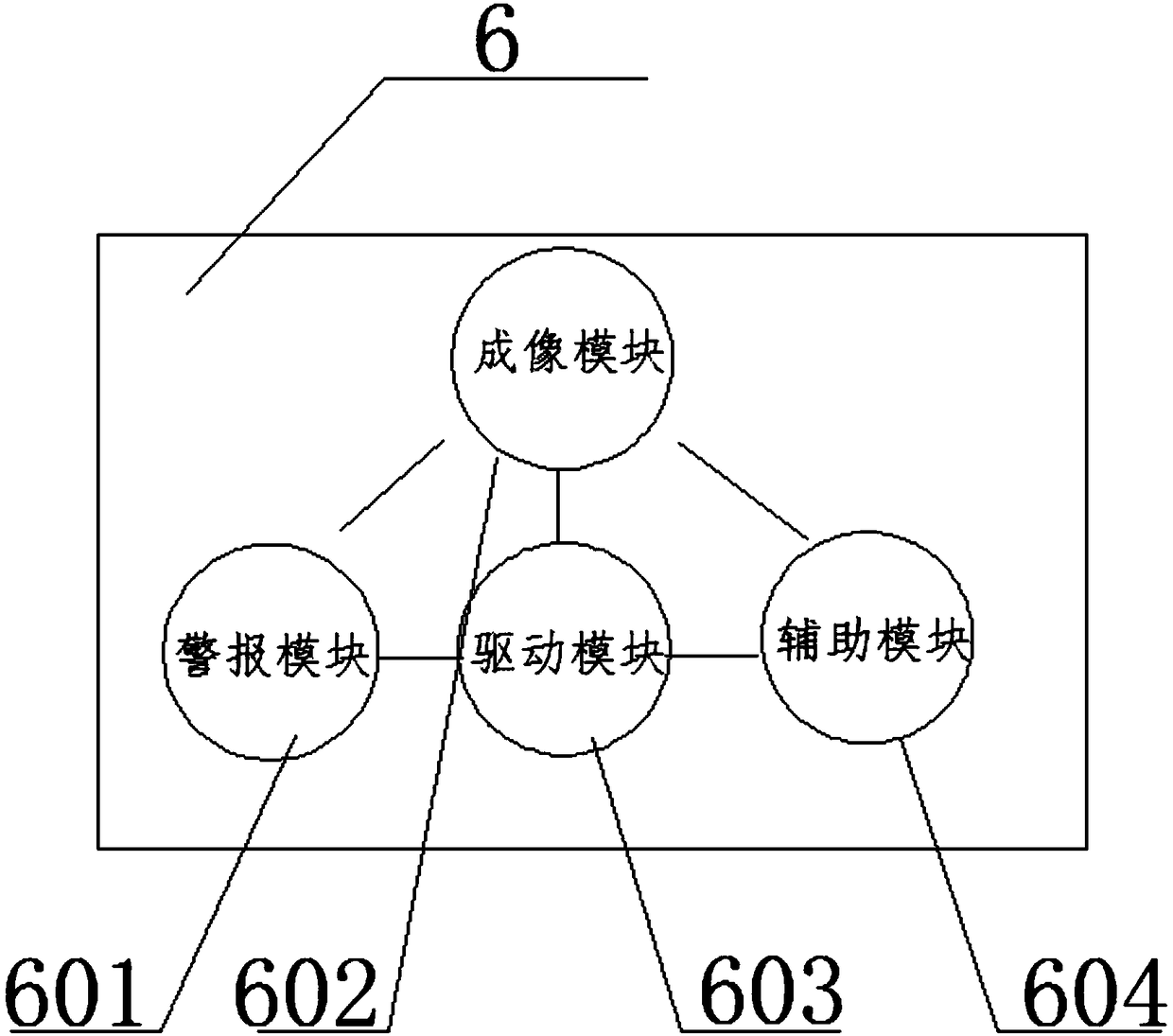

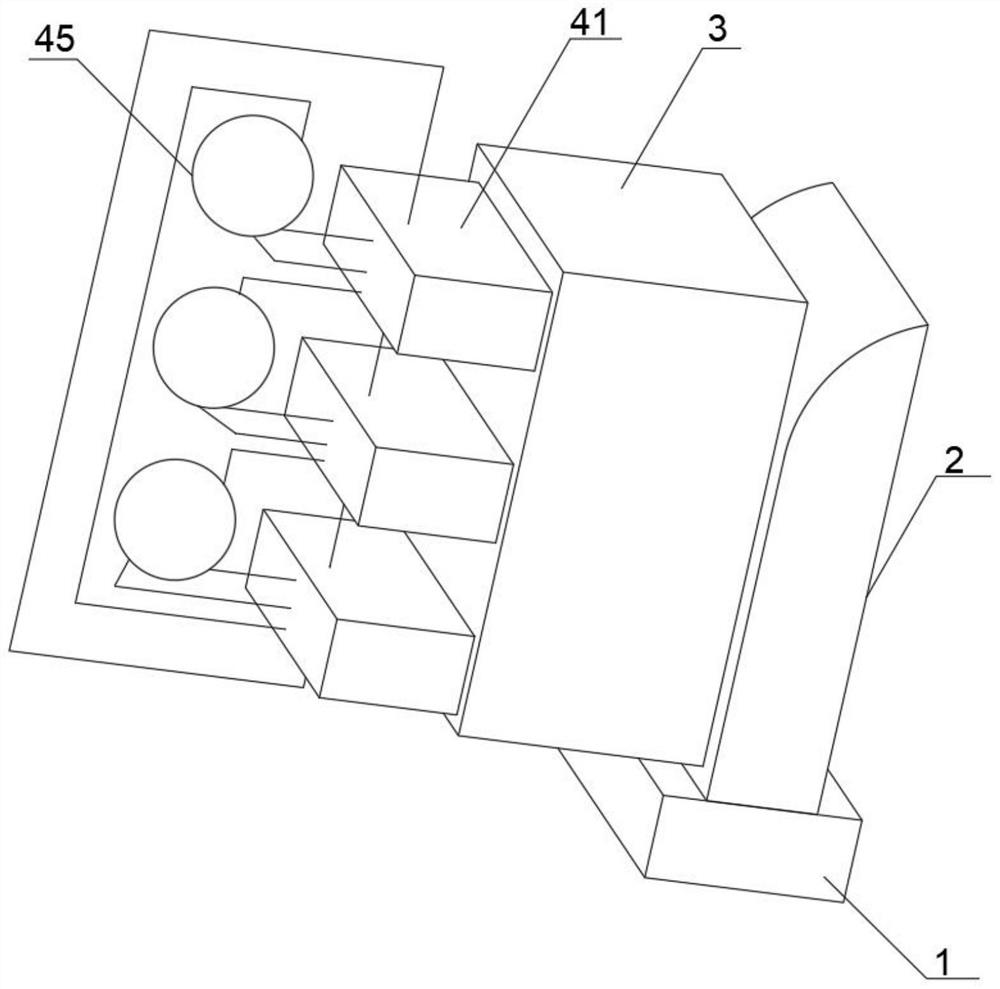

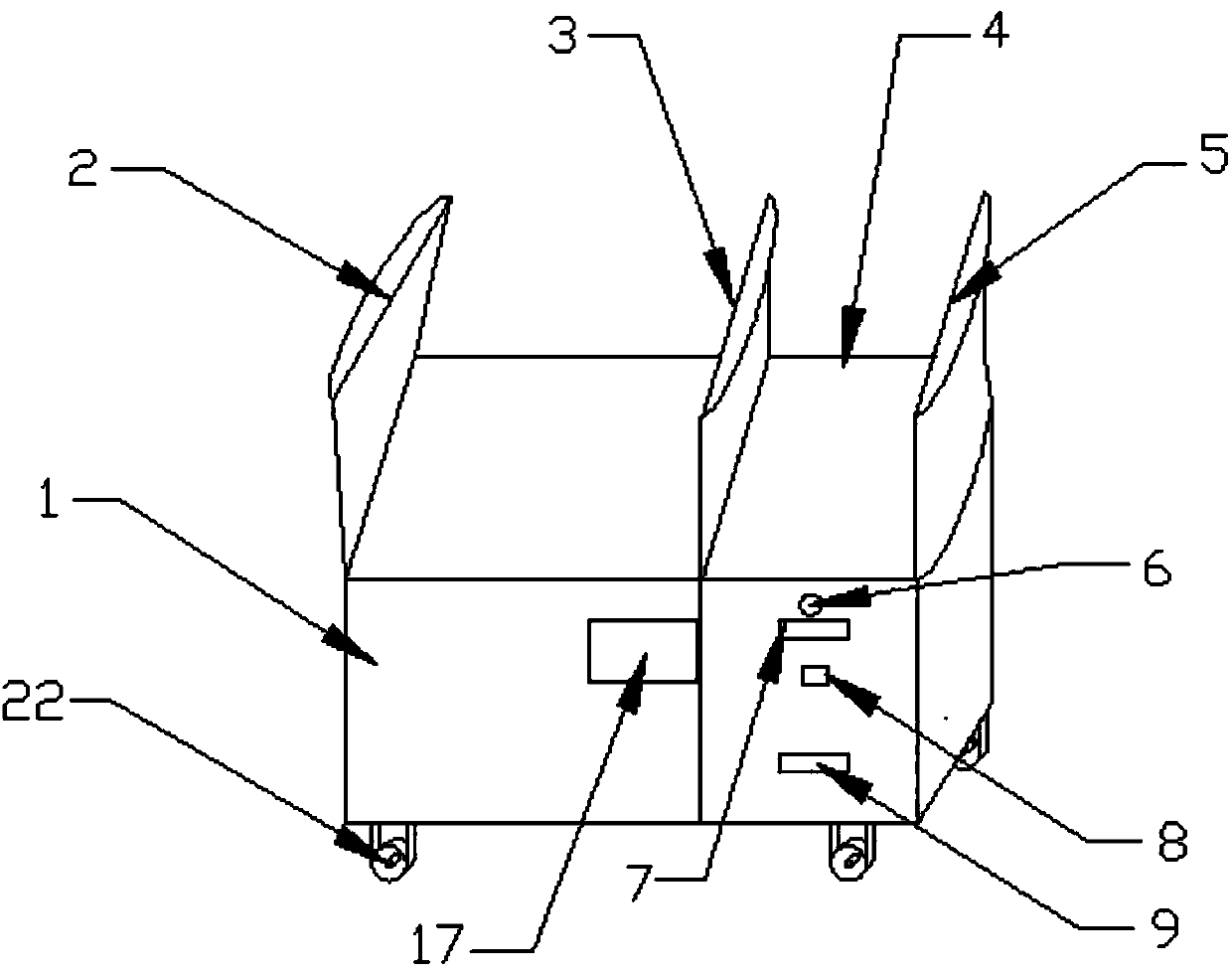

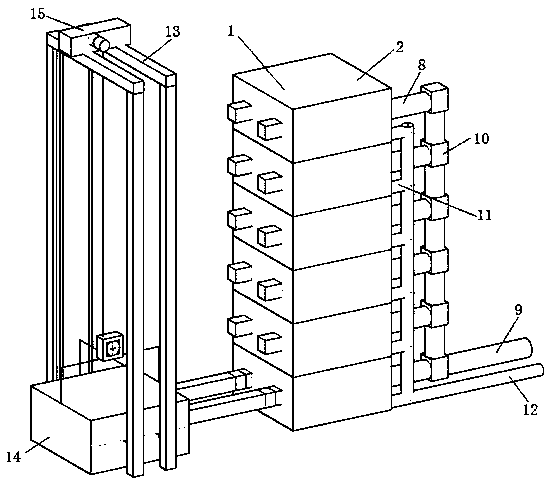

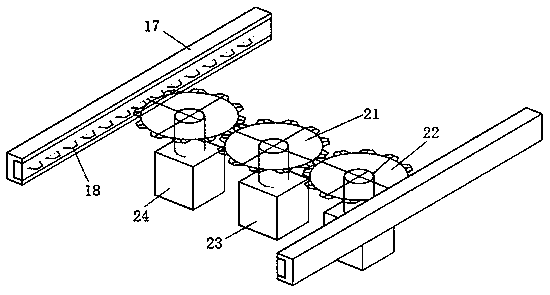

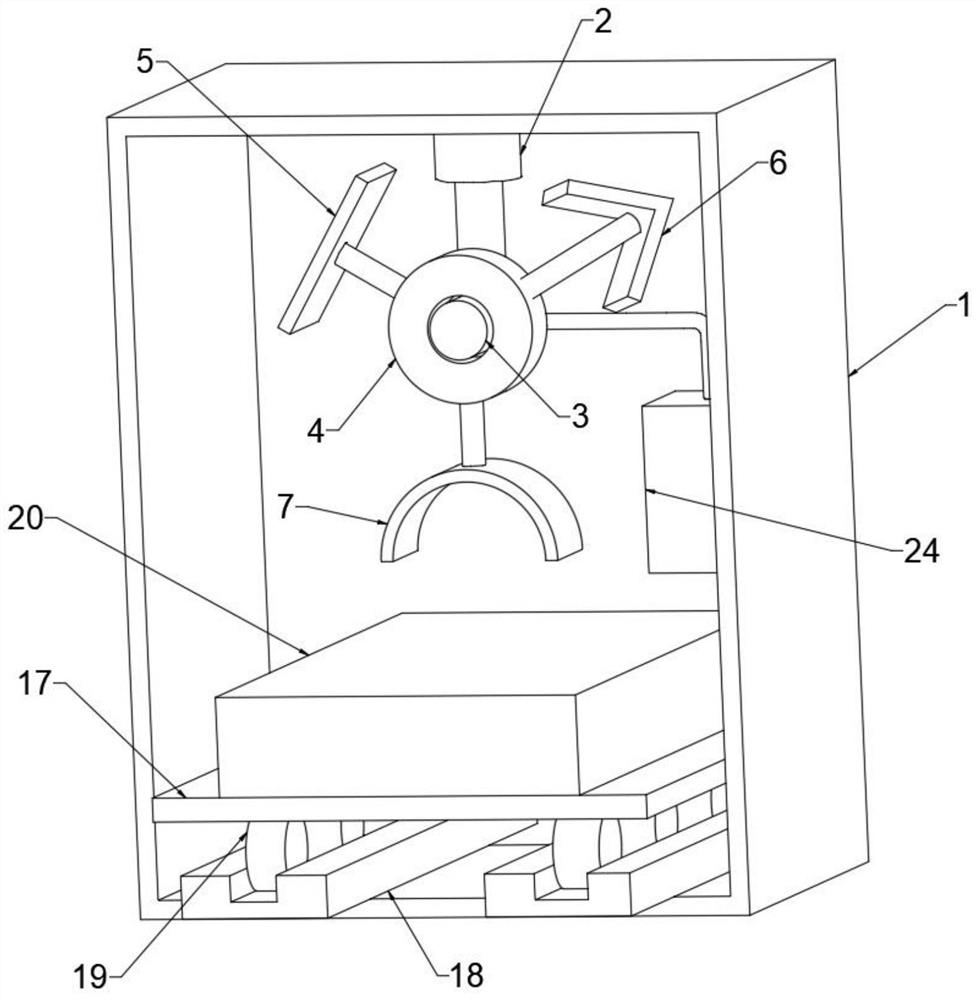

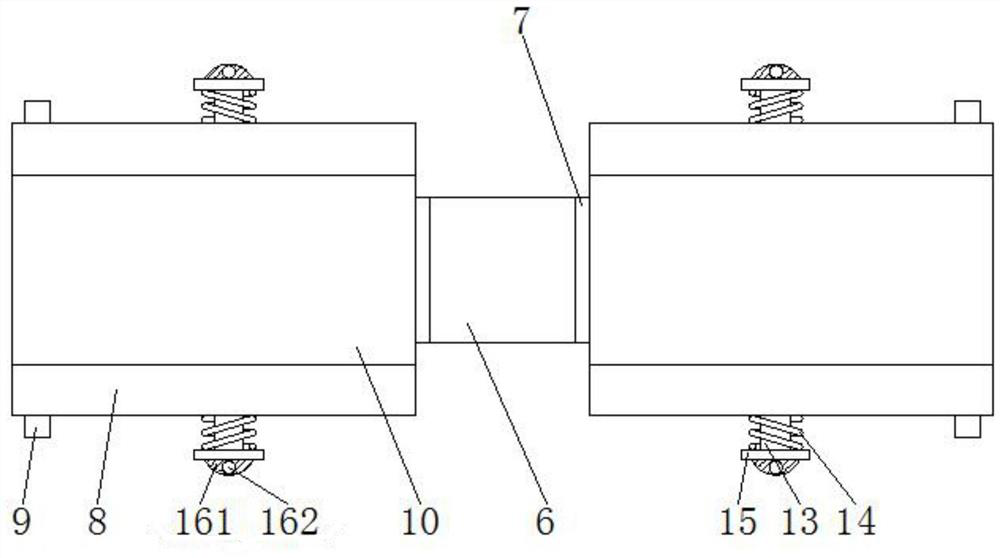

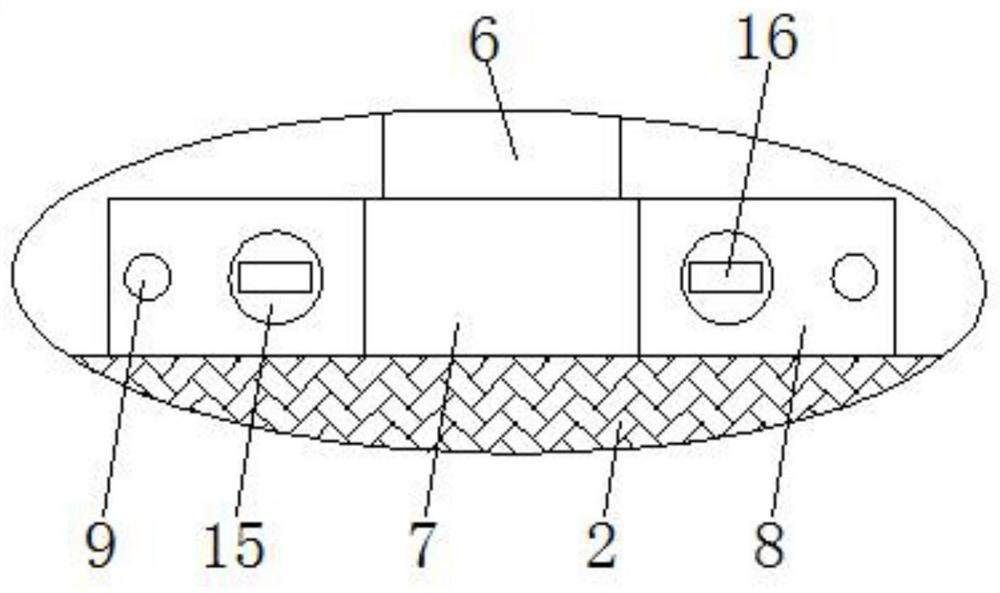

Multi-stage crushing device of construction waste treatment

ActiveCN108097439ARealize purificationImprove sound insulationGrain treatmentsNumerical controlWastewater

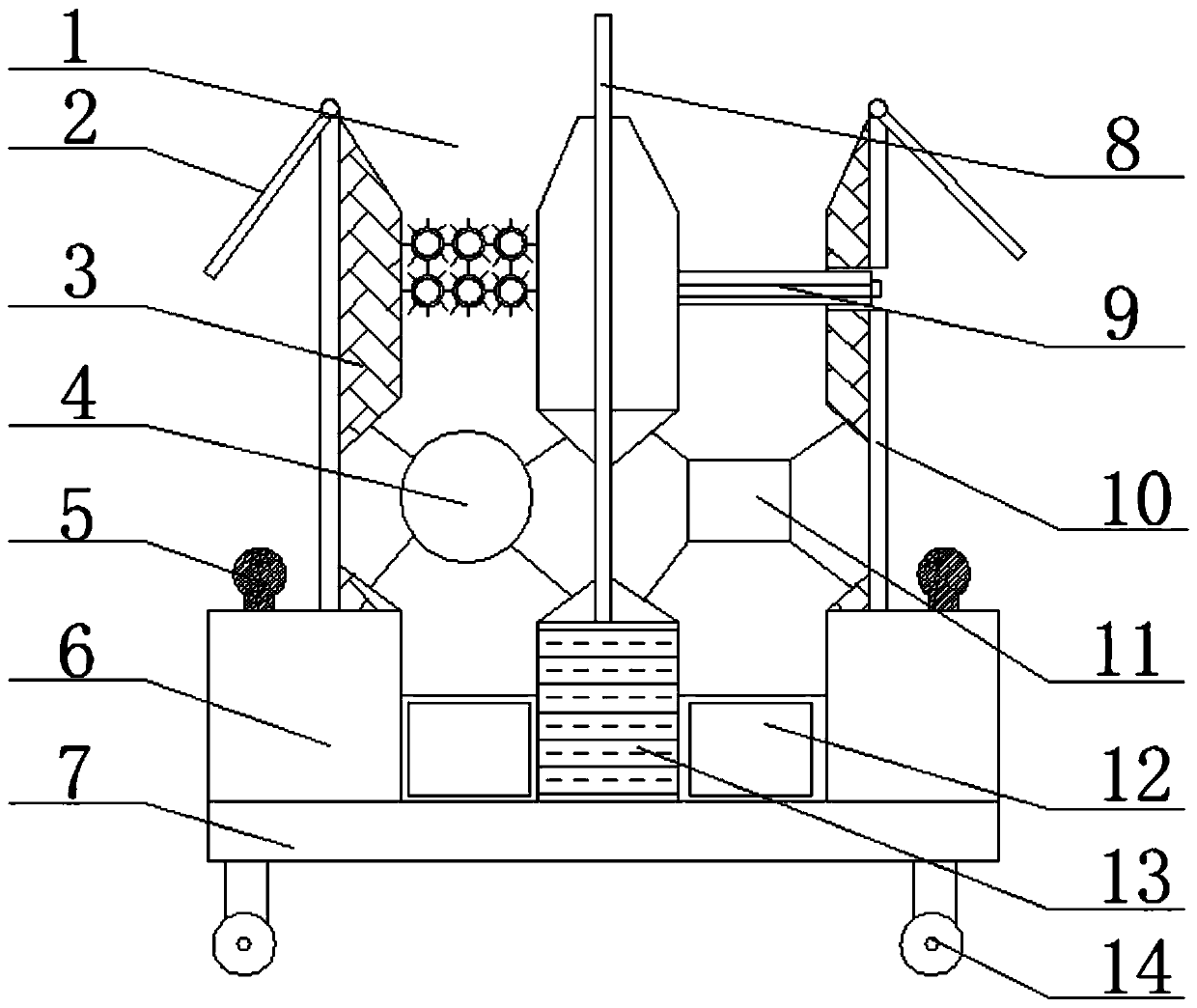

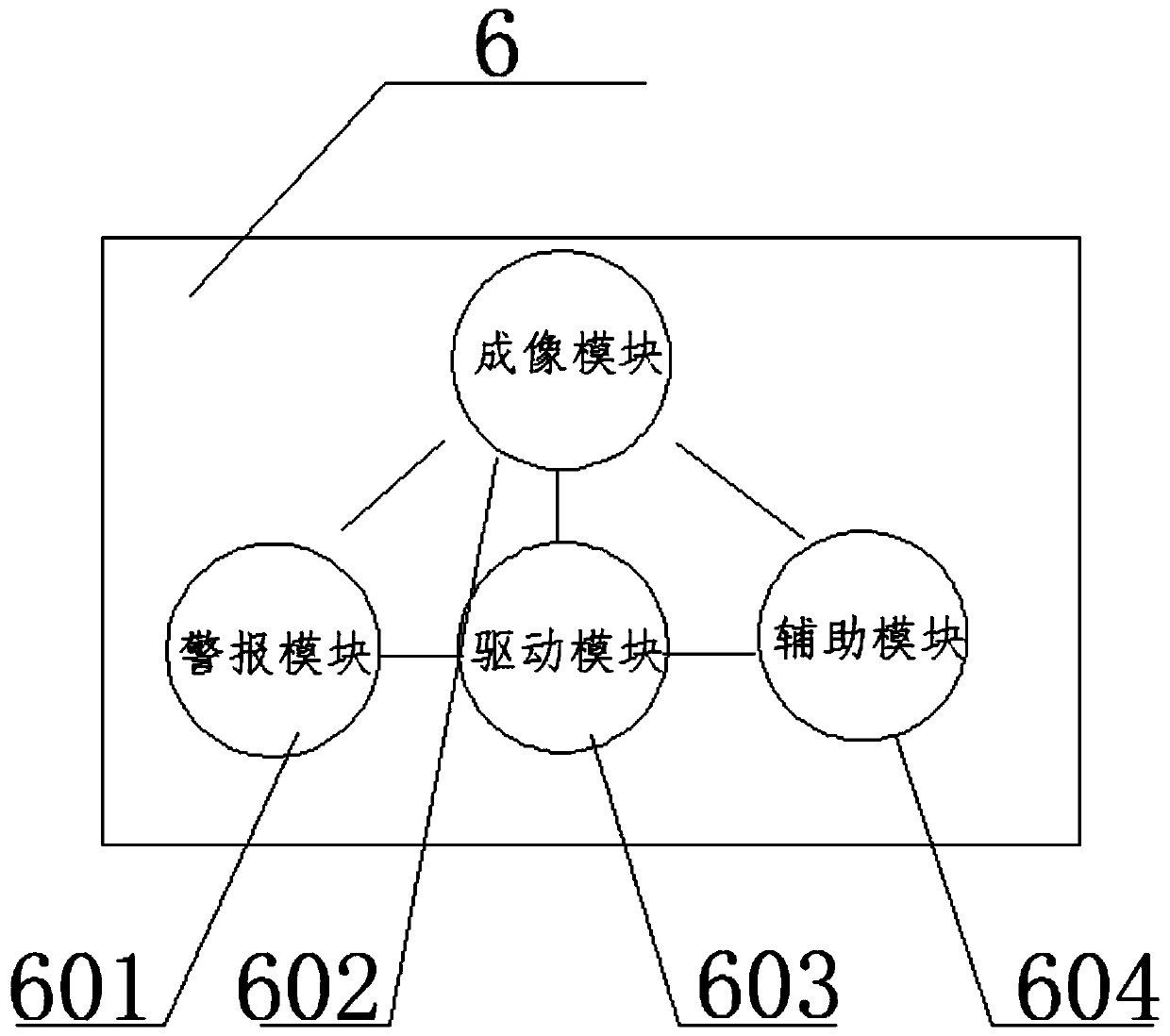

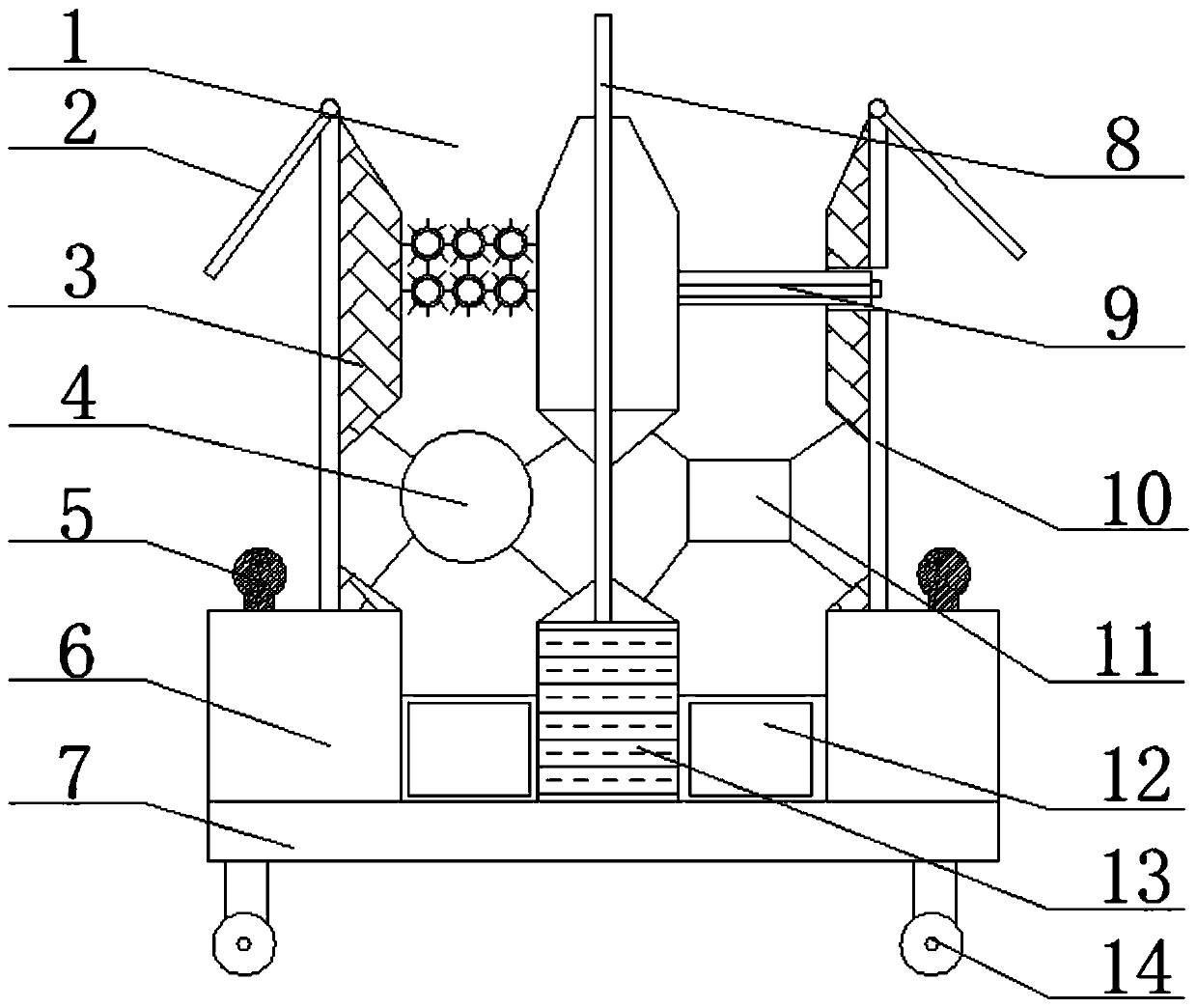

The invention discloses a multi-stage crushing device of construction waste treatment. The multi-stage crushing device comprises a feed inlet, cover plates, a sound insulation board, a crushing mechanism, warning lights, numerical control boxes, warning modules, imaging modules, driving modules, auxiliary modules, a base, a baffle plate, a filter layer, an outer shell, a purification mechanism, discharge openings, a display screen and rollers. The multi-stage crushing device has the beneficial effects that the multi-stage crushing device of construction waste treatment provided by the invention can crush construction solid waste, and can further purify construction wastewater impurities; the arranged warning lights can effectively prompt whether the device breaks down or not, so that staffare warned to maintain the device at first time; the arranged display screen can display parameter data of the device during crushing, so that performance of the device during operation can be reflected; and besides, the sound insulation effect is remarkable, the device can be moved, transfer and storage of the device are convenient, time-saving and effort-saving effects can be achieved, and thedevice is suitable for popularization and utilization.

Owner:罗田县百纳建筑废弃物资处理有限公司

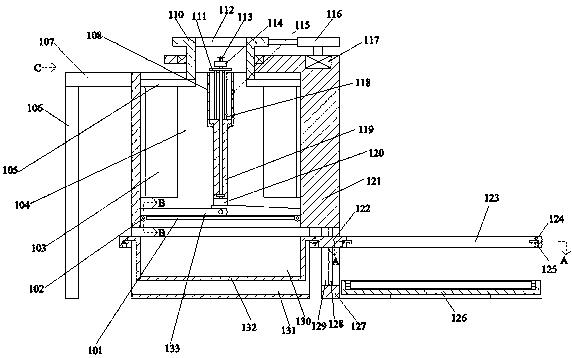

Putty powder producing and processing device

InactiveCN110026108AEasy to importTime-saving and labor-saving effectRotary stirring mixersTransportation and packagingBiochemical engineeringIntegrated design

The invention discloses a putty powder producing and processing device which comprises a tank body, wherein a stirring cavity penetrating up and down is arranged in the tank body; an accommodating cavity is communicated in a lower end wall of the stirring cavity; a supporting platform for the placement of raw materials is fixedly arranged on a left end surface of the tank body; a supporting frameabutted against the ground is fixedly arranged on a lower end surface of the supporting platform; a stirring device for stirring putty powder is arranged in an upper end surface of the tank body; anda discharging device for controlling pouring of the putty powder and preventing the putty powder from blocking is arranged on a lower side of the stirring device. The putty powder producing and processing device adopts the stirring device, the discharging device and a loading device to prevent the putty powder from staying in the device during continuous processing to affect component change of the putty powder while efficiently stirring the putty powder, so that a use effect of the putty powder is reduced; and an integrated design is adopted to prevent unnecessary waste caused by secondary transportation when the putty powder is loaded, thereby greatly reducing production costs and improving production efficiency.

Owner:胡月明

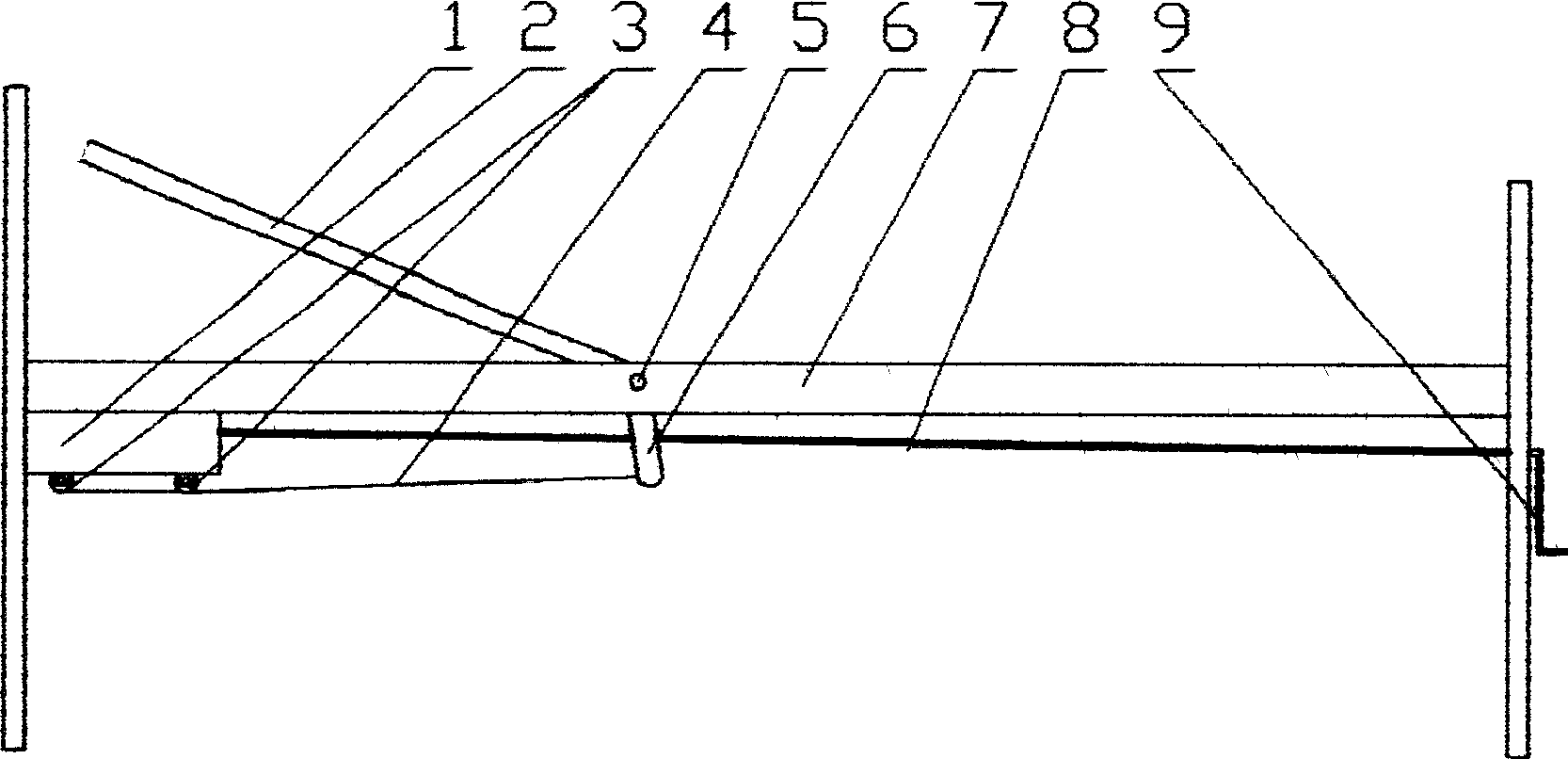

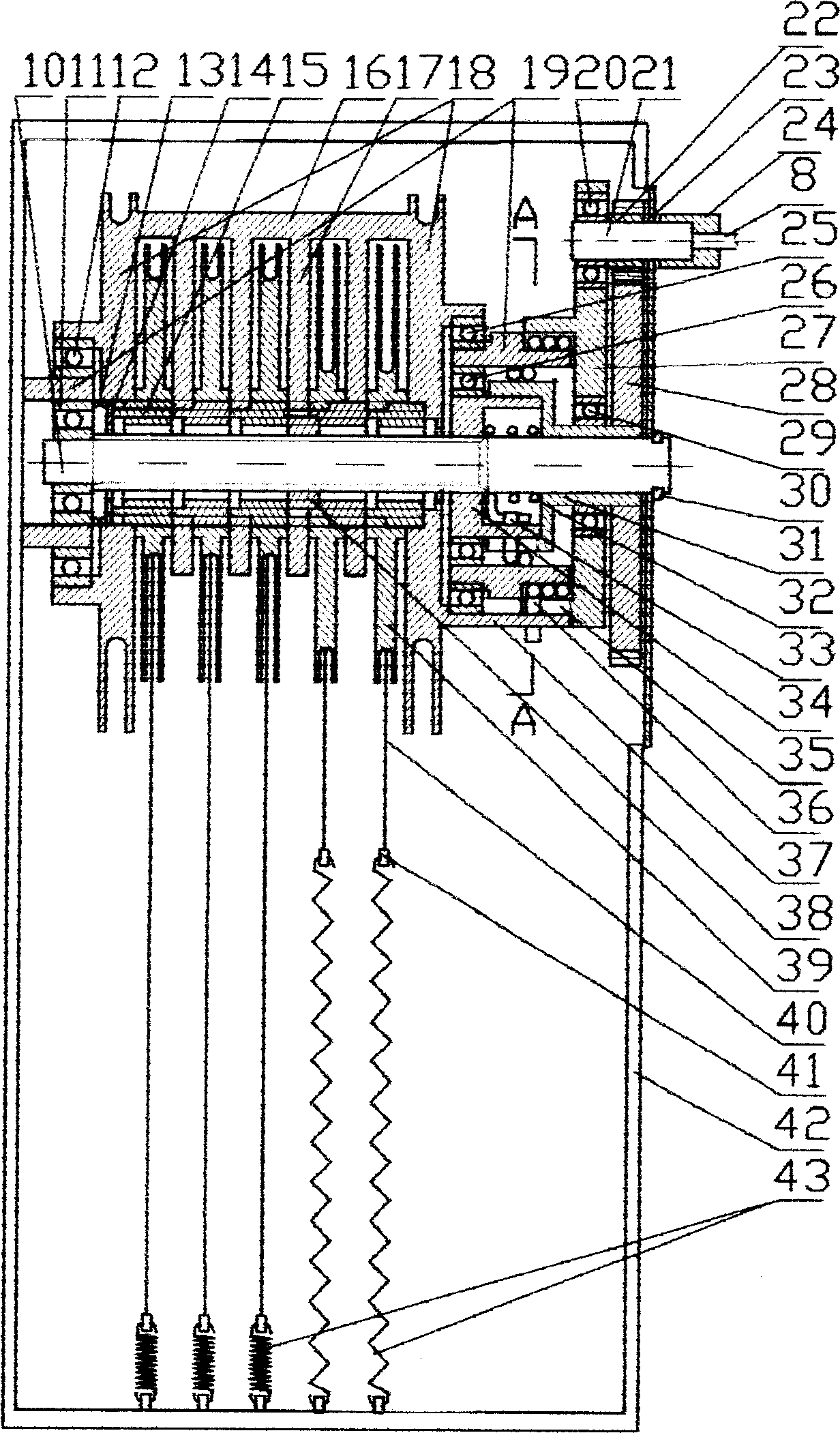

Differential type spring balancing nursing bed

A spring balanced differential nursing bed features that the balancing springs are installed to the movable part of nursing bed for balancing the body weight of patient, the planetary gear structure or gear set structure, and flexible member and its winding device are used for drive mechanism, a spring regulator is used to regulate the number of spring for matching the body weight of patient, and a differential unit is used for loading or unloading springs for balancing the torque.

Owner:孙新利

Processing method of crosshead pin of low-speed diesel engine for MAN-series ship

The invention discloses a processing method of a crosshead pin of a low-speed diesel engine for a MAN-series ship. The crosshead pin comprises a large outer circle and two small outer circles, the twosmall outer circles are coaxially connected to the two sides of the large outer circle respectively, center holes are formed in the end surfaces of the two sides of the small outer circles, and the outer periphery of the large outer circle is provided with a notch plane. The processing method comprises the following specific steps that 1, a boring machine is used for machining the two end surfaces and the notch plane of the crosshead pin in a horizontal station; 2, two centers are adopted for clamping workpieces on a lathe, and machining the large outer circle, the small outer circles and endsurfaces; 3, the boring machine is used for precisely machining all holes in the notch plane and the circumference in a vertical station; 4, a grinding machine is used for grinding the large outer circle and the small outer circles in a supporting and grinding mode; and 5, the polishing lathe is used for clamping the workpieces and polishing the crosshead pin workpieces through two centers. The processing method has the advantages that the procedures are few, the process route is short, the number of times of getting on is small, the processing efficiency of the crosshead pin is greatly improved, the labor intensity of operators is reduced, and the effects of saving time and labor are achieved.

Owner:CSSC MES DIESEL

Sofa with searching device at bottom

InactiveCN107028407ATime-saving and labor-saving effectEasy to useSofasCouchesEngineeringSlide plate

The invention relates to the technical field of living furniture, in particular to a sofa with an object-finding device at the bottom, which includes a backboard and a seat board, the backboard is vertically arranged on one side of the seat board, and the four corners of the bottom Support legs are provided, the bottom of the seat close to the back plate is provided with a limiting plate, the two sides corresponding to the bottom of the seat are respectively provided with side plates, and the limiting plate is located between the two side plates. The inner sides of the two side plates are evenly provided with chute, the two chute are jointly connected with a slide plate, and the slide plate and the limit plate are connected by a spring, and the bottom of the slide plate is connected with a mounting bar. The present invention has the advantages of simple structure and convenient use, which is not only convenient for taking out the articles rolled down under the sofa, but also convenient for cleaning the ground under the sofa.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

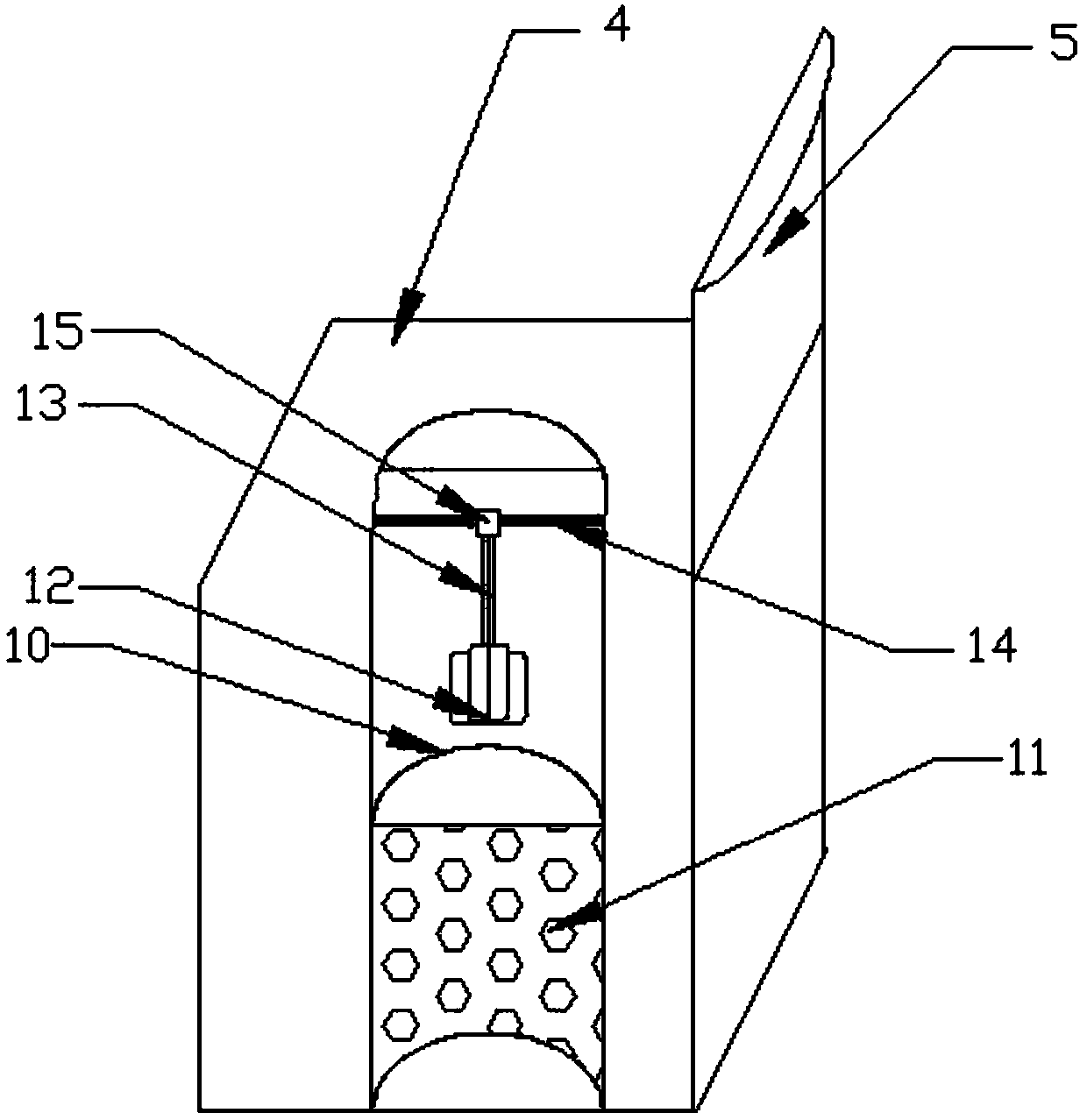

Single-screw type sealed refrigeration compressor

InactiveCN112762647AImprove cooling effectIncrease pump pressureLighting and heating apparatusDomestic refrigeratorsPhysicsCool storage

The invention discloses a single-screw type sealed refrigeration compressor which comprises a compressor body and is characterized in that a multi-layer refrigerator is arranged above the compressor body and is provided with three layers of storage cavities from bottom to top, and the three layers of storage cavities are respectively a freezing cavity, a refrigerating cavity and a fresh-keeping cavity from bottom to top. Condensation pipes are arranged in the freezing cavity, the refrigerating cavity and the fresh-keeping cavity and are connected with the compressor body through pipelines, the number of the condensation pipes in the freezing cavity, the number of the condensation pipes in the refrigerating cavity and the number of the condensation pipes in the fresh-keeping cavity are gradually decreased, flexible air cushions are arranged at the bottoms of the freezing cavity, the refrigerating cavity and the fresh-keeping cavity, and tension films are arranged in the condensation pipes. A flexible traction wire is arranged on one side of each tension film, a gear adjuster is arranged on the compressor body, a purification tank is further arranged on one side of the compressor body, the flexible traction wires are connected with the gear adjuster, and the condensation pipes are connected with the purification tank through a pipeline. The single-screw type sealed refrigeration compressor has the characteristics of saving time and labor and being good in refrigeration effect.

Owner:陈永创

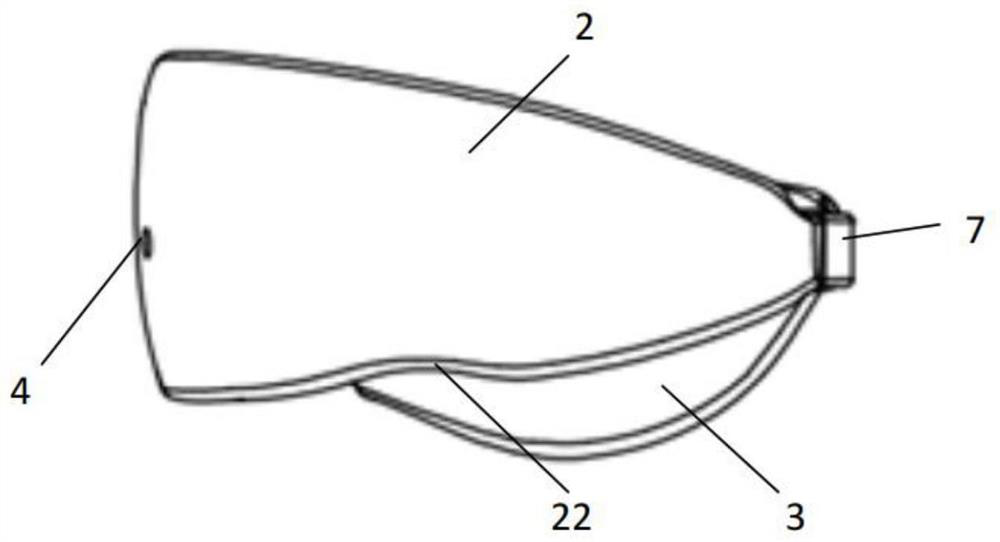

Induction appliance with thickness-adjustable occlusal pad in molar area

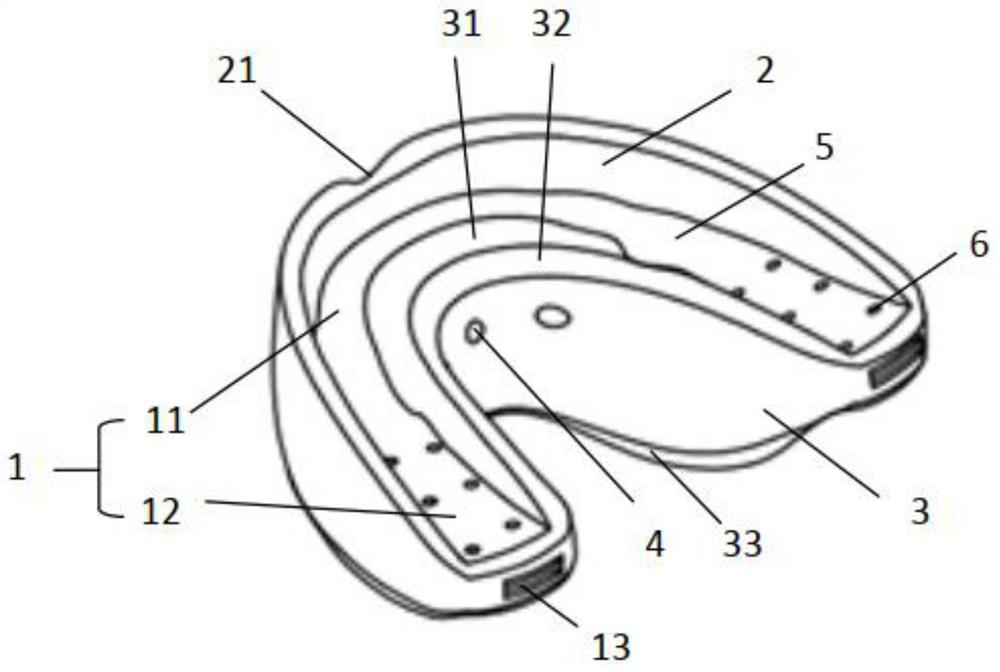

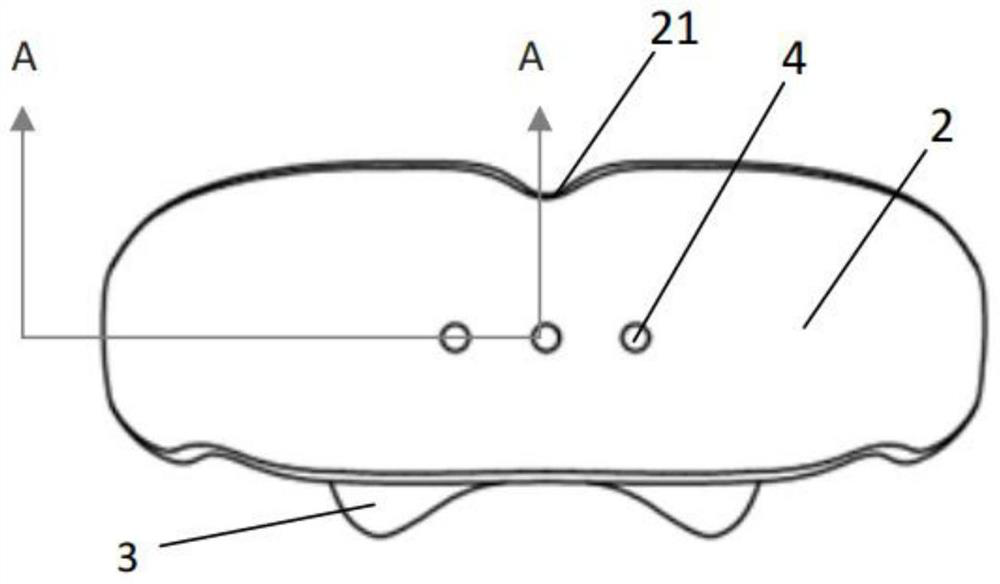

PendingCN113633407AControlling Vertical Growth IssuesMeet the needs of vertical developmentOthrodonticsAnterior occlusionJAW DEFORMITY

The invention provides an induction appliance with thickness-adjustable occlusal pad in molar area, which comprises a U-shaped occlusal pad, the outer edge of the occlusal pad respectively extends upwards and downwards to form a lip-cheek baffle, the inner edge of the occlusal pad respectively extends upwards and downwards to form a tongue baffle, and the occlusal pad, the lip-cheek baffle and the tongue baffle jointly define an up-down integrated induction appliance adaptive to tooth occlusion. An occlusal pad of the induction appliance comprises a front occlusal pad and a molar area occlusal pad, the thickness of the front occlusal pad is fixed and cannot be adjusted, the molar area occlusal pad is additionally provided with a containing groove and an adjusting pad, the adjusting pad is in the shape of a rectangular-like strip block which is detachably placed in the containing groove, the adjusting pad has various sizes and thicknesses of different specifications, and due to the fact that the thickness of the front occlusal pad is not adjustable, the thickness of the molar area occlusal pad can be adjusted by replacing adjusting pads with different sizes and thicknesses, so that the thickness difference of the front occlusal pad and the rear occlusal pad can be realized by adjusting the thickness of the molar area occlusal pad, and the development of different types of vertical malocclusion of children can be controlled.

Owner:LM TECH (BEIJING) CO LTD

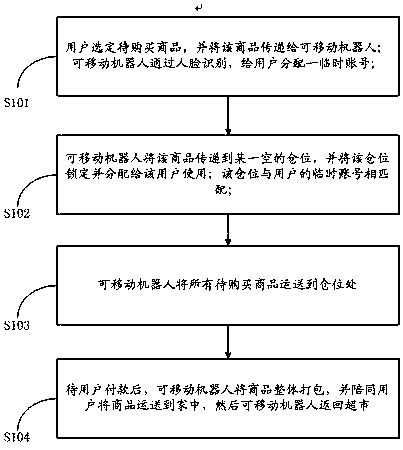

Method for automatically transporting articles to be purchased in supermarket

InactiveCN108217044ATime-saving and labor-saving effectAvoid pushingCharacter and pattern recognitionPayment architectureTemporary Account NumberComputer science

The invention discloses a method for automatically transporting articles to be purchased in a supermarket. The method comprises the following steps that S101, a user selects commodities to be purchased, and transfers the commodities to a mobile robot; the mobile robot allocates a temporary account number to the user through face recognition; S102, the mobile robot transfers the commodities to a certain empty shipping space, locks the shipping space and allocates the shipping space to the user; the shipping space is matched with the temporary account of the user; S103, the mobile robot transports all the commodities to be purchased to the outside of the shipping space; and S104, after the user pays for the commodities, the mobile robot integrally packages the commodities, accompanies the user to transport the commodities to the home and then returns to the supermarket. The method is provided for assisting the user in shopping. The user can be assisted in transporting the commodities tobe purchased to a checkout counter with less time and labor, that is, the shopping space is located nearby the checkout counter. In this way, the user does not need to push a trolley or carry the commodities with hands. Accordingly, the time-saving and labor-saving effects are achieved.

Owner:李汉忠

Combined bread machine

InactiveCN107638101AEasy to manufactureTime-saving and labor-saving effectKitchen equipmentMixing/kneading with vertically-mounted toolsEngineering

The invention discloses a combined bread machine. The machine comprises a baking oven, a flour mixing box body is arranged on one side of the baking oven, and a temperature sensor is arranged on one side of the flour mixing box body; a temperature display screen is arranged on the bottom of the temperature sensor, a stirrer is arranged at the top of a flour mixing barrel, and a telescopic stirringshaft is arranged on the top of the stirrer; a rotation shaft with holes is arranged on the top of the telescopic stirring shaft, the rotation shaft with holes is connected with the telescopic stirring shaft through a fixed ring, and a pigment powder inlet groove is formed in one side of the fixed ring; the stirrer can stir flour in the flour mixing barrel, after the length of the telescopic stirring shaft is adjusted, the stirrer can stir eggs in the flour mixing barrel, and the effects of saving time and labor are achieved; the proper amount of pigment powder is placed in the pigment powderinlet groove, through rotation of the rotation shaft with holes, even bread with various colors can be easily prepared in bread preparation, and the attractive and delicious eating effect is achieved.

Owner:东台市新杰科机械有限公司

Water spraying type tea cup cleaner

InactiveCN108714016AWide range of adaptationPracticalTableware washing/rinsing machine detailsEngineeringWater spray

The invention discloses a water spraying type tea cup cleaner. The tea cup cleaner is characterized by mainly comprising a hairbrush brush head, a hairbrush rod, a cleanser container box, a lead pipe,a handle box, a motor and a battery box, wherein the hairbrush brush head is fixed around the hairbrush rod and is arranged at one end of the hairbrush rod, the other end of the hairbrush rod is connected to one end surface of the cleanser container box, one end of the lead pipe is connected to the end surface of the cleanser container box, and the other end of the lead pipe is connected to the top surface. When the water spraying type tea cup cleaner is used in the cleaning process, clean water and a cleaner can be directly added through a device, so that the water spraying type tea cup cleaner is convenient, practical and strong in economy.

Owner:如皋市昌旭机械制造有限公司

Multifunctional steamed bun machine

ActiveCN108618588AIncrease profitTime-saving and labor-saving effectCooking-vessel materialsFood processingMechanical engineeringUtilization rate

The invention discloses a multi-functional steamed bun machine. The side walls of the box body of each layer of steaming box are respectively provided with a parallel opposite roller way, and the steamed bun dandruff comb is slidably matched on the roller way through a roller; one side of the steamed bun dandruff comb is provided with a baffle with an electromagnetic coil which is matched with oneside of the steam box; the baffle with the electromagnetic coil is provided with a telescopic rod with an electromagnetic coil; the frame is provided with a lifting motor for hoisting the lifting power box body; the two sides of the power box body are respectively glidingly arranged on the vertical support arm of the frame through a sliding block; the side walls of the power box body are respectively provided with parallel slide ways; the slide way is internally provided with a rack; one end of the rack is connected with a telescopic rod with an electromagnetic coil at the tail end, and an active gear is arranged between the parallel sliding ways; and the driving gear is respectively meshed with the rack on the two sides through the driven gear. The multi-functional steamed bun machine can effectively improve the utilization rate of the steam, achieve the effect of time save and labor save, and can automatically take any layer of steamed bun dandruff comb according to the requirement.

Owner:HENAN NORMAL UNIV

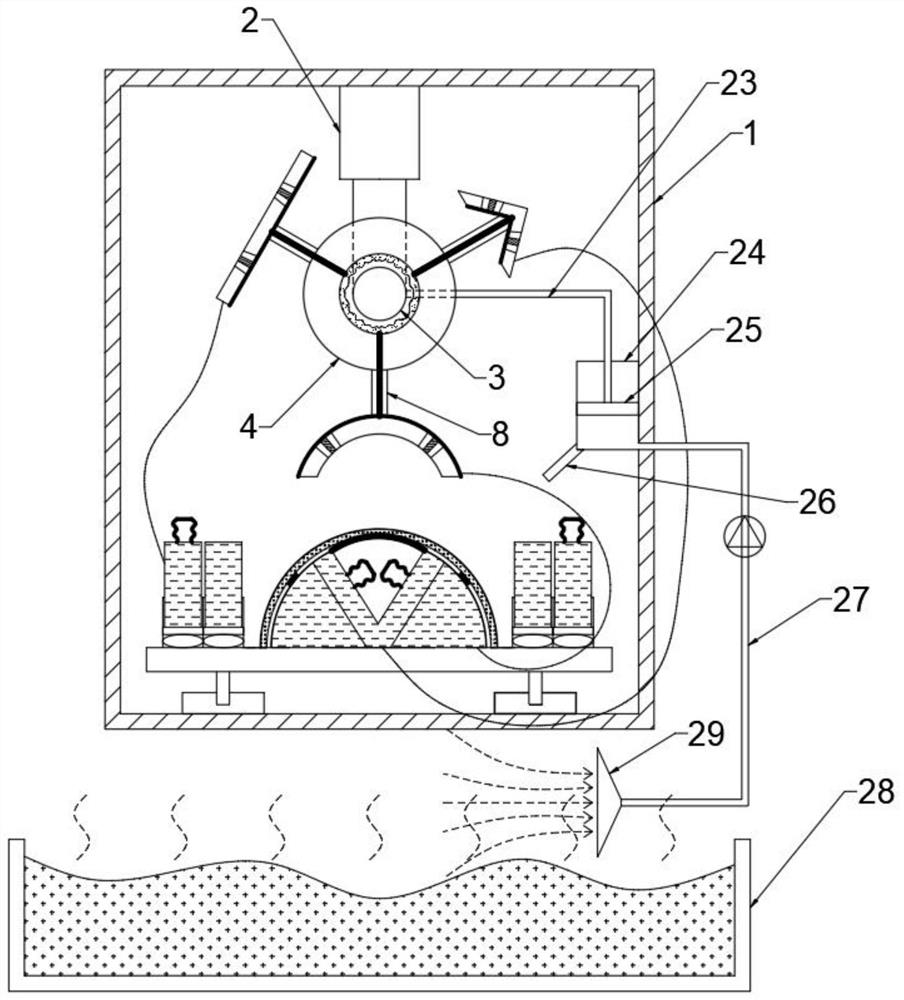

Photovoltaic module steel frame stamping corner connector with protective wrap angles

ActiveCN113579070ATime-saving and labor-saving effectImprove stamping precisionShaping toolsStripping-off devicesSteel frameMechanical engineering

The invention discloses a photovoltaic module steel frame stamping corner connector with protective wrap angles. The photovoltaic module steel frame stamping corner connector comprises a stamping shell and is characterized in that a stamping mechanism is arranged on the top layer of the inner side of the stamping shell, a die pressing mechanism is arranged on the bottom side of the interior of the stamping shell, and an air cooling mechanism is installed on the side wall of the stamping shell; a water cooling mechanism is arranged at the bottom of the stamping shell, the stamping mechanism comprises a telescopic air cylinder, the bottom of the telescopic air cylinder is fixedly connected with a transverse shaft, a main shaft disc is connected to the outer portion of the transverse shaft in a rolling mode, and three sets of connecting rods are fixedly connected to the main shaft disc; and the other ends of the three sets of connecting rods are fixedly connected with a plane pressing plate, a right-angle pressing plate and an arc-shaped pressing plate respectively, the die pressing mechanism comprises a conveying panel, a plurality of sets of rolling wheels are installed below the conveying panel, and a conveying rail is connected to the lower portions of the rolling wheels in a rolling mode. The photovoltaic module steel frame stamping corner connector has the characteristics of automatic switching of stamping modes and high stamping precision.

Owner:江苏凯撒型材科技有限公司

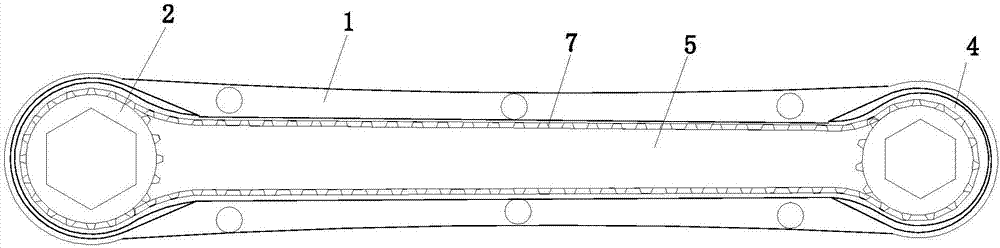

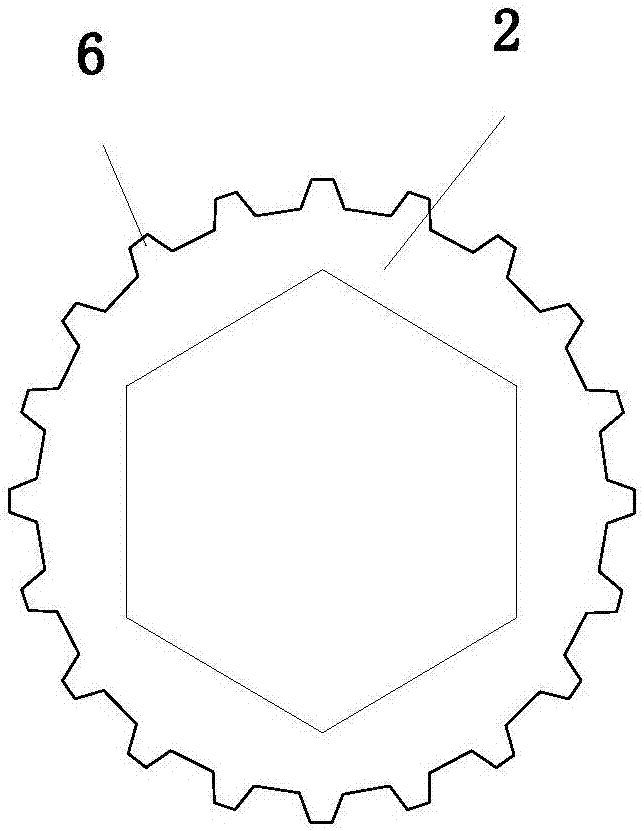

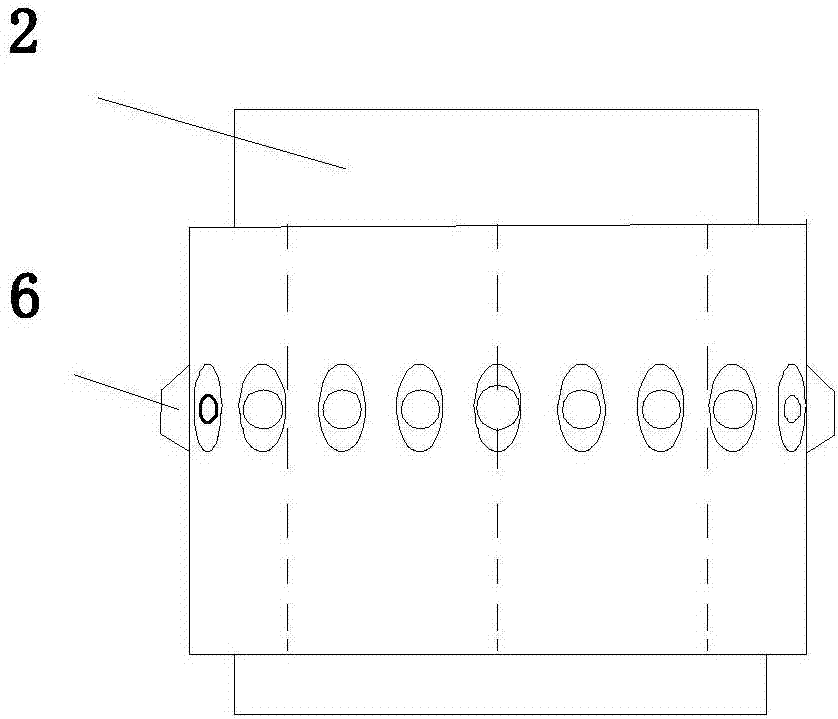

Transmission rotating nut spanner

InactiveCN108000415AAchieve disassemblyFaster and more efficient disassemblyWrenchesScrewdriversWrenchElectrical and Electronics engineering

Owner:龙伟

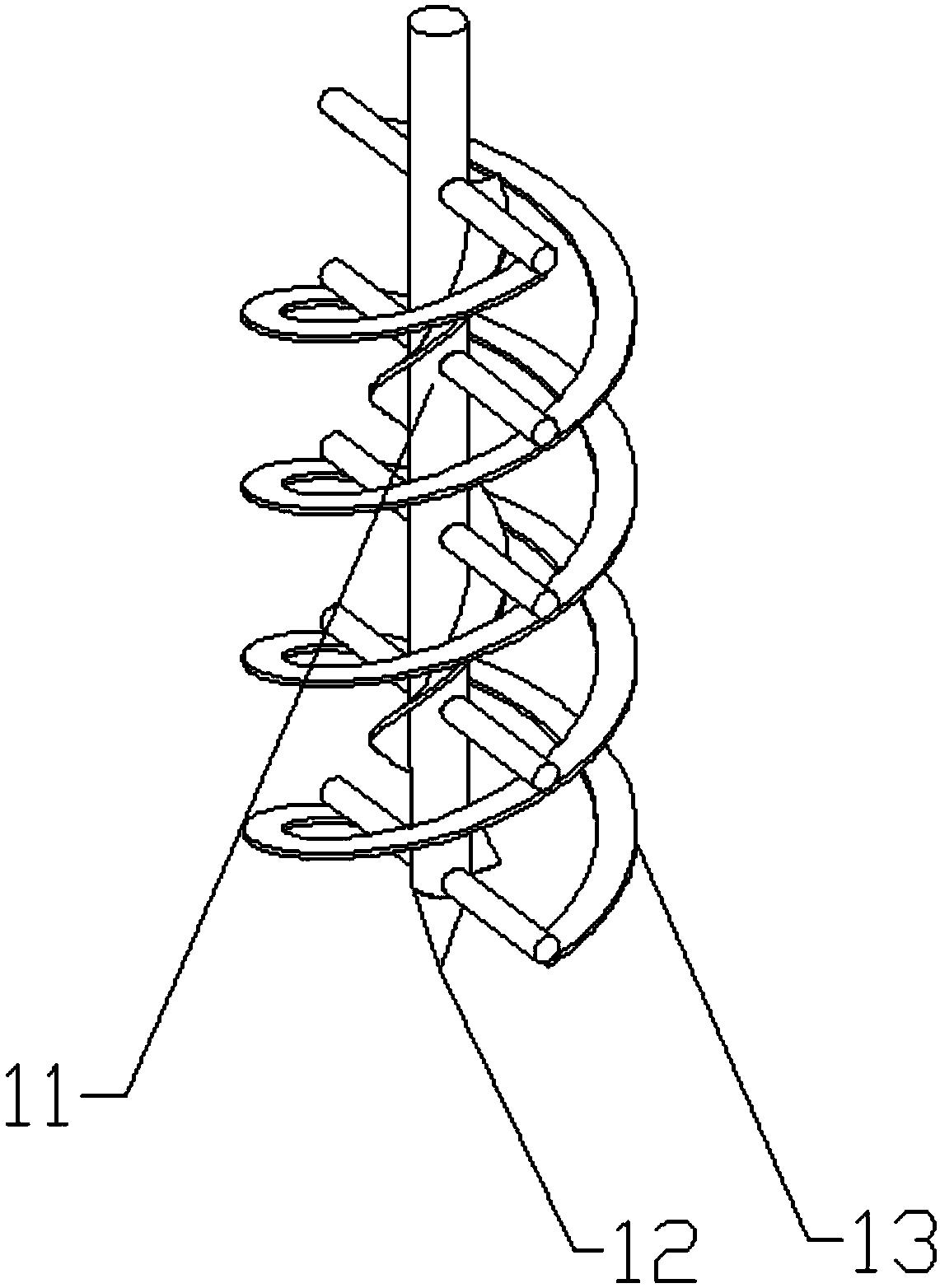

Portable tea tree digging machine

InactiveCN108770418ATime-saving and labor-saving effectPrecise digging positionPlantingFurrow making/coveringCouplingEngineering

The invention relates to the technical field of tea tree cultivation, in particular to a portable tea tree digging machine. The portable tea tree digging machine comprises a portable support, the end,close to a ground, of the portable support is screwed with adjustment foot margins, the end, away from the adjustment foot margins, of the portable support is screwed with a carrying handle, the side, close to the adjustment foot margins, of the portable support is welded with a roller bracket, and a bearing in the roller bracket is connected with a moving roller, one end, away from the moving roller, of portable bracket is welded with an adjusting bolt in the direction close to the carrying handle, one end, away from the portable support, of the adjusting bolt is screwed with an adjusting support, an adjusting nut is thread connected with one end, near the carrying handle, of the adjusting support, a motor mounting bracket is screwed with a base surface of the adjusting support, a rotating motor is screwed with one end, near the carrying handle, of the motor mounting bracket, and one end, away from the carrying handle, of the rotating motor is connected with a digging rotating shaftthrough a coupling. The portable tea tree digging machine transports a rotary shaft bit to a position needed to be pitted through the roller.

Owner:安徽凯盛茶业有限公司

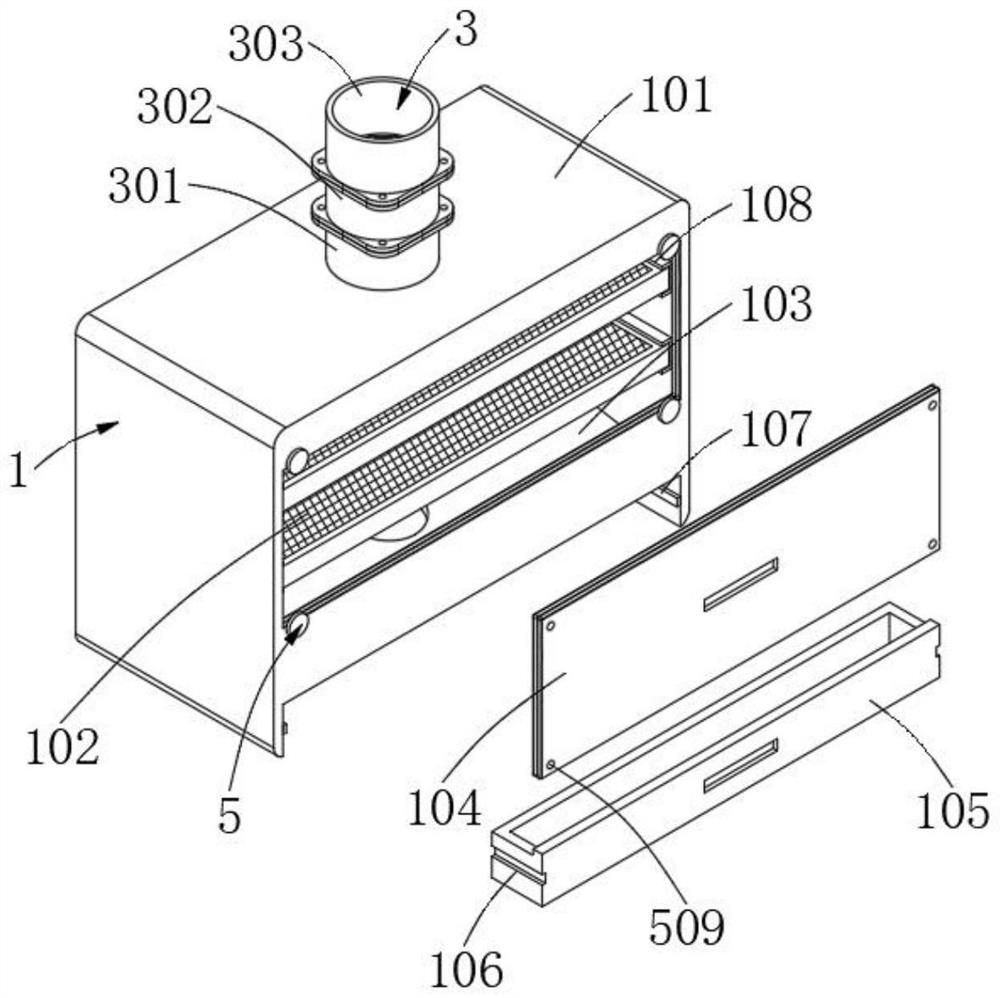

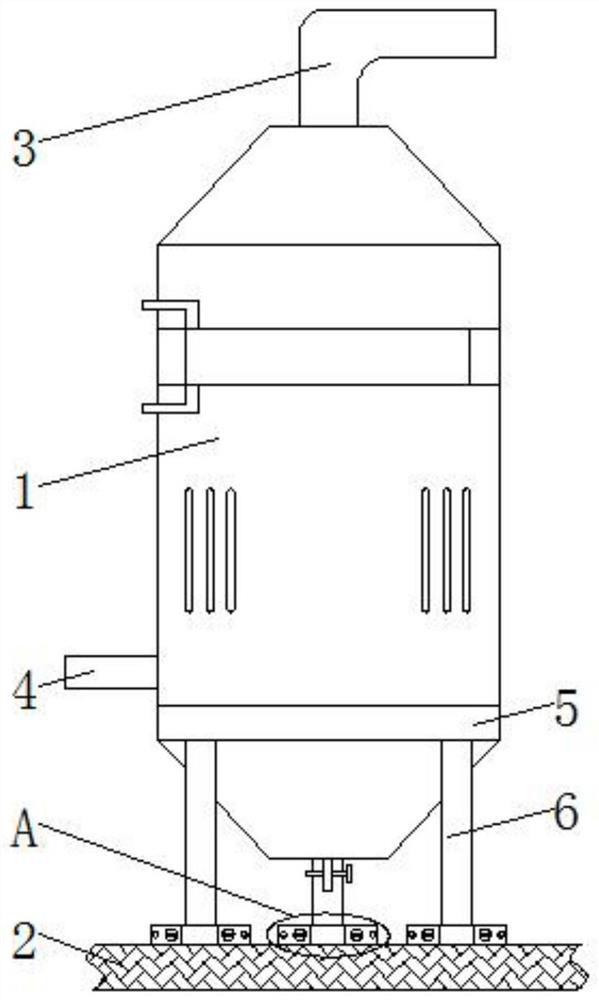

Oil smoke treatment system

PendingCN114849371AIncrease flexibilityImprove disassembly efficiencyDomestic stoves or rangesDispersed particle filtrationExhaust fumesEngineering

The invention discloses an oil smoke treatment system, which comprises: a filtering mechanism, the filtering mechanism comprises a filtering box, an inner cavity of the filtering box is sequentially provided with a filter screen and a material guide plate from top to bottom, the material guide plate is obliquely arranged, the surface of the filtering box is provided with a maintenance plate, the bottom of the filtering box is provided with an oil collection box, and the center axis of the top of the filtering mechanism is provided with a smoke discharge mechanism; and the smoke inlet mechanism comprises a smoke collecting hood body. According to the invention, the locking mechanism is used for replacing the traditional bolt installation, so that a user can open the maintenance plate without auxiliary tools and repeatedly screwing the bolt, the operation is convenient and fast, the effects of saving time and labor are achieved, and the disassembly and assembly efficiency of the filter screen is improved; meanwhile, through the arrangement of the adjusting mechanism, the angle of the exhaust fume collecting hood body can be adjusted, so that the exhaust fume collecting hood body is suitable for production equipment under different working conditions, and the use flexibility and the application range of the oil fume treatment system are improved.

Owner:上海安威消防技术工程有限公司 +2

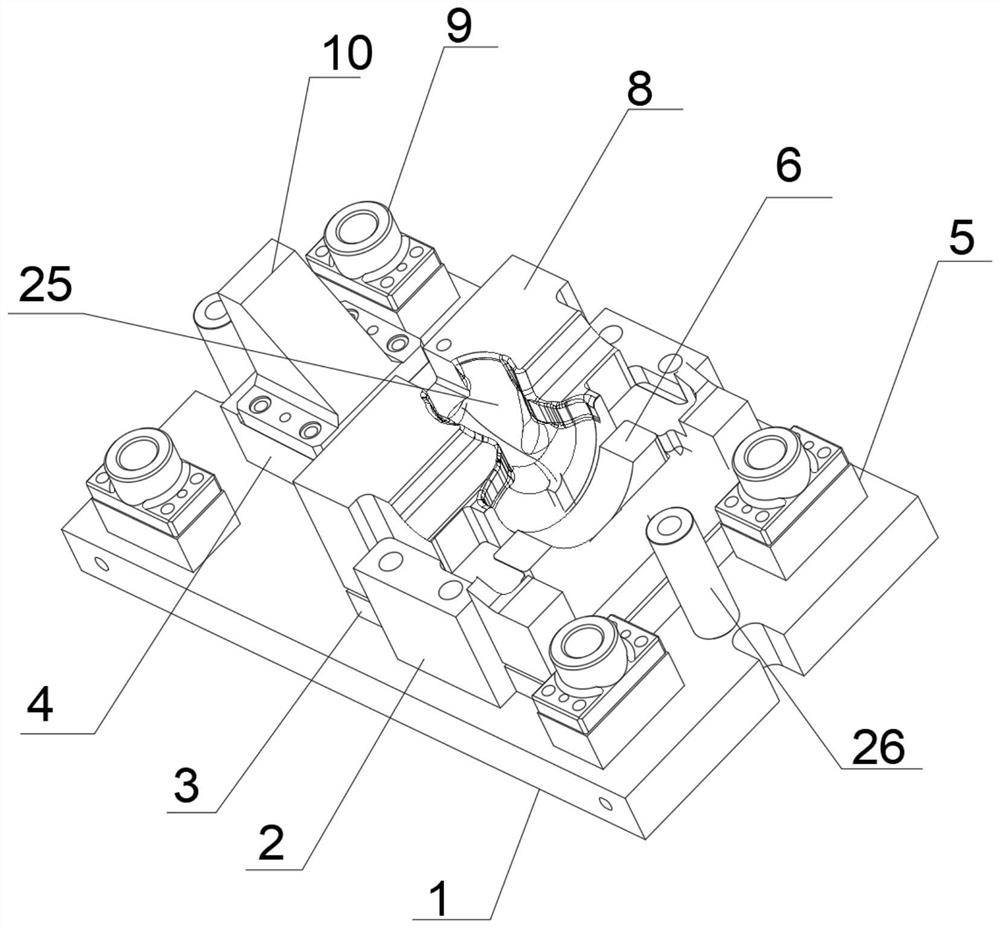

Novel hot end trimming and punching die

InactiveCN112588948AReduce usageReduce labor costsShaping toolsPerforating toolsStructural engineeringMechanical engineering

The invention discloses a novel hot end trimming and punching die. The novel hot end trimming and punching die comprises an upper die base and a lower die base and is characterized in that guide column cushion blocks are arranged at four corners of the surface of the upper die base, outer guide sleeves are arranged above the guide column cushion blocks, upper limiting columns are arranged betweentwo sides of the surface of the upper die base, slotting tool fixing blocks are arranged on the surface of an upper die, a slotting tool is fixedly arranged above the slotting tool fixing block and isin a slope triangular block shape, an upper clamping plate is arranged on one side of the slotting tool fixing block, guiding blocks are fixedly arranged on two sides of the upper clamping plate, anupper stripping plate is arranged above the upper clamping plate, an upper die groove is formed in the upper stripping plate, an upper die punch is arranged on one side of the upper stripping plate, the upper die punch penetrates through the upper stripping plate and is fixed on the upper clamping plate, foot pads are arranged on two sides of the lower side of a lower die plate, outer guide columns are arranged at four corners of the surface of the lower die base, and the outer guide columns and the outer guide sleeves are of matched structures. The novel hot end trimming and punching die hasthe advantages of being high in production efficiency, good in quality durable.

Owner:爱驰威汽车零部件(盐城)有限公司

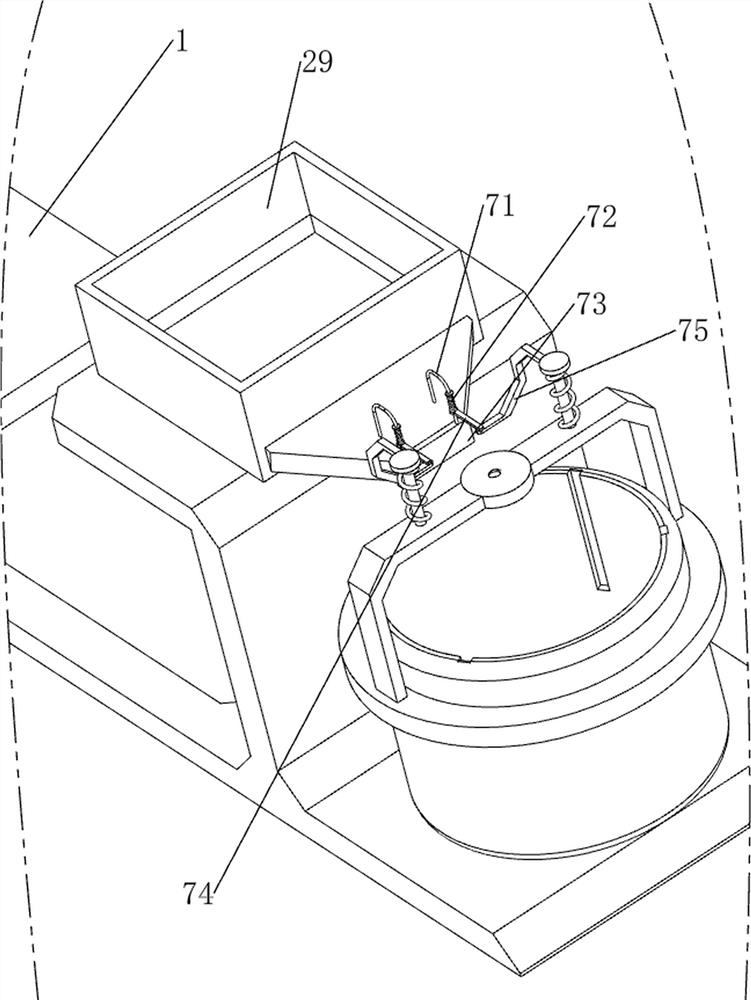

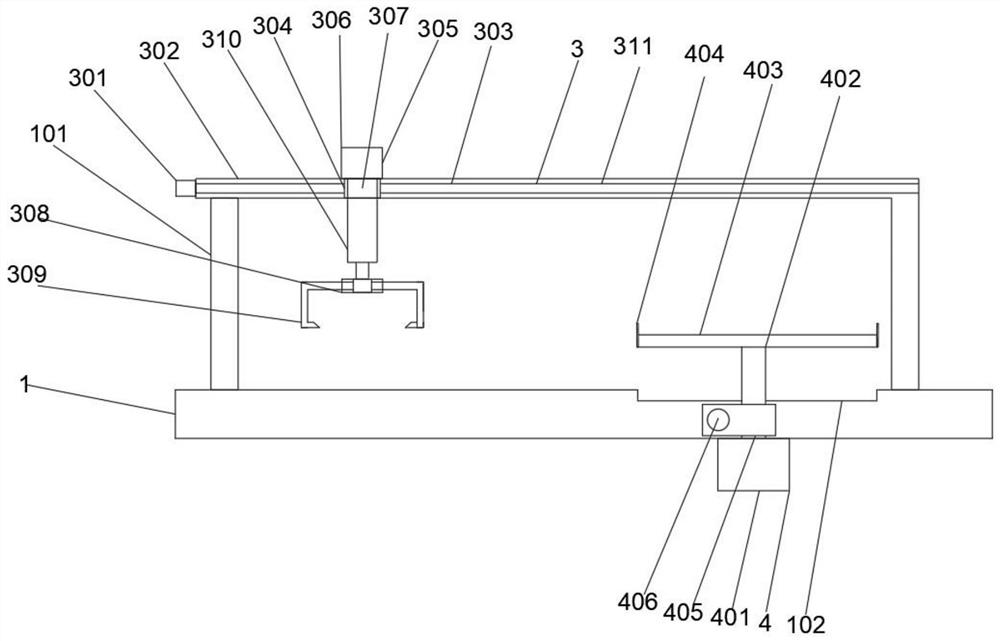

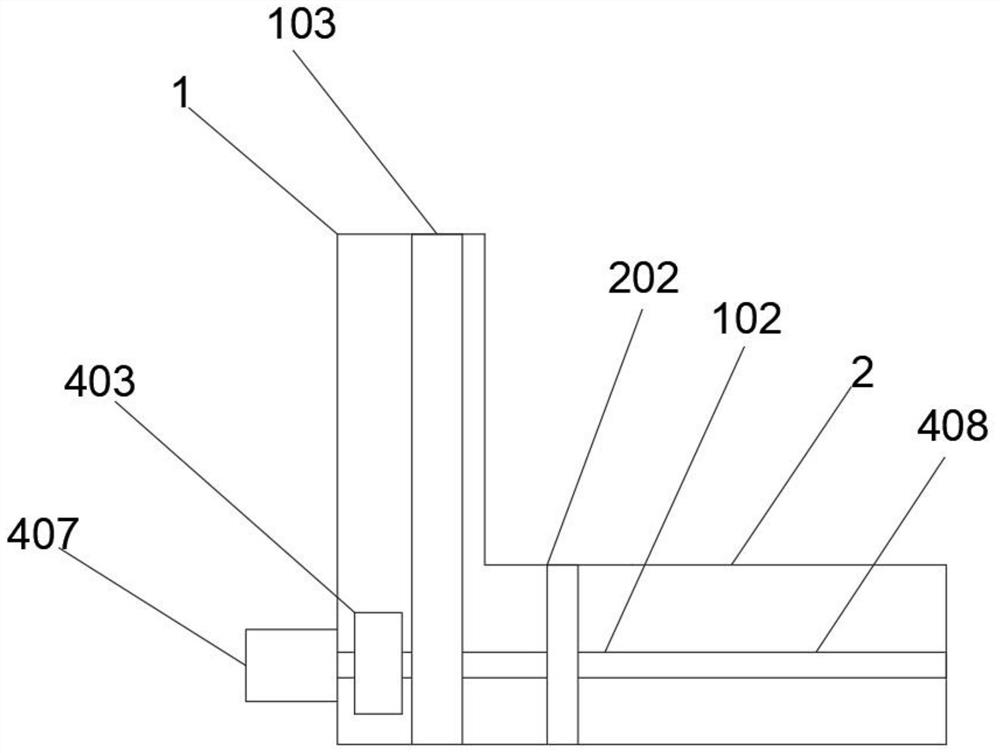

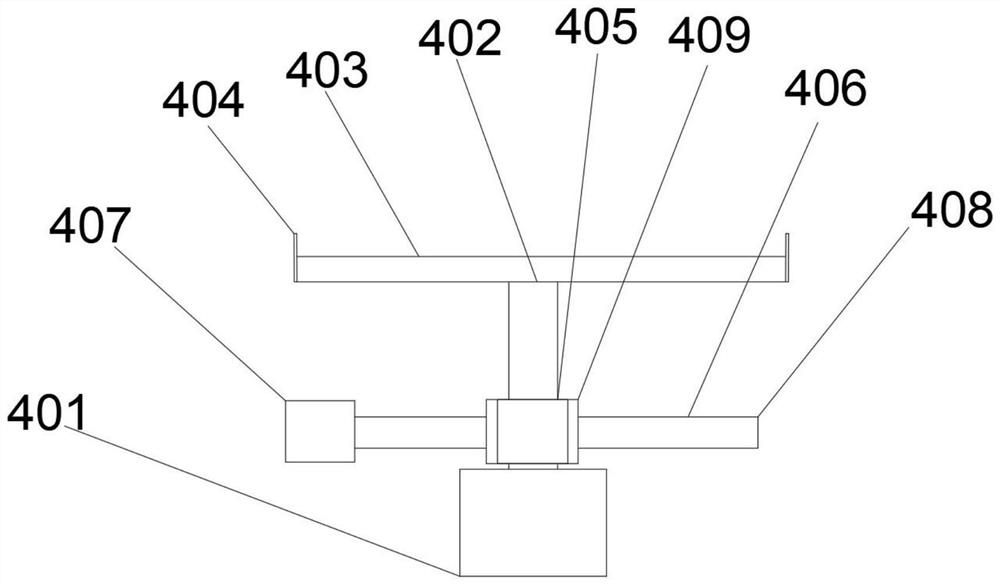

Convenient-to-carry numerically-controlled machine tool for metal plates

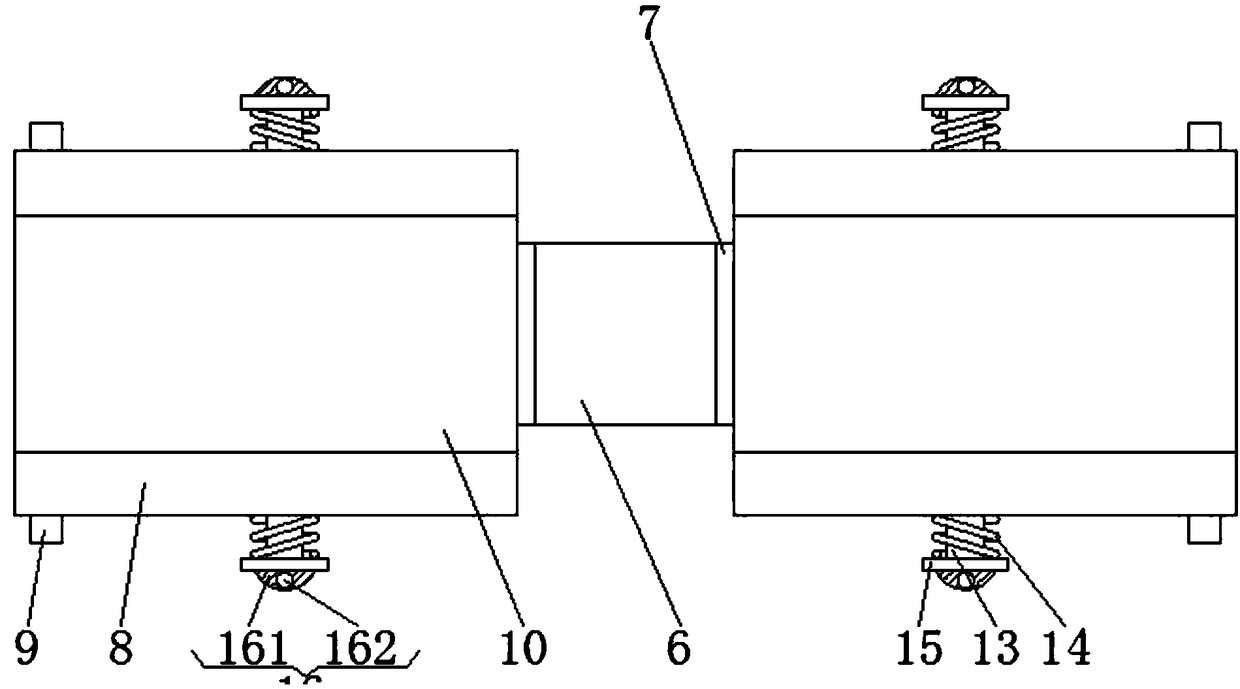

InactiveCN112296731ATime-saving and labor-saving effectImprove work efficiencyMetal working apparatusNumerical controlElectric machinery

The invention discloses a convenient-to-carry numerically-controlled machine tool for metal plates. The machine tool comprises a first base and a second base arranged on one side of the first base; afirst support is arranged at the top end of the first base; a carrying assembly is arranged at the top end of the first support; the carrying assembly comprises a first motor, a supporting rod, a first sliding lead screw, a first threaded sleeve and a first telescopic assembly; the output end of the first motor is connected with a first sliding lead screw; the first threaded sleeve is arranged onthe first sliding lead screw; the first threaded sleeve is arranged on the supporting rod; the first telescopic assembly is arranged on the first threaded sleeve; the first telescopic assembly comprises a first telescopic air cylinder, a first telescopic rod, a first connecting block, a two-way air cylinder and a clamping rod; one end of the first telescopic air cylinder is connected with the first telescopic rod; one end of the first telescopic rod penetrates out of the first connecting block to be connected with the two-way air cylinder; and the two ends of the two-way air cylinder are connected with clamping rods. According to the machine tool, through the carrying assembly, the effects of saving time and labor are achieved, and the effect of improving the working efficiency is achieved.

Owner:江苏云佳金属制品有限公司

Fruiter frostbite device

InactiveCN110651650ADon't worry about frostbiteTime-saving and labor-saving effectSelf-acting watering devicesPlant protectionFruit treeTree trunk

The invention discloses a fruiter frostbite device which structurally comprises a fixed adjusting plate and a watering fixer. The water fixer is provided with clamping teeth and a watering groove. Thefruiter frostbite device has the advantages that the fixed adjusting plate and the watering fixer can be designed to be in the shape of a ring, and through cooperation among a fastener, a tension spring and a spring, a watering device is enabled to be mounted on pawpaw trees according to trunks different in diameter; and fixing is performed at the same time; outside temperature is sensed througha temperature sensing plate, a high-pressure nozzle is driven to spray water when the temperature is too low, water flow impacts in up-down directions, and frost and snow condensed and accumulated onthe pawpaw trees can be beat down or thawn away, so that frostbite death of the pawpaw trees caused by frost and snow do not accumulate on the pawpaw trees is avoided; the pawpaw trees can be supplemented with water in dry winter; by this means of preventing freezing of the pawpaw trees, time-saving and labor-saving effects can be realized, and frostbite of the pawpaw trees caused by falling due to strong wind is avoided.

Owner:谢韦定

Tire mounting and dismounting device

InactiveCN102019822BReduce workloadSimple structure designTyre repairingHydraulic cylinderMechanical engineering

Owner:池学建

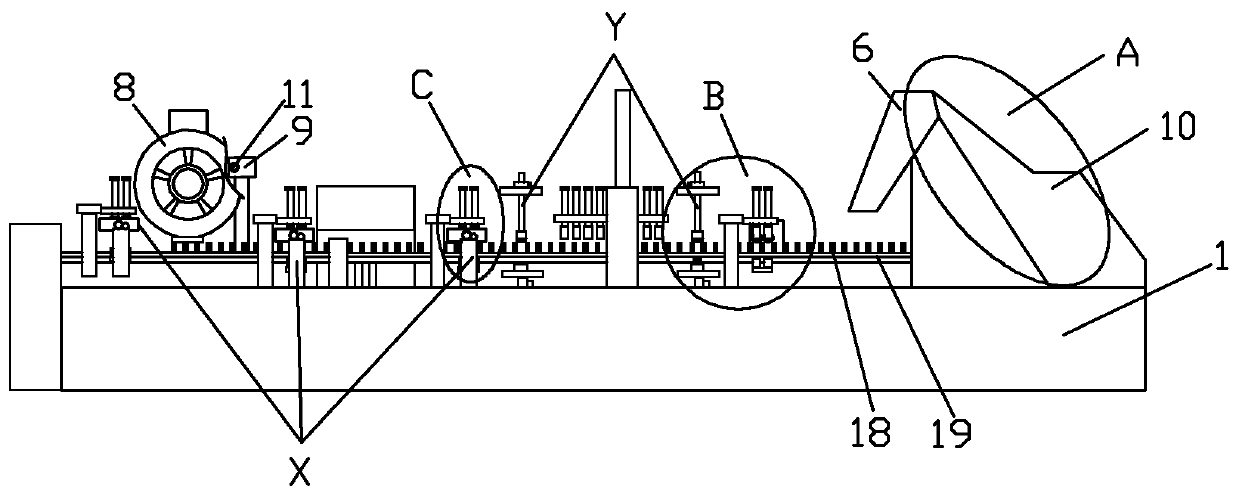

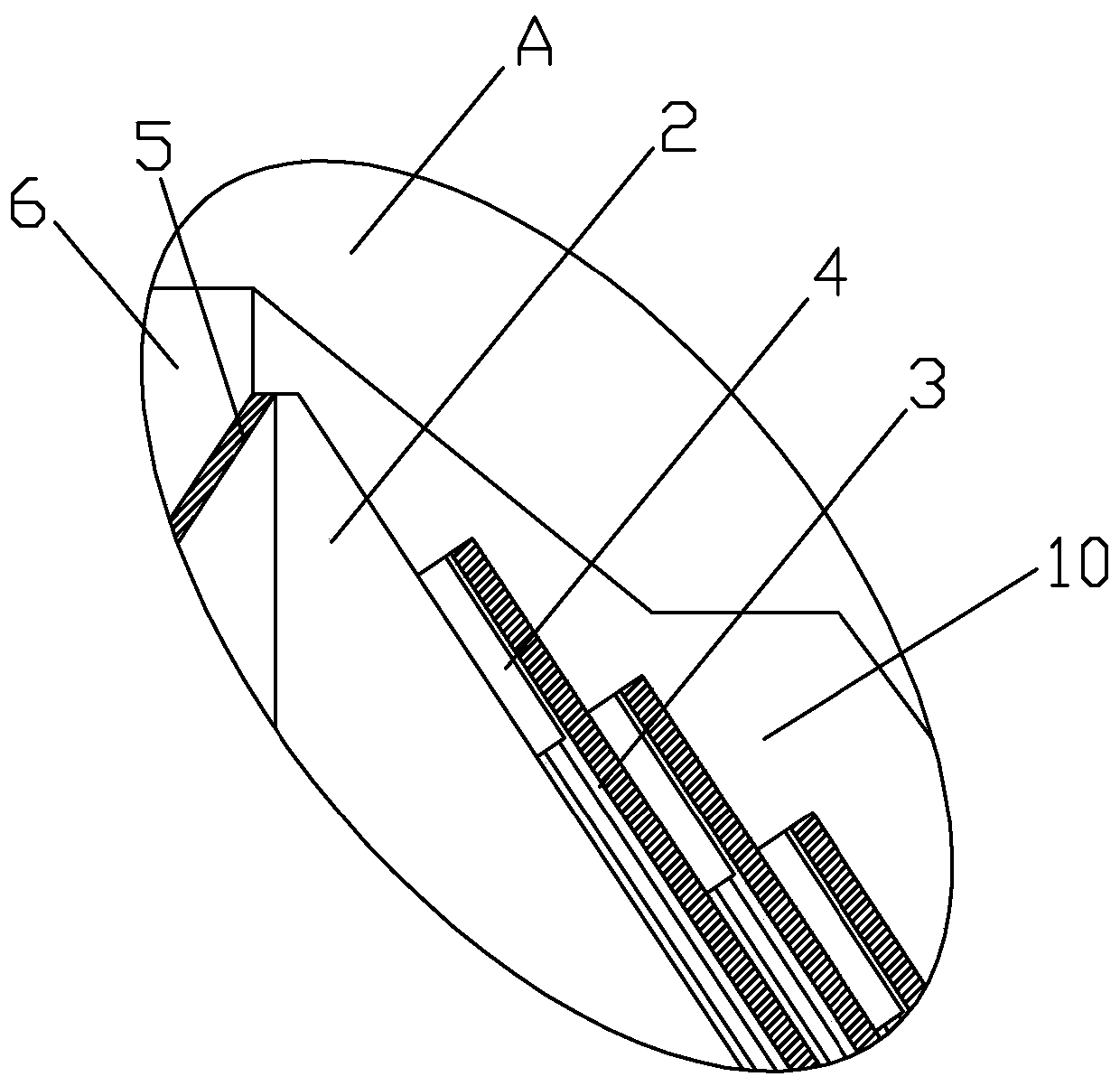

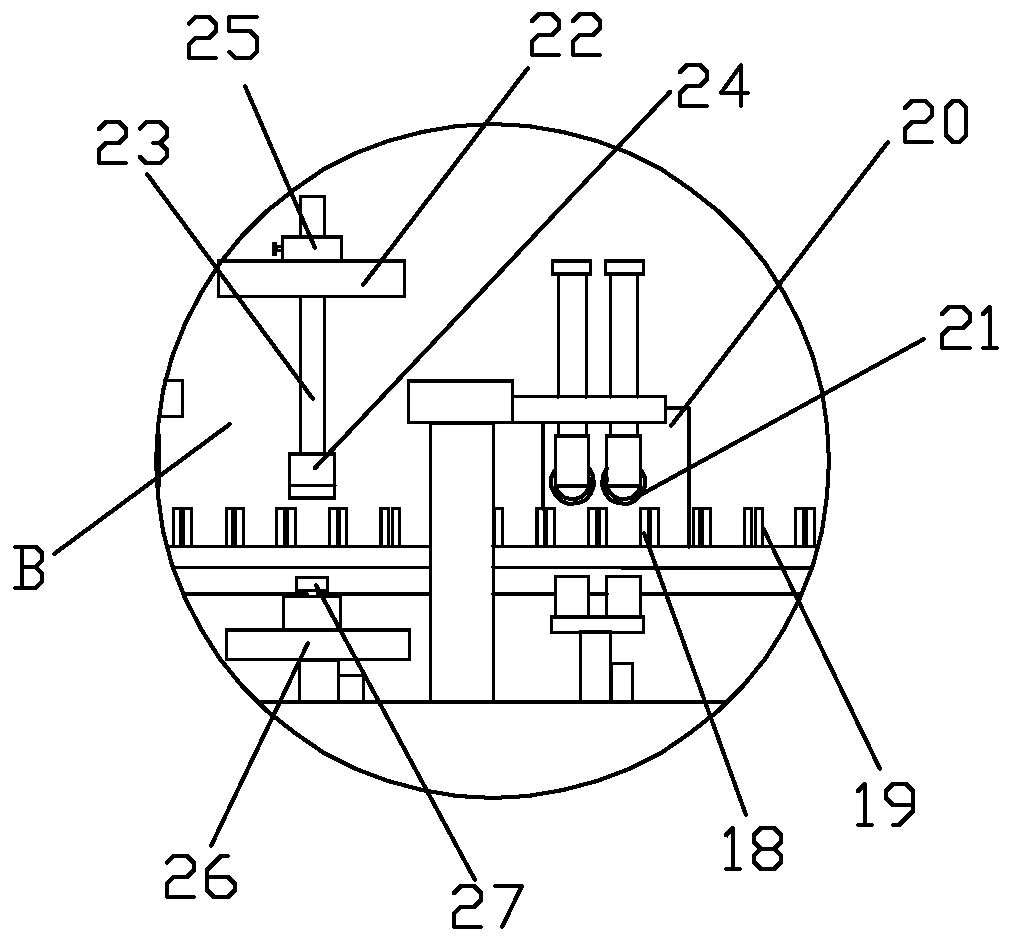

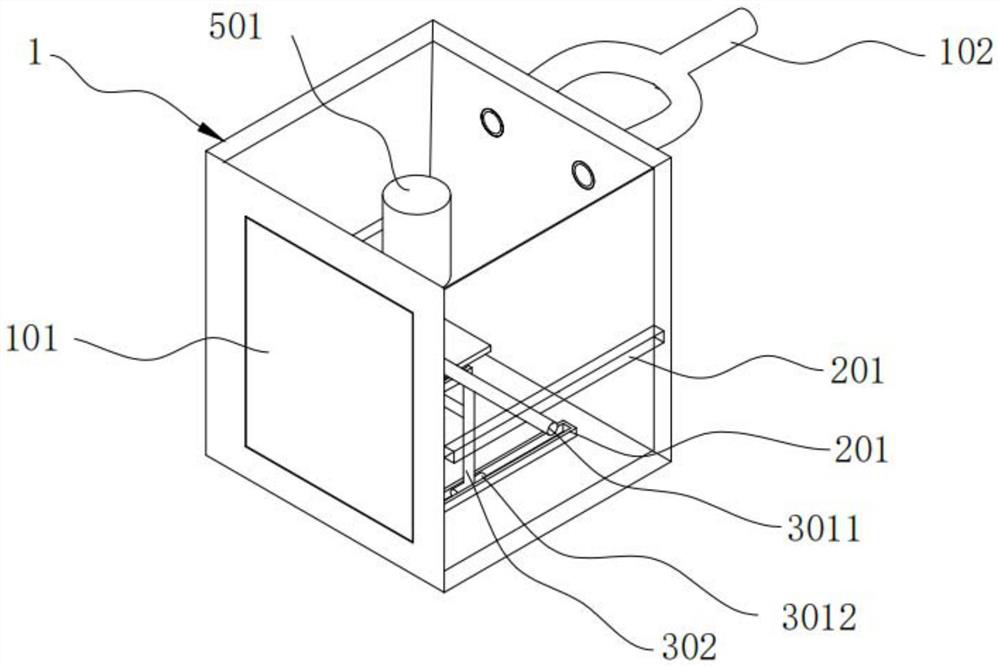

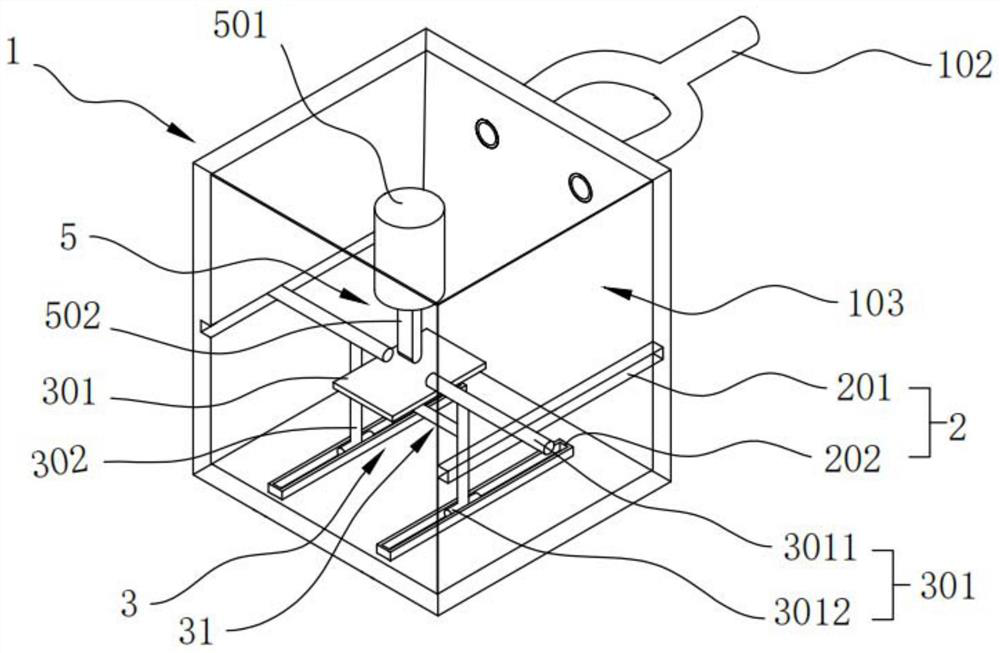

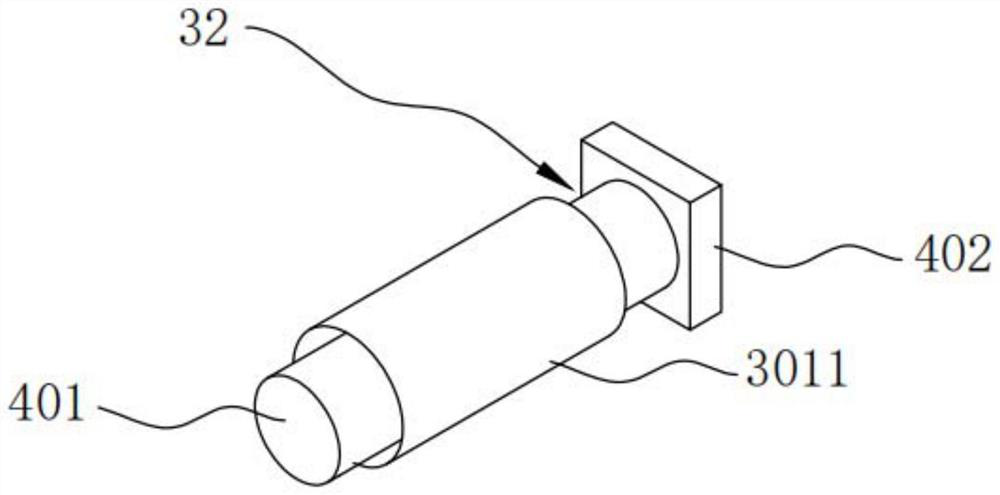

A fully automatic ballpoint pen assembly machine

The invention relates to the technical field of ballpoint pen production, in particular to a fully automatic ballpoint pen assembly machine, which includes an installation platform, a transmission mechanism, a shell feeding mechanism, a direction detection mechanism, a turning mechanism Y, a pen cap feeding mechanism, a pen cap loading mechanism, and pen core assembly Manipulator, refill feeding mechanism, spring-loaded manipulator, inner shell feeding mechanism, inner shell assembling manipulator, hydraulic clamping mechanism X, the installation platform is provided with a horizontally placed transmission mechanism, and the transmission mechanism is close to the shell feeding One end of the mechanism is set as a feed end, and the other end of the transmission mechanism relative to the shell feed mechanism is set as a discharge end, and the shell feed mechanism is located on the right side of the transmission mechanism. The invention has the advantages of convenient use and high production efficiency, can automatically produce the ballpoint pen, has the effect of saving time and labor, and is convenient for actual production and use.

Owner:WENZHOU FEIDA PEN IND

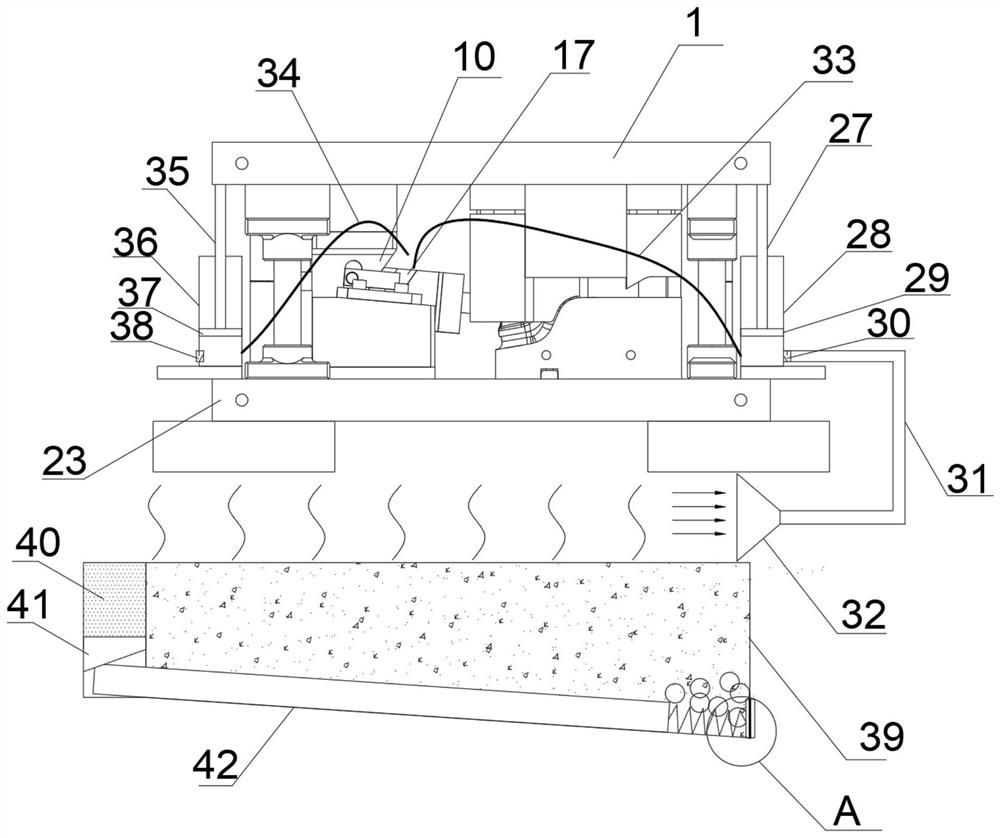

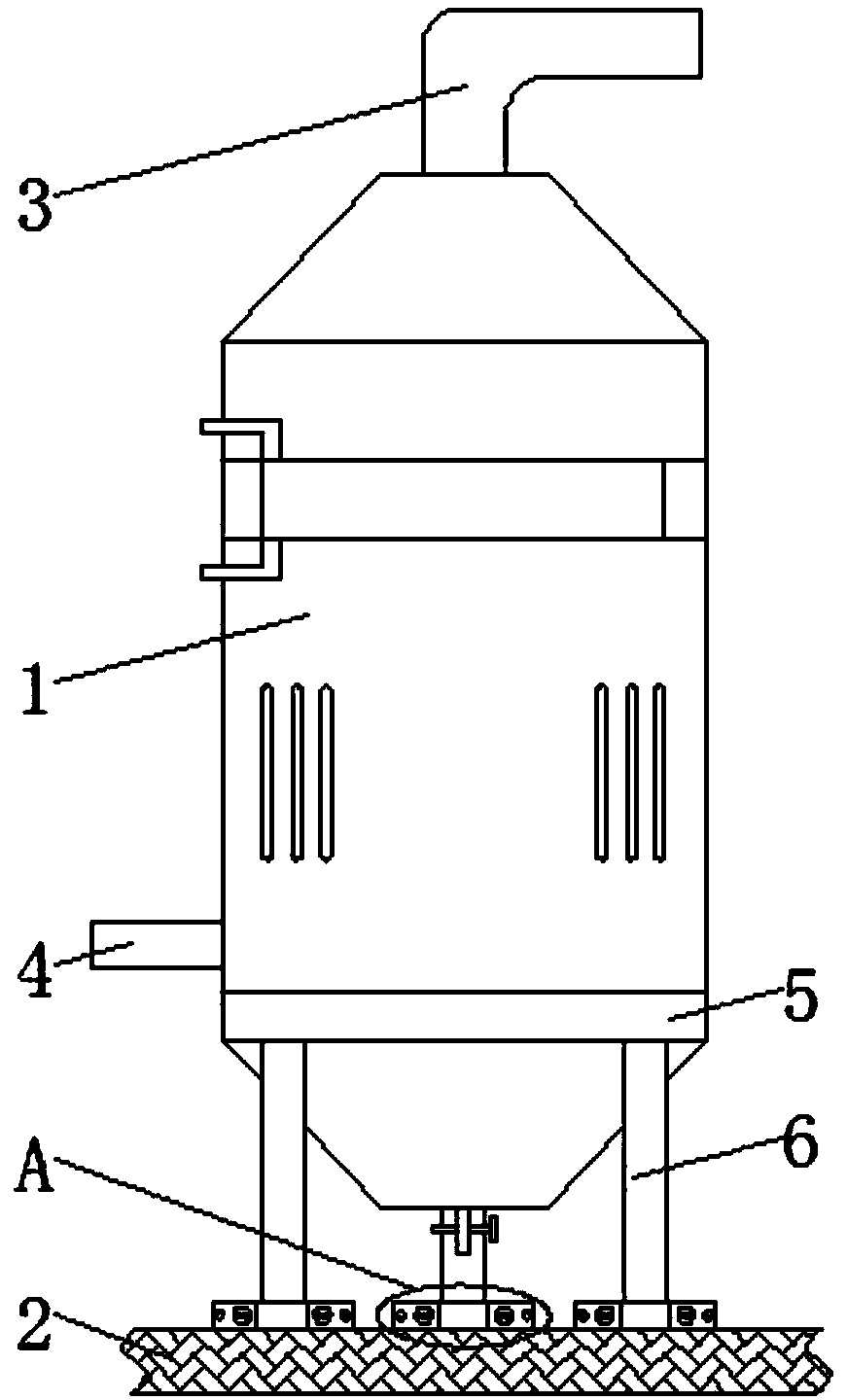

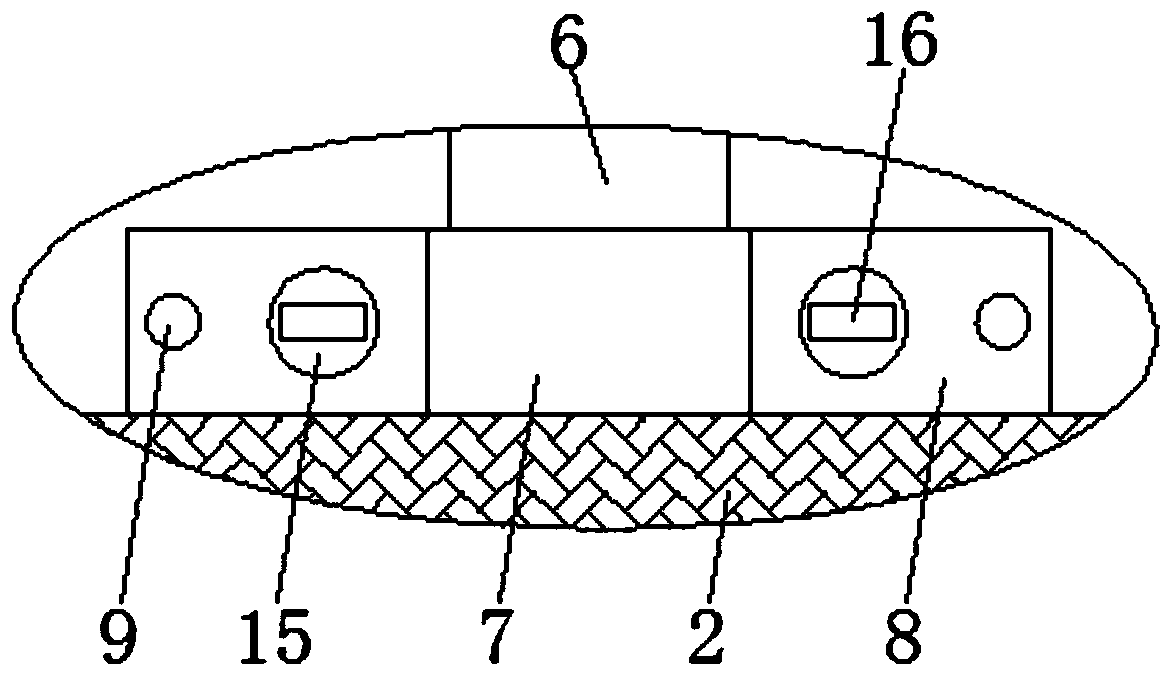

A multi-stage crushing device for construction waste treatment

ActiveCN108097439BRealize purificationImprove sound insulationGrain treatmentsNumerical controlProcess engineering

The invention discloses a multi-stage crushing device of construction waste treatment. The multi-stage crushing device comprises a feed inlet, cover plates, a sound insulation board, a crushing mechanism, warning lights, numerical control boxes, warning modules, imaging modules, driving modules, auxiliary modules, a base, a baffle plate, a filter layer, an outer shell, a purification mechanism, discharge openings, a display screen and rollers. The multi-stage crushing device has the beneficial effects that the multi-stage crushing device of construction waste treatment provided by the invention can crush construction solid waste, and can further purify construction wastewater impurities; the arranged warning lights can effectively prompt whether the device breaks down or not, so that staffare warned to maintain the device at first time; the arranged display screen can display parameter data of the device during crushing, so that performance of the device during operation can be reflected; and besides, the sound insulation effect is remarkable, the device can be moved, transfer and storage of the device are convenient, time-saving and effort-saving effects can be achieved, and thedevice is suitable for popularization and utilization.

Owner:罗田县百纳建筑废弃物资处理有限公司

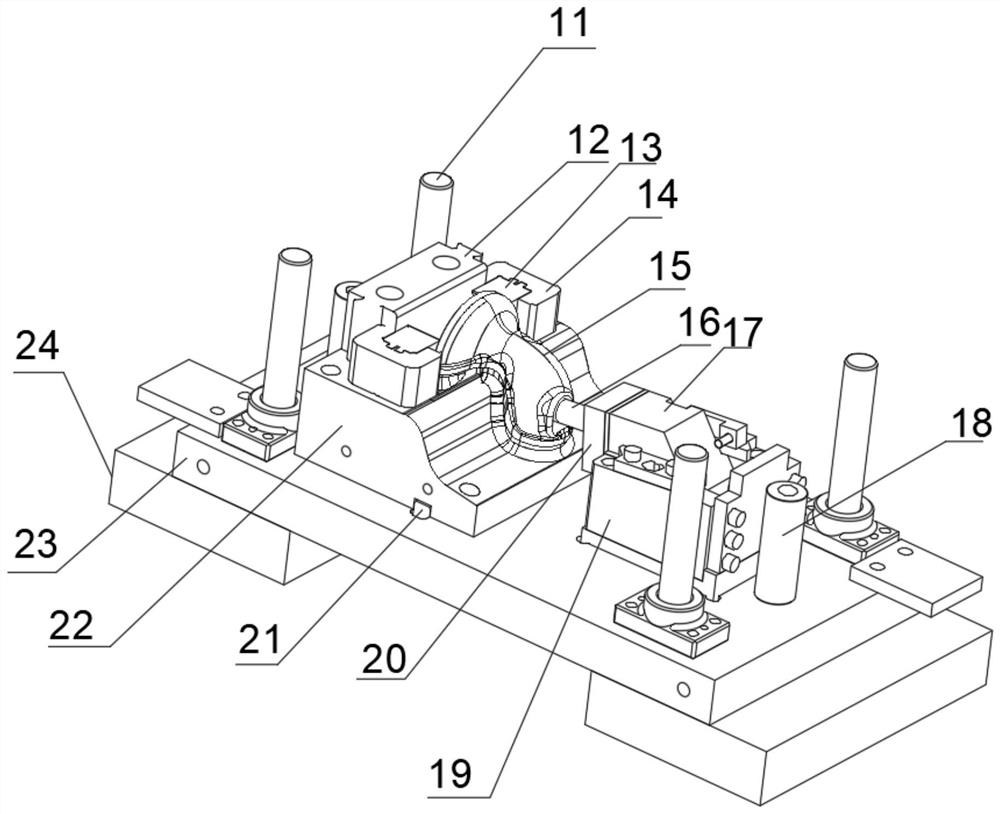

The processing method of the crosshead pin of man series marine low-speed diesel engine

The invention discloses a processing method of a crosshead pin of a low-speed diesel engine for a MAN-series ship. The crosshead pin comprises a large outer circle and two small outer circles, the twosmall outer circles are coaxially connected to the two sides of the large outer circle respectively, center holes are formed in the end surfaces of the two sides of the small outer circles, and the outer periphery of the large outer circle is provided with a notch plane. The processing method comprises the following specific steps that 1, a boring machine is used for machining the two end surfaces and the notch plane of the crosshead pin in a horizontal station; 2, two centers are adopted for clamping workpieces on a lathe, and machining the large outer circle, the small outer circles and endsurfaces; 3, the boring machine is used for precisely machining all holes in the notch plane and the circumference in a vertical station; 4, a grinding machine is used for grinding the large outer circle and the small outer circles in a supporting and grinding mode; and 5, the polishing lathe is used for clamping the workpieces and polishing the crosshead pin workpieces through two centers. The processing method has the advantages that the procedures are few, the process route is short, the number of times of getting on is small, the processing efficiency of the crosshead pin is greatly improved, the labor intensity of operators is reduced, and the effects of saving time and labor are achieved.

Owner:CSSC MES DIESEL

Ship natural gas and diesel dual fuel treatment device

ActiveCN109398662AImprove fastnessThe fastening is convenient for the user to quicklyPropulsion power plantsPropulsive elementsFixed frameFuel treatment

The invention discloses a ship natural gas and diesel dual fuel treatment device. The ship natural gas and diesel dual fuel treatment device comprises a fuel treatment device and the ground, and the fuel treatment device is located at the top of the ground. A smoke outlet pipe communicates with the top of the fuel treatment device, and a flue pipe communicates with the left side of the fuel treatment device. A fixing frame sleeves the surface of the fuel treatment device, the flue pipe is located at the top of the fixing frame, and mounting legs are fixedly connected to the bottom of the fixing frame. Through the cooperative use of fixed plates, moving rods, fastening springs, round blocks, drive plates, inserting rods, inserting slots, T-shaped blocks and T-shaped grooves, the ship natural gas and diesel dual fuel treatment device solves the problem that the fastening mode is not only time-consuming and labor-consuming, but also affects the efficiency of workers due to that fact thata plurality of bolts need to be used for fastening traditional desulfurization equipment during installation, the ship natural gas and diesel dual fuel treatment device has the advantages of simple operation and convenient and fast installation, a user can conveniently fasten a desulfurization device quickly, the effect of saving time and effort is achieved, and the ship natural gas and diesel dual fuel treatment device is suitable for promotion.

Owner:张冠新

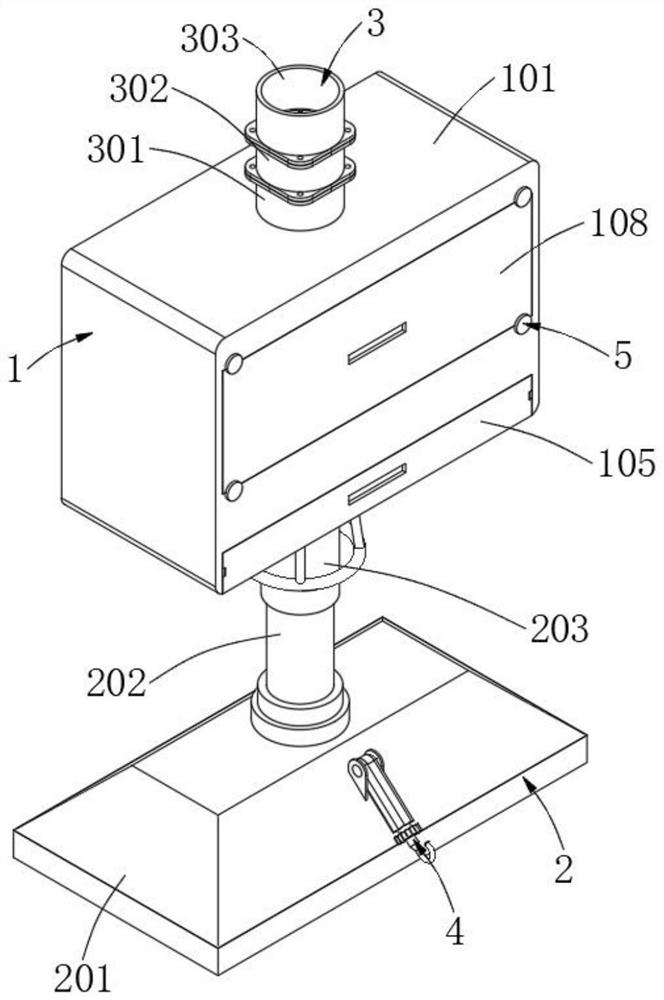

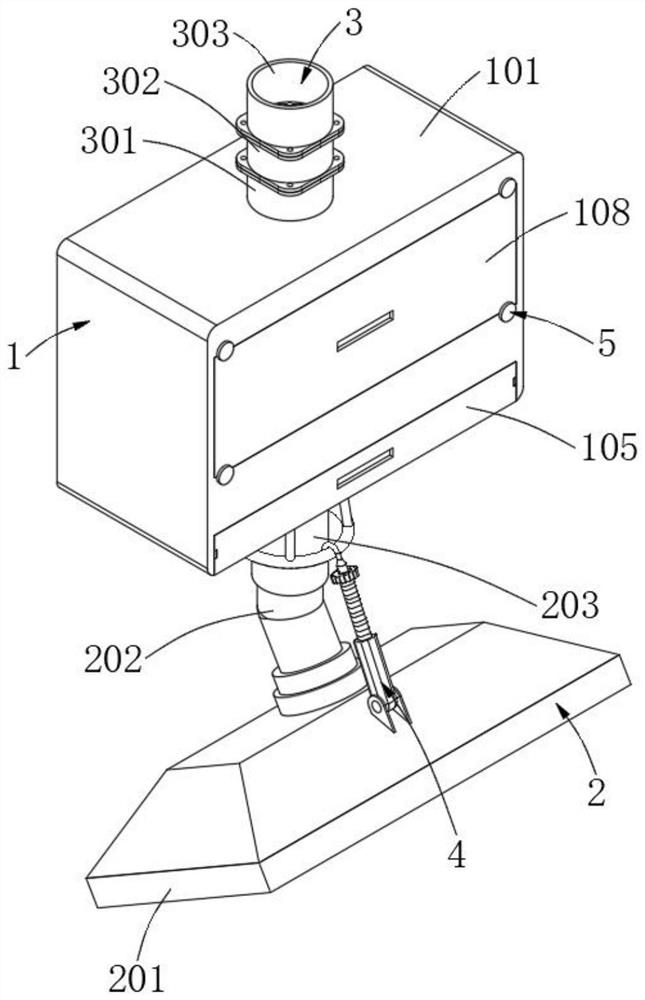

Pathological sampling device and pathological sampling method

InactiveCN112197991AEasy to cutTime-saving and labor-saving effectWithdrawing sample devicesSurgeryPathological

The invention discloses a pathological sampling device and a pathological sampling method. The pathological sampling device comprises a mounting piece which is fixedly arranged; a slide way which is arranged on the mounting piece; a sample carrying table which is used for carrying and fixing a sample, is movably arranged on the slide way and can be driven to move along the slide way through external force; and a cutting assembly which is arranged on the mounting piece and located on the moving path of the sample carrying table, and is used for cutting the sample on the sample carrying table. Through the arrangement, time and labor can be saved during pathological sampling.

Owner:GUANGZHOU KINGMED DIAGNOSTICS CENT

A marine natural gas and diesel dual fuel processing device

ActiveCN109398662BImprove fastnessThe fastening is convenient for the user to quicklyPropulsion power plantsPropulsive elementsFuel treatmentProcess engineering

The invention discloses a marine natural gas and diesel dual-fuel processing device, which includes a fuel processing device and a ground, the fuel processing device is located on the top of the ground, the top of the fuel processing device is connected with a smoke outlet pipe, and the left side of the fuel processing device is connected with a flue The surface of the fuel processing device is covered with a fixed frame, the flue pipe is located on the top of the fixed frame, and the bottom of the fixed frame is fixedly connected with mounting legs. The present invention solves the problem of using a large number of bolts for traditional desulfurization equipment through the cooperation of fixed plates, movable rods, fastening springs, round blocks, transmission plates, insert rods, slots, T-shaped blocks and T-shaped grooves. It is fastened. This fastening method is not only time-consuming and laborious, but also affects the work efficiency of workers. The ship's natural gas and diesel dual-fuel processing device has the advantages of simple operation and convenient installation, which is convenient for users to quickly fasten the desulfurization device. , to achieve the effect of saving time and effort, suitable for promotion.

Owner:张冠新

Medical tape laminating device

The invention discloses a medical adhesive tape laminating device, which comprises a casing, a laminating opening, medical adhesive tape, gauze, a glue pressing shaft, a cutting knife, a movable glue pressing shaft, a clip film and a push frame. The upper side of the casing is provided with a sticker There are four medical tapes inside the fitting mouth, gauze is arranged on the upper side of the medical tape, a glue switch is arranged on the right side of the fitting mouth, and a movable strip is arranged on the front side of the casing, so The movable bar is provided with a pinch switch, the upper left corner of the movable bar is provided with a movable pressing block, the lower right corner of the movable bar is provided with a cutting switch, and the middle part of the front side of the housing is provided with a push button. The medical tape sticking device is provided with a tape clamp. By fixing a plurality of medical tapes with a plurality of tape clamps, the gauze is directly placed in the middle of the tape, and medicine is put on the gauze, and then the gauze is directly oriented at the patient's wound and pasted. up, so as to achieve the effect of saving time and effort.

Owner:广东联高技术推广服务有限公司

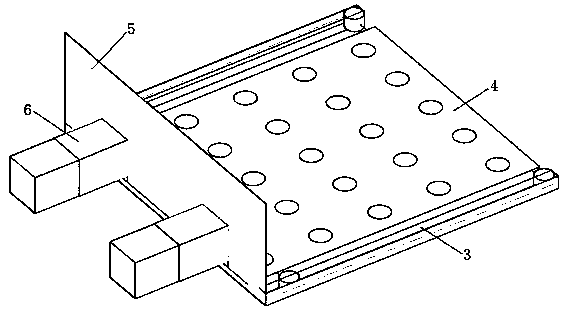

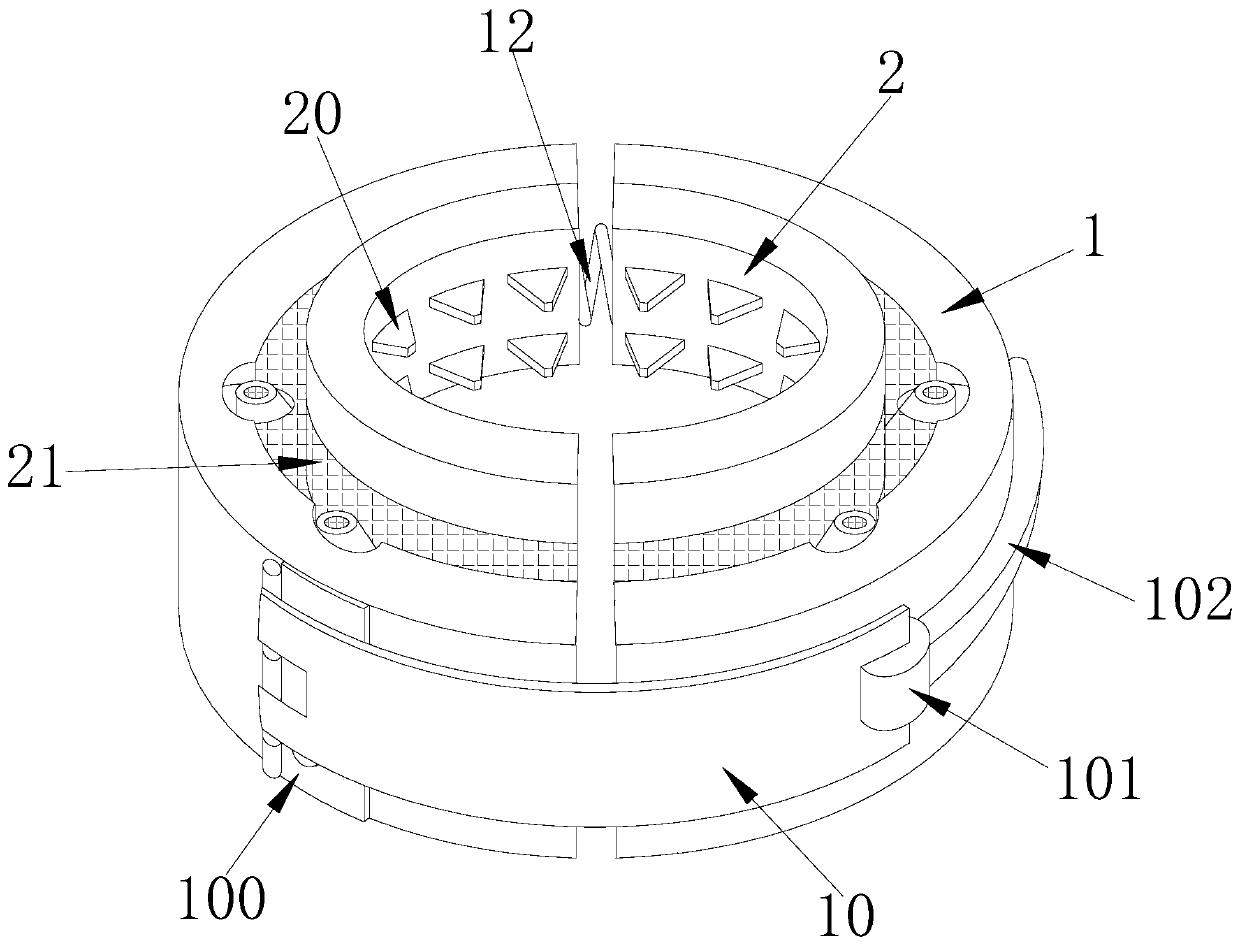

Placement equipment for test tubes in clinical laboratory

ActiveCN113070117AAvoid mutual influenceReasonable structural designTest tube stands/holdersCircular discMechanics

The invention relates to placement equipment for test tubes in a clinical laboratory, the placement equipment comprises a plurality of test tube placement racks, the plurality of test tube placement racks are movably arranged in a support frame, and two ends of each test tube placement rack are rotatably arranged on two No.1 support discs respectively; a novel test tube rack is arranged and adopts an annular structure, the plurality of test tube racks are placed at different positions in space, the plurality of test tube racks can be effectively prevented from influencing each other when test tubes are placed on the test tube racks; the test tube racks are arranged on the same equipment, and therefore, more test tubes can be placed; the novel test tube rack is reasonable in structural design, the effect of light adjustment can be achieved in the actual use process, the effect of saving time and labor can be achieved in the actual use process, and therefore the novel test tube rack has higher practical value.

Owner:临沂华大医学检验所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com