Combined bread machine

A bread machine and composite technology, applied in vertical installation tools for mixing/kneading, baking, household utensils, etc., can solve problems such as unstable bread quality, low production efficiency, and difficulty in unloading and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

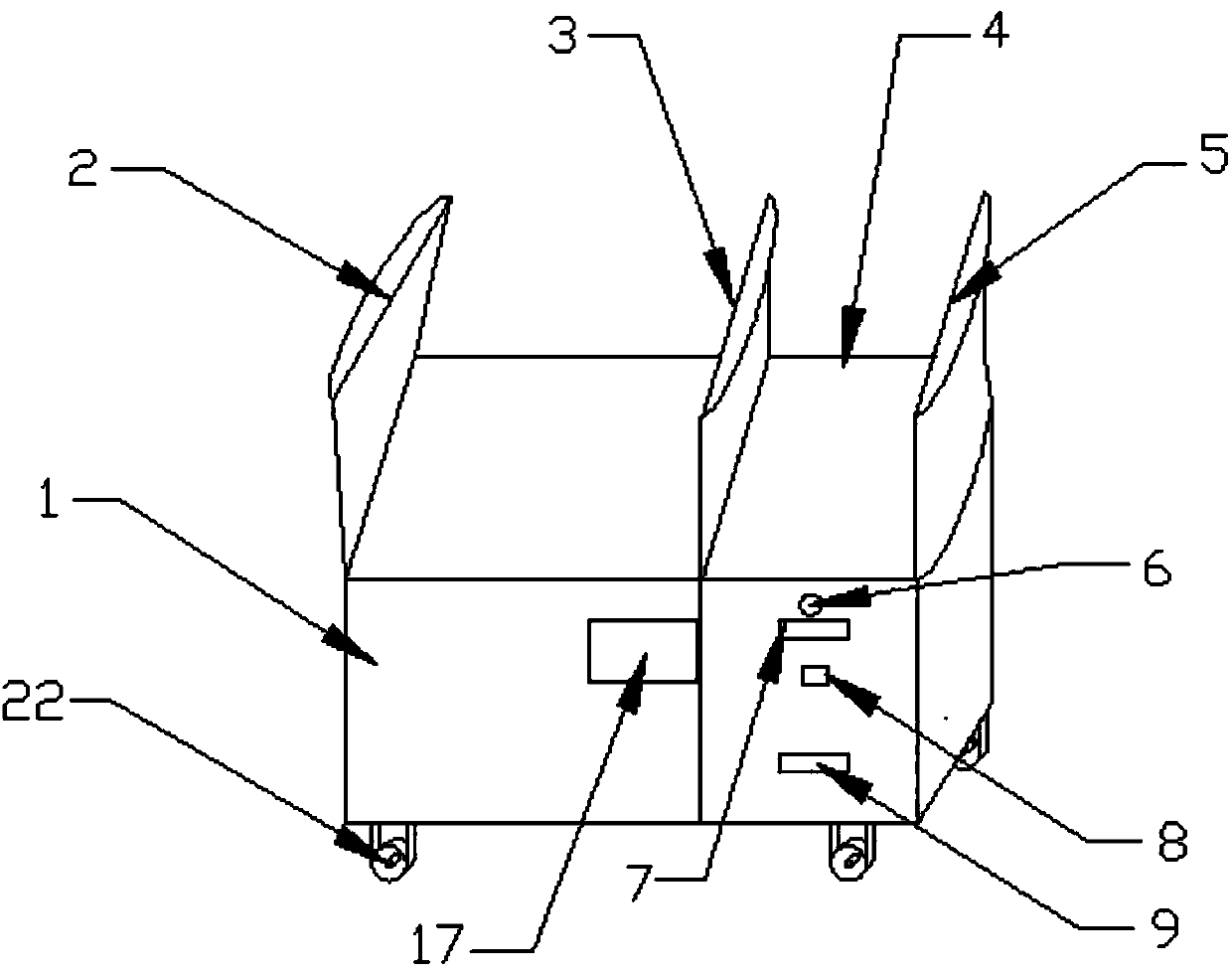

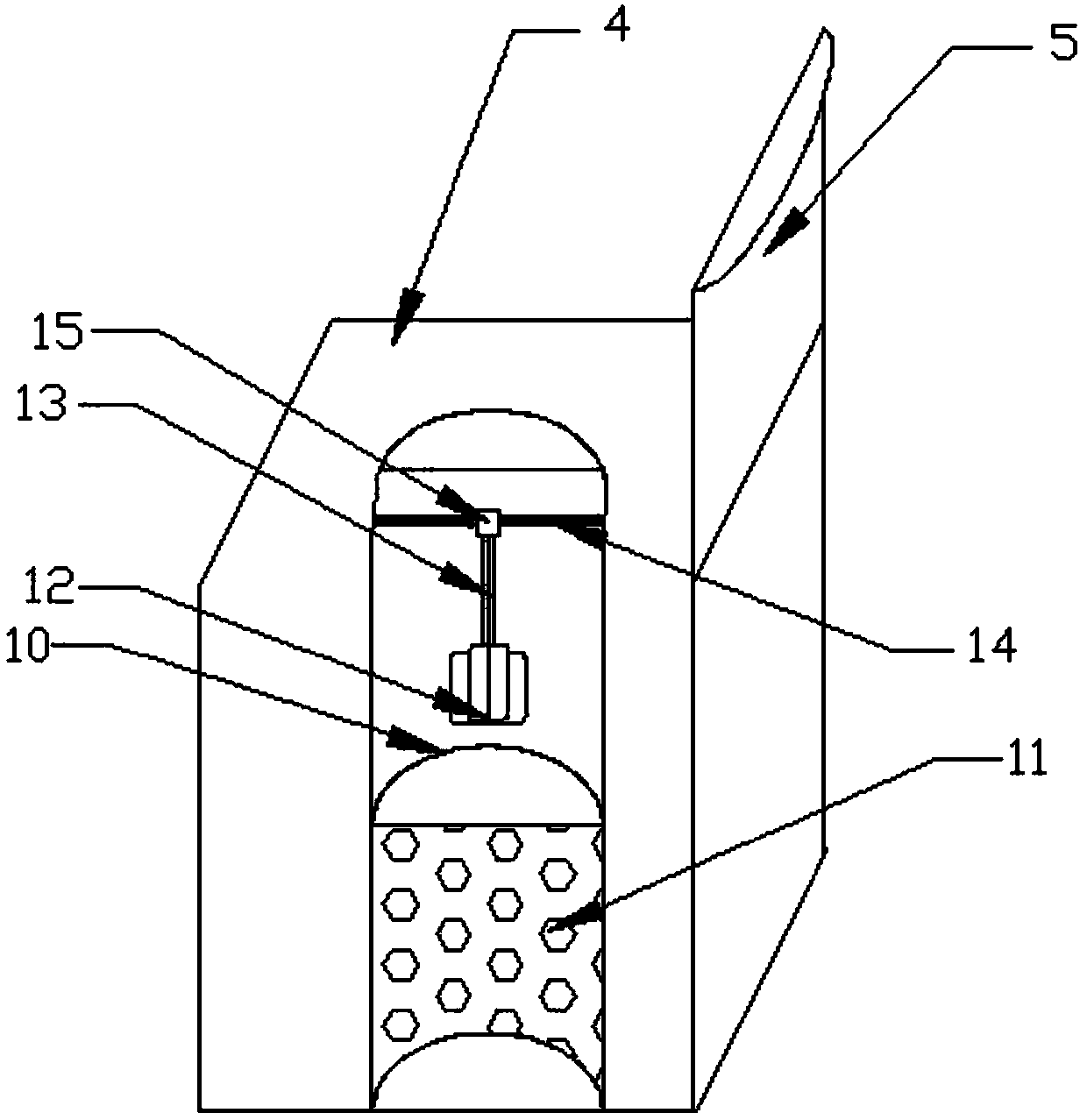

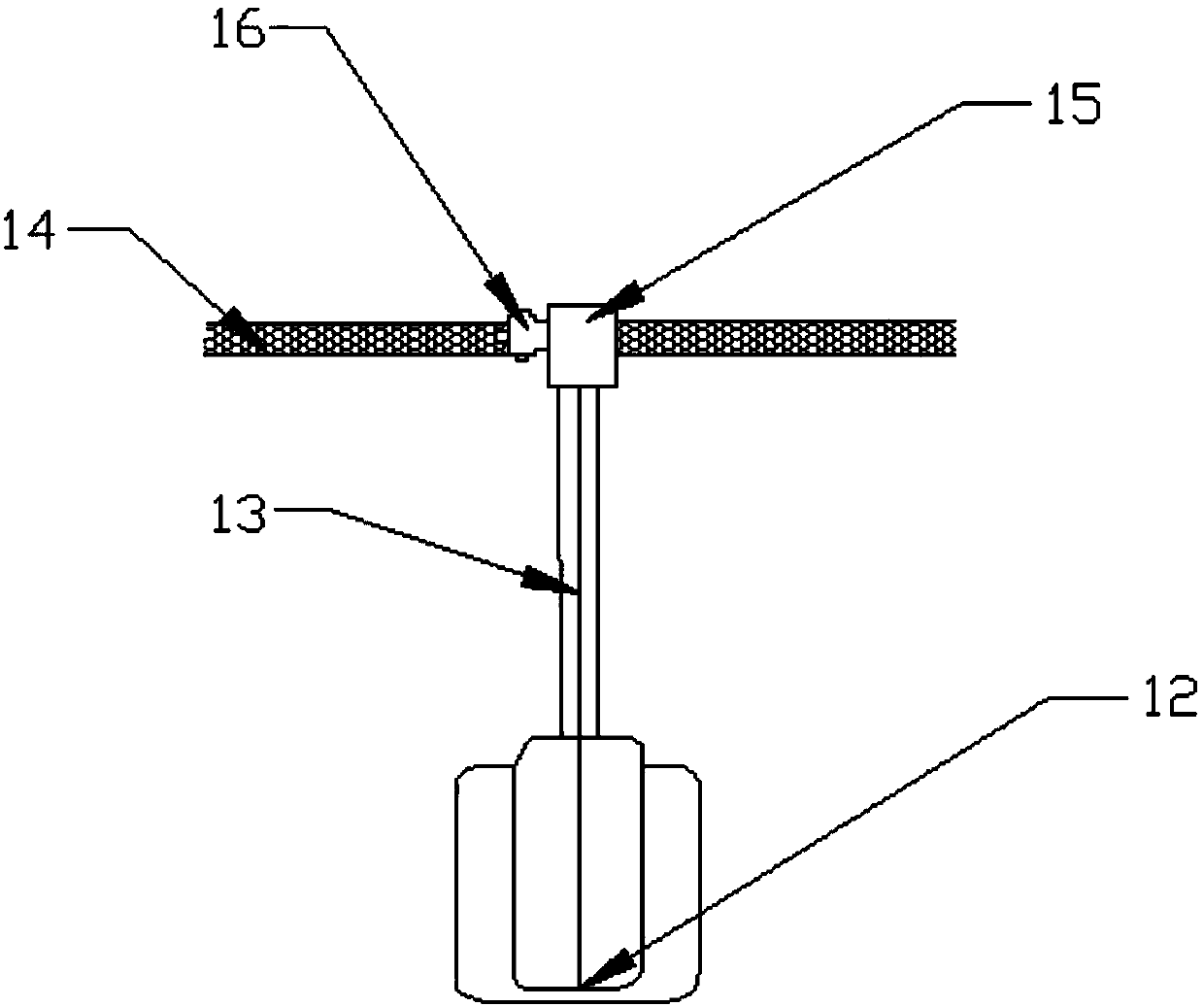

[0019] Such as Figure 1-4 As shown, the present invention provides a compound bread machine, comprising a baking case 1 and a first top cover 2 arranged on the top of the baking case 1, a second top cover 3 is provided on one side of the first top cover 2, and the baking case 1 One side of the kneading box 4 is provided with a third top cover 5, one side of the kneading box 4 is provided with a temperature sensor 6, and the bottom of the temperature sensor 6 is provided with a temperature Display screen 7, the bottom of temperature display screen 7 is provided with time regulating table 8, and the inside of kneading box 4 is provided with kneading bucket 10, and the inside of kneading bucket 10 is provided with water injection hole 11, and the top of kneading bucket 10 is provided with There is a stirrer 12, the top of the stirrer 12 is provided with a telescopic stirring shaft 13, and the top of the telescopic stirring shaft 13 is provided with a rotating shaft 14 with a hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com