Processing method of crosshead pin of low-speed diesel engine for MAN-series ship

A crosshead pin and processing method technology, applied in the field of mechanical processing, can solve the problems of increasing vertical lathe, low processing efficiency, increasing the time for getting on and off the vehicle, etc., to ensure grinding accuracy, low processing efficiency, and short process routes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments. All equivalent changes and modifications made according to the content of this specification belong to the technical scope of the present invention.

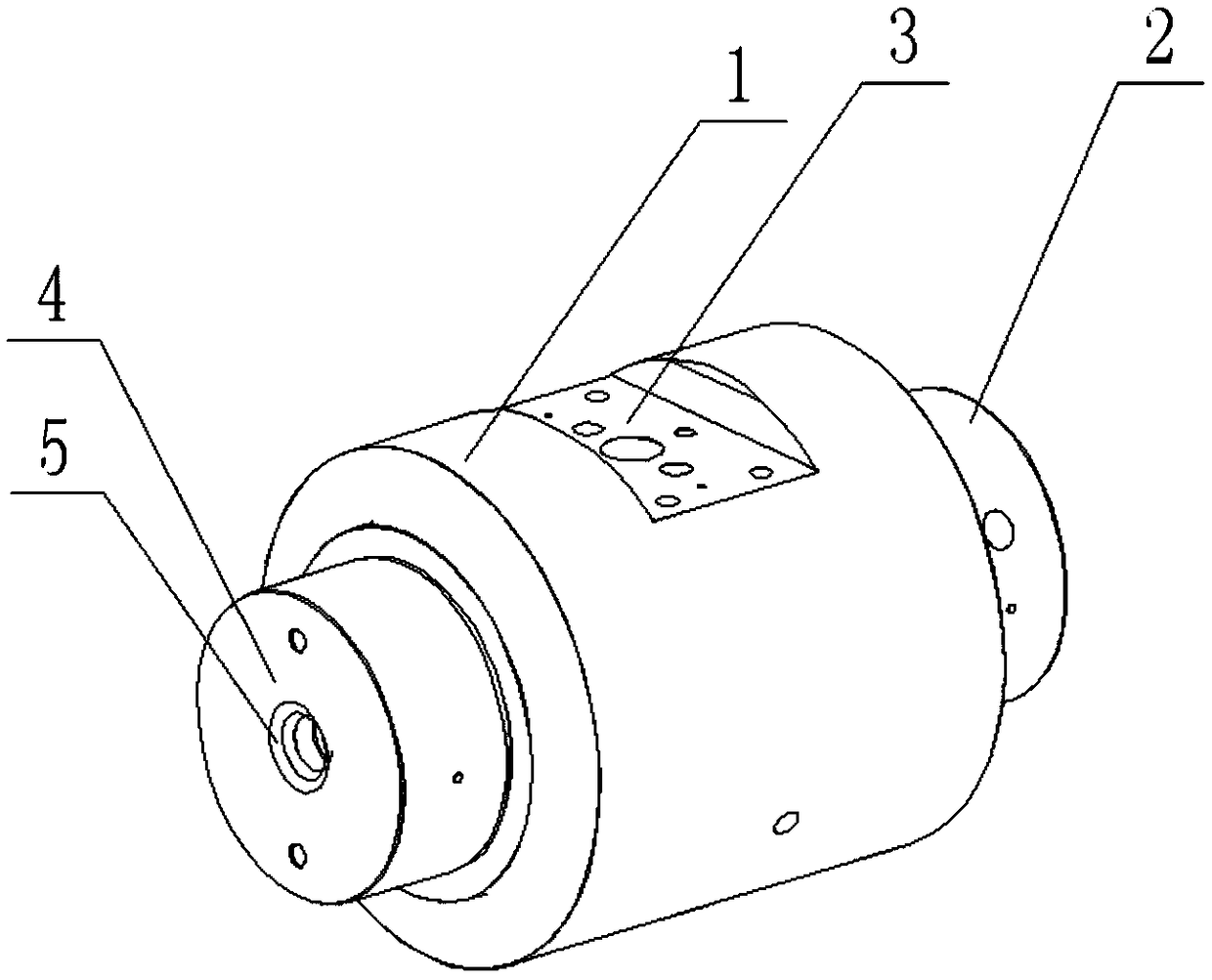

[0057] The present invention is used to process crosshead pins of MAN series marine low-speed diesel engines, please refer to figure 1 , the crosshead pin includes a large outer circle 1 and two small outer circles 2, the two small outer circles 2 are coaxially connected to both sides of the large outer circle 1, and the end faces 4 on both sides of the small outer circle 2 A center hole 5 is provided on the top, and a notch plane 3 is provided on the outer periphery of the large outer circle 1 .

[0058] For the processing method of the crosshead pin of the MAN series marine low-speed diesel engine, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com