Oil smoke treatment system

A technology of oil fume treatment and oil collection box, which is applied in the direction of oil fume removal, household stove/stove, separation method, etc. It can solve the problems that the fume collection hood does not have the adjustment function, the disassembly process is cumbersome, time-consuming and labor-intensive, etc., to improve the flexibility of use The degree and scope of application, and the effect of improving disassembly and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the embodiments and the accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

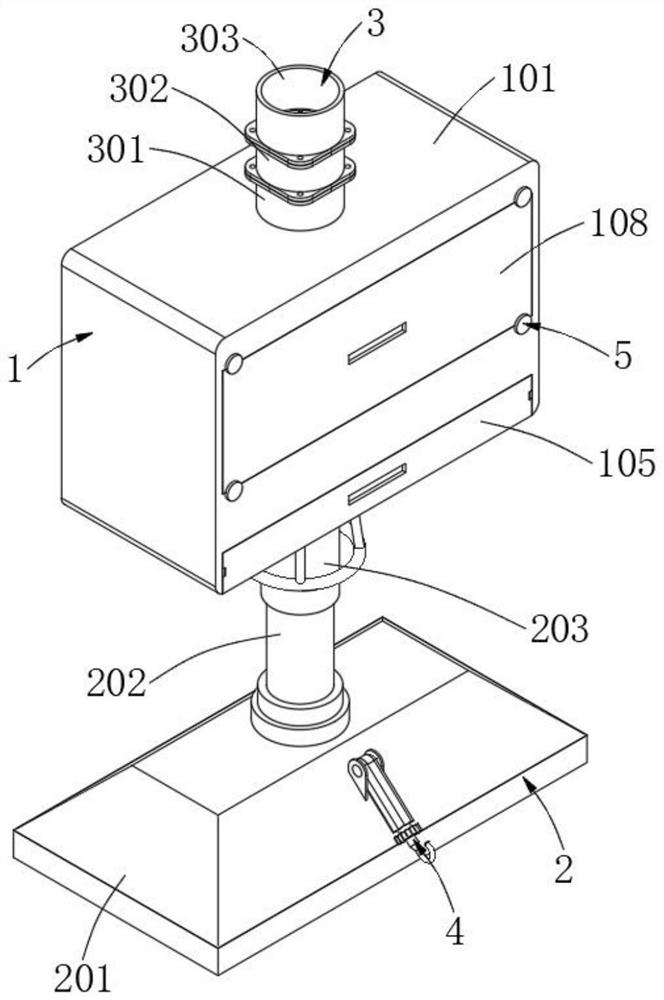

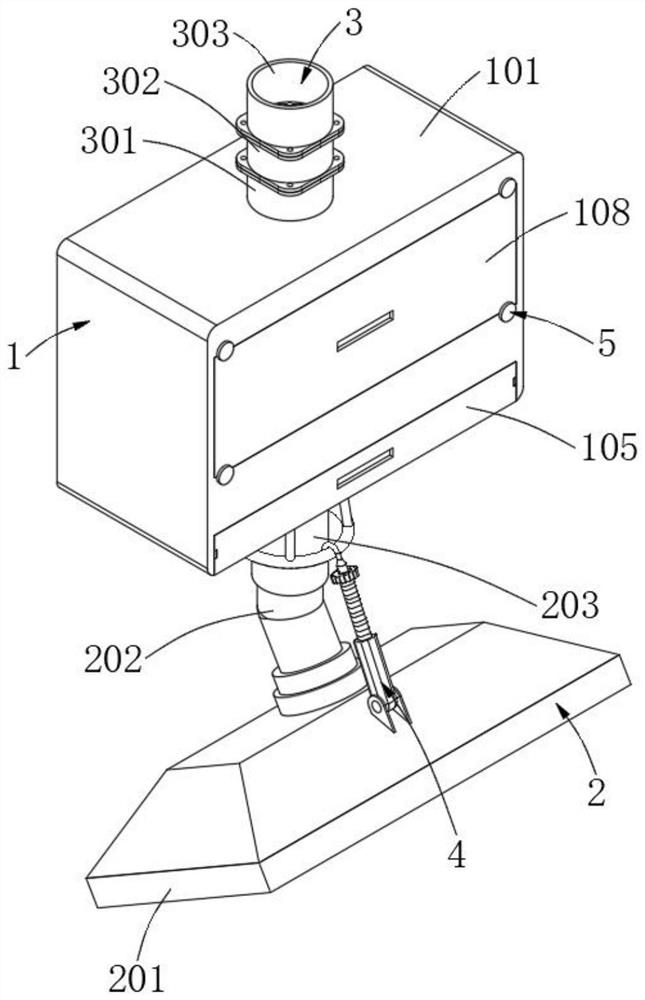

[0033] like Figure 1-7 As shown, an oil fume treatment system includes a filter mechanism 1 , a smoke intake mechanism 2 , an adjustment mechanism 4 and a locking mechanism 5 .

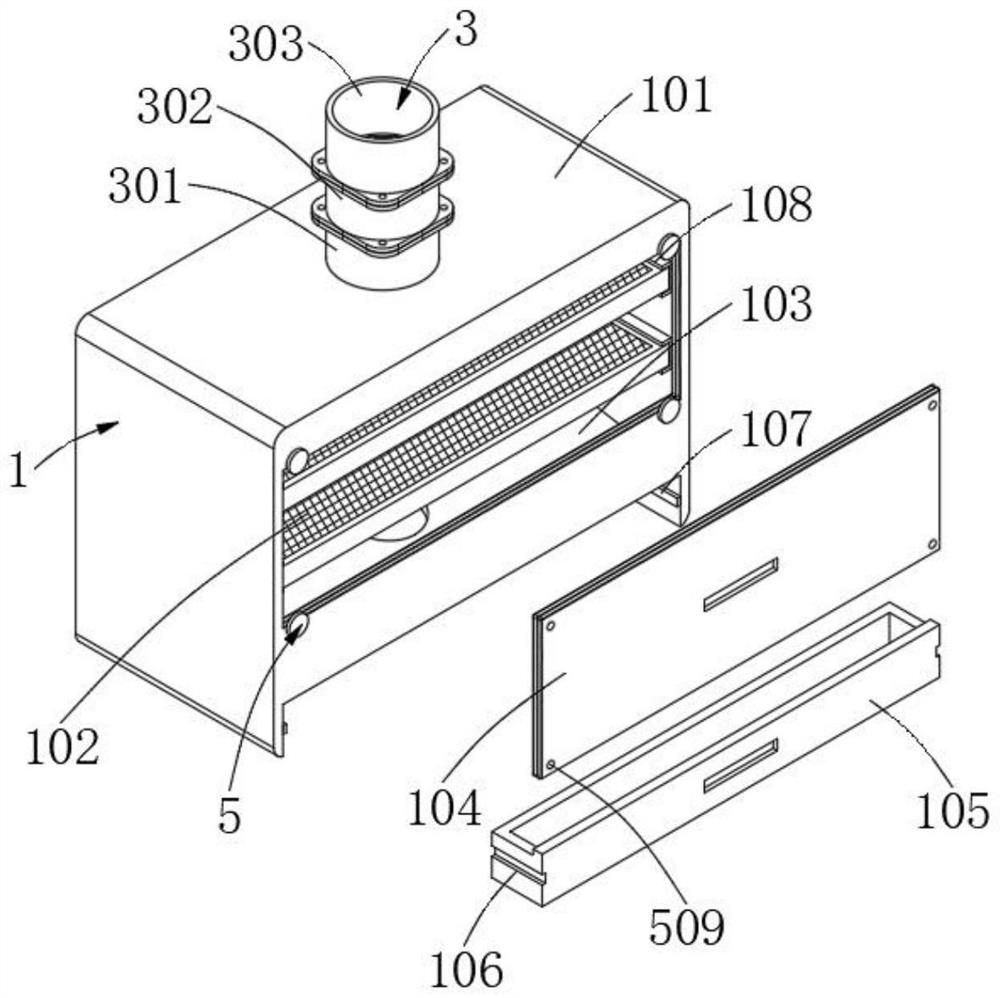

[0034] The filter mechanism 1 includes a filter box 101. The inner cavity of the filter box 101 is sequentially provided with a filter screen 102 and a material guide plate 103 from top to bottom. An access panel 104 is installed on the surface of the filter box 101 , an oil collecting box 105 is arranged at the bottom of the filter box 101 , and a smoke exhaust mechanism 3 is arranged at the central axis of the top of the filter mechanism 1 .

[0035] The smoke inlet mechanism 2 includes a smoke collecting hood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com