Sewing machine lifting platform

A lifting table and sewing machine technology, applied in the field of lifting table, can solve problems such as troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

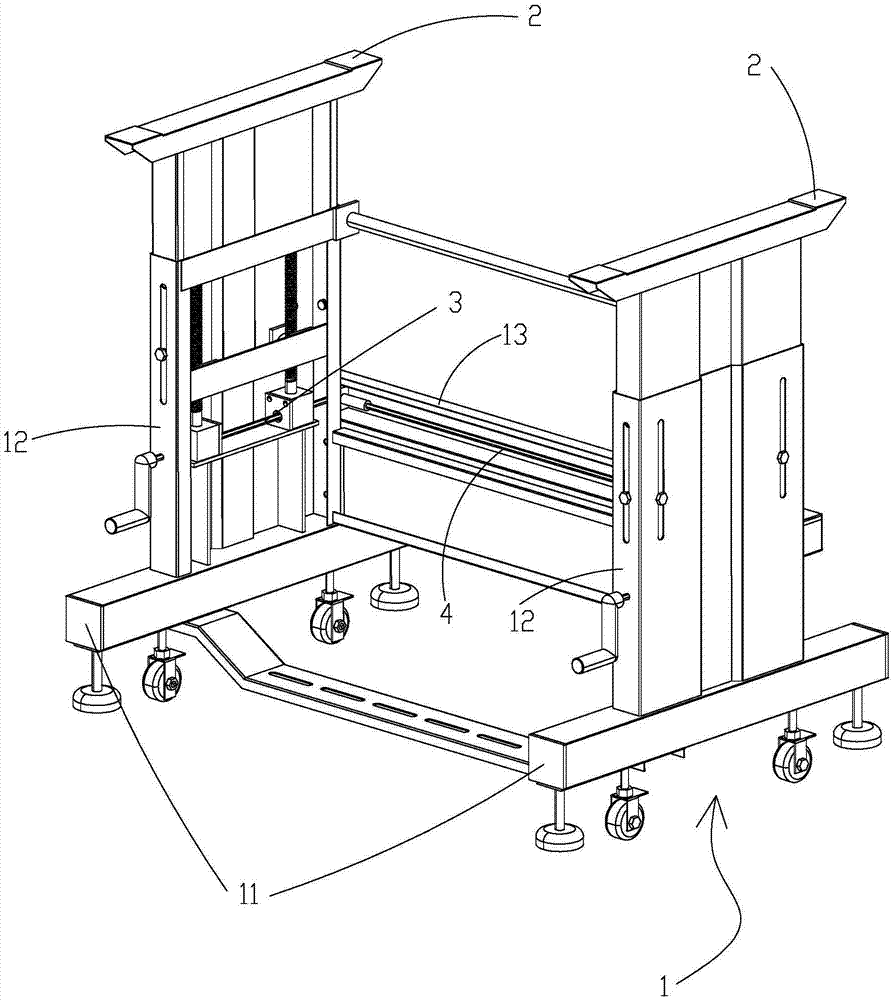

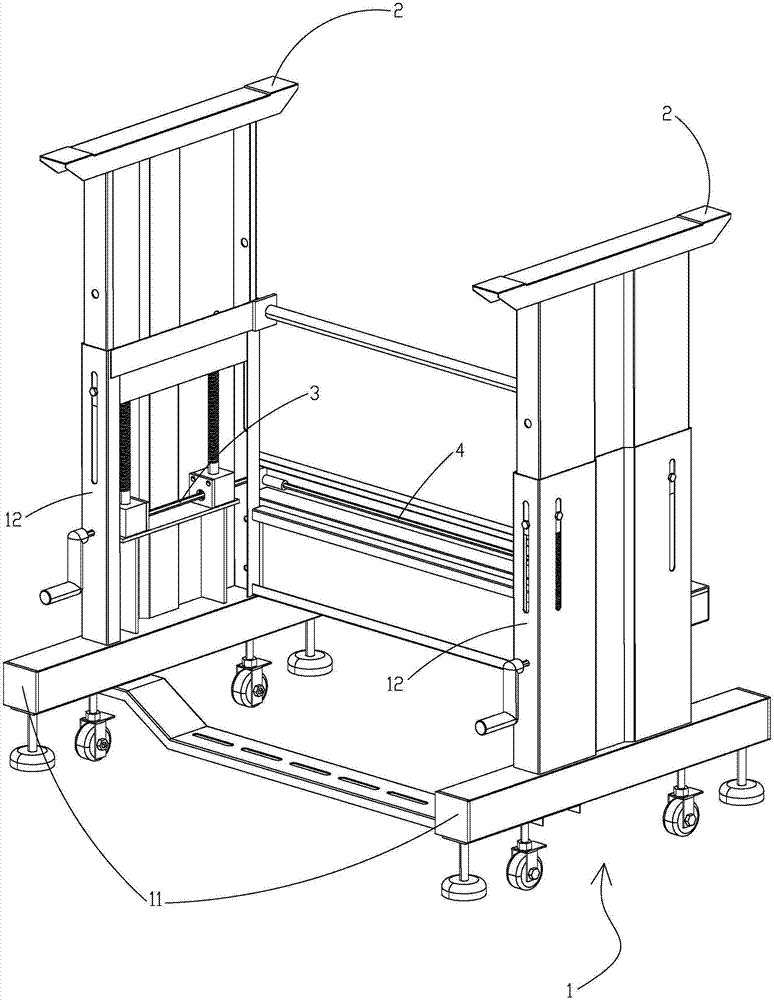

[0028] Attached below Figures 1 to 8 To further describe the invention.

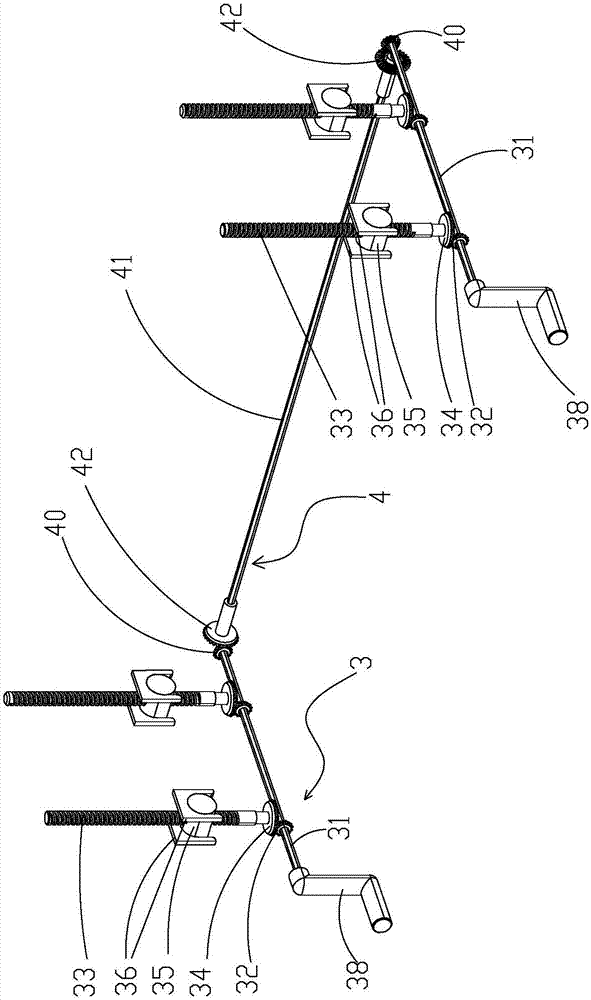

[0029] A sewing machine lifting platform, comprising a frame 1 and a lifting platform 2 capable of lifting relative to the frame 1, characterized in that the frame 1 includes a bottom frame 11 and a vertical guide plate 12 arranged on the bottom frame 11 , the vertical guide plate 12 is two and the positions are symmetrically arranged, the lifting table 2 is two and is respectively arranged on the two vertical guide plates 12, the lifting table 2 and the vertical guide plate 12 is provided with a driving device 3 that drives the lifting platform 2 to rise and fall relative to the vertical guide plate 12, and a drive device 3 is provided between the two driving devices 3 when one of the driving devices drives one of the lifting platforms relative to the vertical guide plate 12. When lifting, another driving device drives the linkage device 4 of the relative vertical guide plate 12 synchronous lifting of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com