High-resilience toughened glass breaker

A tempered glass and breaker technology, applied in life-saving equipment, building rescue and other directions, can solve the problem that tempered glass cannot be easily broken, and achieve the effects of reducing water resistance, simple use, and accurate tapping points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

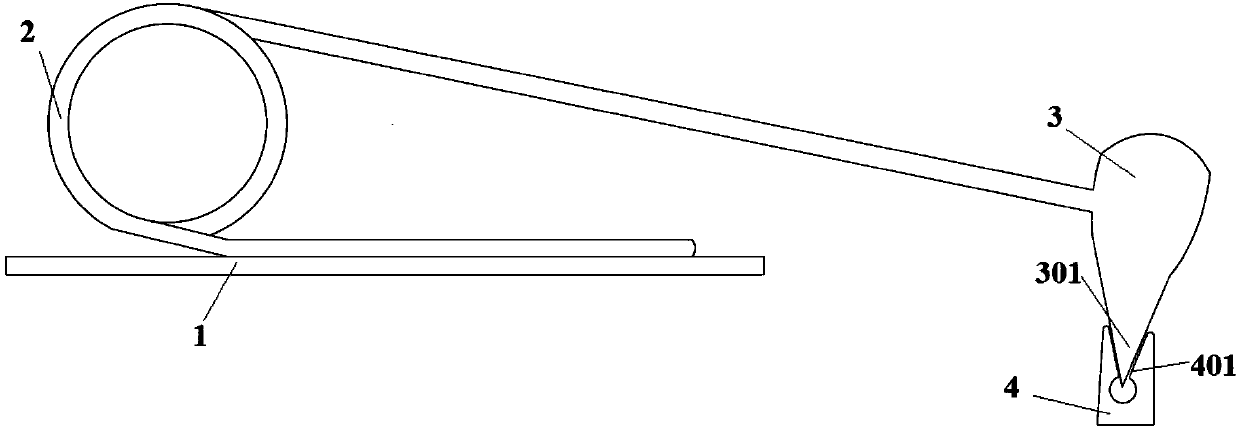

[0030] see Figure 1-3 As shown, the present invention is a strong rebound tempered glass breaker, including torsion spring 2 and inertial sphere 3;

[0031] One end of the torsion spring 2 is fixed on a surface of the base 1 by welding; the other end of the torsion spring 2 is fixed with an inertial sphere 3;

[0032] One end of the inertial sphere 3 cooperates with the plastic cover 4; at ordinary times, the plastic cover 4 plays a protective role to the tungsten steel tip 301, and prevents the tungsten steel tip 301 from causing damage to the tempered glass when the car is vibrating.

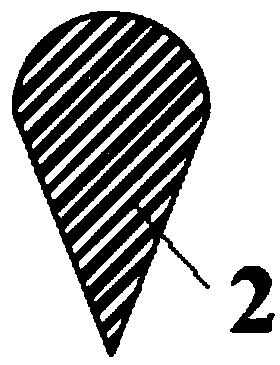

[0033] Among them such as figure 1 As shown, the rotation range of the torsion spring 2 is 0 to 180 degrees; the linear cross section of the torsion spring 2 is a circular structure; where as image 3 As shown, the linear cross section of the end where the torsion spring 2 is connected to the inertia ball 3 is a wedge-shaped structure, which has the advantage of reducing the resistance of w...

Embodiment 2

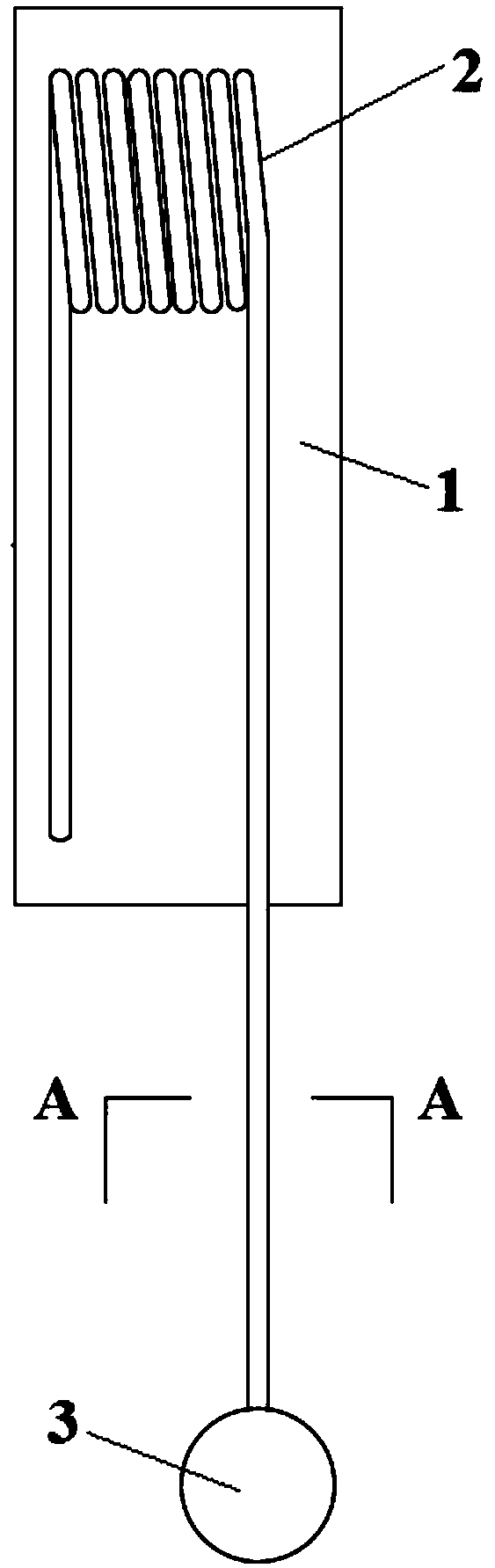

[0039] see Figure 3-5 As shown, the present invention is a strong rebound tempered glass breaker, including torsion spring 2 and inertial sphere 3;

[0040] One end of the torsion spring 2 is fixed on a surface of the base 1 by welding; the other end of the torsion spring 2 is fixed with an inertial sphere 3;

[0041] One end of the inertial sphere 3 cooperates with the plastic cover 4; at ordinary times, the plastic cover 4 plays a protective role to the tungsten steel tip 301, and prevents the tungsten steel tip 301 from causing damage to the tempered glass when the car is vibrating.

[0042] Among them such as Figure 4 As shown, the rotation range of the torsion spring 2 is 0 to 180 degrees, and the linear cross section of the torsion spring 2 is a circular structure; where as image 3 As shown, the linear cross section of the end where the torsion spring 2 is connected to the inertia ball 3 is a wedge-shaped structure, which has the advantage of reducing the resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com