Offcut separation device for coconut fiber board edge cutting machine

A separation device and trimming machine technology, which is applied in metal processing and other directions, can solve the problems of blocking the trimming machine, jamming of the trimming machine, and inability to perform normal shearing, etc., and achieves reasonable device design, low cost, and anti-jamming good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

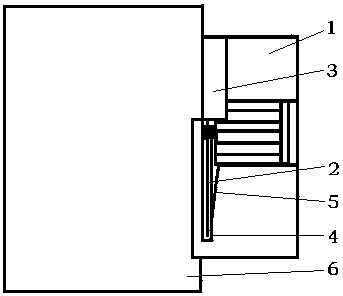

[0011] Such as figure 1 Shown, a kind of coconut palm board trimming machine edge material separating device is characterized in that by trimming machine 1, trimming knife 2, trimming machine shield 3, notch 4, separation plate 5, coconut palm board conveyor belt 6 composition. The notch 4 is located below the edge trimmer 1, and is 35 cm long and 1 cm wide; the separation plate 5 is 15 cm long and 6 cm high, and the separation plate 5 is obliquely welded on the outside of the notch 4, and the front end is close to the edge trimmer 2, The rear end is slightly far away from the trimming knife 2.

[0012] The working principle of the present invention is that when edge trimmer 1 trims the edge of coconut palm board, because the front end of separation plate 5 is close to the outside of edge trimming knife 2, the edge material removed by edge trimm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com