Self-weight hanging basket

A hanging basket and center of gravity technology, applied in the direction of lifting devices, etc., can solve the problems of narrow space, instability, and weak flexibility in substations, and achieve the effect of comfortable working conditions, ensuring stability, and improving the gripping space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

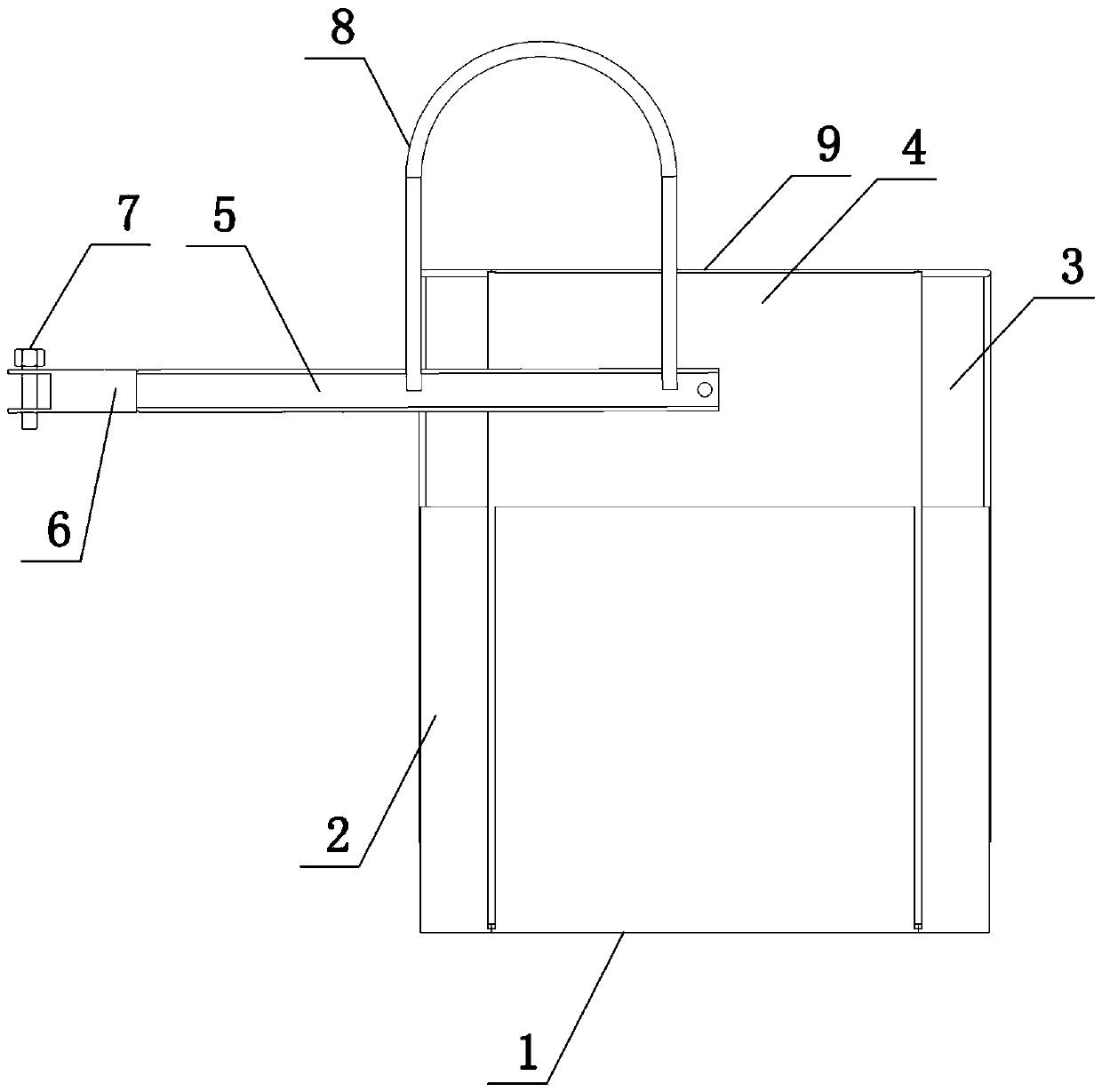

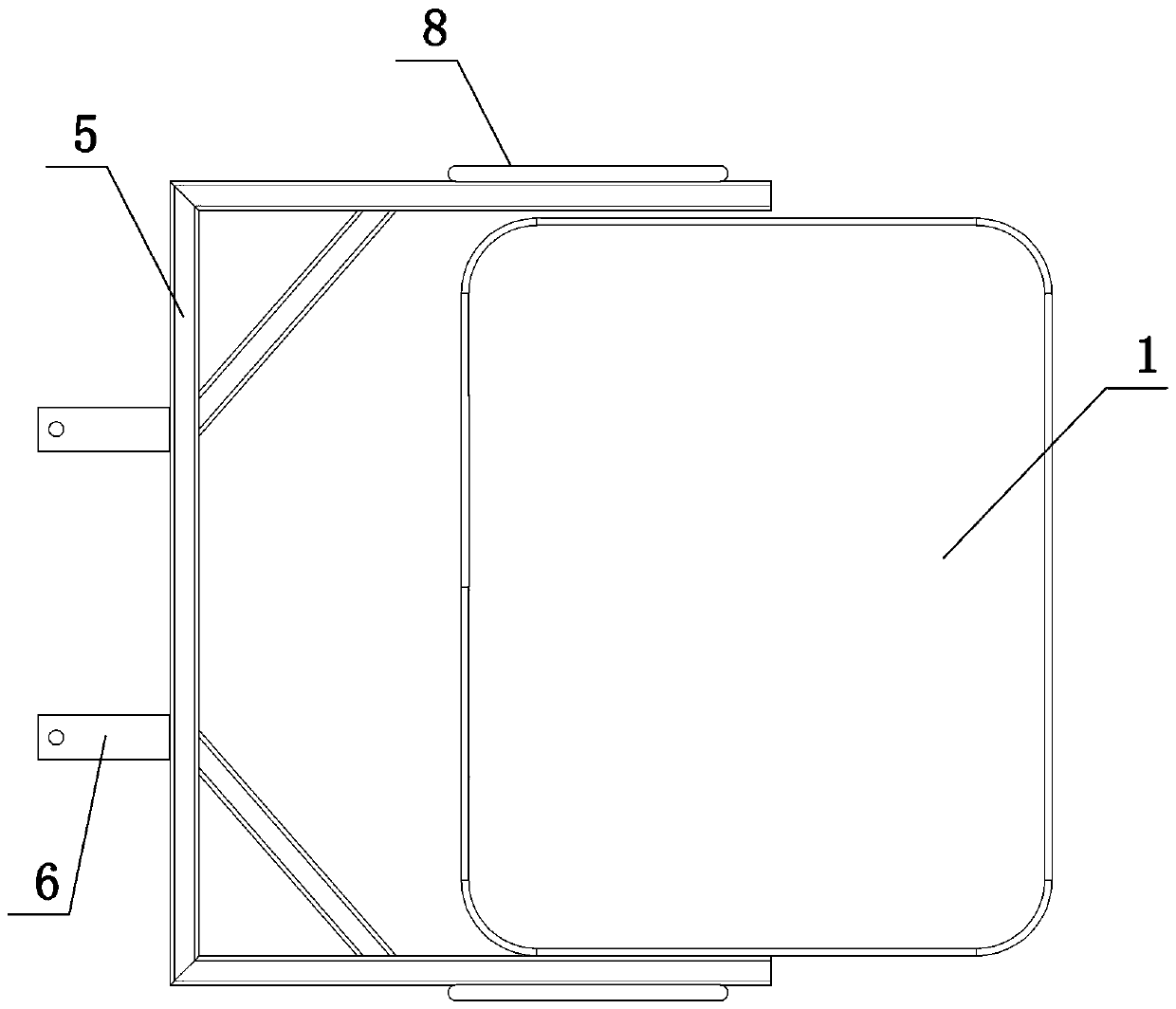

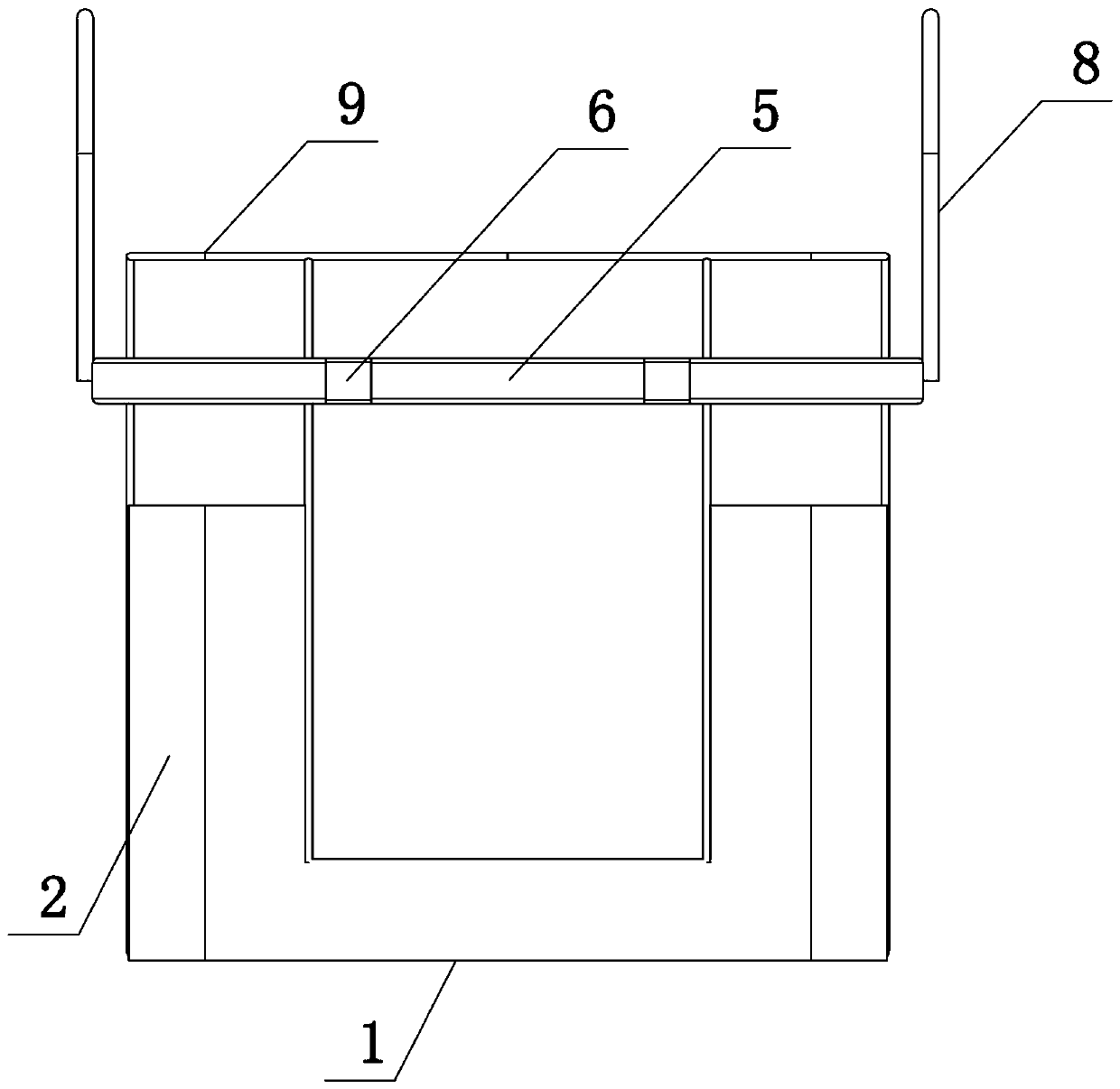

[0034] Such as Figure 1 to Figure 4 As shown, the present invention includes a hanging basket main body and a hanging basket support. The hanging basket main body includes a bottom plate 1, a side baffle 2 and a guardrail 3. The side baffle 2 is fixedly connected to the upper end of the bottom plate 1, and the guardrail 3 is fixedly connected to the side baffle 2. The upper end of the guardrail 3 is provided with a connecting plate 4, and the hanging basket bracket includes a fixed connection between the first bracket 5 and the second bracket 6. The first bracket 5 is a U-shaped structure, and the second bracket 6 is two, which are made of square steel. The two ends of the first bracket 5 are respectively connected to the two oppositely arranged connecting plates 4 through rotating shafts, the hinge point is located above the center of gravity of the main body of the hanging basket, and the end of the second bracket 6 away from the first bracket 5 is fastened. mechanism, the ...

Embodiment 2

[0036] The present invention includes a hanging basket main body and a hanging basket support, the hanging basket main body includes a bottom plate 1, a side baffle 2 and a guardrail 3, the side baffle 2 is fixedly connected to the upper end of the bottom plate 1, and the guardrail 3 is fixedly connected to the upper end of the side baffle 2, A connecting plate 4 is arranged on the guardrail 3, and the hanging basket support includes a first support 5 and a second support 6 fixedly connected, the first support 5 is a U-shaped structure, and the second support 6 is two, which are made of square steel. The two ends of the bracket 5 are respectively connected to the two opposite connecting plates 4 through rotating shafts, the hinge point is located above the center of gravity of the main body of the hanging basket, and the second bracket 6 is provided with a fastening mechanism at the end of the first bracket 5 away from it. The fixing mechanism adopts bolts 7; the upper end surf...

Embodiment 3

[0039] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 7 As shown, a seat 12 is arranged on the upper end surface of the base plate 1 , and the seat 12 is rotationally connected with the base plate 1 through a rotating shaft 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com