Automobile door handle automatic painting equipment

An automatic painting and door handle technology, which is applied in painting booths, spraying devices, liquid spraying devices, etc., can solve the problems that the production capacity cannot reach the expected effect, the quality cannot be guaranteed, and the loss of painting employees, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

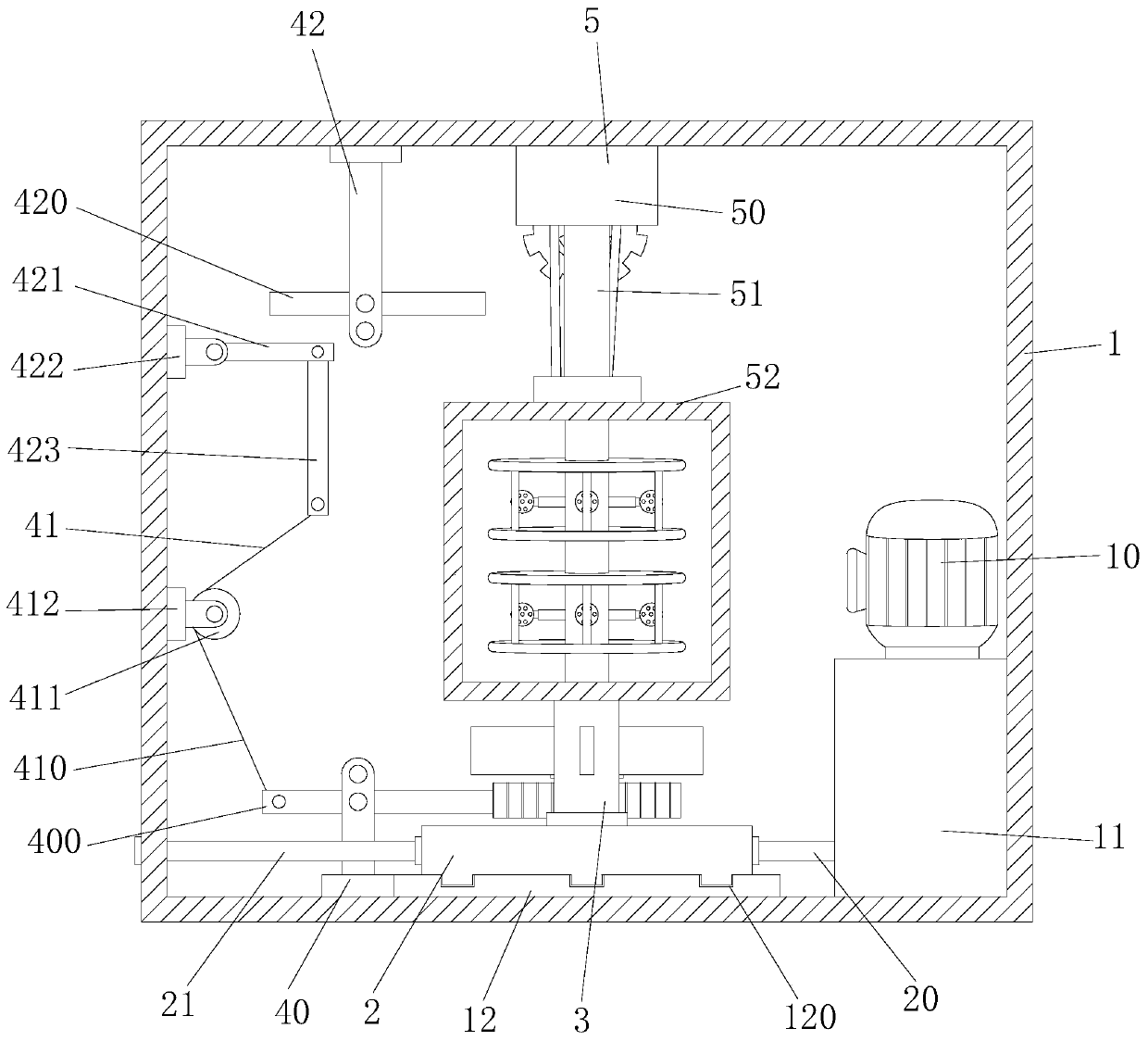

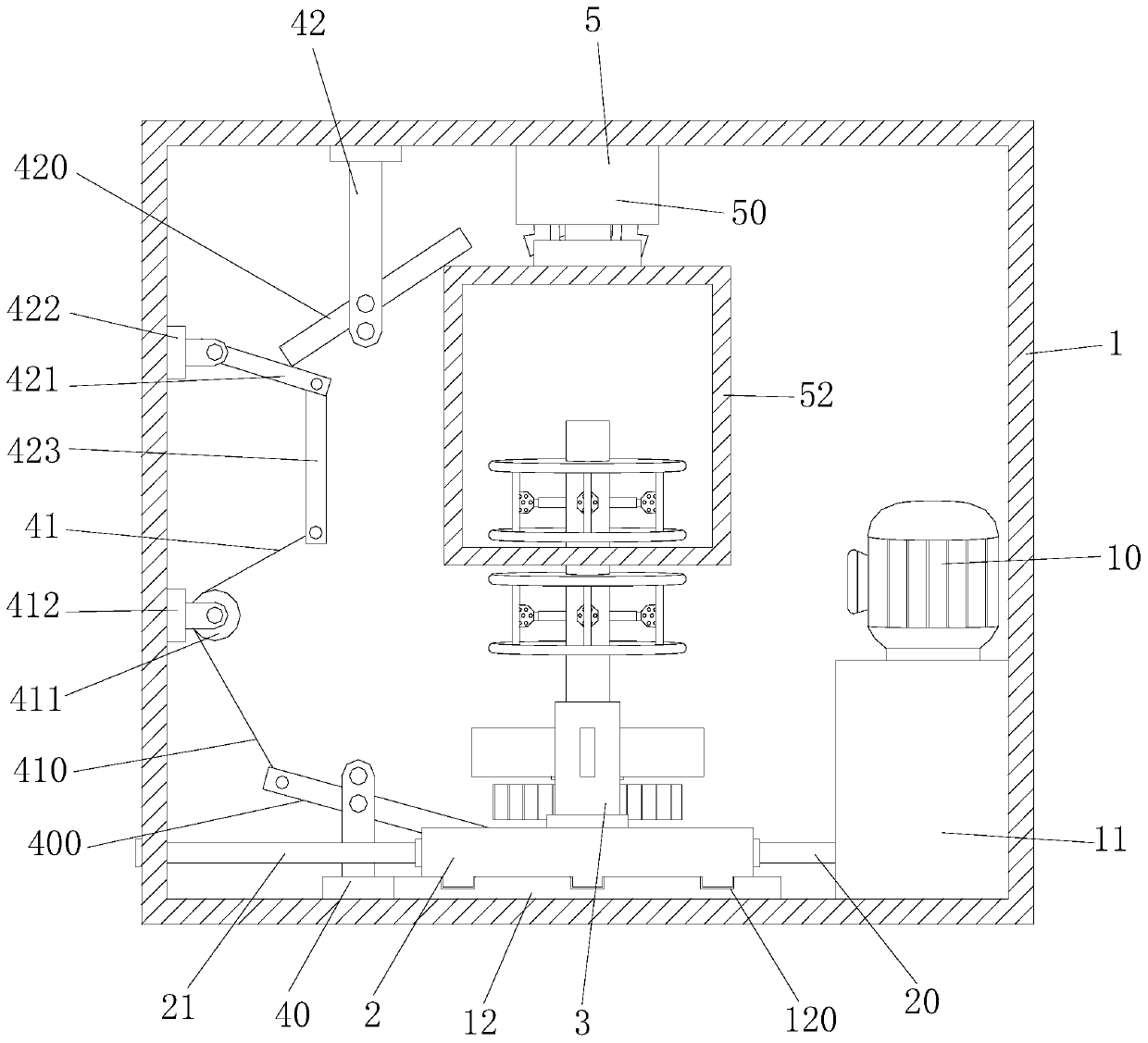

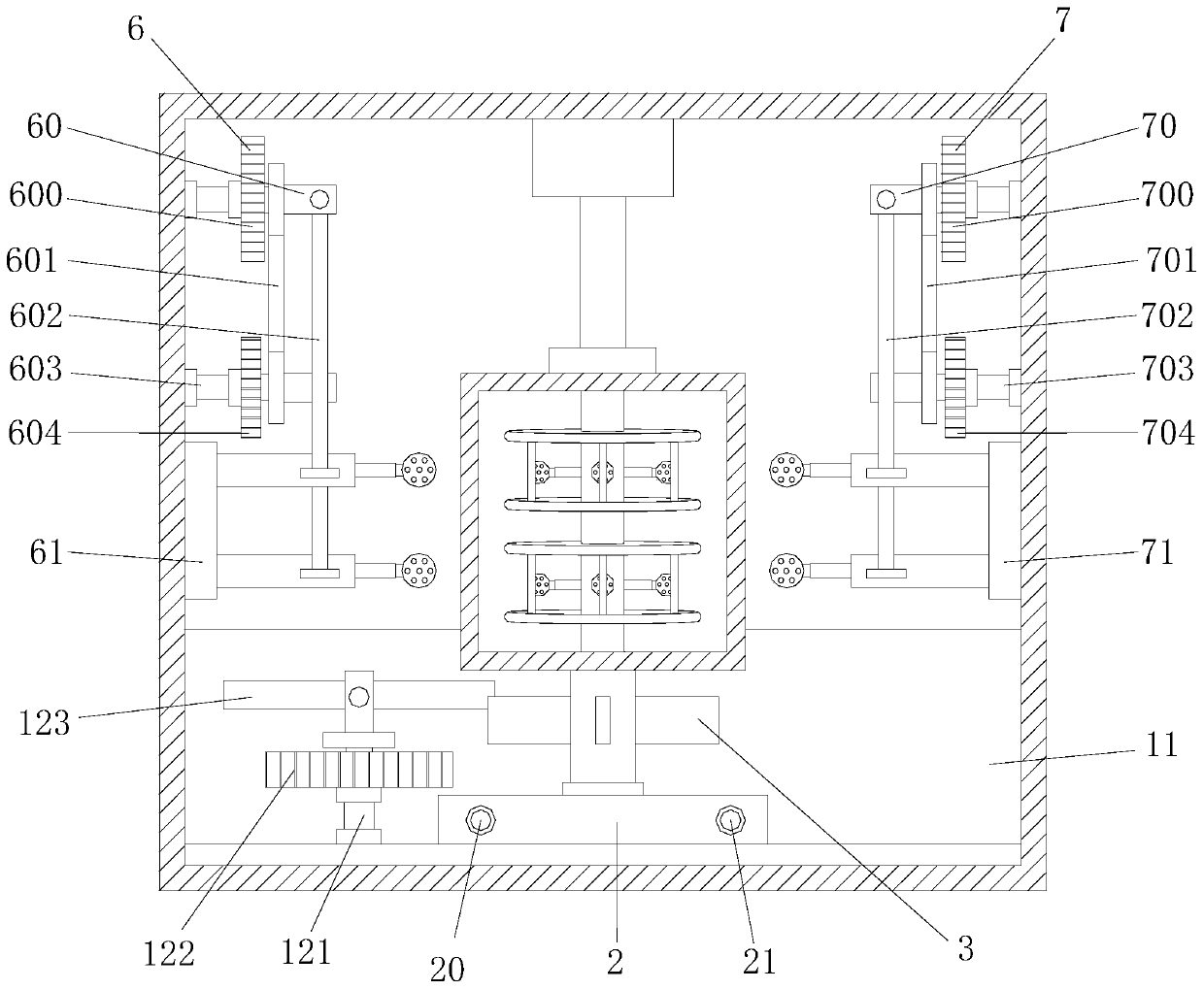

[0034] See Figure 1-Figure 6 , The present invention provides a technical solution for automatic paint spraying equipment for automobile door handles: the structure includes a sprayer device outer shell 1, a conveying sliding bottom plate 2, a rotating paint spraying device 3, a rotating device drive mechanism 4, a protective cover retractable device 5, and a first exterior The spray paint transmission mechanism 6 and the second external spray paint transmission mechanism 7. The sprayer equipment outer shell 1 is connected to the outer surface of the transmission sliding bottom plate 2 and the protective cover telescopic device 5 by bolts riveting, and the transmission sliding bottom plate 2 is embedded in On the inner bottom surface of the sprayer equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com