Blackboard with full-automatic blackboard eraser

A blackboard eraser, fully automatic technology, applied in the field of teaching equipment, can solve the problems of not being able to meet the integrated structure of teaching equipment, the single function of the blackboard, and hidden dangers to human health, so as to achieve a clean wiping effect, solve health risks, and reduce pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

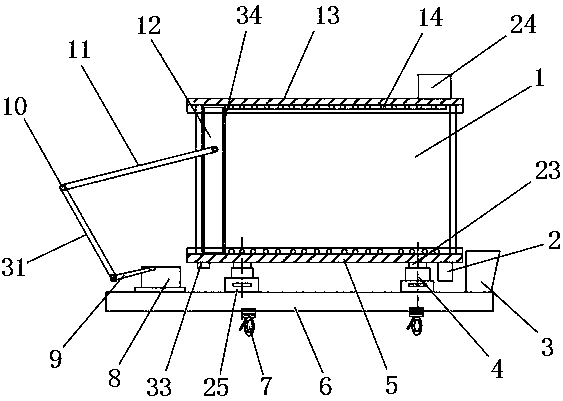

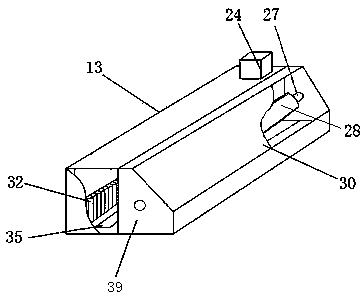

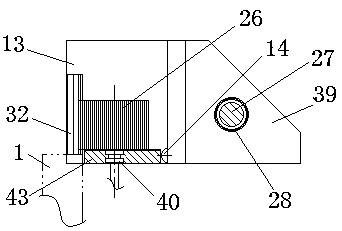

[0026] The present invention will be further described below in conjunction with drawings and embodiments. see Figure 1 to Figure 14 , a blackboard with a fully automatic blackboard eraser, four universal wheels 7 are installed under the base 6, and a motor 8 (model: Y630-10 / 1180) is installed on the left side of the base 6, and the motor 8 is connected to There is a crank 9, and the crank 9 is sequentially connected with a connecting rod 31 and a rocker 11 through a hinge 10; a base 25 is installed between the motor 8 and the waste collection box 3, and two hydraulic lifters 4 are connected to the bottom of the blackboard Benxiu 1. Elevator 4 is connected with pedal control panel 29, and pedal control panel 29 is positioned at the base 25 outsides of rectangular structure, and telescopic link 23 upper end is equipped with slide rail 5 to connect with blackboard this rest 1 bottom limit; Switch is housed below slide rail 5 left ends Button 33, distance sensor 2 is housed bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com