Grinding device for producing tire molds

A tire mold, grinding machine technology, applied in the direction of grinding/polishing safety devices, grinding machines, manufacturing tools, etc., can solve the problems of corrosion and difficult maintenance of metal parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

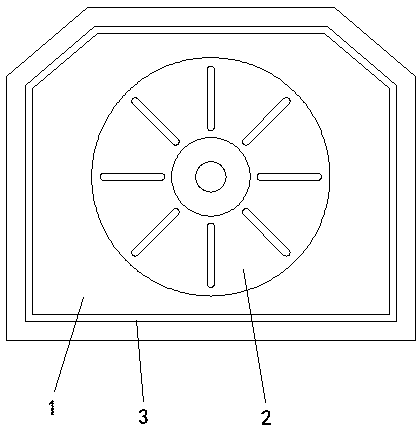

[0018] The grinder 1 is provided with a faceplate 2 and a tool holder assembly, the grinder 1 is provided with a groove 3, the groove 3 is arranged around the faceplate 2, the tool holder assembly is provided with a casing 4, and the casing 4 is provided with an opening, and the opening matches the groove 3;

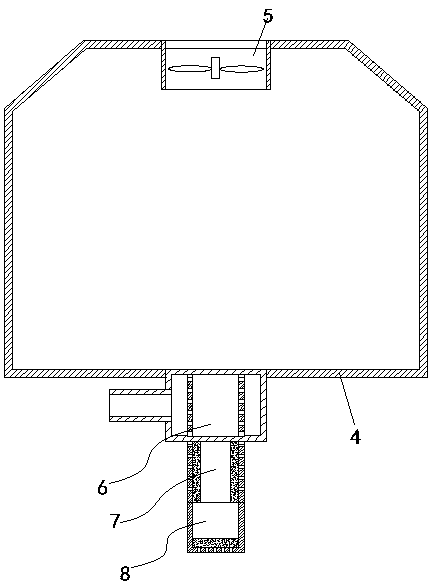

[0019] The top of the casing 1 is provided with an upper through hole, and the casing 1 is provided with a fan 5, and the fan 5 is fixed on the casing 1 through the upper through hole; the bottom of the casing 1 is provided with a lower through hole, and the lower end of the casing 1 is provided with a spray tube 6, which It is fixed on the shell 1 through the lower through hole; the lower end of the spray tube 6 is coaxially provided with an exhaust cylinder 7, and the lower end of the exhaust cylinder 7 is coaxially provided with a collection box 8;

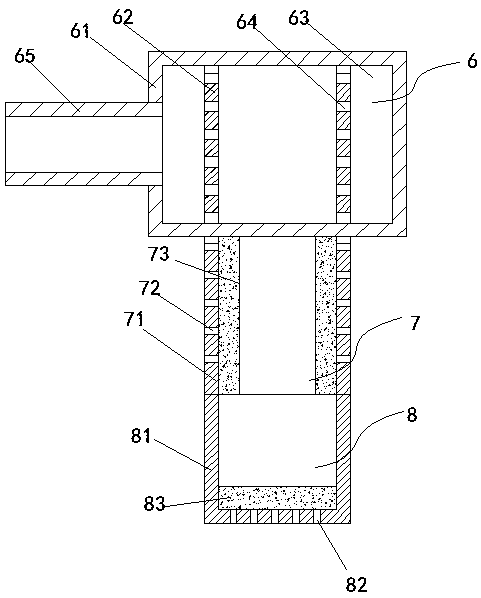

[0020] The spray tube 6 comprises an outer cylinder 61 and an inner cylinder 62, the outer cylinder 61 and the inner cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com