Removable precast wall mold

A prefabricated wall and mold technology, applied in the direction of molds, mold fixing devices, mold auxiliary parts, etc., can solve the problems of manpower consumption, steel waste, waste, etc., to save steel and manpower, better economic benefits, shorten construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

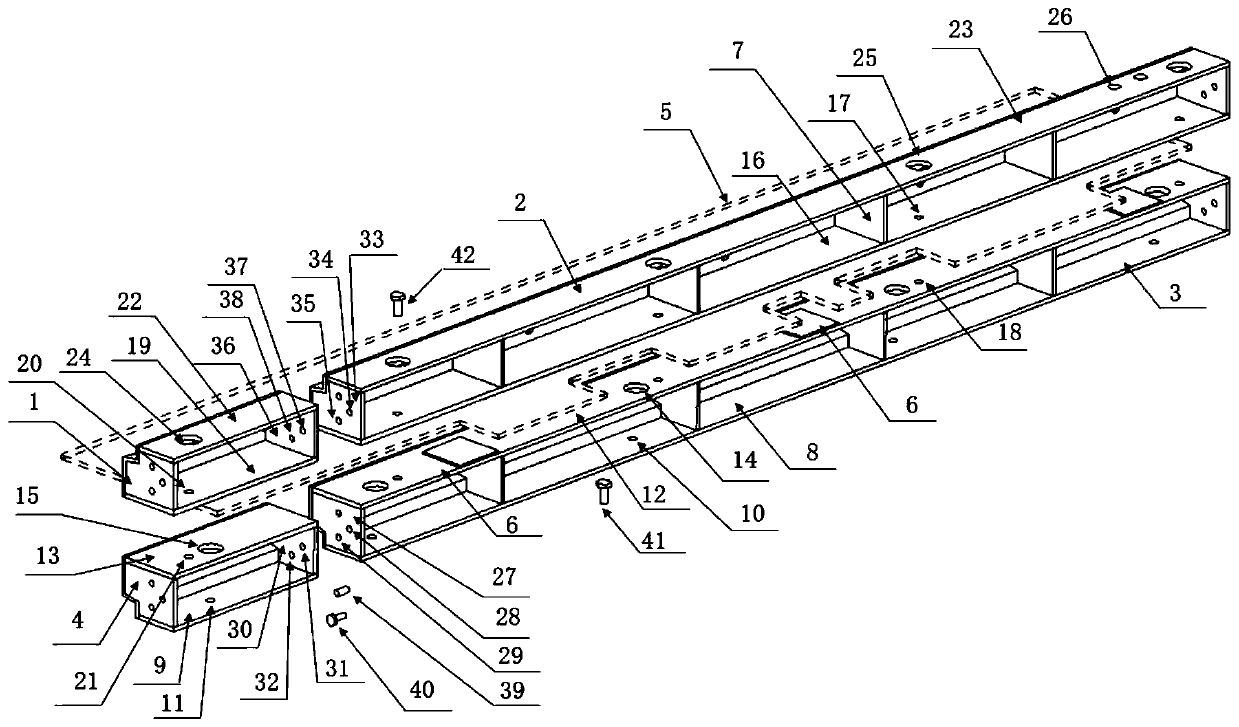

[0013] like figure 1 As shown, a detachable prefabricated wall mold includes first to fourth modules, the first to fourth modules are assembled together by positioning pins and bolts, and fixed on the workbench to form a detachable prefabricated Wall mold. The first to fourth modules are all welded by upper and lower horizontal plates and rib plates on both sides.

[0014] (1) The detachable prefabricated wall mold structure is designed into four parts: the first module 1, the second module 2, the third module 3, and the fourth module 4.

[0015] (2) The first module 1, the second module 2, the third module 3, and the fourth module 4, after assembly, there is a gap in the middle, which is used for the installation of the waterproof steel plate 5 of the wall, and through three positioning The block 6 is positioned with the waterproof steel plate 5 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com