Self-propelled container carrying system

A handling system and container technology, applied in transportation and packaging, multi-axis trolleys, trolleys, etc., can solve the problems of low loading and unloading efficiency, complicated control, and low utilization of site area, achieve safe handling, reduce labor hours, and shorten loading and unloading. The effect of the time to carry the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

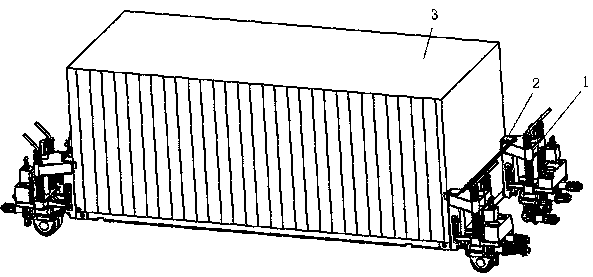

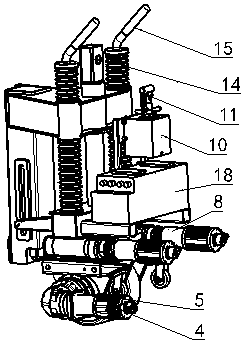

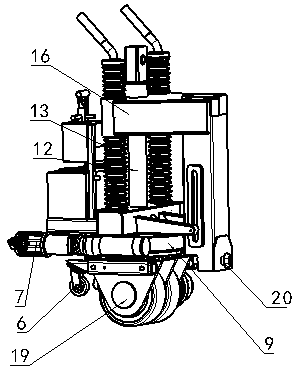

[0015] Such as Figure 1-3 As shown, the present invention is a self-propelled container handling system, which includes integrated drive lift trucks 1 installed at the four corners of the container 3, and the integrated drive lift trucks 1 at the two front corners of the container 3 are connected by connecting rods 2. The integrated driving lift car 1 at the two rear corners of the container 3 is connected through a connecting rod 2, and the connecting rod 2 adopts a rigid or flexible lock cable, and the lateral overturning of the integrated driving lifting car 1 through the connecting rod 2 Playing a supporting role, the integrated driving lift car 1 includes a driving wheel set 19, a slewing support 9, a fixed frame body 20, a guide shaft 13, a lifting frame body 16, and a hydraulic cylinder 12. The driving wheel set 19 is driven to decelerate The device 8 is connected with the drive motor 4, the drive wheel set 19 is provided with an auxiliary wheel set 6, the slewing supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com