Card pushing mechanism applied to printer, and printer

A technology of printer and card feeding, applied in the directions of printing device, printing, object supply, etc., can solve the problem of card receiving failure, and achieve the effect of improving the probability of successful push

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

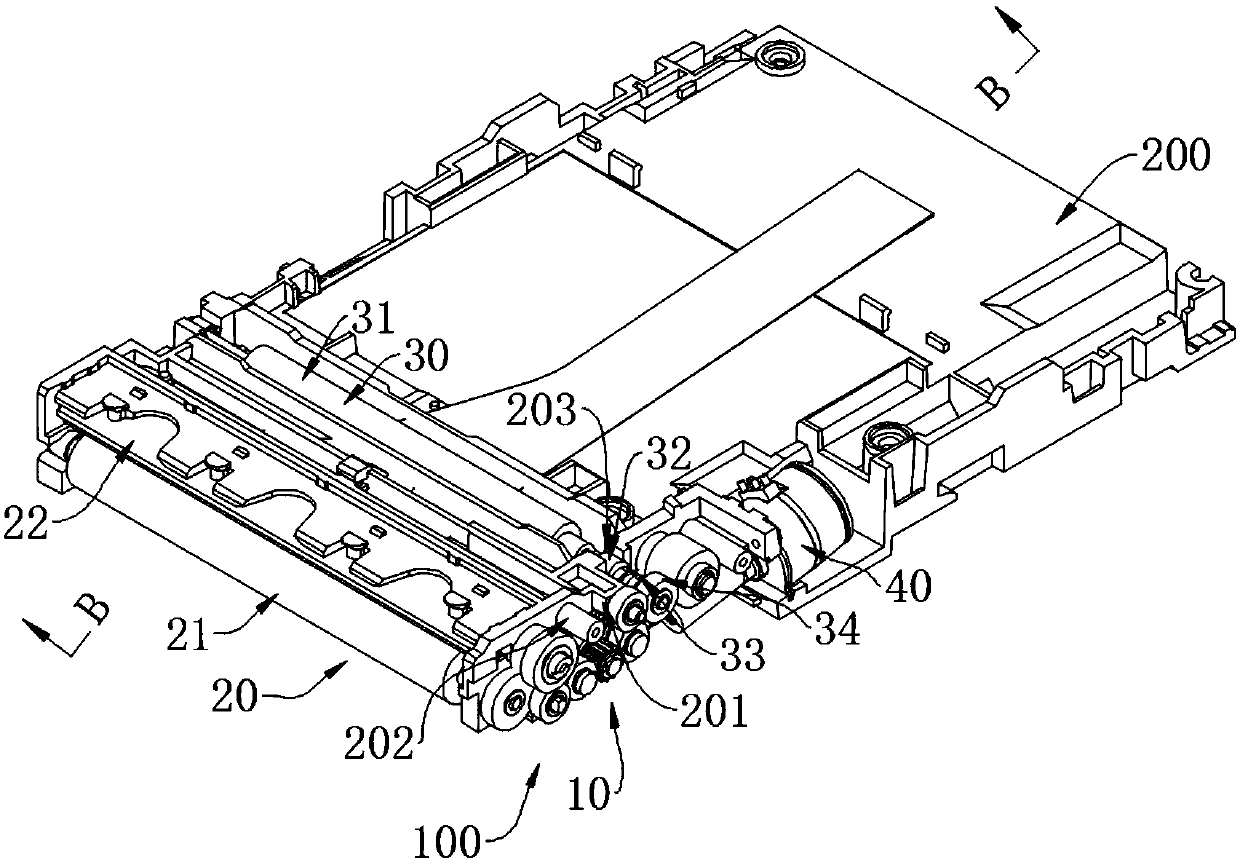

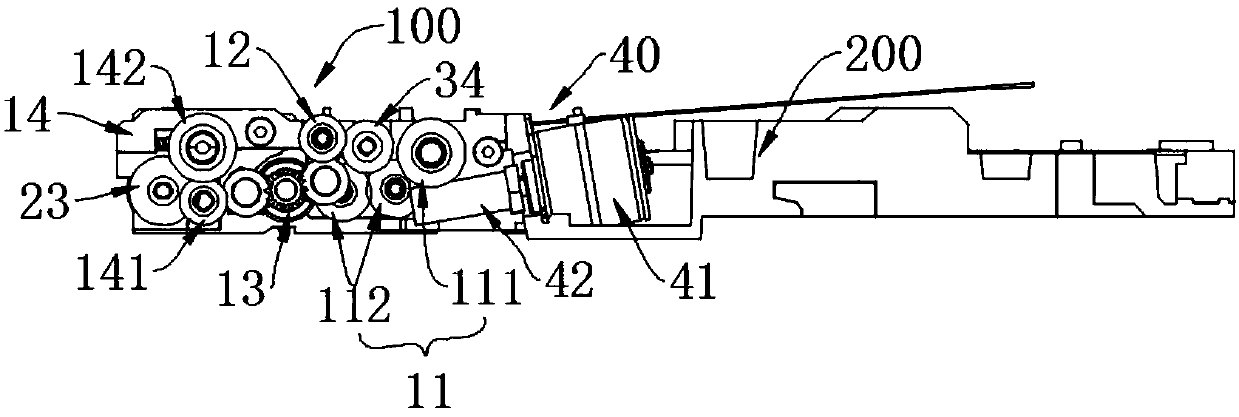

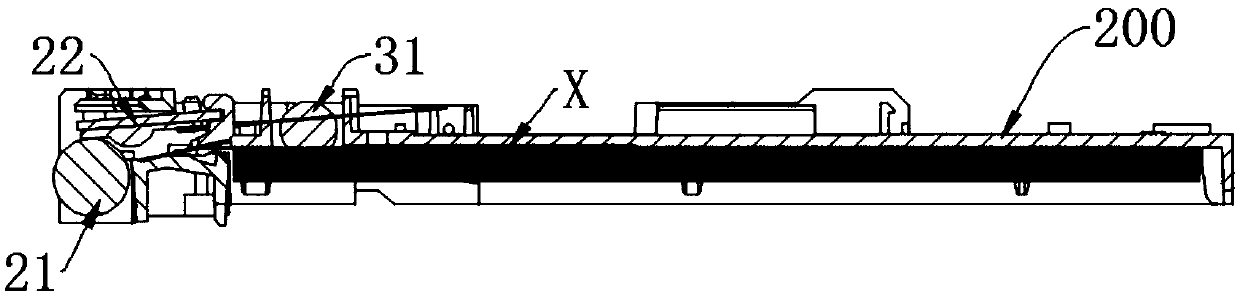

[0034] refer to Figure 1 to Figure 7 As shown, the card feeding mechanism 100 includes a card feeding device 30 , a printing device 20 , a transmission device 10 and a driving device 40 . The card feeding device 30 is located upstream of the printing device 20 and is used to push the card X to a first direction. The printing device 20 is used to receive the card X pushed by the card feeding device 30 , the printing device 20 leaves printing marks on the card X, and continues to push the card X to the first direction. The driving device 40 is connected with the transmission device 10 , and the driving device 40 drives the transmission device 10 . By arranging the card feeding device 30 upstream of the printing device 20, the problem that the card X is skewed during the transport process, and the skew cannot be pushed in place can be avoided.

[0035] The transmission device 10 is connected with the card feeding device 30 and the printing device 20 at the same time, and pushes...

Embodiment 2

[0051] refer to Figure 1 to Figure 7 As shown, the printer includes the card feeding mechanism 100 in Embodiment 1, and further includes a base 200 on which the card feeding mechanism 100 is arranged. The first rubber roller 31 and the second rubber roller 21 are arranged in parallel on the machine base 200, and the axes of the first rubber roller 31 and the second rubber roller 21 are perpendicular to the first direction. The base 200 is provided with a first bump 201 that cooperates with the first stopper 131A, and the first stopper 131A cooperates with the first bump 201 to increase the frictional resistance between the two and improve the position limitation. stability. The base 200 is provided with a second protrusion 202 that cooperates with the second limiting portion 131B, and the second limiting portion 131B is surface-fitted with the second protrusion 202 , so that the position limiting stability is high.

[0052] In the embodiment, the end of the first rubber rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com