Hanging basket special for cleaning glass curtain wall

A glass curtain wall and cleaning technology, which is applied in the field of special hanging baskets, can solve problems such as large force bearing area, potential safety hazards in construction, and shaking of hanging baskets, and achieve the effects of improving safety, increasing grip, and preventing swinging and shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

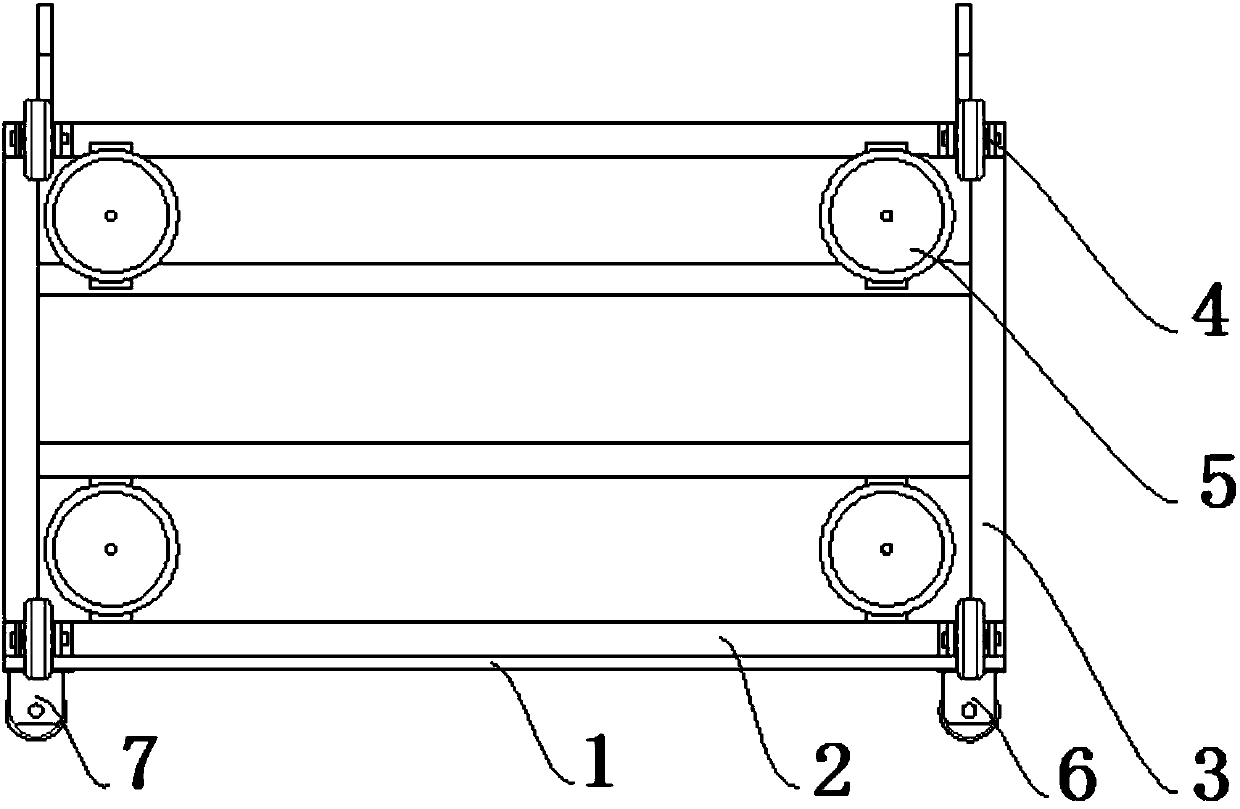

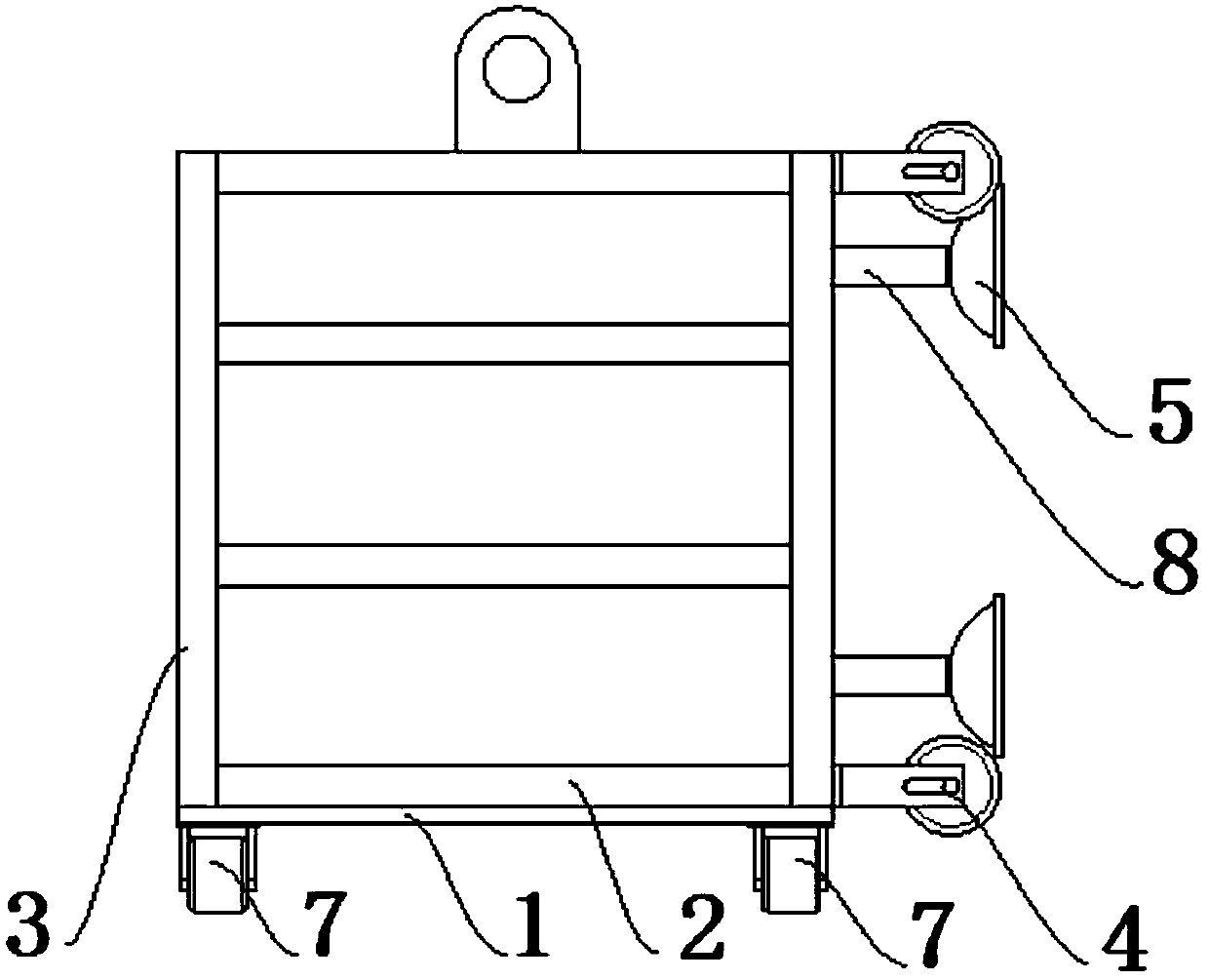

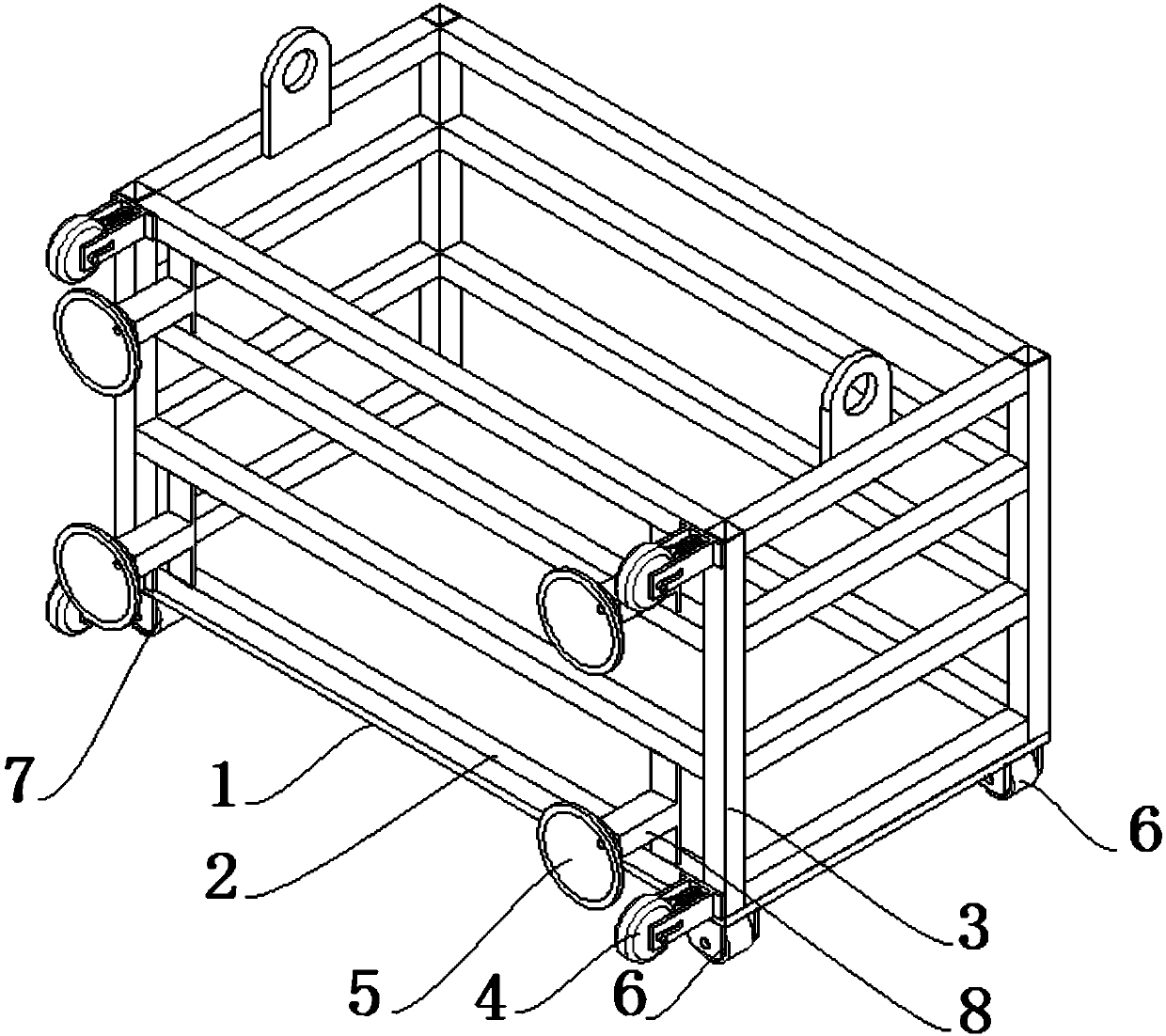

[0023] like Figure 1 to Figure 5 As shown in the figure, the present invention is a special hanging basket for cleaning glass curtain walls, including a hanging basket body, a suspension mechanism, a lifting mechanism, a safety lock, and an electrical control box. The lock is located at the top of the lifting mechanism, and the electrical control box is fixedly installed in the middle of the hanging basket body. The hanging basket body, the hoisting mechanism and the safety lock are respectively connected with the suspension mechanism through steel wire ropes. The hanging basket body includes a bottom plate 1, the bottom plate 1 is a rectangular structure, and the bottom plate 1 has an uneven rubber insulating anti-skid pad. The upper part of the bottom plate 1 is provided with a fence, the fence is welded into a rectangular frame by the column 3 and the beam 2, the four corners of one side of the hanging basket body are respectively provided with rubber suction cups 5, the ...

Embodiment approach

[0024] In a preferred embodiment, the rubber roller assembly 4 includes a mounting seat 41 , a support frame 42 , a compression spring 46 , a compression spring positioning shaft 45 , a spring push plate 47 , a rubber roller 43 , and a roller shaft pin 44 . The left and right ends of the mounting seat 41 are respectively The support frame 42 is fixedly connected. The support frame 42 is provided with a waist-shaped hole, and the waist-shaped hole extends along the length direction of the support frame 42. A rubber roller 43 is installed in the middle of the support frame 42. The mounting hole of the rubber roller 43 and the waist-shaped hole of the support frame 42 are inserted into the roller shaft pin 44. The middle of the mounting seat 41 is provided with a compression spring positioning shaft 45, and the compression spring positioning shaft 45 is on the mounting seat 41. On the same side as the support frame 42, the compression spring positioning shaft 45 is covered with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com