IU type three-dimensional code bolt self-locking padlock

A three-dimensional code bolt and self-locking technology, which is applied in the field of locks, can solve the problems of fragile lock bolt insertion mode, difficult key slot processing, and limited order of magnitude, so as to achieve firm locking mode, enhanced prying resistance, and miniaturization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

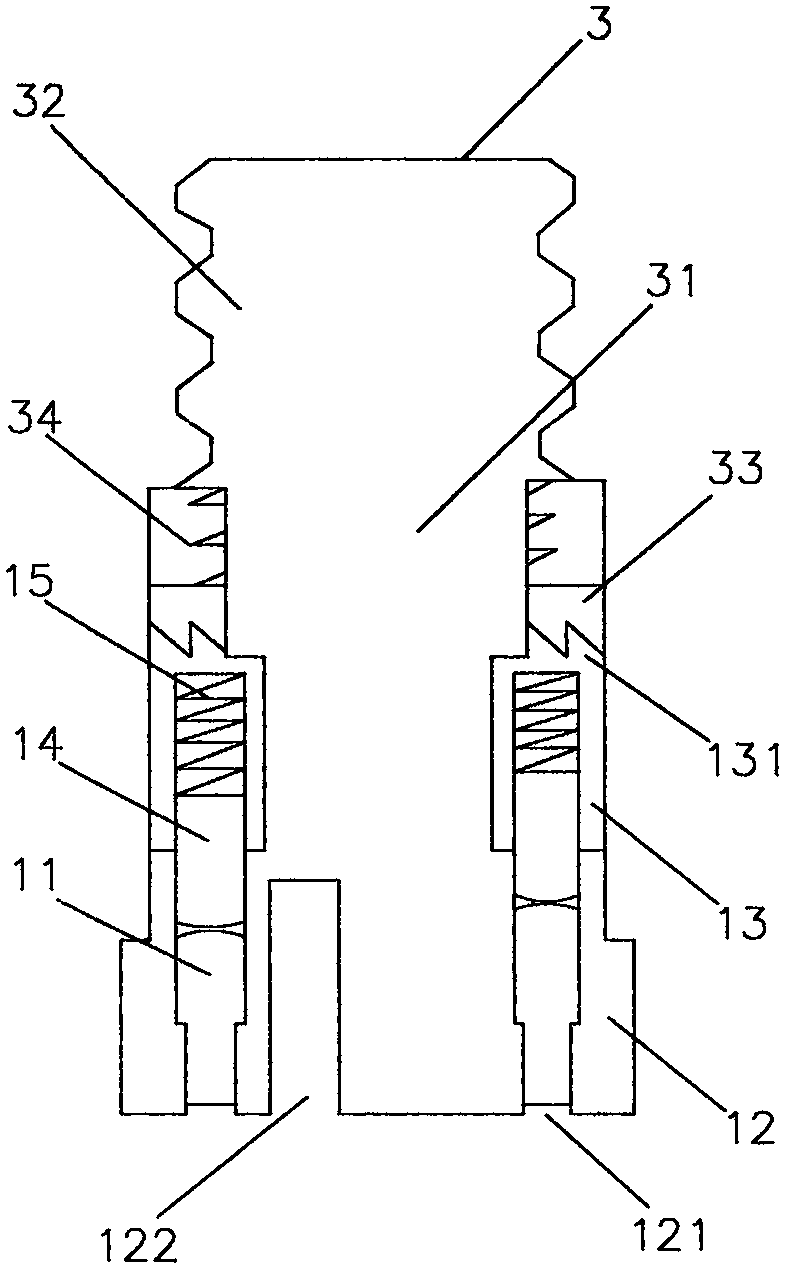

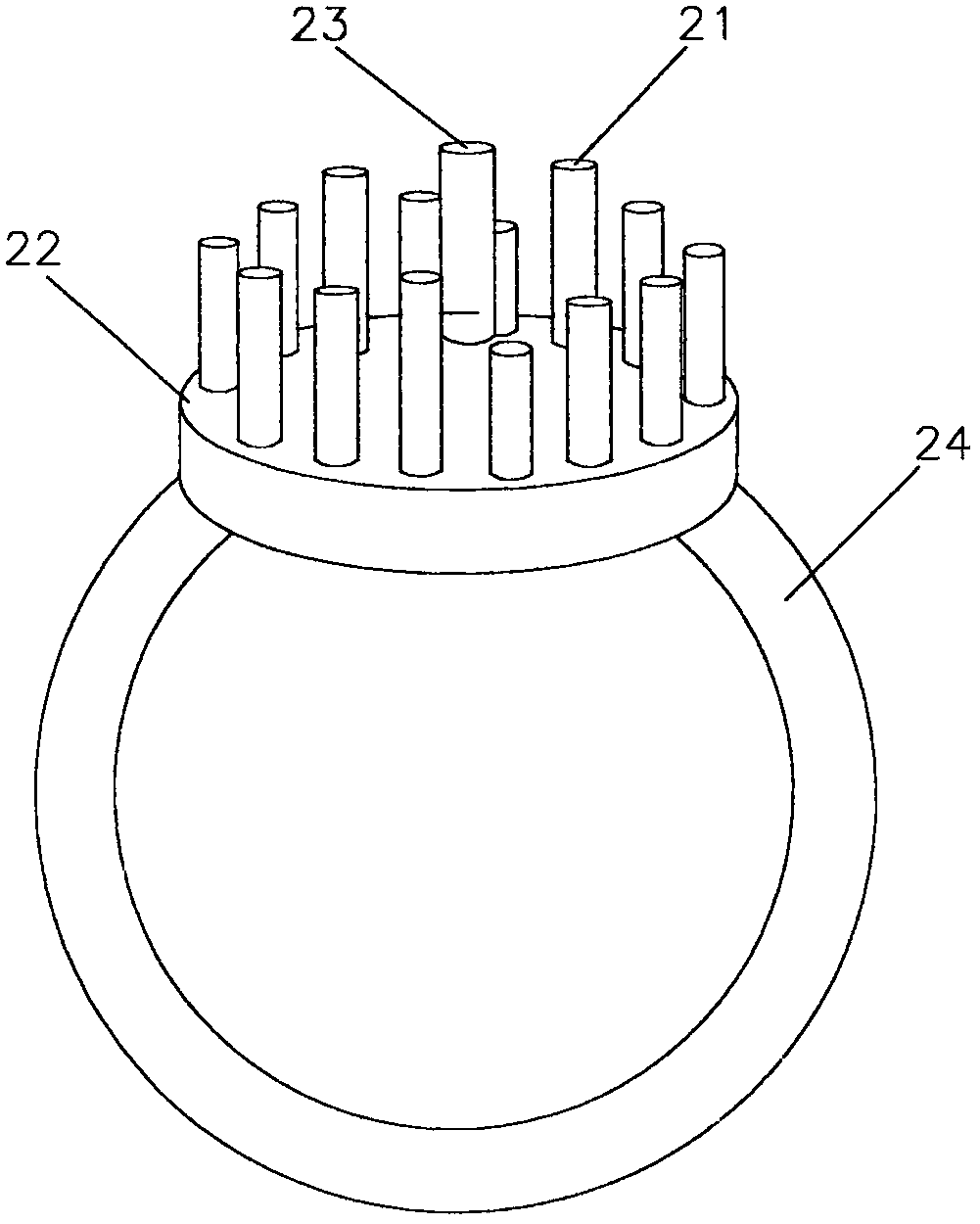

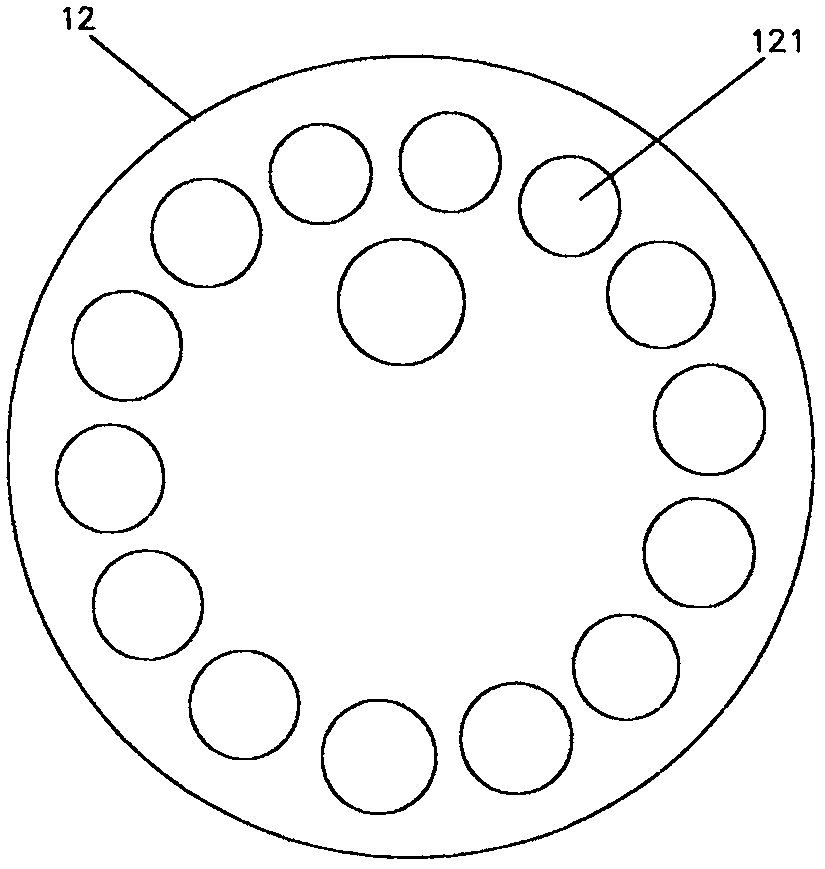

[0020] Implementation column, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown: an IU type three-dimensional code bolt self-locking padlock, which is composed of a three-dimensional code bolt self-locking lock core 1, a lock tube 4, an I-shaped locking bar 5 and a U-shaped locking bar 6, wherein the three-dimensional code bolt self-locking lock core 1 includes code lock screen 12, embolus honeycomb 13, screw shaft rod 3, helical tooth pad 33, compression spring 34, lock code 11, embolus 14 and spring 15, code lock screen 12 and embolus honeycomb 13, closely attached According to the two-dimensional arrangement, the code lock screen 12 has many holes 121 that are thin at the front and thick at the back, and the holes 121 through which the two ends are connected. There are lock codes 11 of various code numbers, forming a three-dimensional layout of lock codes 11. The lock codes 11 are in the shape of needle cylinders, thin in front and thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com