Washing machine rinsing method

A washing machine and motor speed technology, applied in the field of washing machine rinsing, can solve the problems of waste of water resources, unfavorable energy saving and emission reduction, large water consumption, etc., and achieve the effect of improving the quality of rinsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

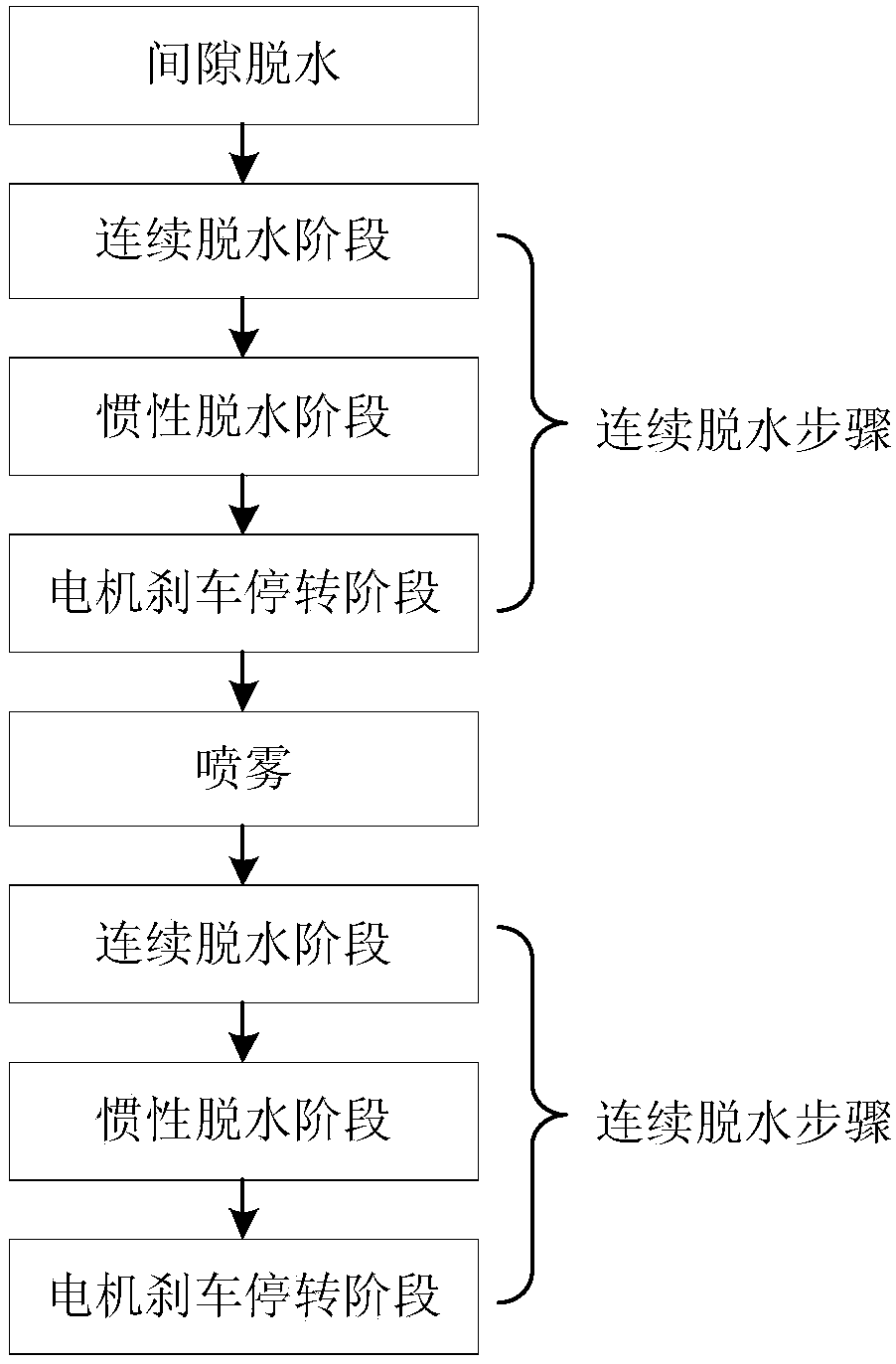

[0023] A washing machine rinsing method, comprising the steps of:

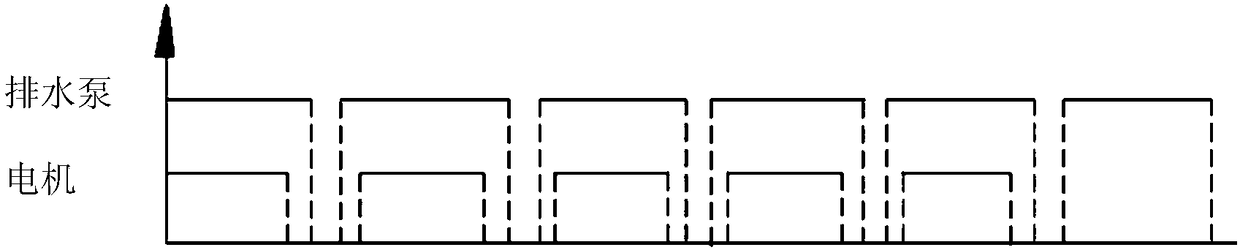

[0024] Intermittent dehydration according to the type of washing machine motor and the length of the interval determined by the drainage method;

[0025] According to the turbidity of the laundry water, the continuous dehydration steps are carried out in a cycle, and between the adjacent continuous dehydration steps, when the motor stops rotating, the inner tub is sprayed.

[0026] The continuous dehydration step is divided into a continuous dehydration stage, an inertial dehydration stage and a motor brake stop stage, wherein the running time of the inertial dehydration stage is ≤ 60 seconds, and the braking time of the motor brake stop stage is ≤ 10 seconds.

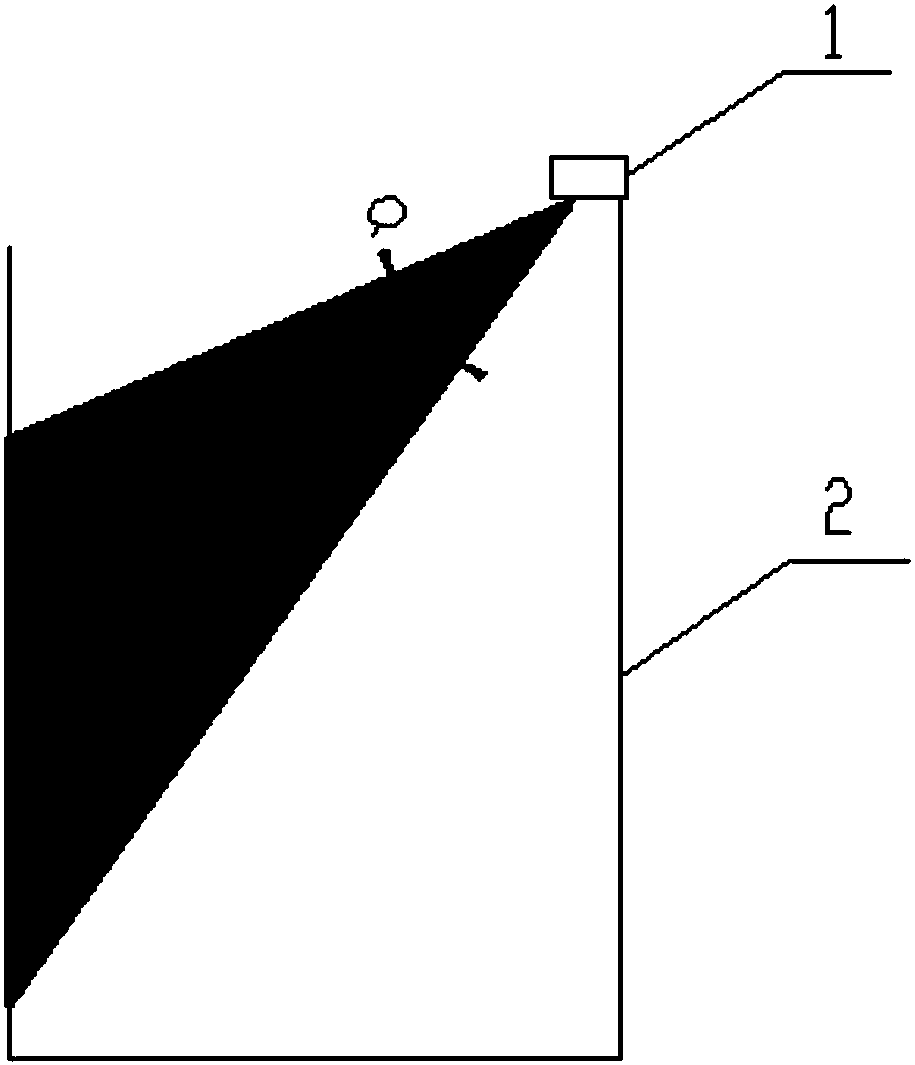

[0027] An example such as figure 1 As shown in Table 1, in this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com