Optical glass component applied to smart camera and corresponding manufacturing process

A smart camera and optical glass technology, applied to color TV parts, TV system parts, electrical components, etc., can solve problems such as poor effect, laborious installation process, high cost of optical glass components, etc., to reduce Low cost, good effect, easy and labor-saving assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

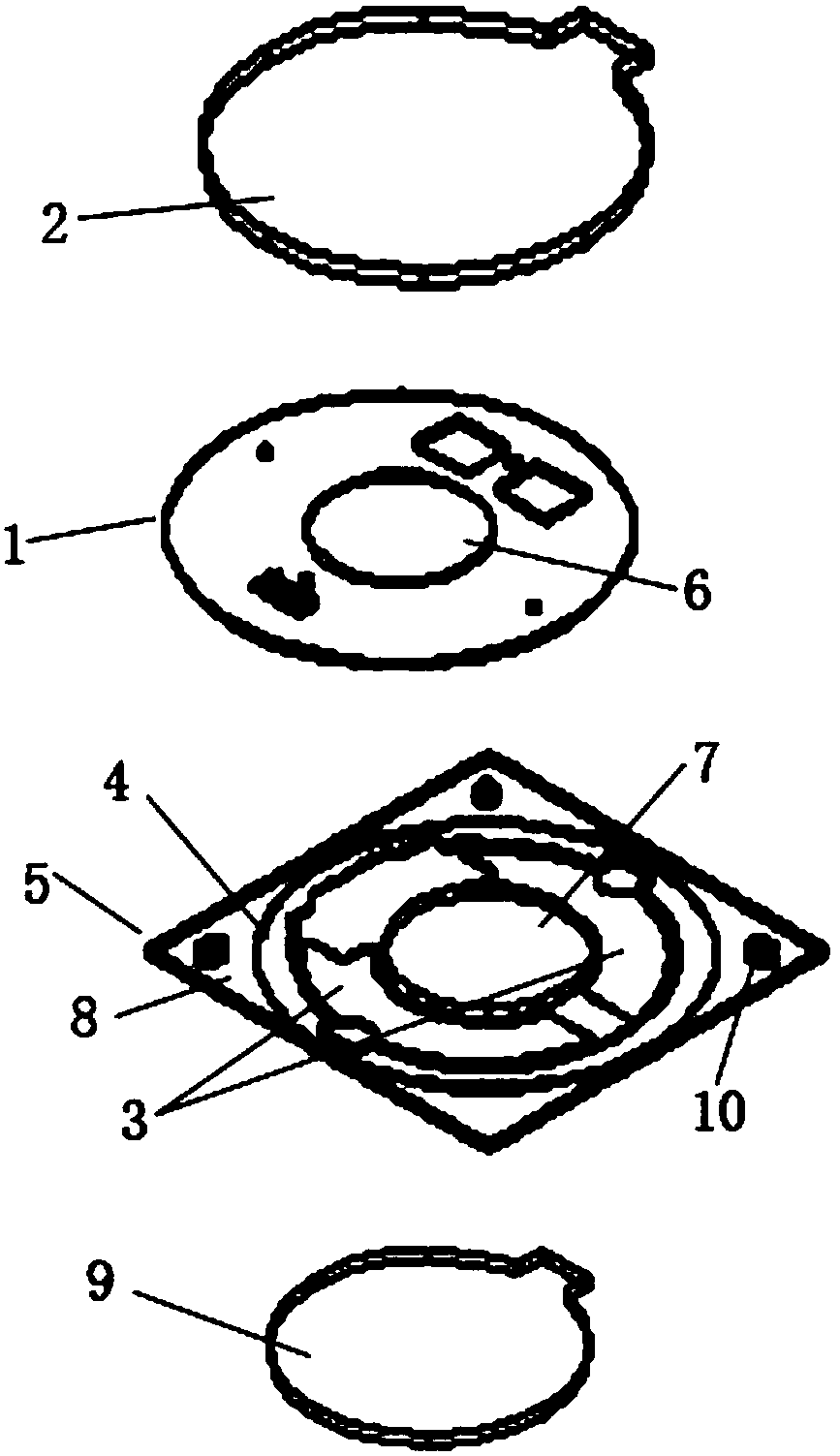

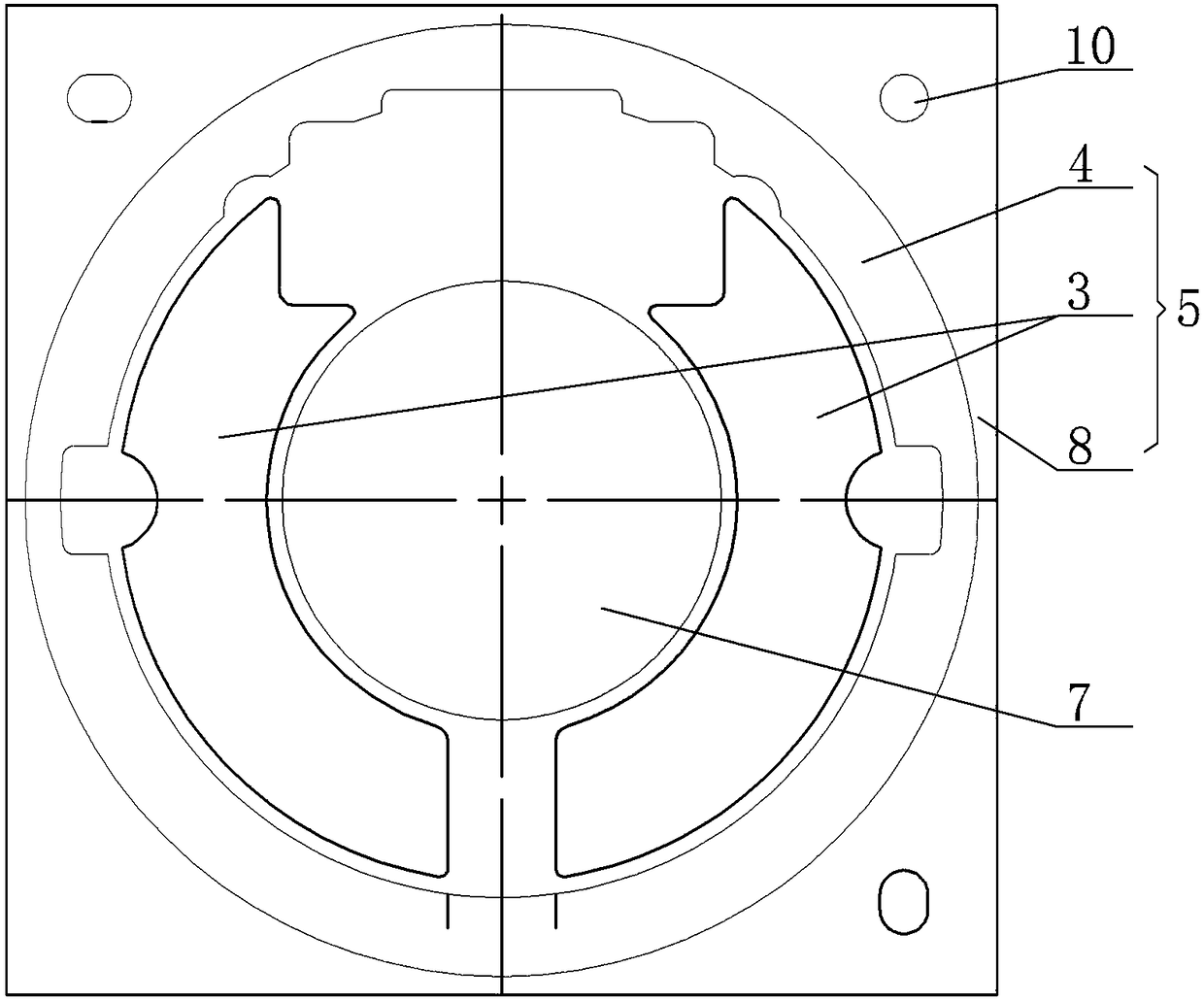

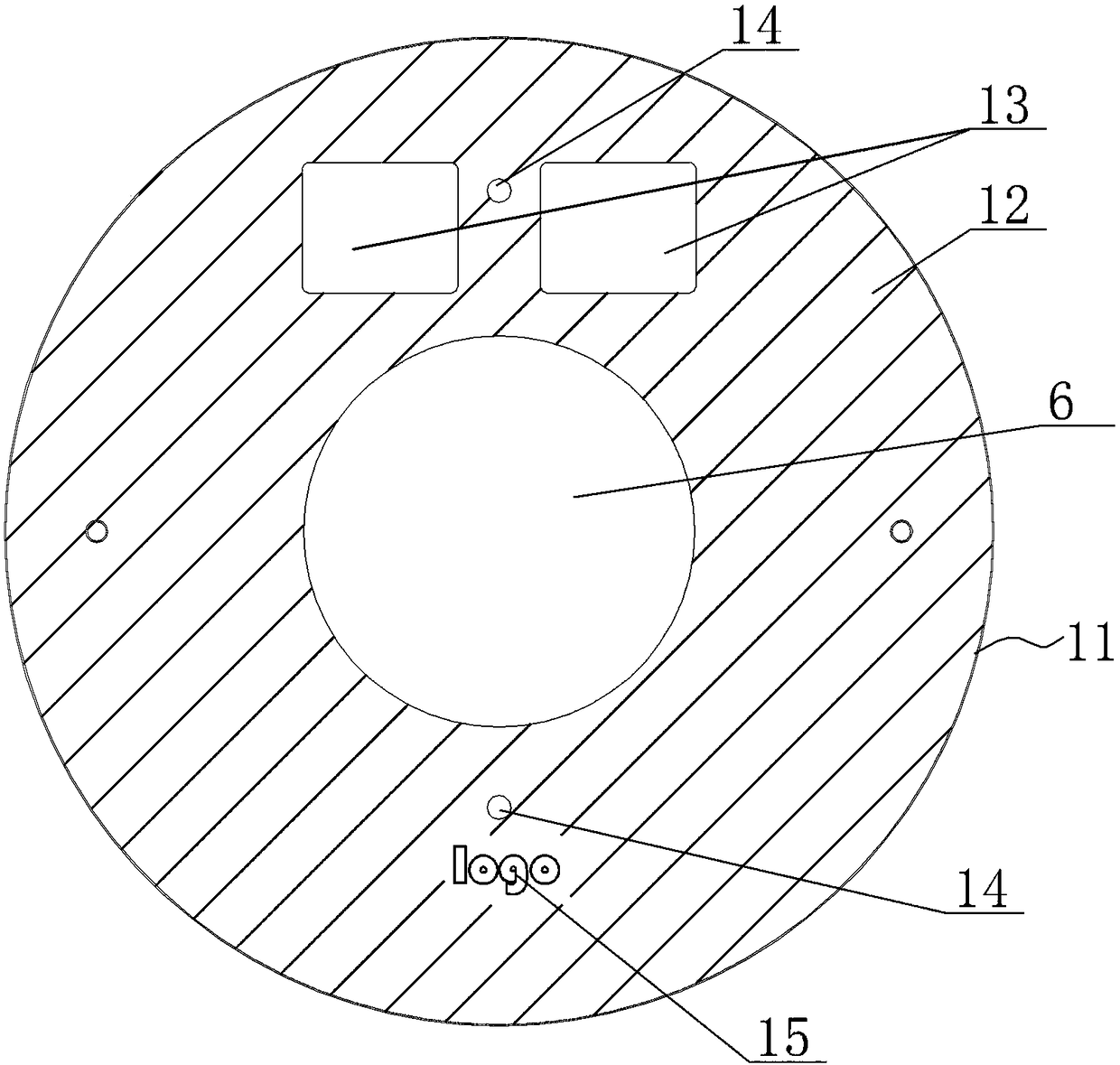

[0029] An optical glass component applied to a smart camera, see Figure 1-Figure 3 : It includes glass 1, the front of the glass 1 is covered with a front protective film 2, the back of the glass 1 is pasted with a composite layer 5 formed by a combination of graphite 3 and glue 4, and the composite layer 5 includes a part of the inner ring Graphite 3, the glue 4 of the outer ring part, the graphite 3 corresponds to the window area 6 of the glass 1 as the center avoiding the hole structure 7, the back of the graphite 3 and the glue 4 are compounded on the corresponding release film 8, the The front side of the glue 4 is attached to the corresponding position of the outer ring part of the back of the glass 1, and the release film 8 is provided with an escape through hole corresponding to the window area 6, and the escape through hole of the release film 8 The back periphery is pasted with window protection film 9.

[0030] The outer ring part of the window protective film 9 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com