Rotation support placement tool

A slewing bearing and tooling technology, applied in the direction of manufacturing tools, tool storage devices, etc., can solve the problems of occupying a large space, difficult production operations, inconvenient production work, etc., and achieve the effect of stable placement and saving placement space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

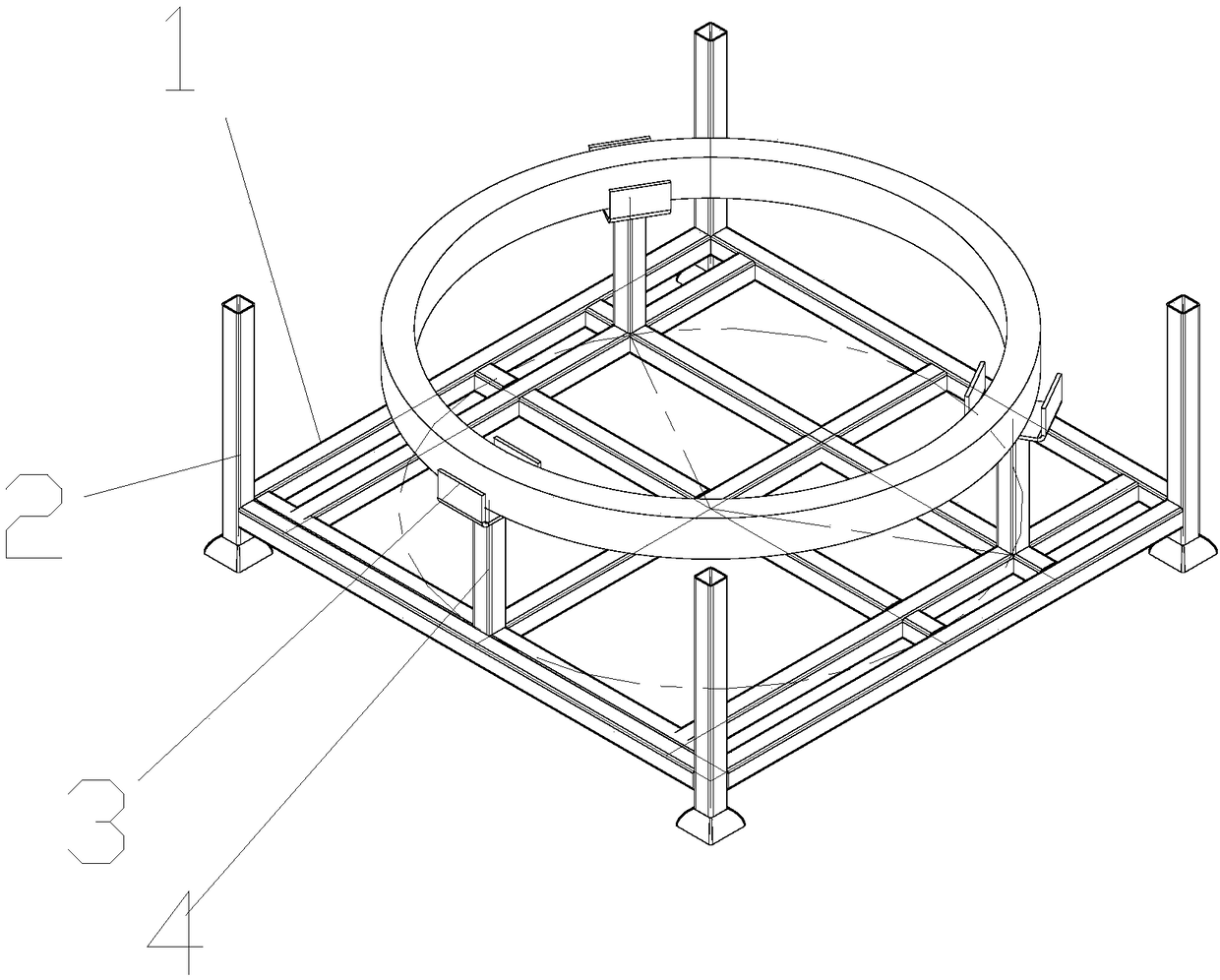

[0011] Such as figure 1 As shown, a tool for placing a slewing bearing includes a base 1, a support frame 3, legs 2 and a limit groove 4, the base 1 is a square, and a vertically upward leg is provided at each of the four corners of the base 1 2. On the three sides of the base 1, a support frame 3 is fixed in the vertical direction, and a limit groove 4 is fixed on the top of the support frame 3, and the height of the support frame 3 is smaller than the height of the legs 2. The limit groove 4 upper end of the top of the support frame 3 is fixed with a layer of buffer rubber pad, the rubber pad can protect the workpiece from being scratched by the limit groove 4 of metal material, and can also play an anti-slip effect. The base 1 can To stack up and down, it is necessary to use a crane to stack one tooling on another tooling to save storage space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com