Road surface obstacle removal equipment for bridge construction

A technology for road surface and bridge construction, applied in road cleaning, roads, roads, etc., can solve the problems that garbage cannot be completely swept into the garbage bin, waste time and energy, and the effect is not very good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

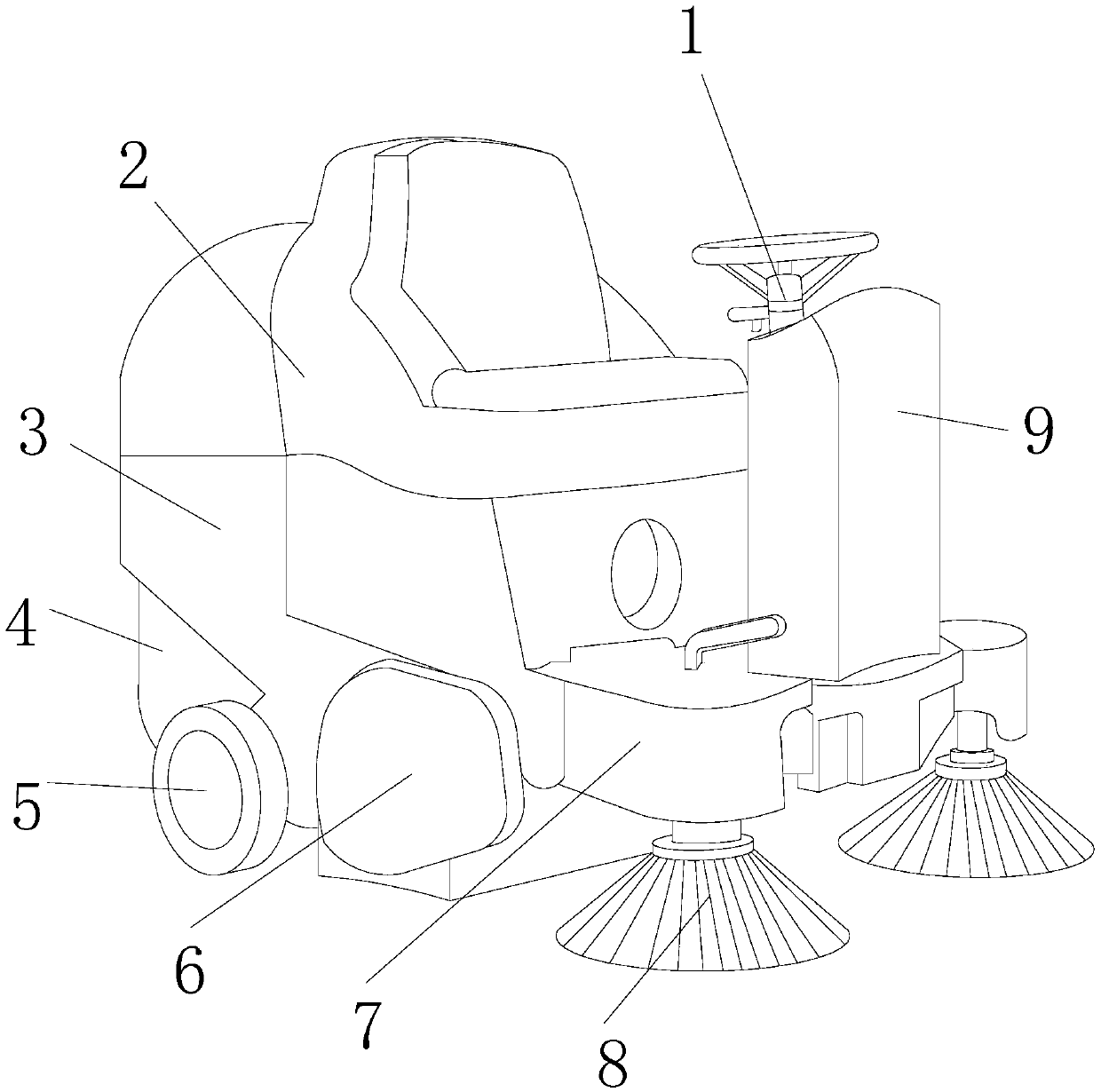

[0021] see Figure 1-Figure 4 , the present invention provides a road surface obstacle removal equipment for bridge construction. 9. The steering wheel 1 is located at the top of the box body 9, and the steering wheel 1 is mechanically connected to the cleaning mechanism 8 located below the body 3 through the box body 9. Two road wheels 5 are installed at the bottom of the body 3, and the The dustbin 4 is movably installed at the rear end of the body 3, the body 3 is provided with a seat 2, the body 3 is fixedly connected to the bottom frame 7, and the end of the bottom frame 7 away from the seat 2 is vertically fixed There is an underframe 7, and two side plates 6 are installed on both sides of the underframe 7.

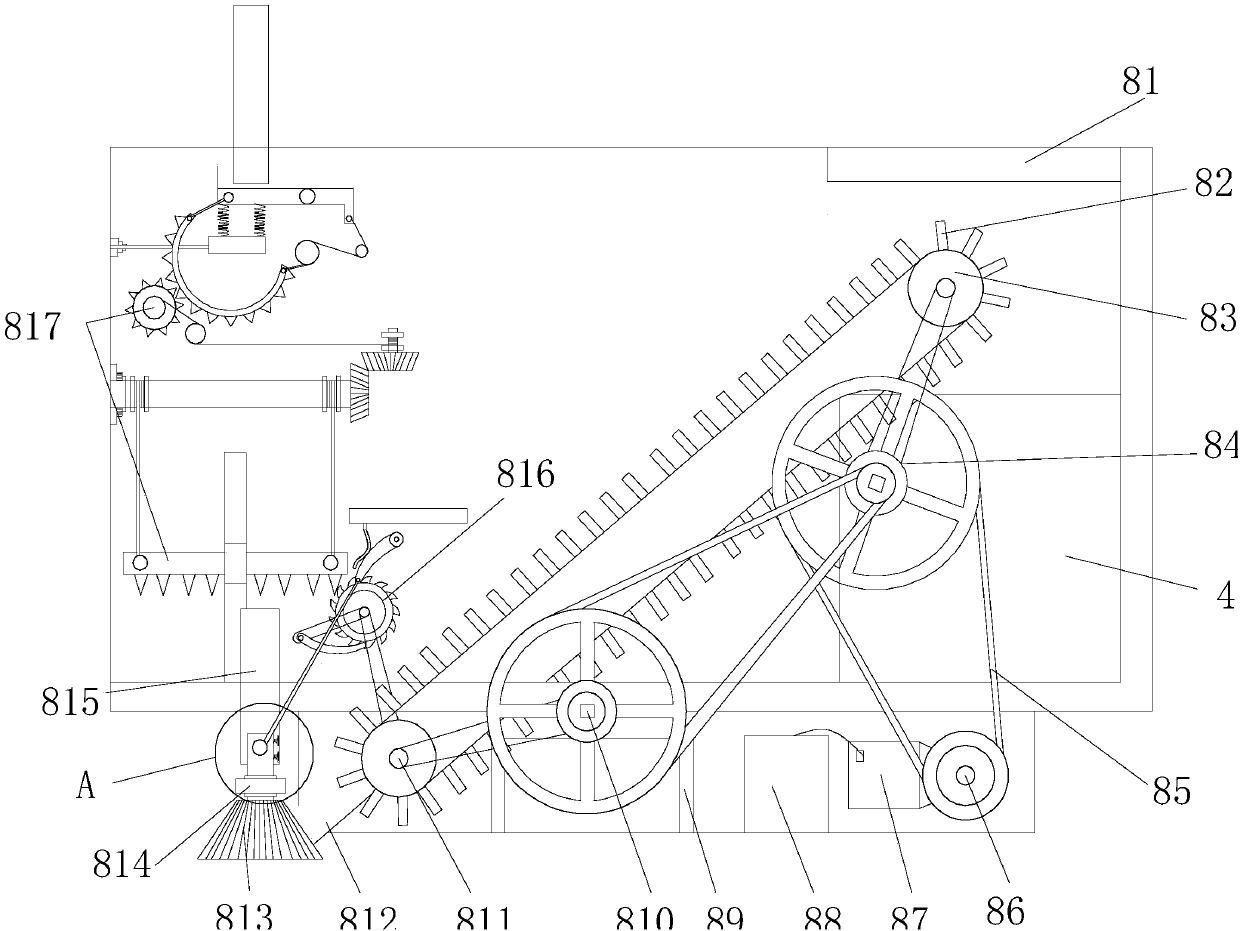

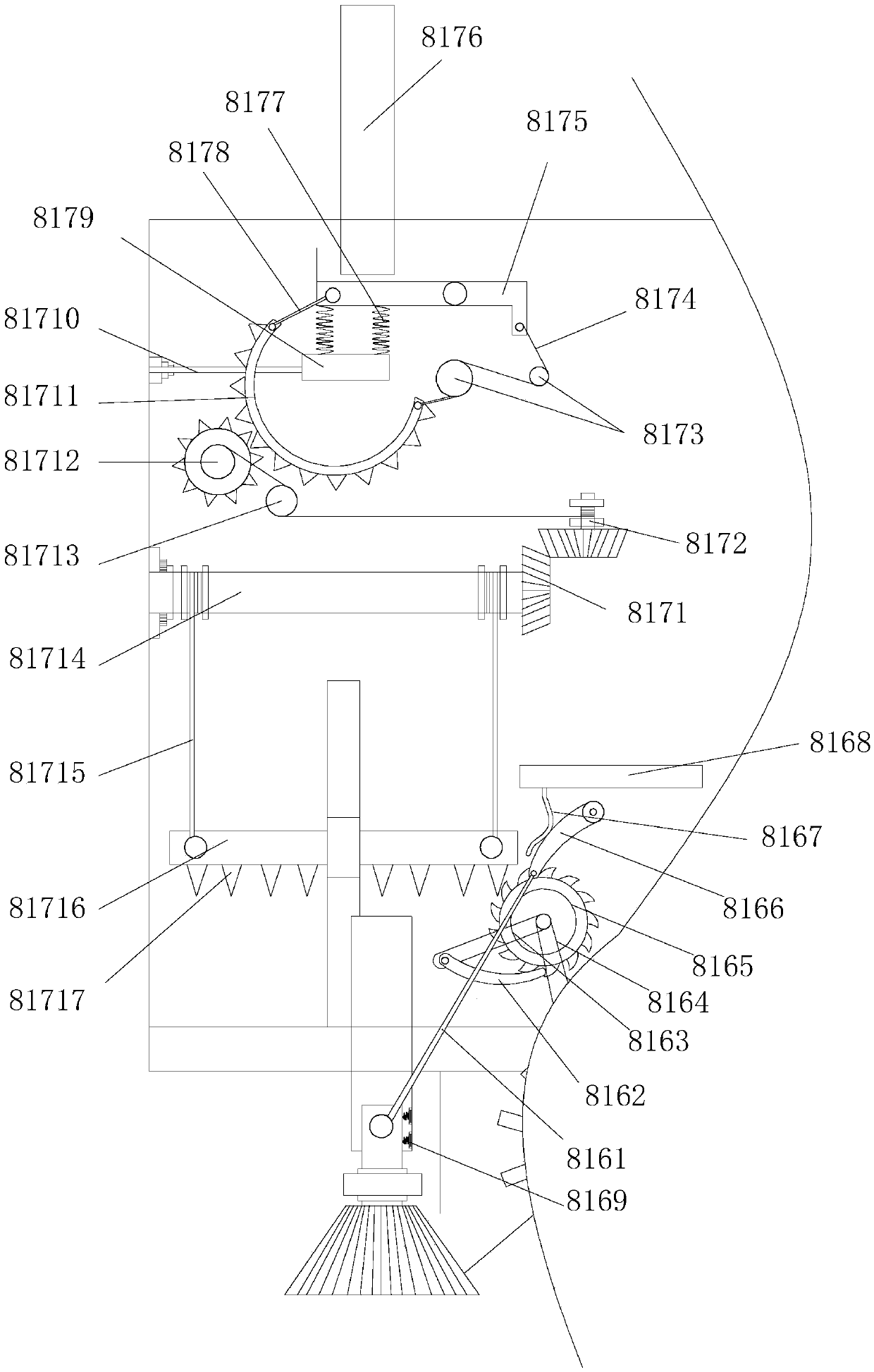

[0022]The cleaning mechanism 8 is provided with an intercepting block 81, a conveyor belt 82, a first transmission wheel 83, a first transmission gear 84, a transmission belt 85, a starting wheel 86, a motor 87, a storage battery 88, a support frame 89, a second tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com