A Calculation Method of Multi-failure Mode Correlation Reliability of Mechanical Parts

A failure mode and mechanical parts technology, applied in random CAD, design optimization/simulation, geometric CAD, etc., can solve problems such as calculation accuracy and efficiency that cannot meet engineering needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

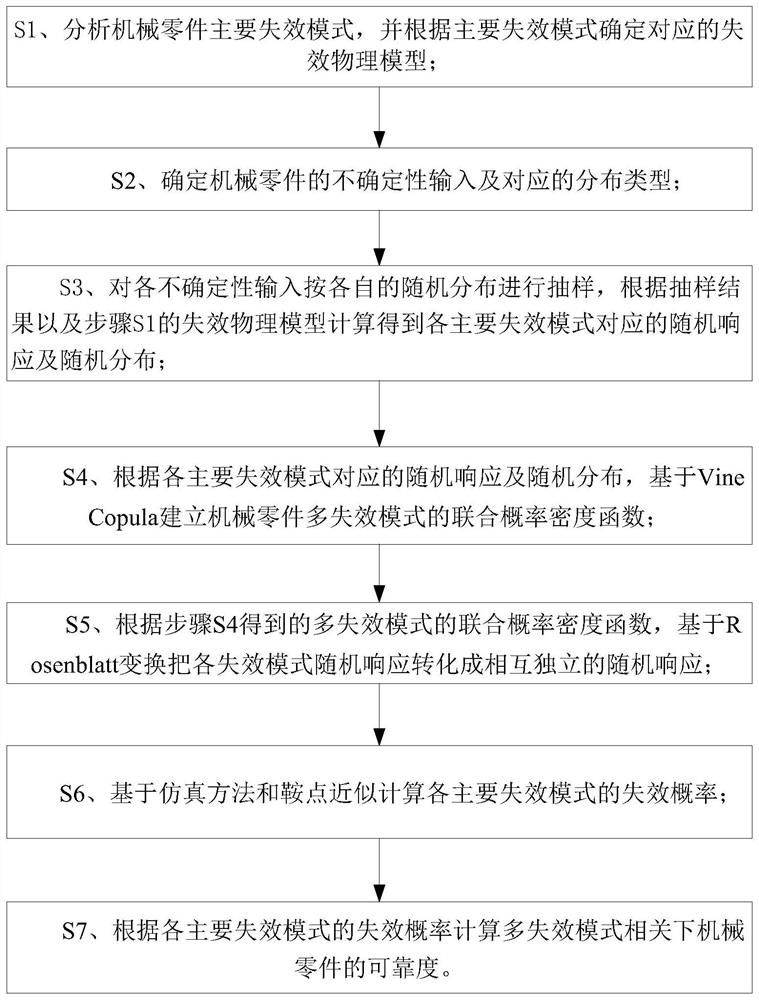

[0044] Such as figure 1 Shown is the solution flow chart of the present invention, the technical solution of the present invention is: a method for calculating reliability related to multiple failure modes of mechanical parts, including:

[0045] S1. Analyze the main failure modes of mechanical parts, and determine the corresponding failure physical model according to the main failure modes.

[0046] In this embodiment, a certain machine transmission shaft under the action of torque is taken as the research object. According to its main functions and working conditions, the transmission shaft generally has three main failure modes: static strength failure, stiffness failure and fatigue failure.

[0047] The physical model of failure can be deter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com