Engine valve collet dismounting and mounting auxiliary tool

A technology of engine valves and auxiliary tools, which is applied in the direction of manufacturing tools and hand-held tools, can solve the problems of inconvenient operation and poor versatility, and achieve the effect of improving operation safety and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

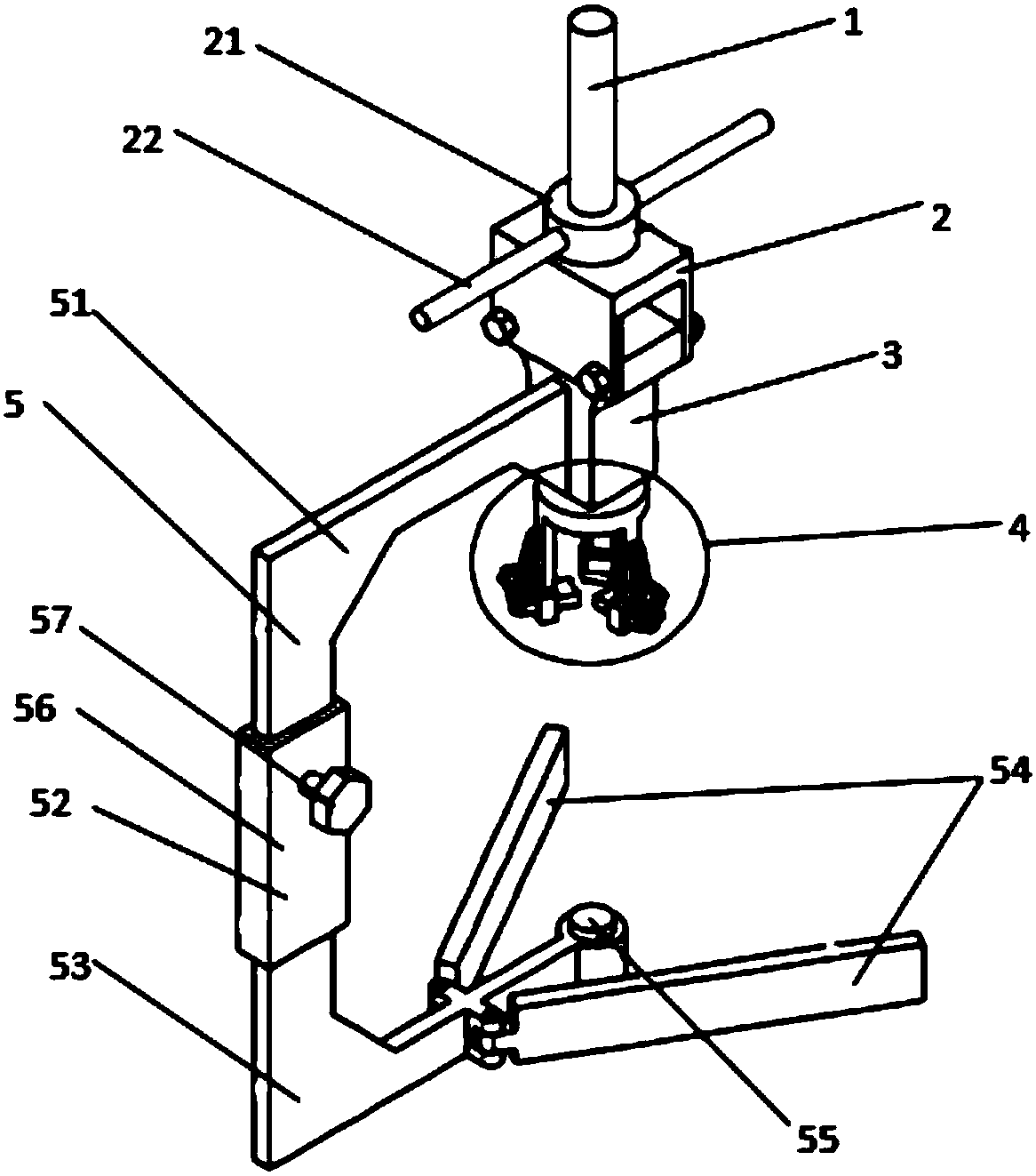

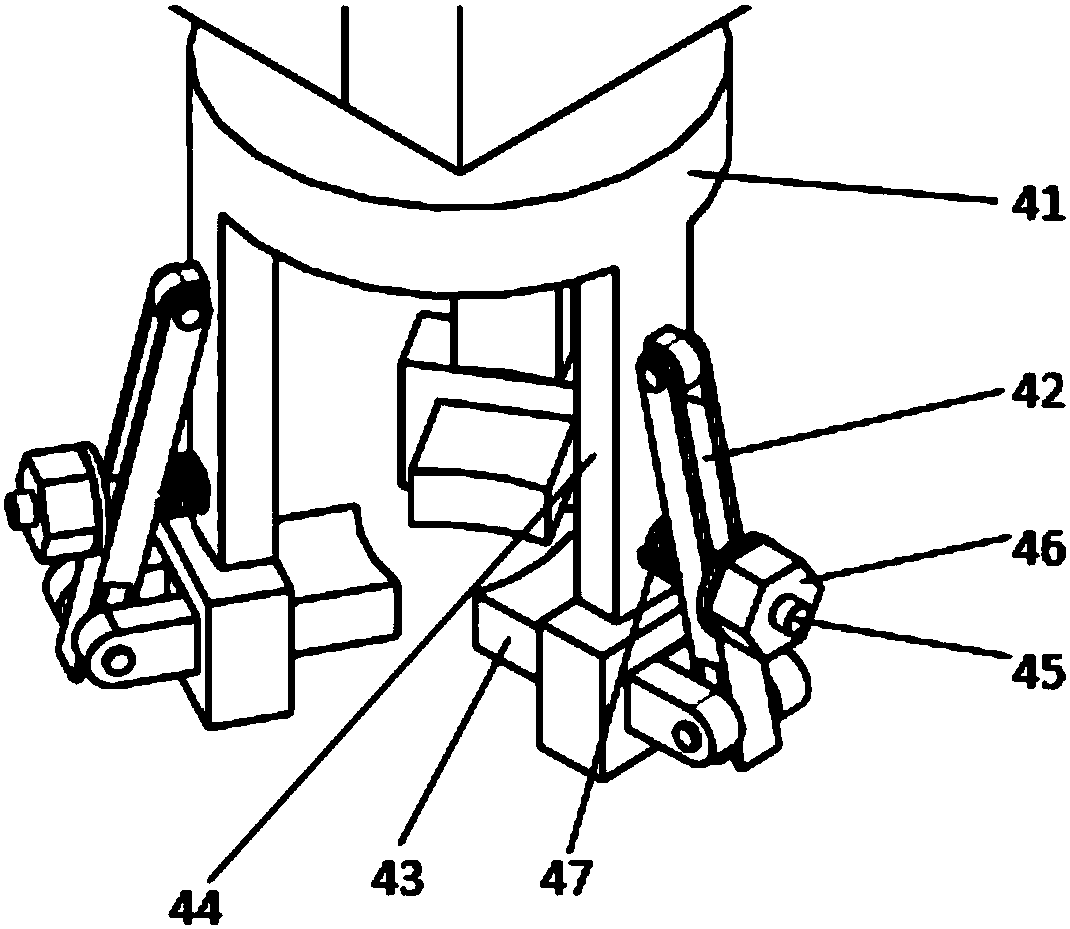

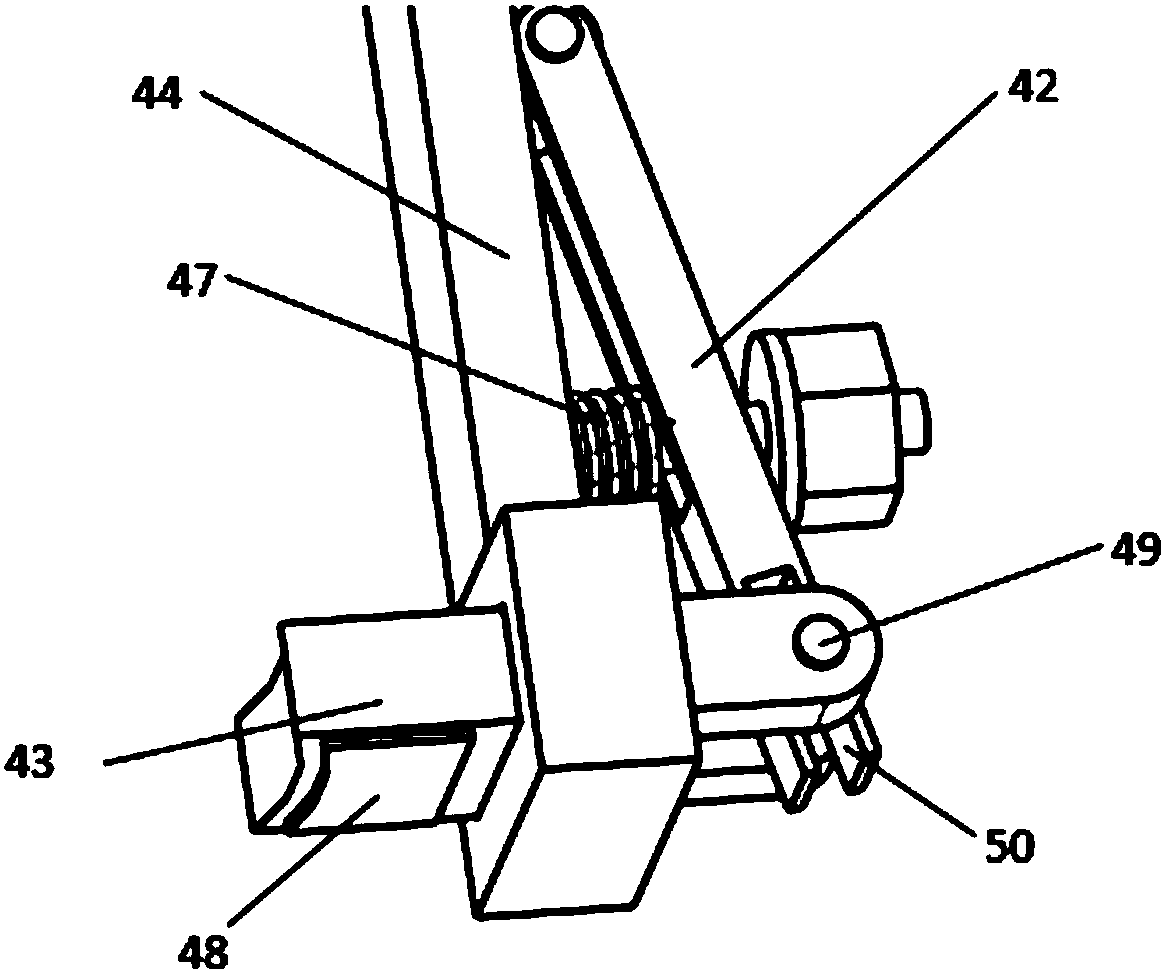

[0024] Such as figure 1 As shown, a kind of auxiliary tool for disassembling and assembling the engine valve lock clip includes a screw rod 1, a fixed bracket 2, a guide block 3, a press-fit mechanism 4, and a bracket 5, and the guide block 3 is installed on the top of the bracket 5, and the fixed The deck 2 is installed on the top of the guide block 3, and the screw 1 passes through the fixed deck 2 and the guide block 3 in the vertical direction, and the bottom of the screw 1 is connected with the press-fitting mechanism 4. handle 22 to move the screw rod 1 downward, and press the spring seat 8 through the press-fitting mechanism 4 to compress the valve spring 7, and after sending the valve spring 8 to the installation position of the valve lock clip 9, the valve lock clip can be completed. 9 installation or disassembly work.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com