Double-line automatic charging and mixing equipment

A technology of automatic feeding and mixing equipment, which is applied in the directions of packaging, unsealing of packaged objects, transportation and packaging, etc. It can solve problems such as dumping and a large amount of manual labor handling, and achieve the effects of avoiding slipping, reducing resistance and mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

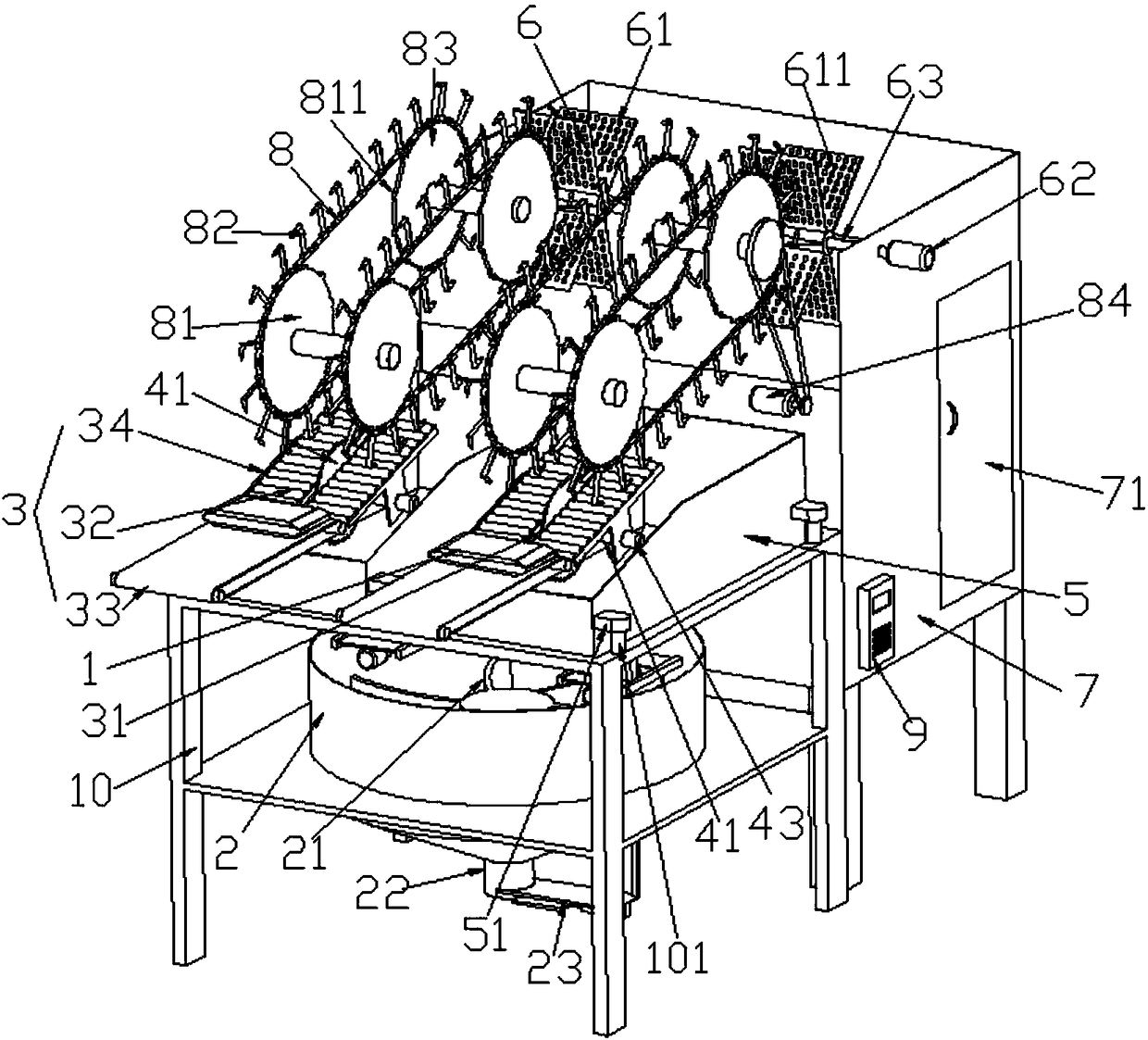

[0053] Such as Figure 1 to Figure 5 As shown, a double-line automatic feeding and mixing equipment is characterized in that: it includes a flour bag 1, a stirring device 2, a conveying device 3, a breaking device 4, a flour box 5, a packaging bag removing device 6, and a packaging bag box 7, Packaging bag hook device 8, console 9; support frame 10;

[0054] The conveying device 3, the breaking device 4, the flour box 5, the packaging bag removing device 6, and the packaging bag hooking device 8 are two in number and arranged side by side;

[0055] The conveying device 3 includes a belt conveying belt part 33, a roller conveying part 34

[0056] The flour bag 1 is horizontally placed on the belt conveyor belt part 33, and the belt conveyor belt part 33 is arranged horizontally;

[0057] The roller conveying part 34 is arranged near the end of the belt conveying belt part 33, and the roller conveying part 34 includes two rows of rollers 32; a gap 31 is arranged in the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com