Bag breaking equipment

A bag breaking and equipment technology, applied in the field of bag breaking equipment, can solve the problems of high labor intensity, etc., and achieve the effect of convenient switching of equipment, reducing resistance and avoiding slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

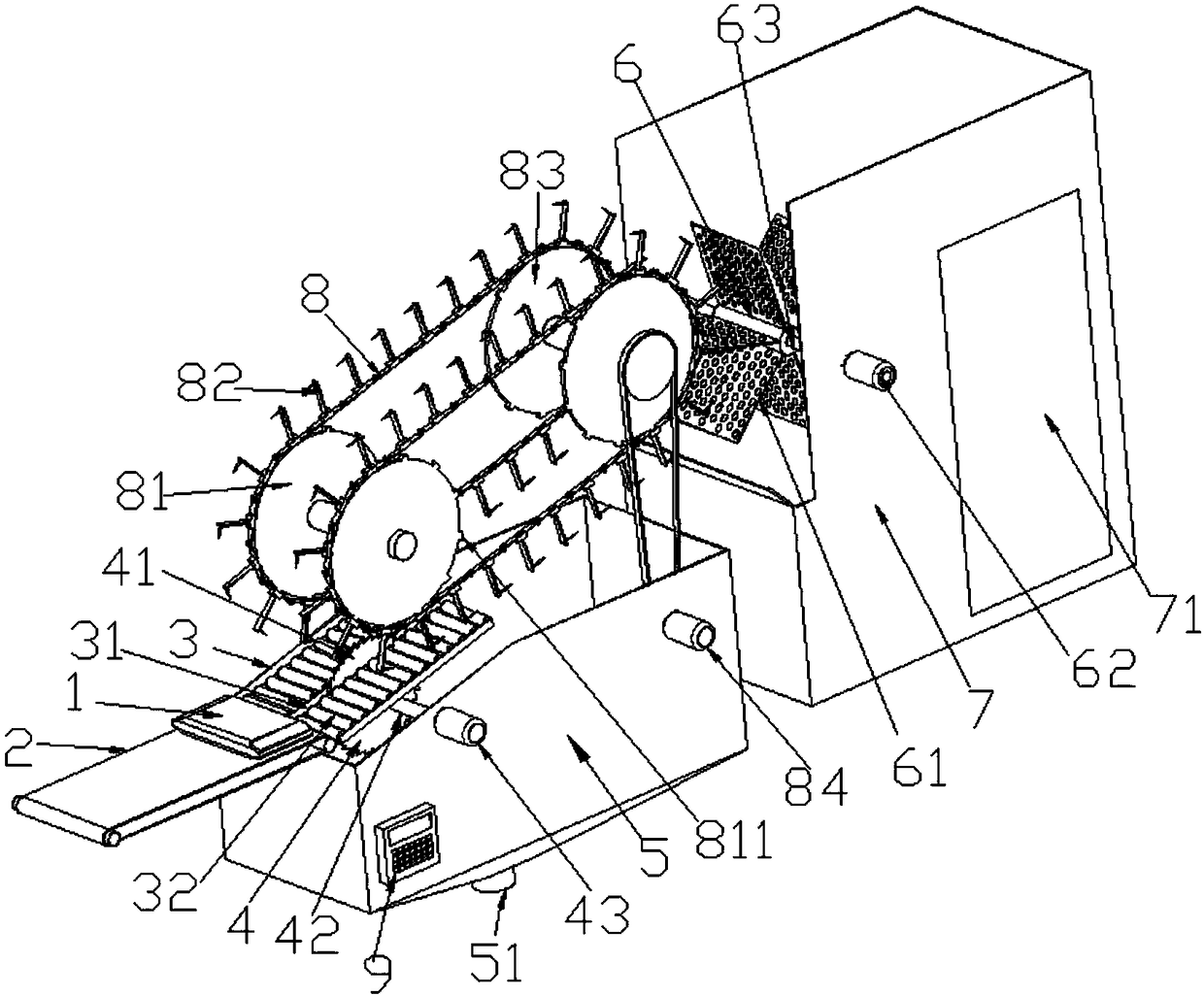

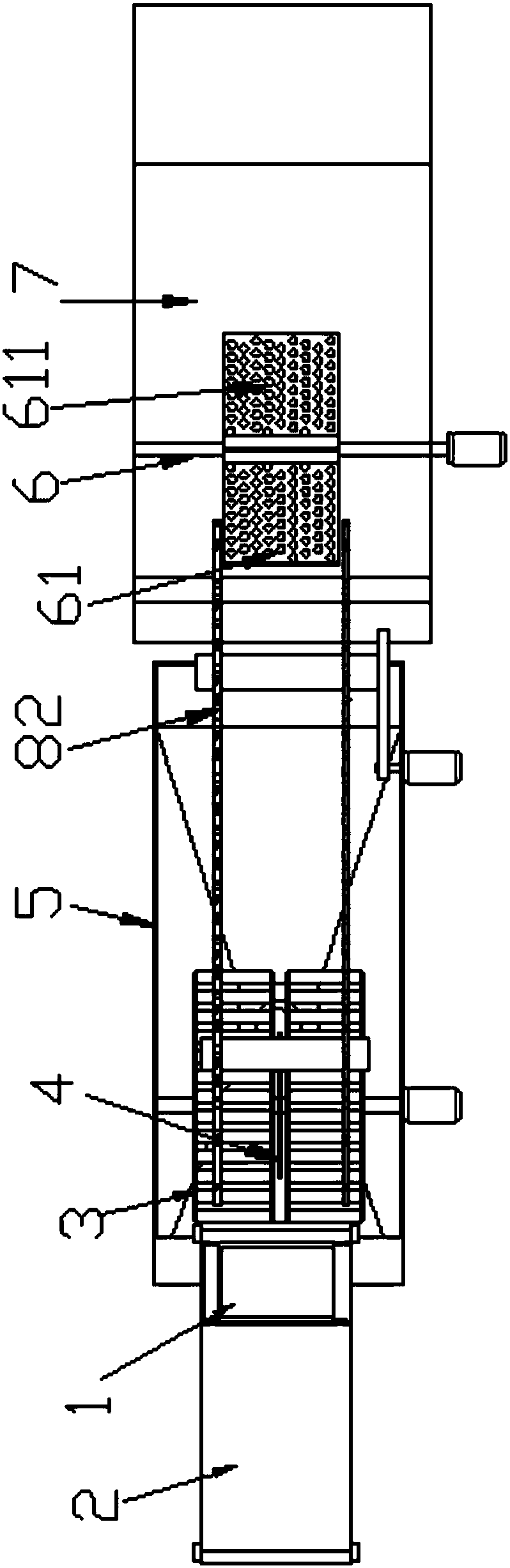

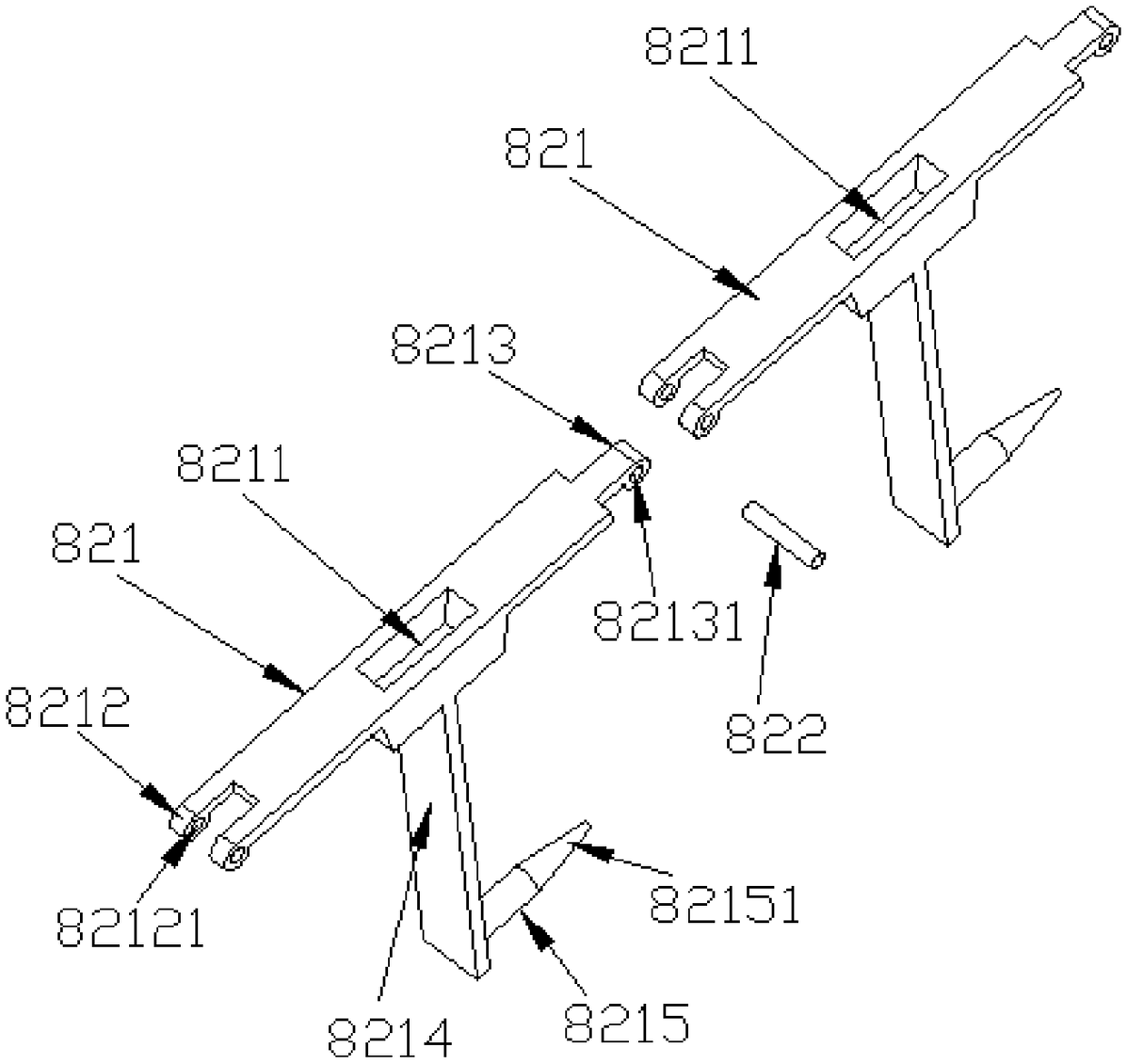

[0042] Such as Figure 1 to Figure 4 As shown, a bag breaking equipment is characterized by: including flour bag 1, conveyor belt 2, roller conveyor belt 3, bag breaking device 4, flour box 5, packaging bag removal device 6, packaging bag box 7, packaging bag Hook device 8, console 9;

[0043] The flour bag 1 is placed horizontally on the conveyor belt 2, and the conveyor belt 2 is arranged horizontally;

[0044] The roller conveyor belt 3 is arranged next to the end of the conveyor belt 2, and the roller conveyor belt 3 includes two rows of rollers 32; a gap 31 is provided between the two rows of rollers 32;

[0045] The roller conveyor belt 3 is arranged obliquely; the roller conveyor belt 3 is located at the upper left of the flour box 5;

[0046] The bag breaking device 4 includes a cutting wheel 41, a first rotating shaft 42, a first motor 43, the cutting wheel 41 is arranged in the gap 31, and the outer edge of the cutting wheel 41 is higher than the roller conveyor. The conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com