Automatic feeding and stirring equipment

A mixing equipment and automatic feeding technology, which is applied in packaging, cutting and unsealing, transportation and packaging, etc., can solve the problems of a large number of manual labor handling, unpacking, dumping, etc., and achieve the convenience of equipment switching, avoiding slipping, and reducing resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

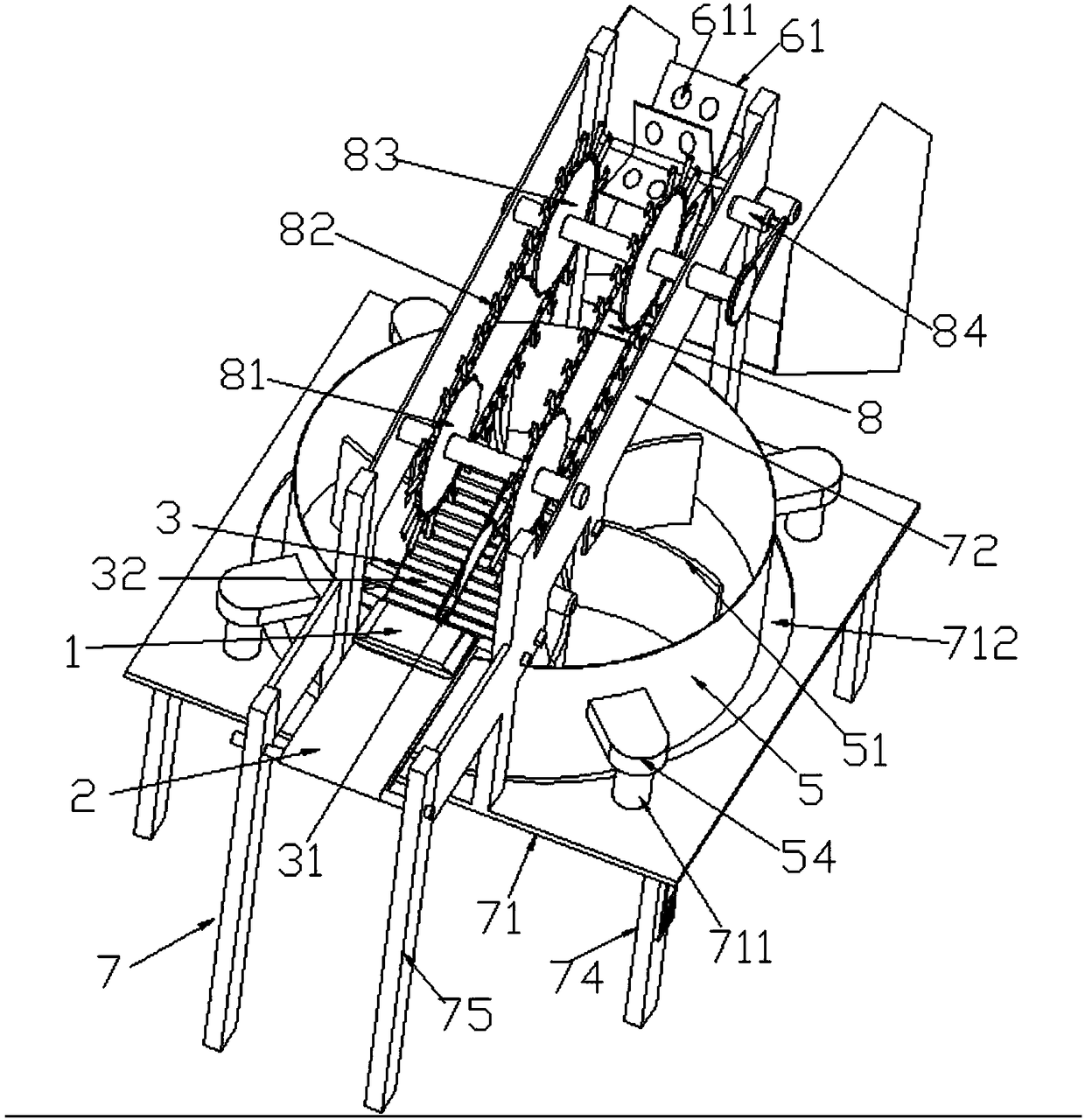

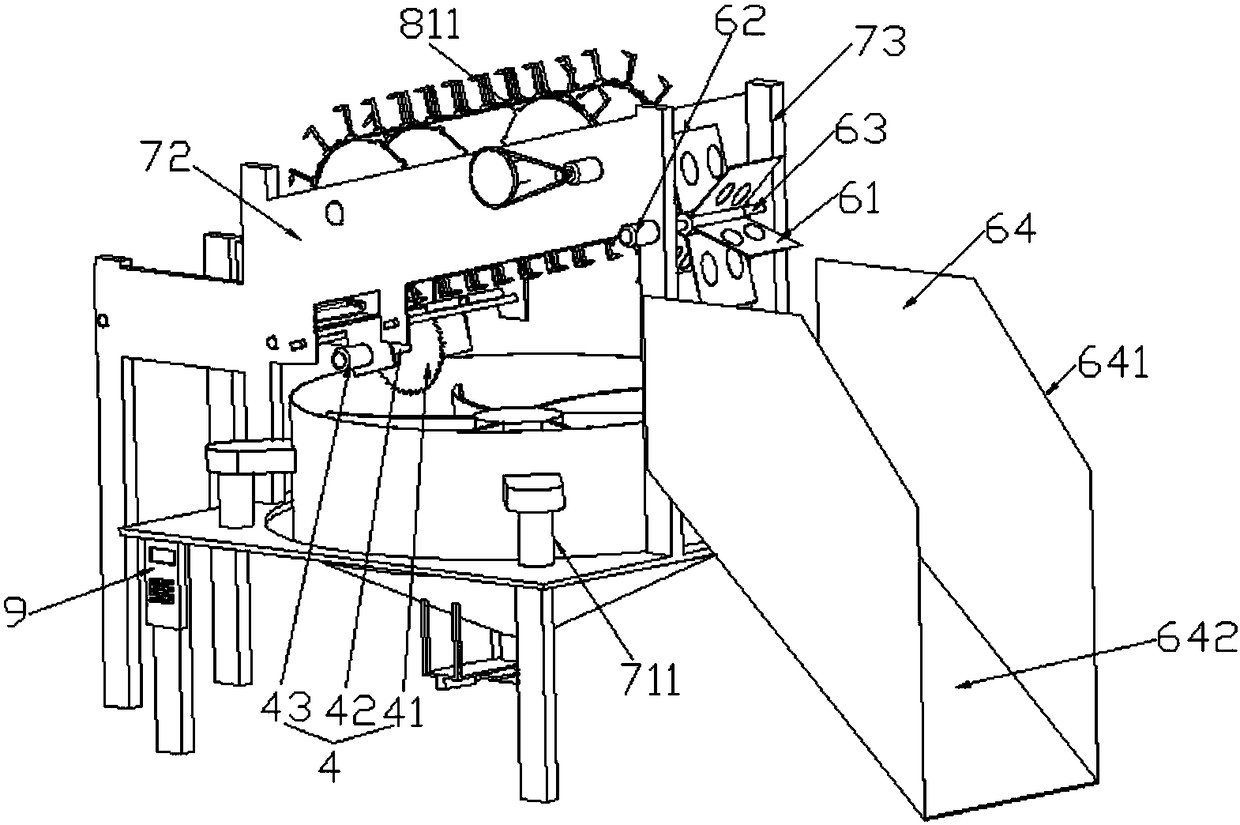

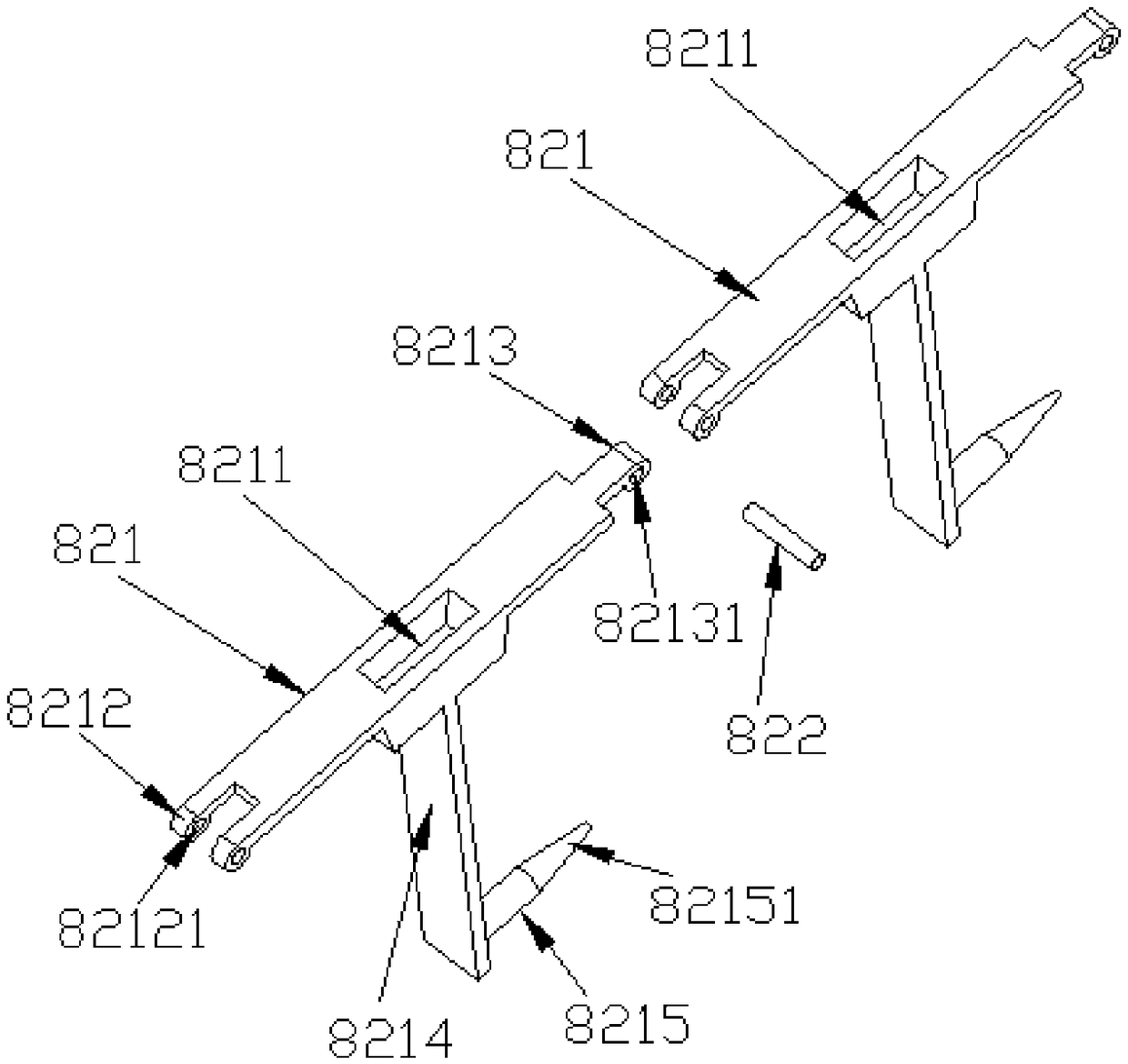

[0052] Such as Figure 1 to Figure 5 As shown, an automatic feeding and mixing equipment is characterized in that: it includes a flour bag 1, a conveyor belt 2, a roller conveyor belt 3, a bag breaking device 4, a stirring device 5, a packaging bag removing device 6, a support frame 7, and a packaging bag Bag hook device 8, console 9;

[0053] Described support frame 7 comprises support platform 71, short base column 74, long base column 75; Described support platform 71 is fixed on the short base column 74, and described support platform 71 is provided with electronic weighing device 711, and described support A large circular hole 712 is provided on the platform 71;

[0054] The support platform 71 is also provided with a column 73, and the side plate 72 is fixed on the long bottom column 75 and the column 73;

[0055] The conveyor belt 2, the roller conveyor belt 3 and the bag breaking device 4 are fixed in the middle of the side plate 72,

[0056] The flour bag 1 is hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com