An anti-loosening rail clamp

A rail presser and anti-loosening technology, which is applied in the direction of rail system, load hanging components, transportation and packaging, etc., can solve the problems of high labor intensity, increased vibration of the upper cover, and high danger in the operation process, and can achieve the Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

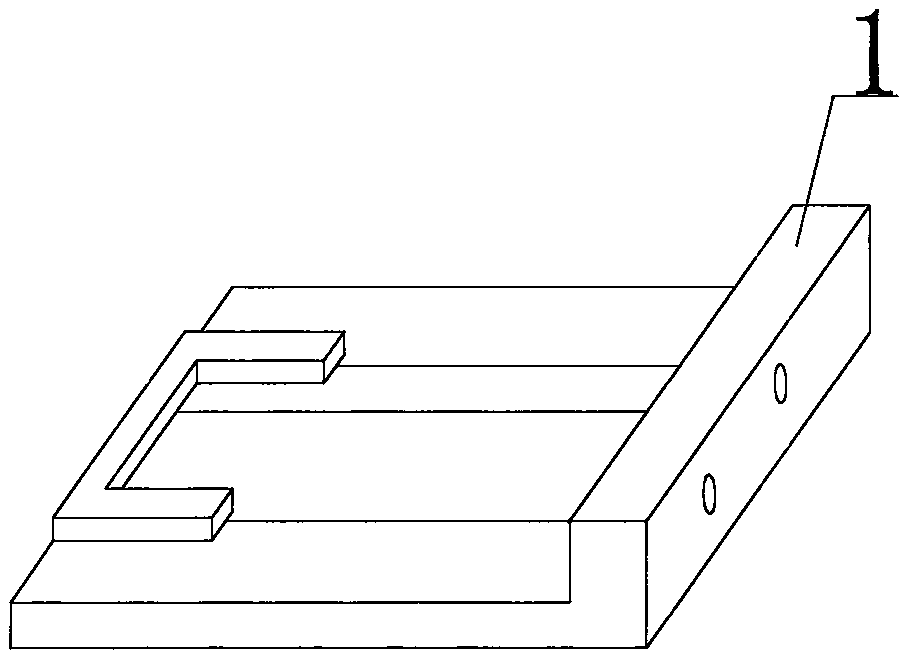

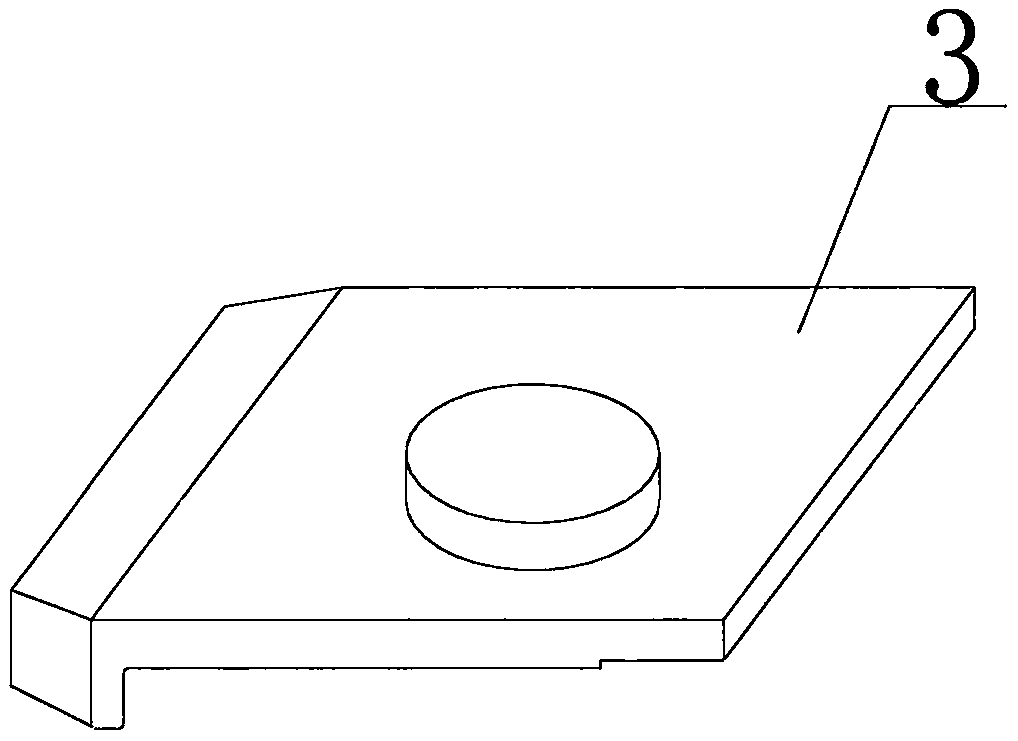

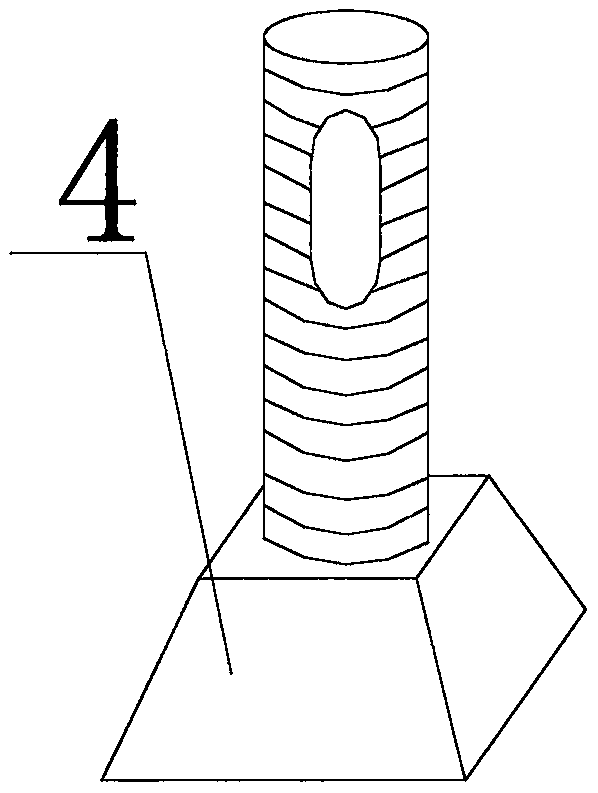

[0020] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , the present invention relates to an anti-loosening rail clamp, comprising a base 1, a pin 2, an upper cover plate 3, a T-shaped bolt 4, a spring washer 8, a flat washer 7 and a lock nut 6, characterized in that it also includes a pin 5 and spacer 9, the pin 5 is processed by steel wire; two bolt holes are drilled in the middle of the outer edge of the base 1 and a screw thread is tapped in the drilled bolt hole, and a screw thread is connected to the drilled bolt hole. Bolt 10; the upper part of the T-shaped bolt 4 has an oval or circular through hole, and the pin 5 passes through the oval or circular through hole on the T-shaped bolt 4 and bends the two ends of the pin 5; The position of the oval or circular through hole on the upper part of the T-bolt 4 should ensure that after the lock nut 6 is tightened, the installed pin 5 is located at 1 to 2 mm above the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com