Electrospinning device with automatic control of lifting and discrete collection device

An automatic control and collection device technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problem of unreasonable space occupied by equipment, and achieve a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

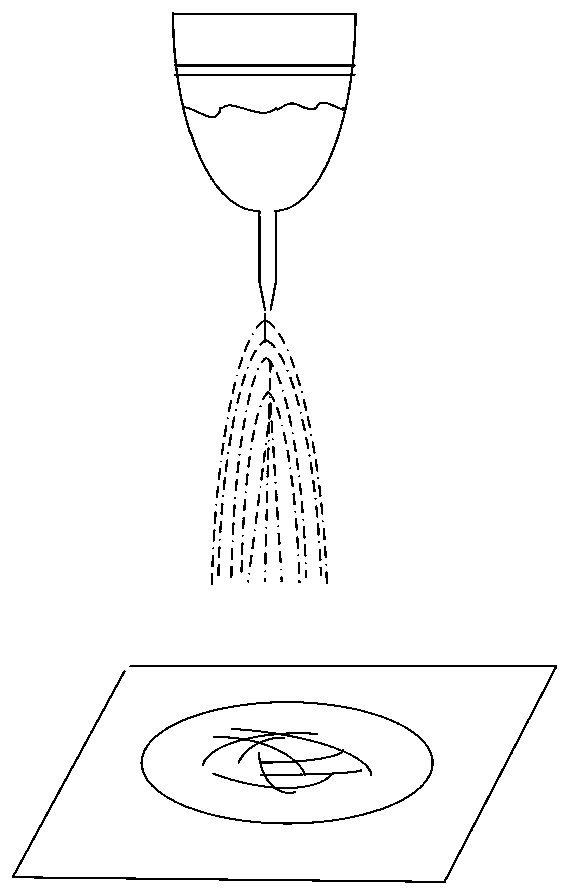

Method used

Image

Examples

Embodiment 1

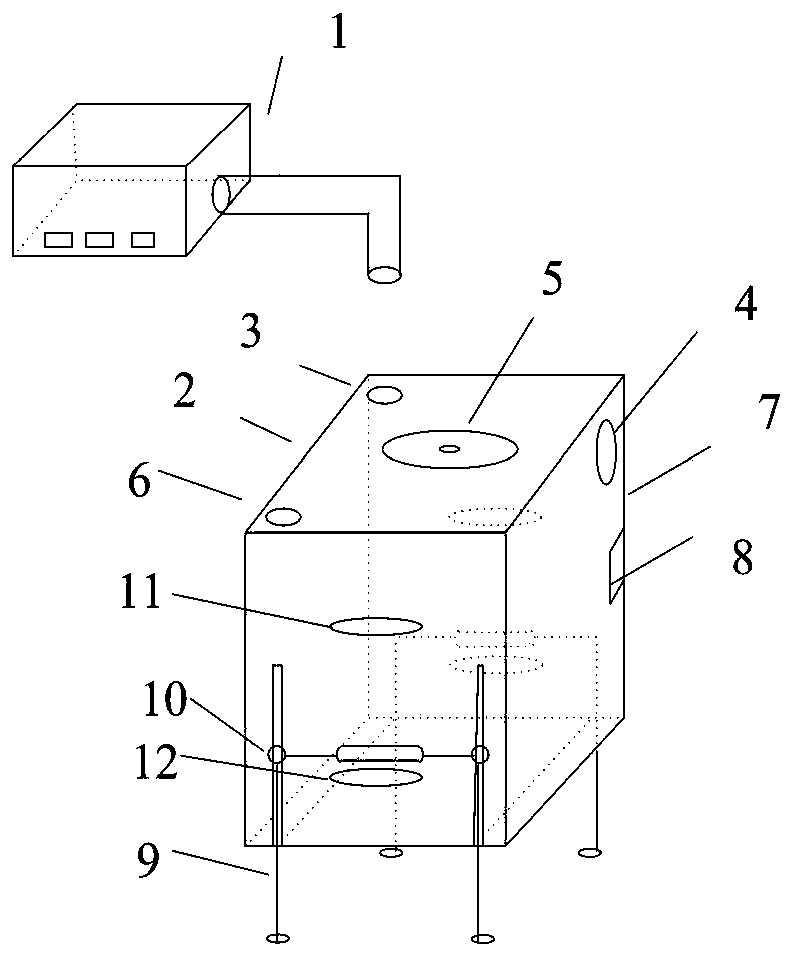

[0012] Embodiment 1: This embodiment provides an electrospun fiber sample collection device, which can be more used in scientific research, as a low-cost electrospun fiber experiment sample collection device. The collection device is composed of constant temperature and humidity air source, box body, intake valve, exhaust valve, rubber pad, support platform, slideway, electrode jack, side door, clasp handle, telescopic U-shaped outrigger and other parts.

[0013] The constant temperature and humidity air source is a common device in the control field, which can output air through pipes, and the temperature, humidity and flow rate of the air can be adjusted. The box body is a rectangular space made of acrylic material. Acrylic material is low in cost, easy to process, has good airtightness, is transparent and easy to observe, and can customize rectangular spaces of various sizes according to the requirements of electrospinning experiments. There is a slideway at the bottom of ...

Embodiment 2

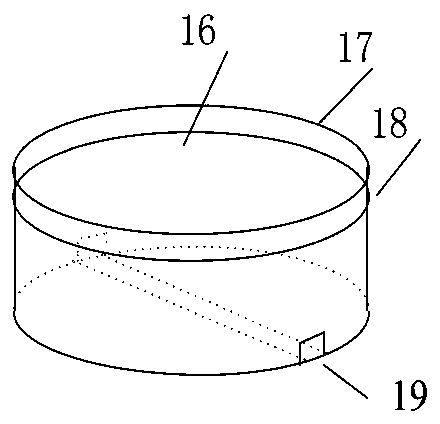

[0017] Embodiment 2: An electrospinning device with a separate collection device capable of automatic control of lifting, including a hollow rectangular box and a pallet, an air intake valve is arranged on the box, and an exhaust valve is arranged accordingly. The air intake valve described above is connected to a constant humidity and constant temperature air source machine to supply air to the inside of the box. The top surface of the box has a rubber pad, and the rubber pad has a pinhole for inserting the electrospun fiber jet needle into the box. A metal slideway is set, and the support platform is a cylindrical metal body, and a chute matching with the metal slideway on the bottom surface of the box body is opened at the bottom so that it can be slidably connected to the metal slideway; the electrodes on the box body The jack is connected to the metal slideway, the electrode jack is connected to the negative pole of the high-voltage power supply through the power line, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com