clutch structure

A clutch and friction ring technology, applied in the field of clutch structure, can solve problems such as size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following descriptions are exemplary in nature only and are not intended to limit the invention, application, or use. It should be understood that throughout the drawings, corresponding reference numerals indicate similar or corresponding parts and features.

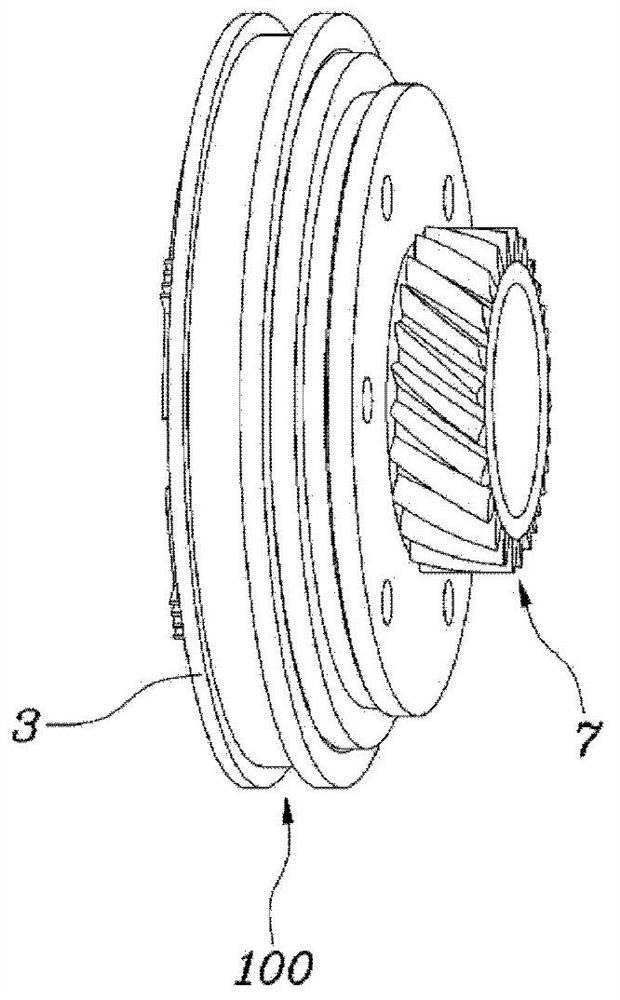

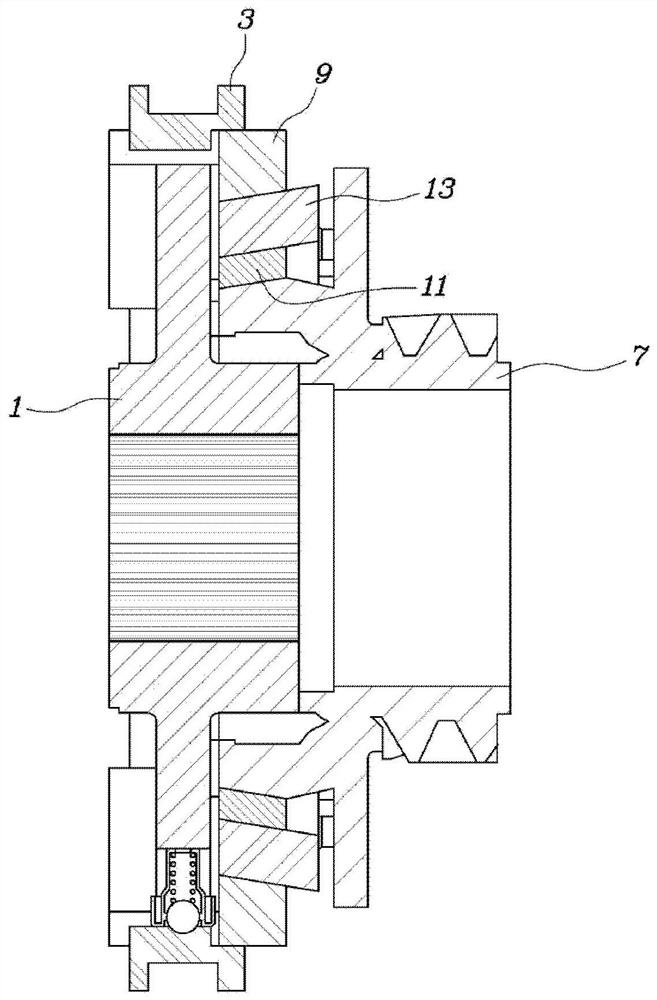

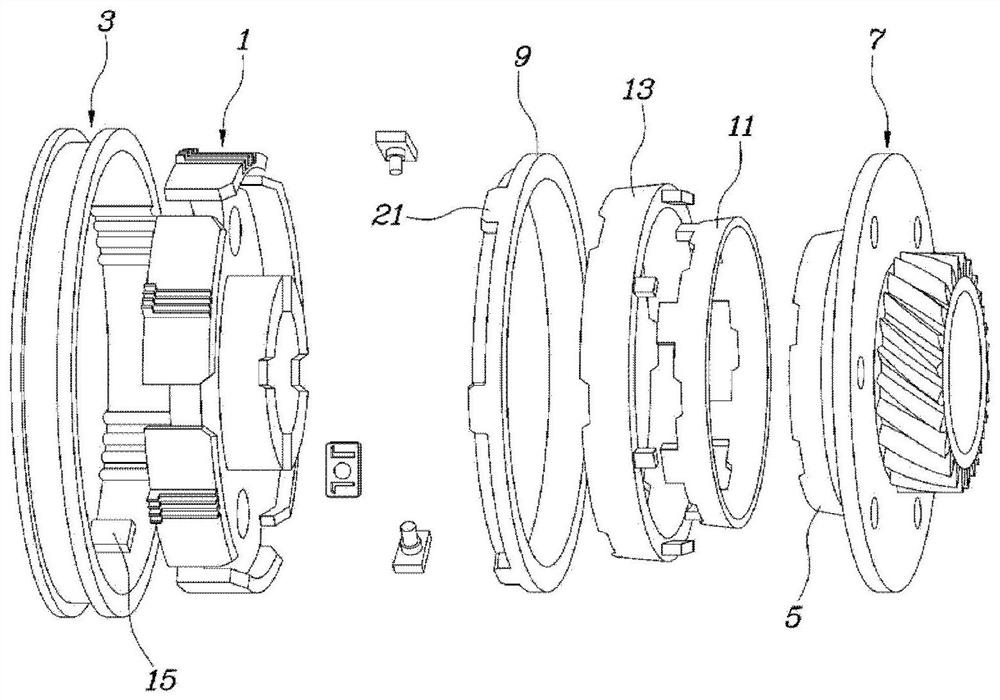

[0032] refer to Figure 1 to Figure 4 , the structure of the clutch 100 according to the present invention includes: a hub 1 fixed to the rotating shaft; a sleeve 3 mounted on the outer peripheral surface of the hub 1 to slide linearly; a clutch gear 7 mounted on the rotating shaft to rotate relative to the rotating shaft and The clutch cone 5 is integrally formed, and the clutch cone 5 protrudes toward the hub 1 in such a manner that the outer diameter gradually decreases; the first friction ring 9 is arranged between the clutch gear 7 and the hub 1 and is configured to be pressed toward the clutch gear 7 , so as to generate friction between the clutch cone 5 and the hub 1, thereby transmitting torque; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com