Filter achieving long-time stable running and mixed shaft seal assembly of filter

A stable operation and filter technology, which is applied in the direction of engine sealing, filter separation, engine components, etc., can solve the inconsistent concentricity of the brush shaft, sealing flange and nylon bushing, easy to change matching dimensions, and long brush shaft length and other problems to achieve the effect of saving maintenance time and maintenance costs, prolonging stable operation time, and convenient purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

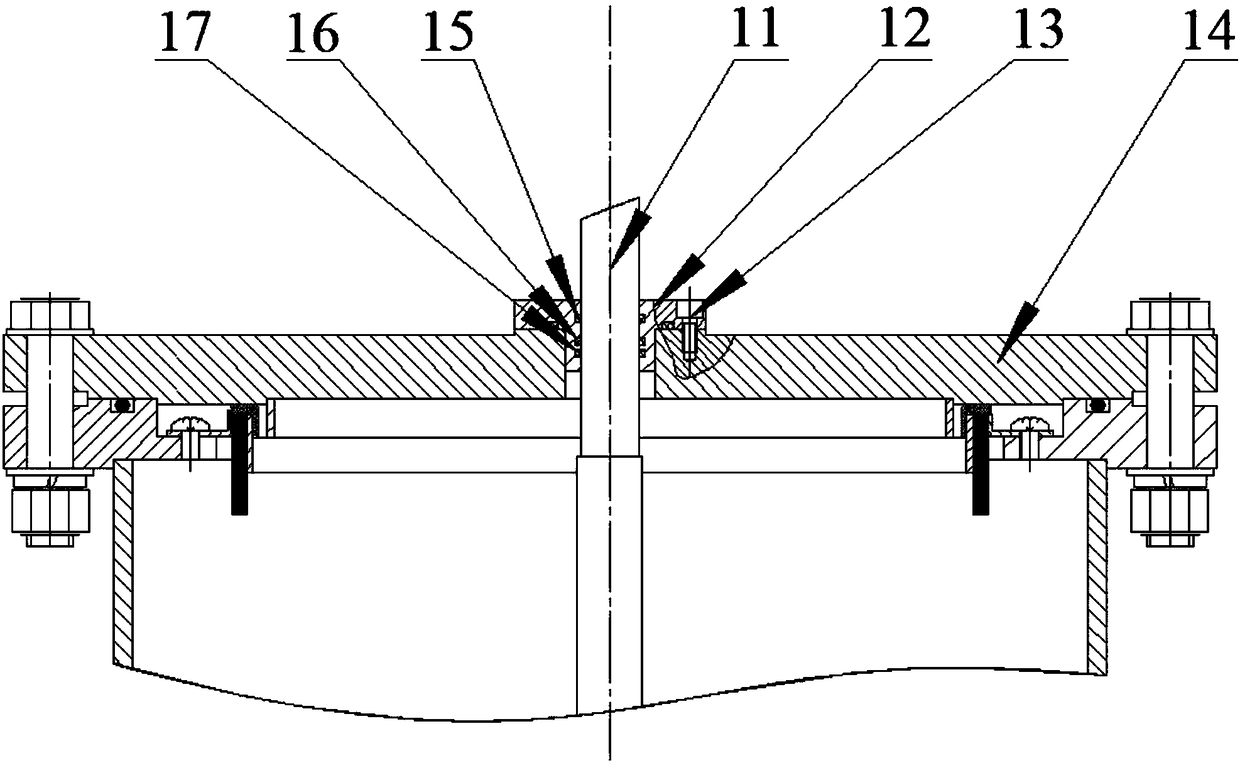

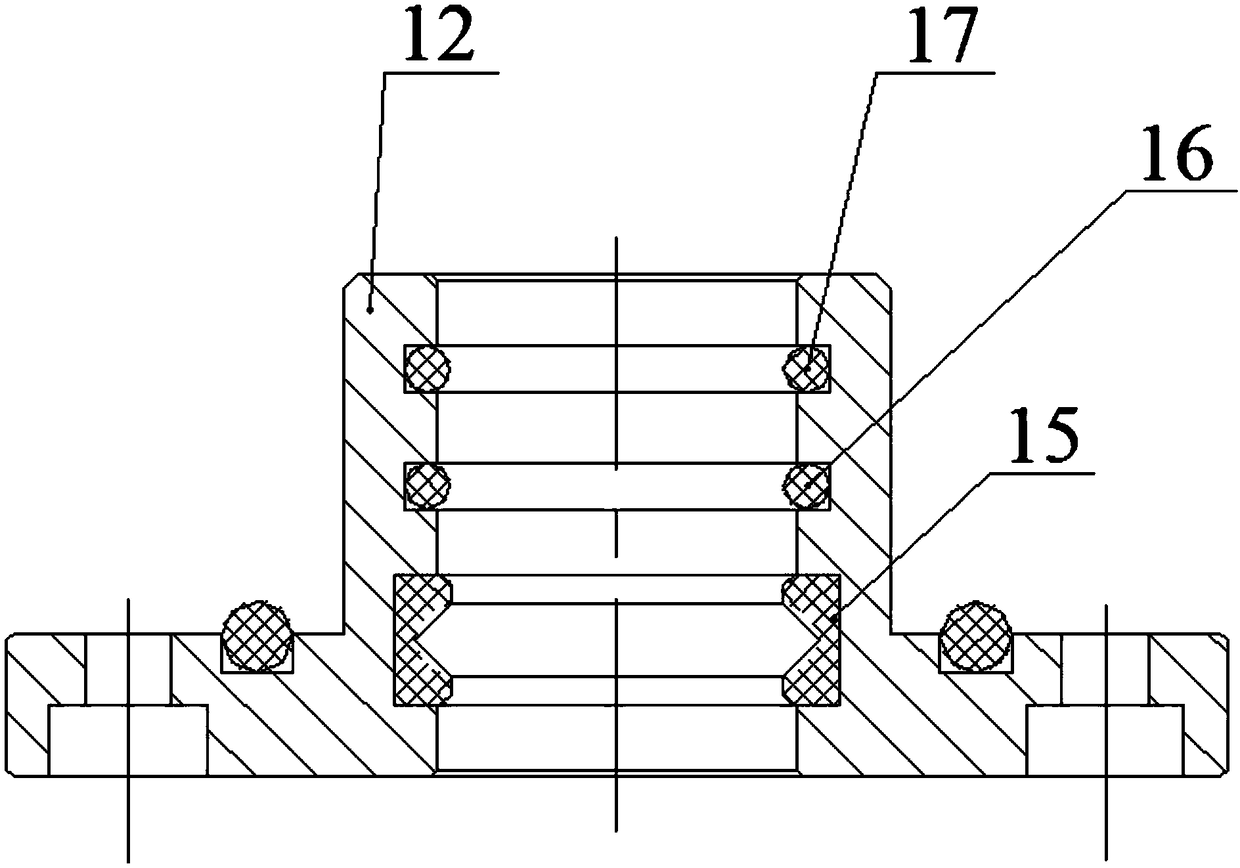

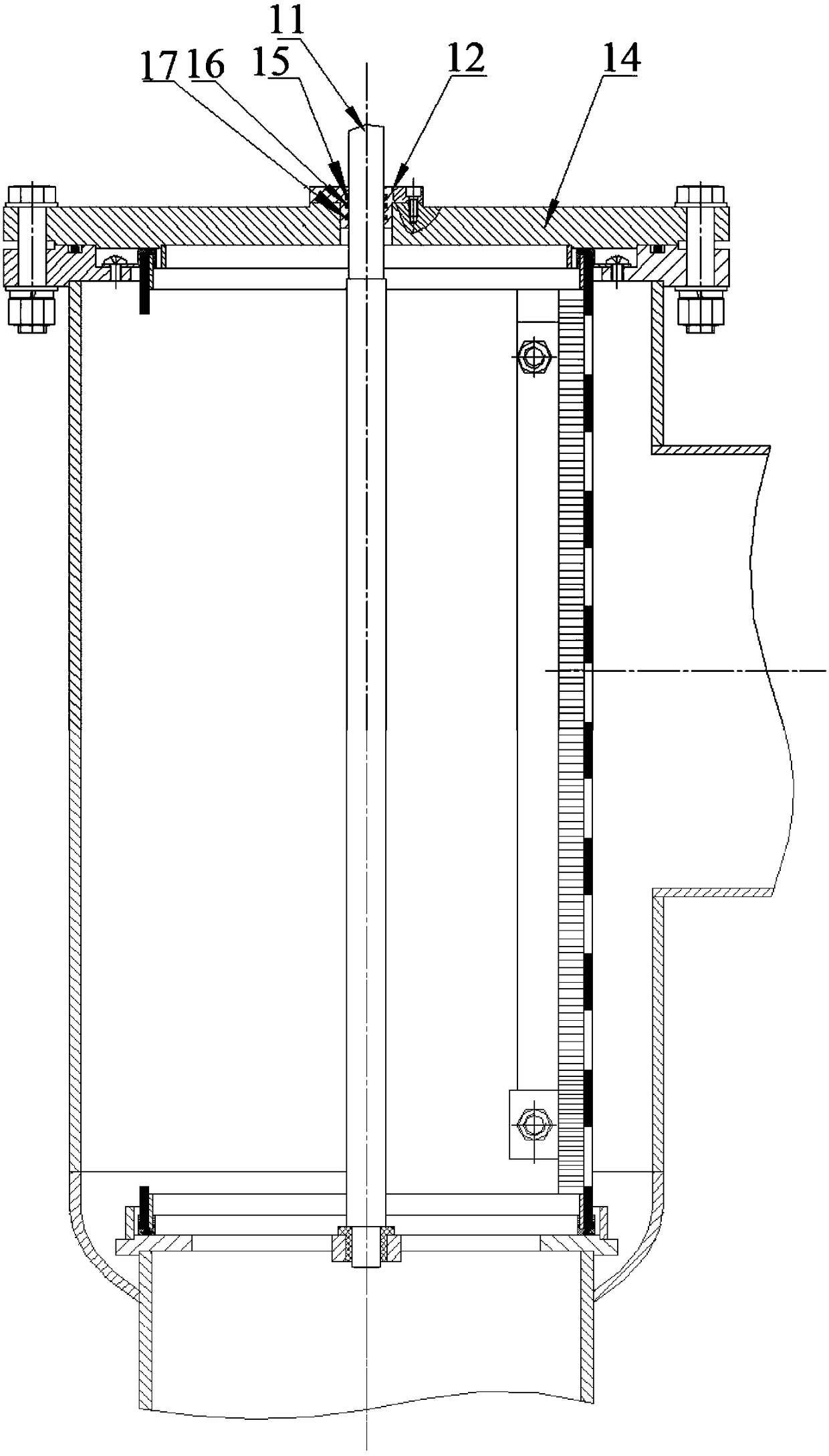

[0033] to combine Figure 4, a filter shaft seal assembly in this embodiment, including a sealing flange 21, fastening bolts 22, and a packing gland 23, the sealing flange 21 is provided with an upper ear seat 211 and a lower ear seat 212, and the upper ear There are threaded holes at the corresponding positions of the seat 211 and the packing gland 23, and the fastening bolts 22 pass through the threaded holes provided on the packing gland 23 and the upper lug seat 211 to connect the sealing flange 21 and the packing gland 23 as a whole. A fixing hole 213 is defined on the lower lug seat 212 . The lower part of the packing gland 23 is inserted into the sealing flange 21, and an upper cavity is formed inside the sealing flange 21, and five circles of graphite packing 25 are arranged in the upper cavity, and between the graphite packing 25 and the packing gland 23 1. A sealing gasket 24 is arranged between the graphite packing 25 and the sealing flange 21 . Graphite packing 2...

Embodiment 2

[0036] A filter with long-term stable operation in this embodiment includes a brush shaft 29, a filter cartridge cover, a filter cartridge and the shaft seal assembly as described in Embodiment 1. The filter cartridge cover is open, the lower part of the sealing flange 21 is inserted into the filter cartridge cover, the sealing flange 21 of the shaft seal assembly is provided with an upper ear seat 211 and a lower ear seat 212, and the upper ear seat 211 and the packing gland 23 correspond to positions A threaded hole is opened at the place, and the fastening bolt 22 passes through the threaded hole provided on the packing gland 23 and the upper lug seat 211 to connect the sealing flange 21 and the packing gland 23 as a whole. The lower ear seat 212 and the corresponding position of the filter cartridge cover are provided with fixing holes 213, and the fastening bolts 22 pass through the fixing holes 213 to connect the sealing flange 21 and the filter cartridge cover as a whole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com