A stainless steel lamp post system and its manufacturing method

A technology of stainless steel and production methods, applied in the field of architectural decoration, to achieve the effect of easy selection of size and beautiful appearance of lampposts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

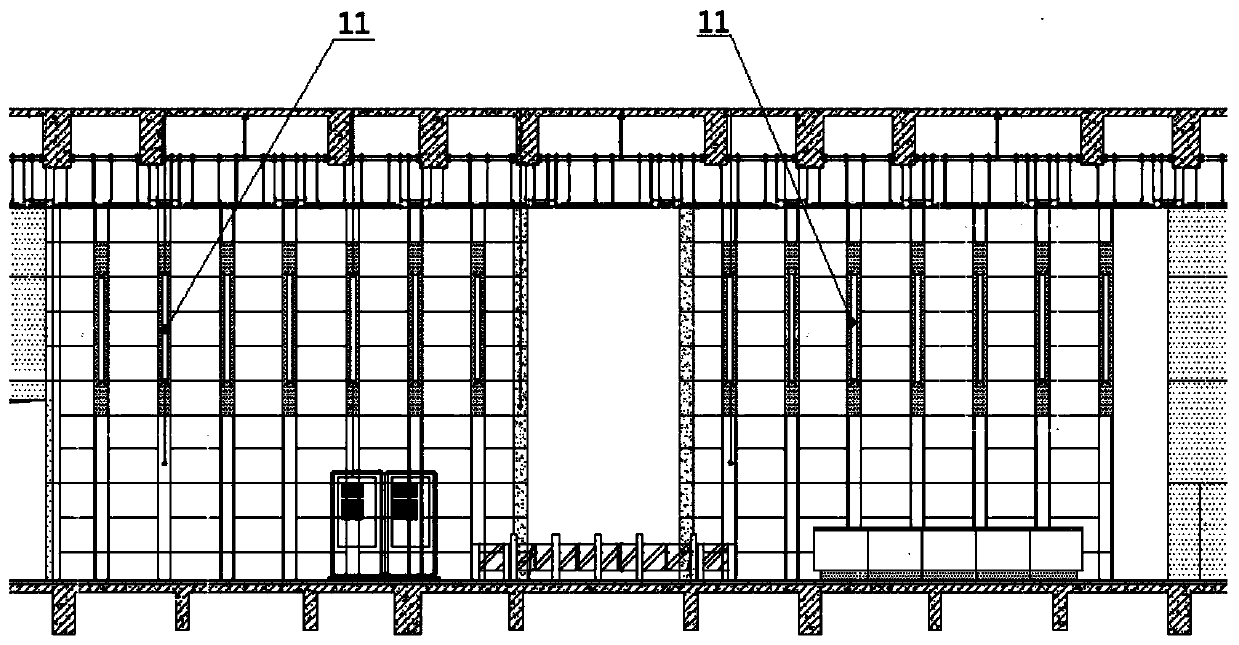

[0026] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

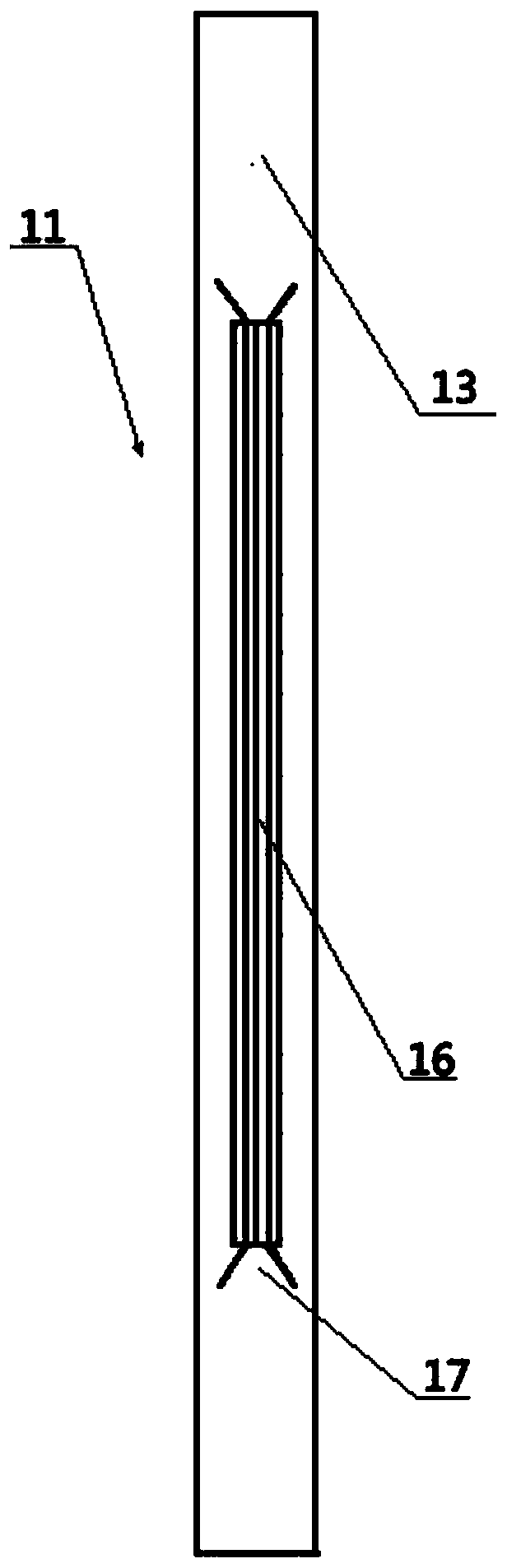

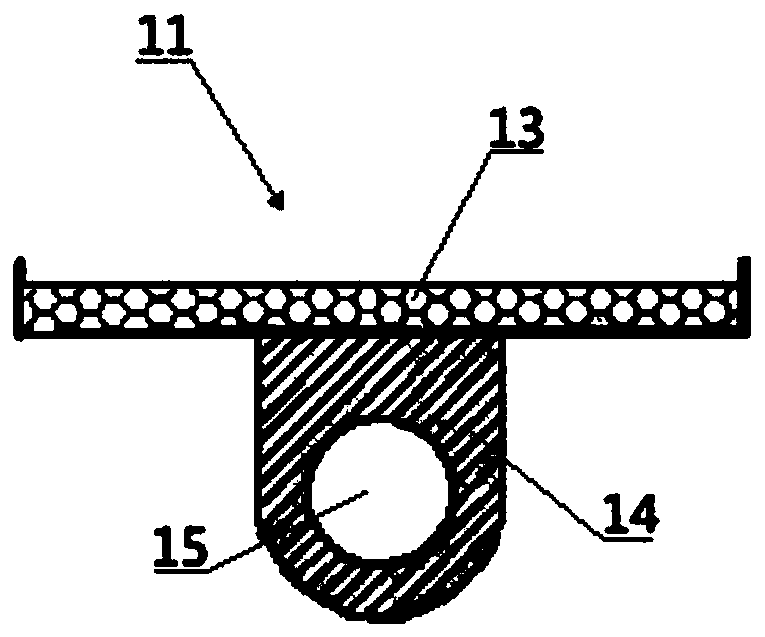

[0027] Such as Figure 2 to Figure 6 As shown, a single lamp post unit of the stainless steel lamp post system includes: a lamp post body 16 , a lamp post cover 14 and a lamp post bottom plate 13 .

[0028] Such as figure 2 As shown, the lamp post body 16 is elongated as a whole with a U-shaped cross section. Such as Figure 4 As shown, the U-shaped opening is bent inward to form a mounting piece 161 .

[0029] The lamp post cover plate 14 covers the upper and lower ends of the lamp post body 16 and has lamp installation holes 15 for installing spotlights 17 . Such as image 3 and Figure 5 As shown, in this embodiment, the lamp installation hole 15 is circular. In other embodiments, according to the effect of the light, the lamp installation hole 15 can also adopt other shapes.

[0030] The lamp post base plate 13, the lamp post...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com