A composite roof truss with frp cables for the lower chord

A technology of bottom chord and roof truss, applied in the direction of truss structure, joists, girders, etc., can solve the problems of low shear resistance and low thermal conductivity, and achieve the effect of beautiful form, large spanning ability and clear force transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

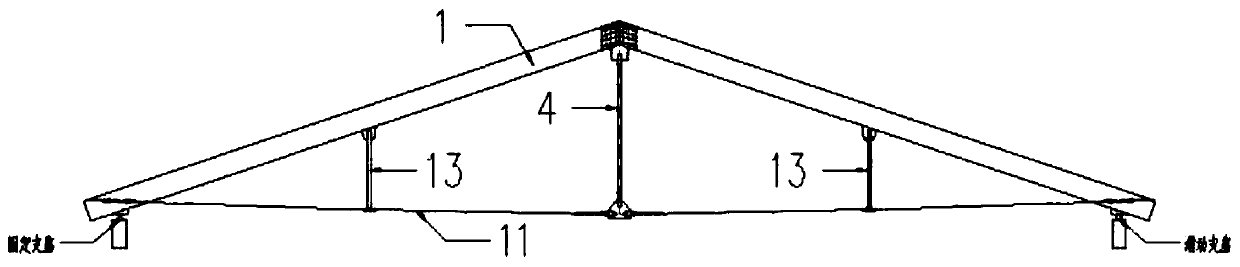

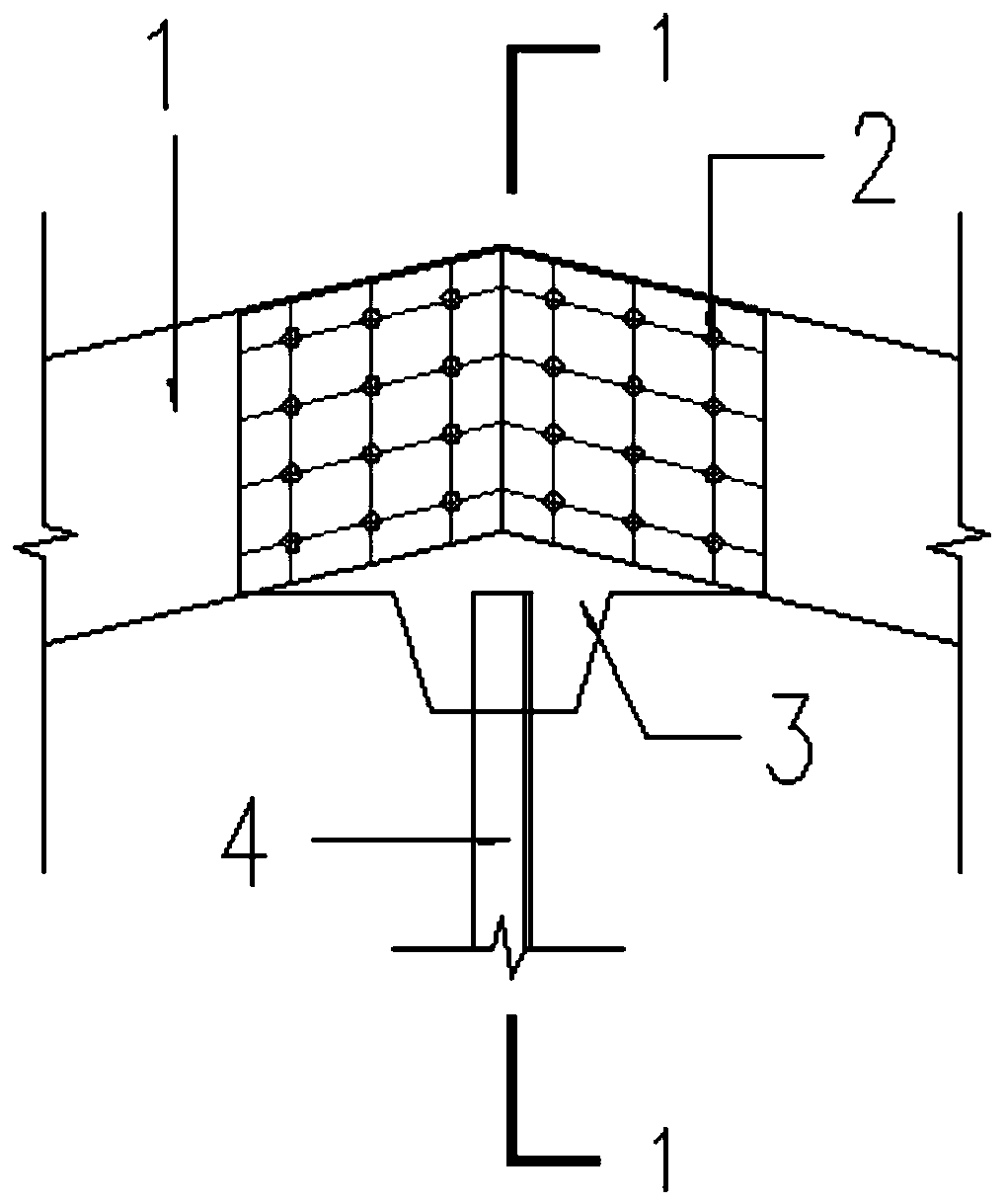

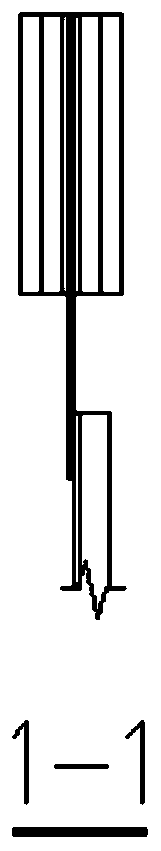

[0022] Such as figure 1 Shown in -7: a composite roof truss with FRP cables for the lower chord, including upper chord 1, bolt 2, upper connecting plate 3, web bar 4, lower connecting plate 5, hole 6, pin shaft 7, fork ear 8, sheath 9. Sleeve 10, FRP cable 11, intermediate sleeve 12, intermediate web 13, intermediate connecting plate 14 and reserved through hole 15;

[0023] The upper chord 1 is "herringbone", broken line or curved. The upper chord 1 is connected to the upper connecting plate 3 by bolts 2 or welding, and the lower end of the upper connecting plate 3 is connected to the web 4 by welding. The web 4 is connected to the lower connecting plate 5 by welding, the lower connecting plate 5 is provided with a hole 6, and a pin 7 matching the hole 6 is arranged in the hole 6, and the pin 7 is connected to There are fork ears 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com