Patents

Literature

34results about How to "Beautiful form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combination type bar code and application system thereof

InactiveCN101414360AReduce workloadReduce the chance of errorRecord carriers used with machinesProgramming languageHandwriting

The invention relates to a combined bar code, which is a new bar code that is formed by proper combination of a single-dimensional bar code with numbers, letters and signs or the combination of numbers, letters and signs and a two-dimensional bar code with the information of senders and recipients; the single-dimensional bar code can be recognized by naked eyes but the two-dimensional bar code can not be recognized by naked eyes. The invention also relates to an application system adopting the bar code, which at least comprises: a bar code generating part and a bar code recognizing and processing part; the bar code generating part at least comprises: an editing module, a bar code generating module, and a printing module; the bar code recognizing and processing part at least comprises: an input interface, a decoding module, a message processing module, and an output module. The system of the invention is characterized by the flexible, convenient and rapid use, and the adoption of the system can not only reduce error probability, but also greatly save labor cost and reduce the workload of post clerks; furthermore booked handwritings can be much clearer and forms can be more beautiful.

Owner:沈群华

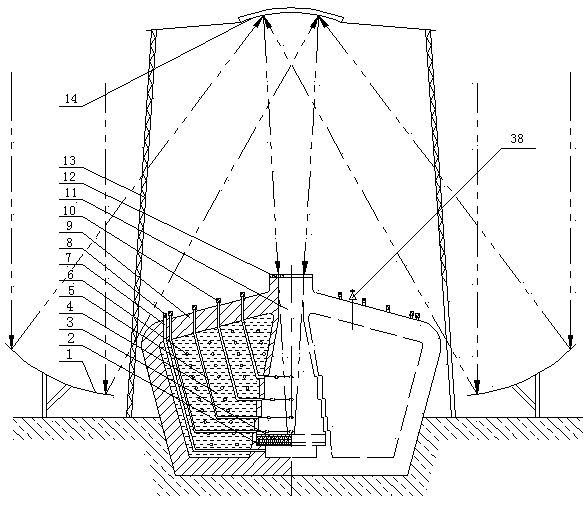

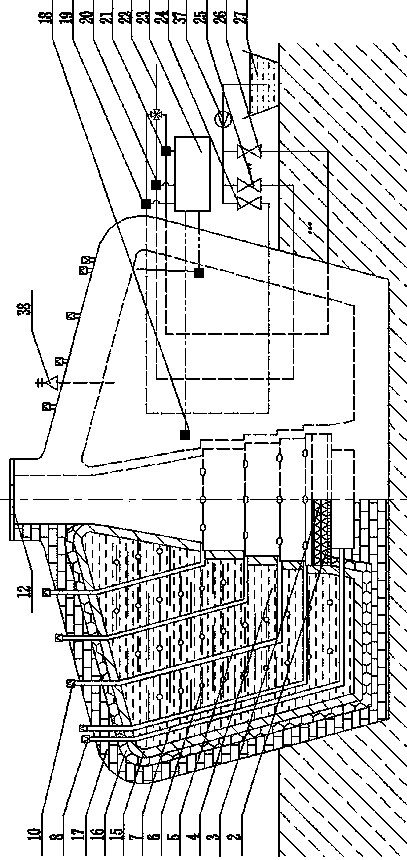

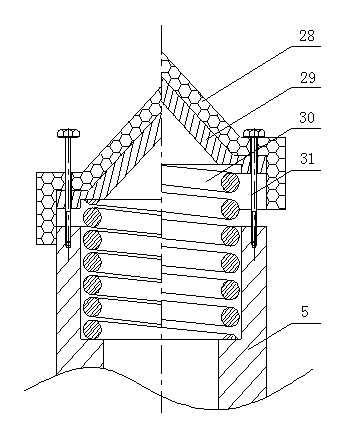

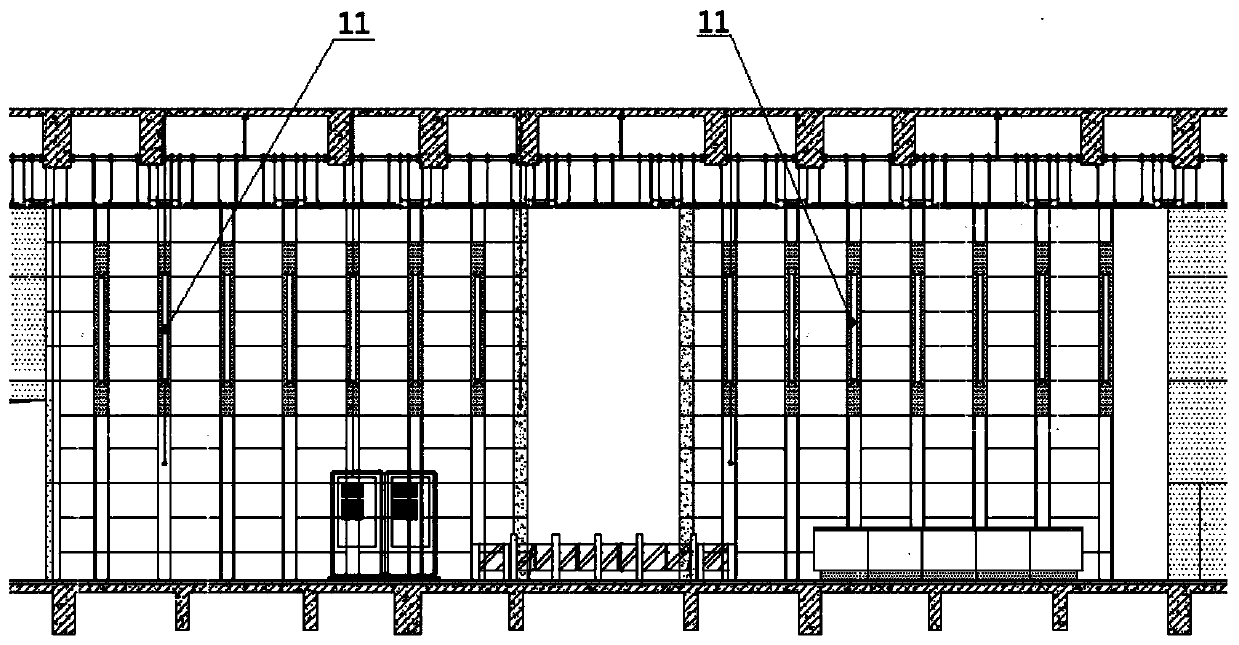

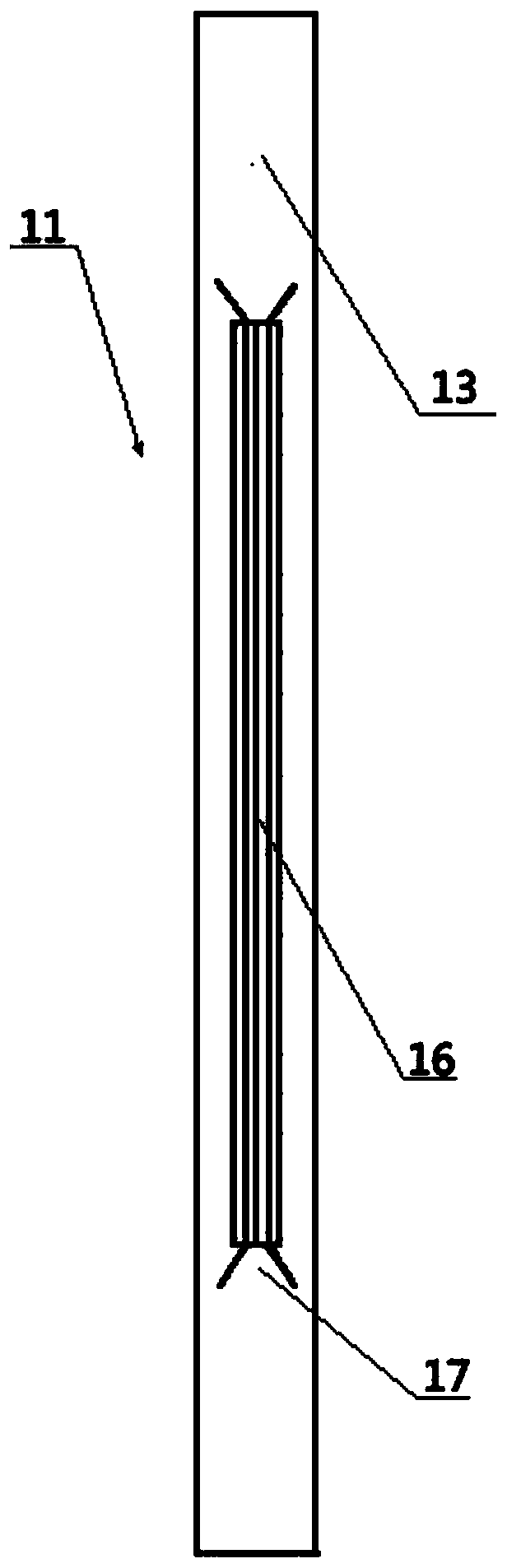

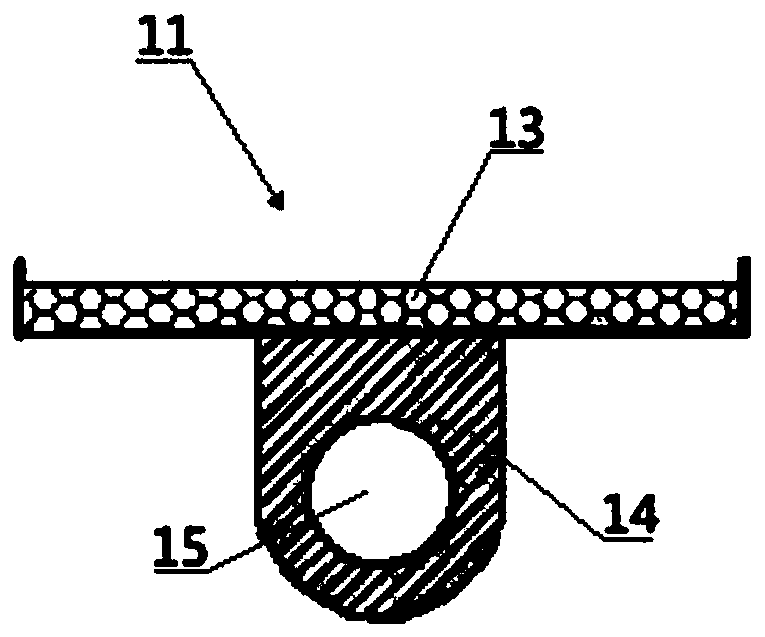

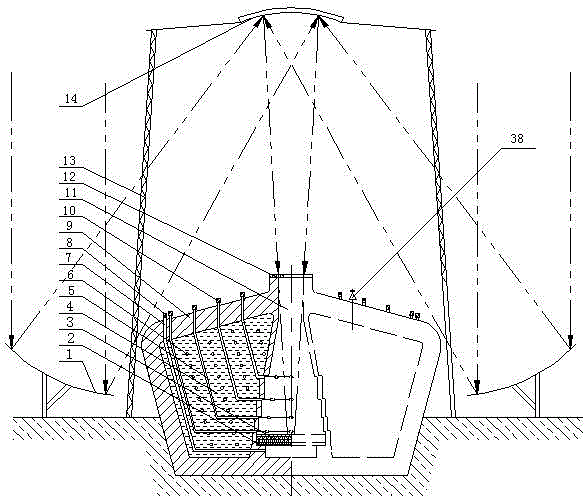

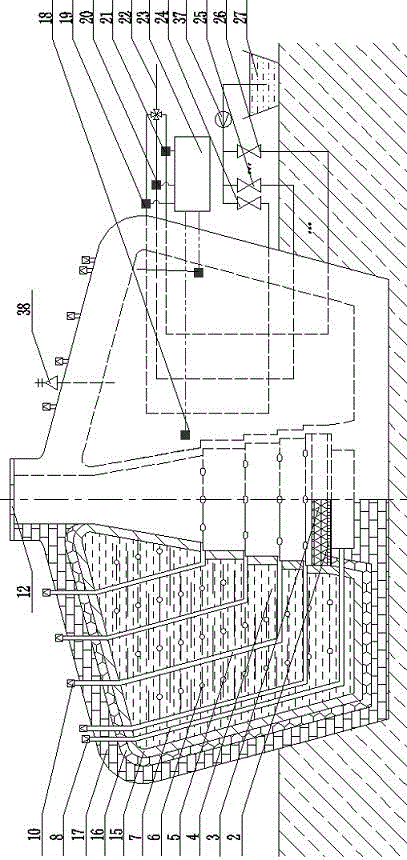

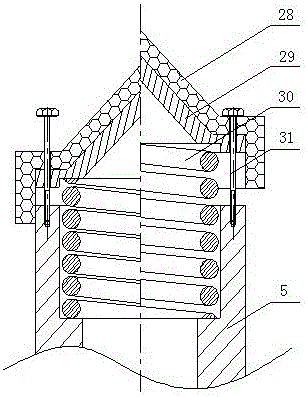

Large-capacity well type solar heat collection-storage device

InactiveCN103629827ASimple structureIncrease volumeSolar heating energySolar heat devicesCold airThermodynamics

The invention relates to the field of solar heat collection and storage technologies and discloses a high-temperature large-capacity well type solar heat collection-storage device. A primary reflector of the large-capacity well type solar heat collection-storage device is a concave mirror reflector, and a plurality of the primary reflectors are fixed on the ground to form a reflector array; a secondary reflector is mounted in the air and is a convex mirror reflector which is opposite to the primary reflectors, a conical solar well is arranged below the secondary reflector, and a heat absorbing body is arranged at the bottom of the solar well; a heat storage tank body is a hollow tank body, the middle of the heat storage tank body is the solar well, a part of the heat storage tank body is buried underground and is filled with a heat storage medium; a hot air pipe and a cold air pipe penetrate through the heat storage tank body, are immersed into the heat storage medium and are communicated with the air above the solar well and the heat storage tank body; pipe mouths, which are located on the sidewall of the solar well, of the hot air pipe and the cold air pipe are respectively located above and below the heat absorbing body. The large-capacity well type solar heat collection-storage device integrates advantages of point focus heat collection and fuse salt heat storage, does not need a specific heat transfer system, and has the advantages of simple structure, low maintenance cost, large heat storage capacity, small floor space and more artistic form.

Owner:QINGHAI UNIVERSITY

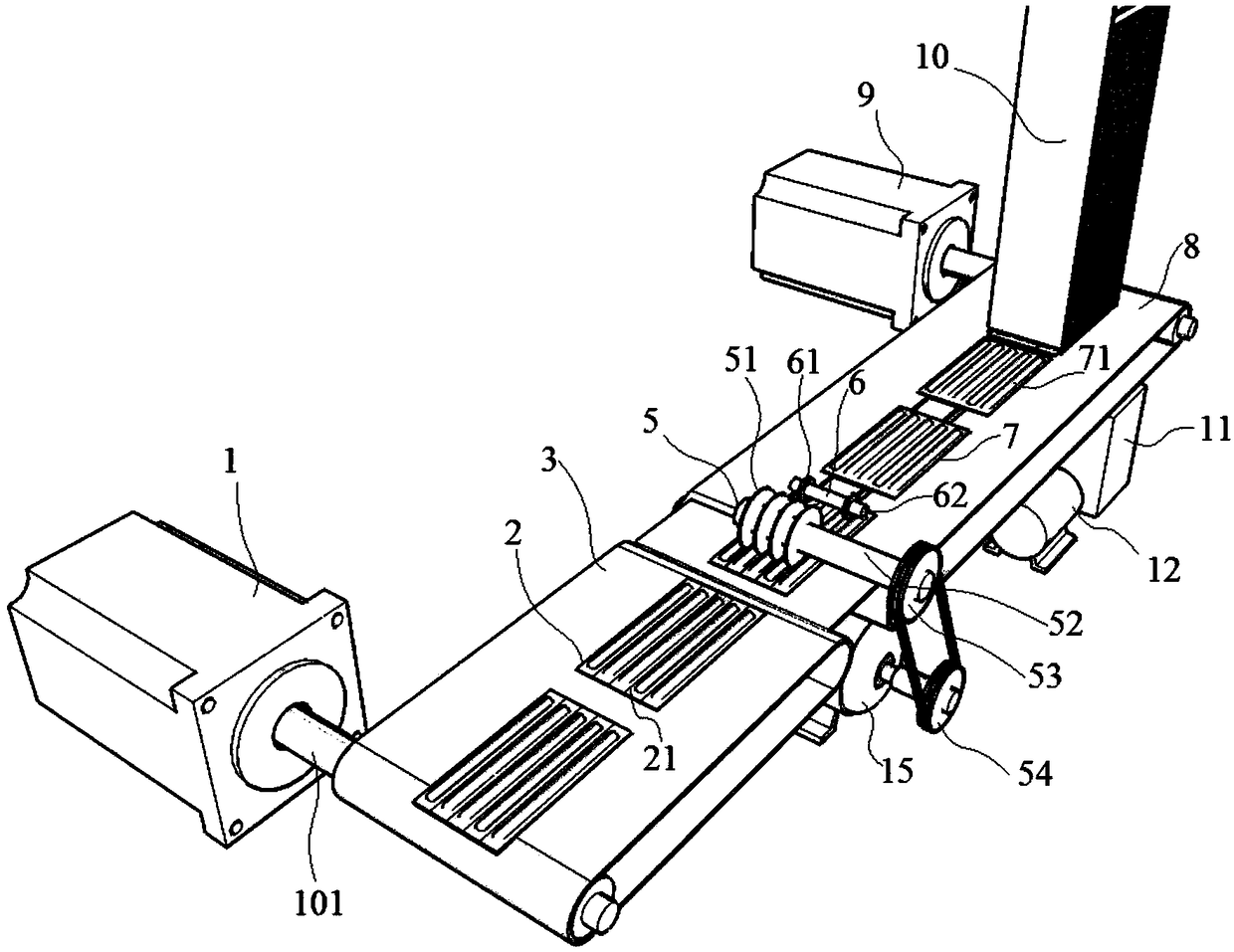

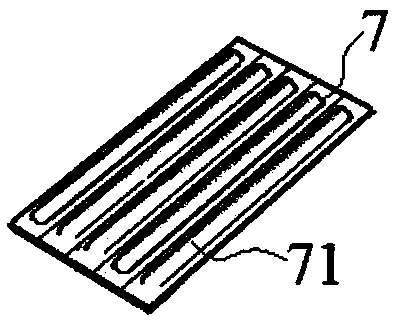

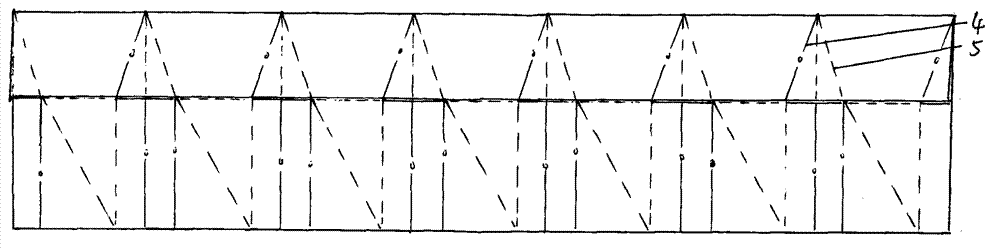

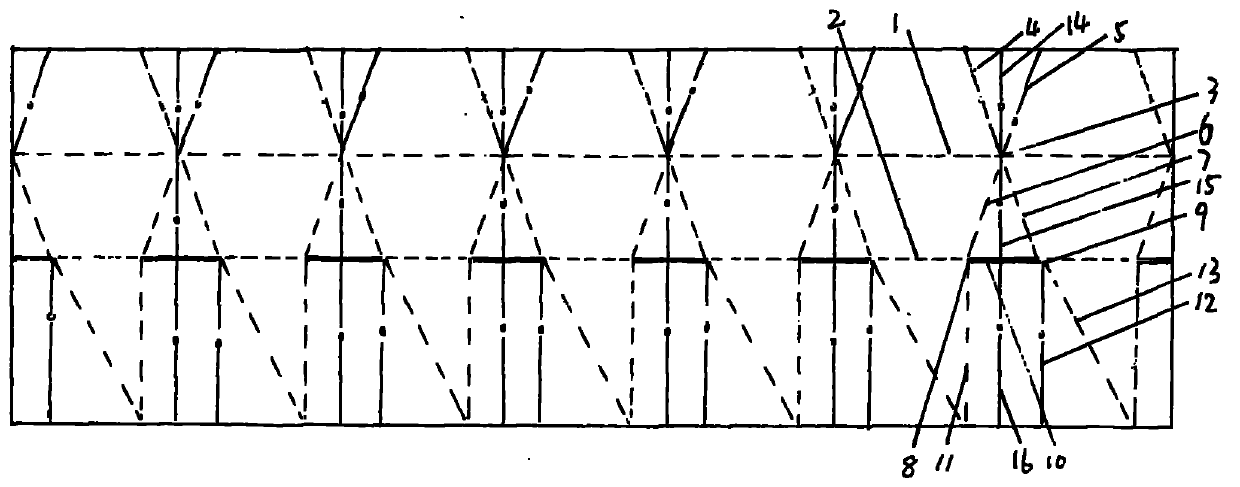

Die-cutting machine and die-cutting method thereof

ActiveCN108247748AReduce security risksIncrease productivityMetal working apparatusMotor driveProduct group

The invention discloses a die-cutting machine and a die-cutting method thereof, and belongs to the technical field of product packaging. The die-cutting machine includes a die-cutting template and a die-cutting tool. A plurality of grooves are formed in the die-cutting template evenly. The die-cutting tool includes die-cutting blades. The die-cutting blades are located in the grooves. The die-cutting method of the die-cutting machine includes the following steps that a feeding conveying belt motor, a vacuum sucker motor, a receiving conveying belt motor and a die-cutting motor are started; product groups before die-cutting are conveyed to a guiding device, receiving pressing wheels on a receiving pressing shaft press on both sides of each product group before the die-cutting, and the receiving pressing shaft rotates to drive the receiving pressing wheels to rotate; and the receiving pressing wheels drive the product groups before the die-cutting to move forwards to the die-cutting template, the die-cutting motor rotates, an output shaft of the die-cutting motor drives a die-cutting motor belt pulley to rotate, a die-cutting tool wheel rotates, a die-cutting tool shaft rotates, thedie-cutting blades drive the product groups before the die-cutting to rotate in the grooves, and die-cutting is achieved. According to the die-cutting machine and the die-cutting method thereof, the fact that dividing dotted lines can be added to product packaging is achieved, and splitting is fast and convenient.

Owner:马鞍山邦德医疗器械有限公司

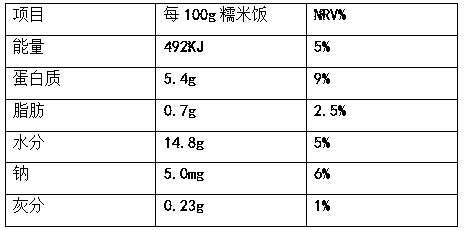

Method for making cooked seven-colored glutinous rice

InactiveCN109380653AHas health benefitsUnique national styleNatural extract food ingredientsFood ingredient functionsClitoria ternateaLycianthes biflora

The invention discloses a method for making cooked seven-colored glutinous rice. According to the cooked seven-color glutinous rice, colorful glutinous rice is prepared from high-quality long glutinous rice which is dyed with edible plant extracts, and the colorful glutinous rice is endowed with unique fragrance and is processed and prepared into the cooked glutinous rice. The colorful glutinous rice has seven colors in all, namely red, yellow, green, blue, purple, black and white, the colors are respectively derived from lycianthes biflora, butterflybush flowers and ginger, shiny cinquefoil roots, clitoria ternatea linn, peristrophe roxburghiana, wild blueberry leaves and liquidambar formosana hance's leaves, and the white color is the original color of glutinous rice. The cooked seven-colored glutinous rice can be added with other stuffing to achieve multiple tastes, different colors can be freely combined according to personal preference, and the cooked seven-colored glutinous ricehas a unique ethnic style. After vacuum packaging, the cooked seven-colored glutinous rice made by using the method can be preserved for eight months or longer under a normal temperature condition, can be instantly eaten after being slightly heated, and is safe, convenient and rapid to use.

Owner:谢林峰

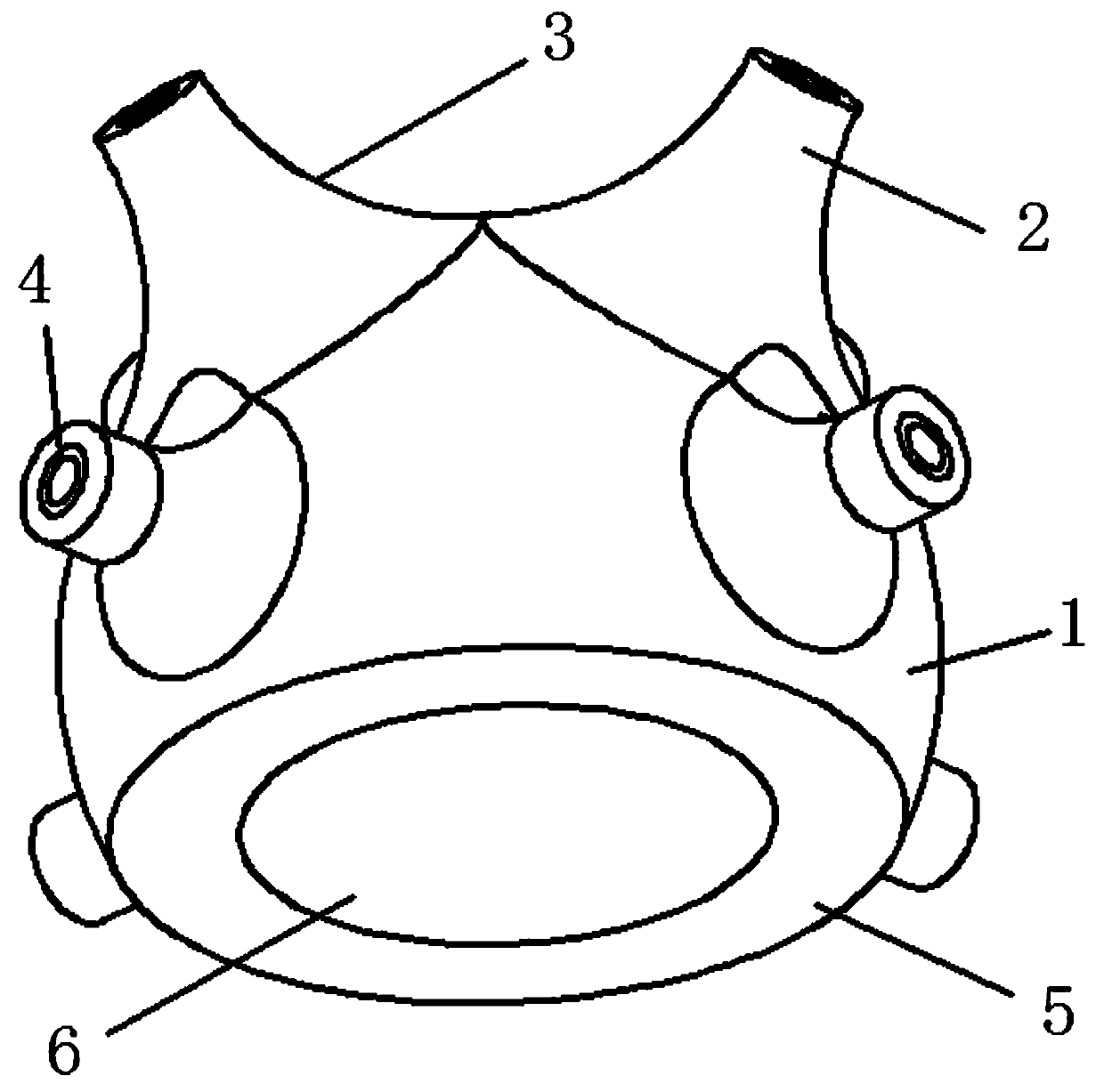

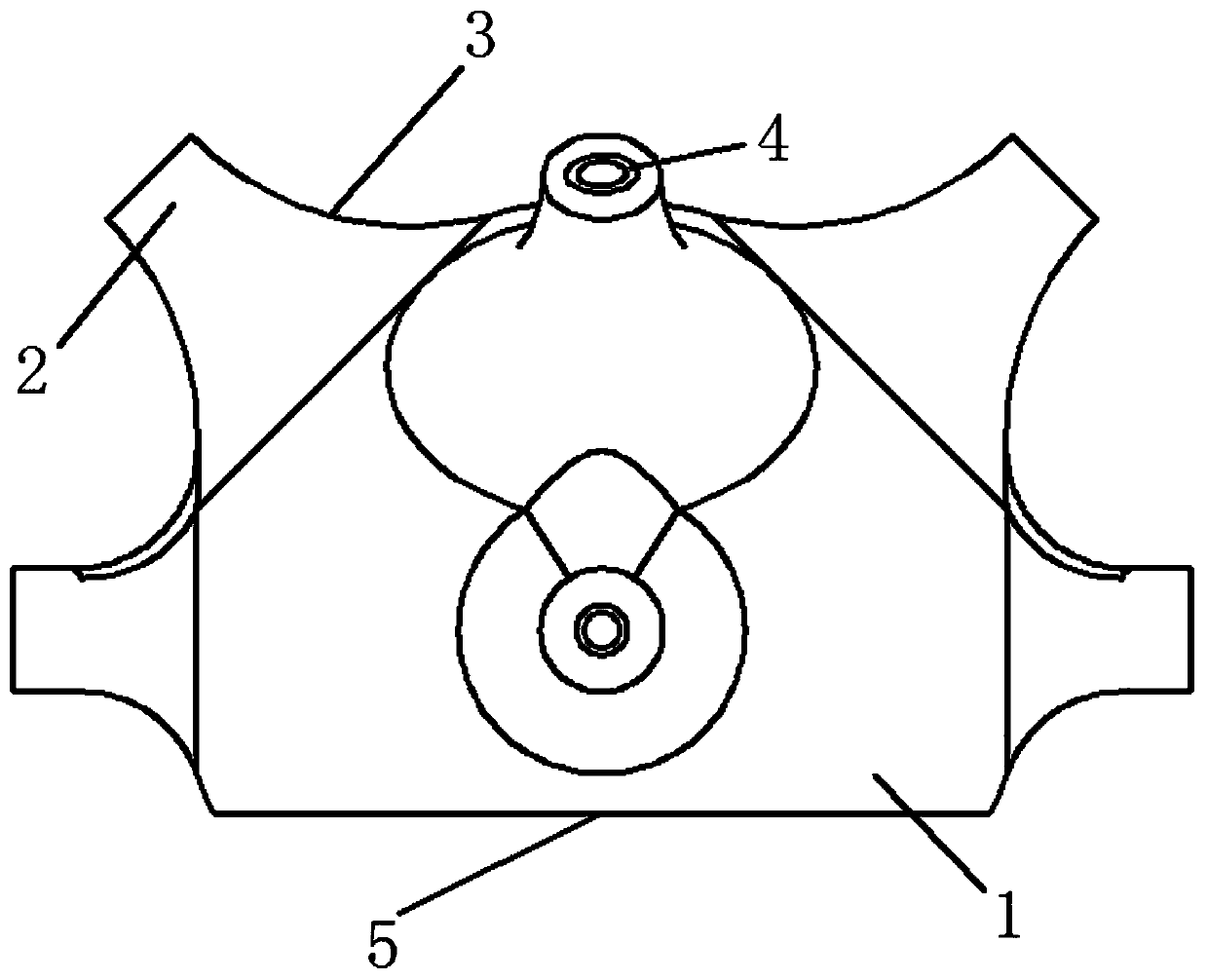

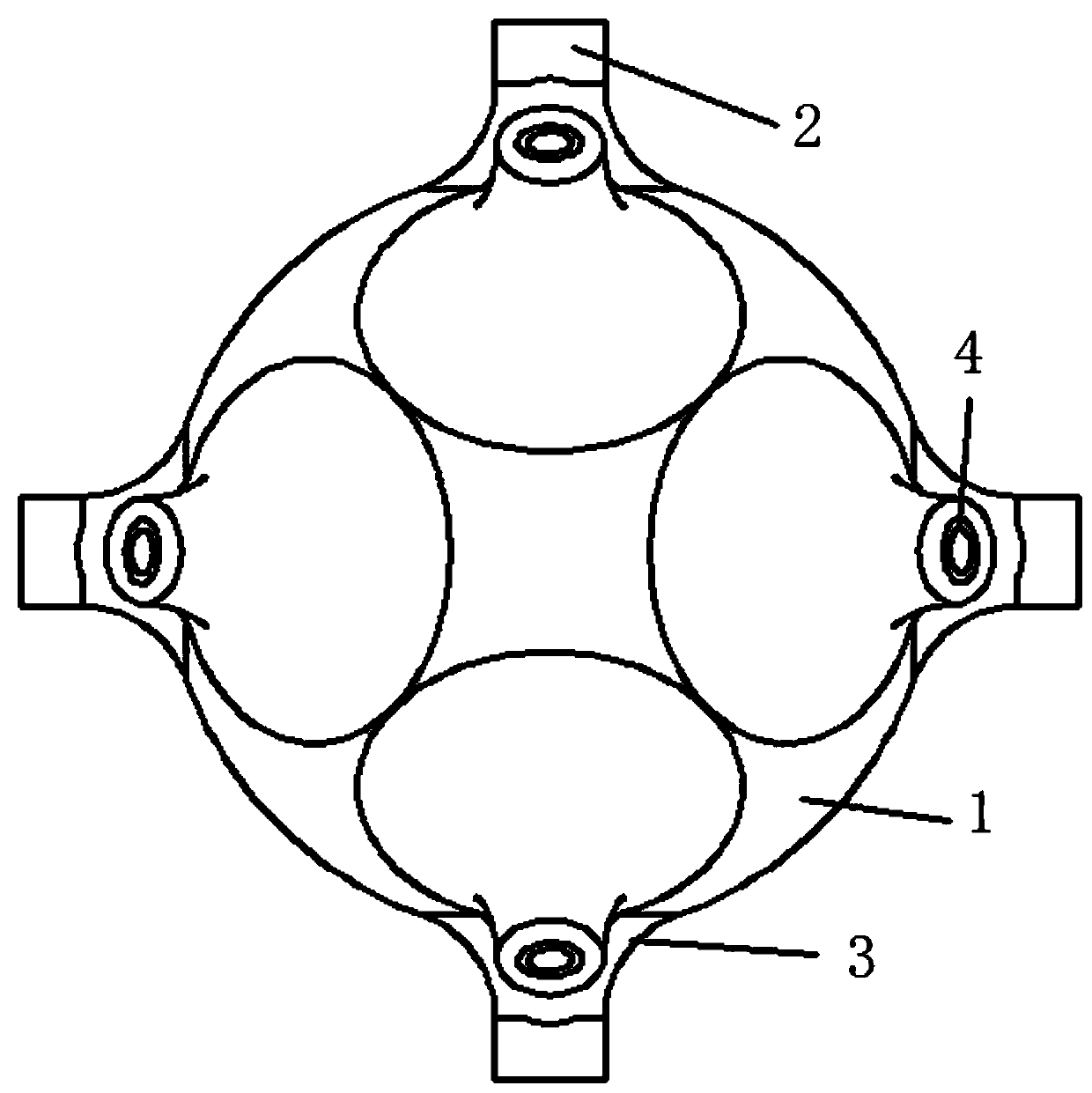

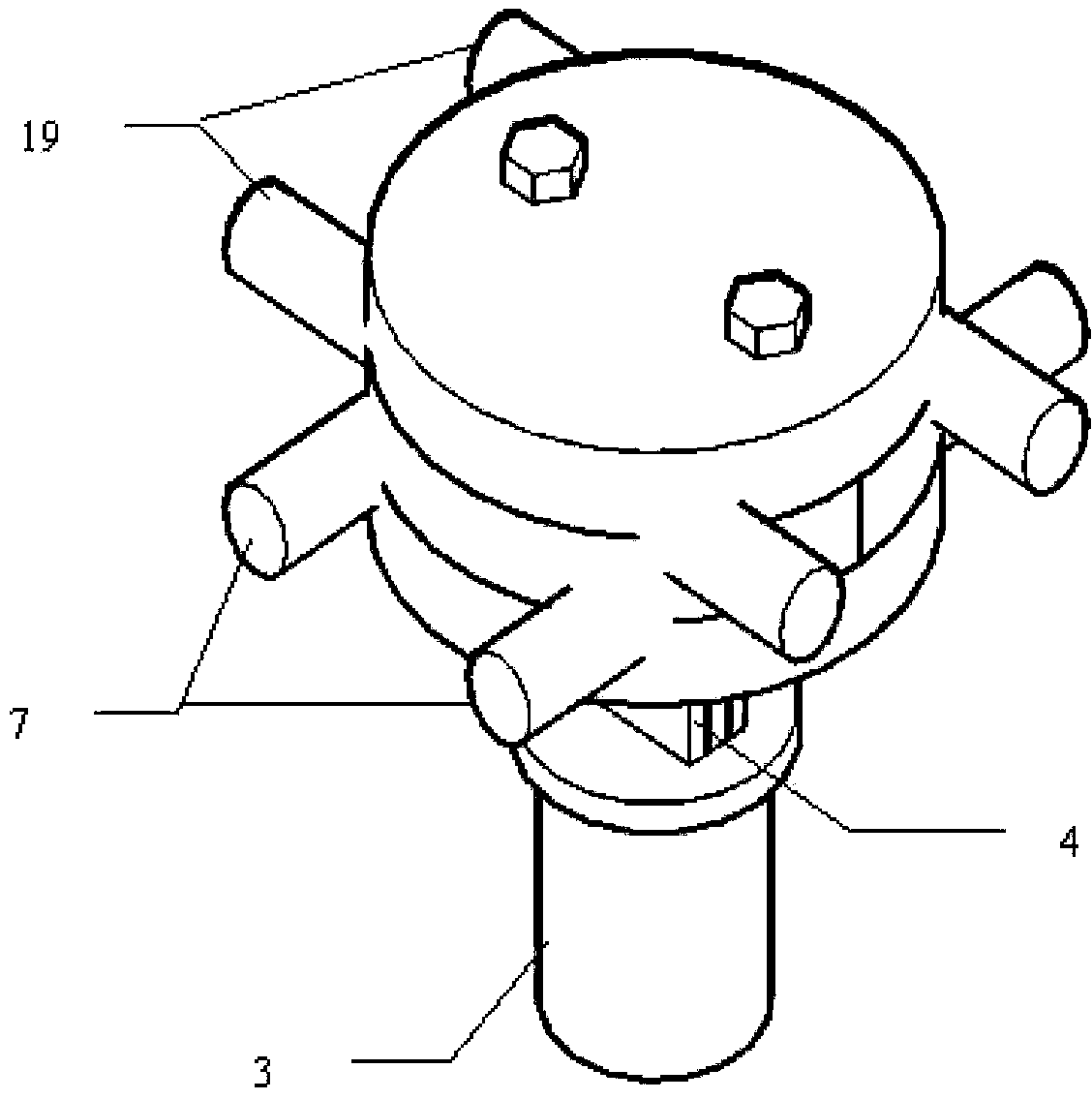

Novel bolt-ball joint and preparation method thereof

PendingCN107829494ALight weightImprove bearing capacityFoundry mouldsBuilding constructionsSolid structureSteel ball

The invention relates to a novel bolt-ball joint and a preparation method thereof, and belongs to the technical field of bolt-ball joint design. The novel bolt-ball joint comprises a steel ball and branch tubes, a cavity structure is arranged inside the steel ball, the branch tubes are arranged on the steel ball and used for connecting and bearing steel rods, the steel ball and the branch tubes are integrally formed, the steel ball is in the shape of a partially cut ball crown, the height of the ball crown is larger than the radius of the steel ball, the branch tubes with solid structures arearranged outwards along the normal direction of the steel ball and uniformly distributed along the circumferential direction of the steel ball, counter bored holes are formed in the branch tubes alongthe normal direction, fillet surfaces for smooth coherent transition of the adjacent branch tubes are arranged on the surface of the steel ball, the surface of the steel ball is in the shape of a curved surface calculated by topological optimization taking the number of the branch tubes, the positions of the branch tubes, the diameters of the branch tubes and the diameters of the counter bored holes as parameters, and the stress of the curved surface is matched with that of the borne steel rods. The bolt-ball is subjected to topological optimization analysis, so that the bolt-ball joint meetsbearing capability, the dead weight of the bolt-ball joint is greatly reduced, and service performance is improved.

Owner:HENAN UNIVERSITY

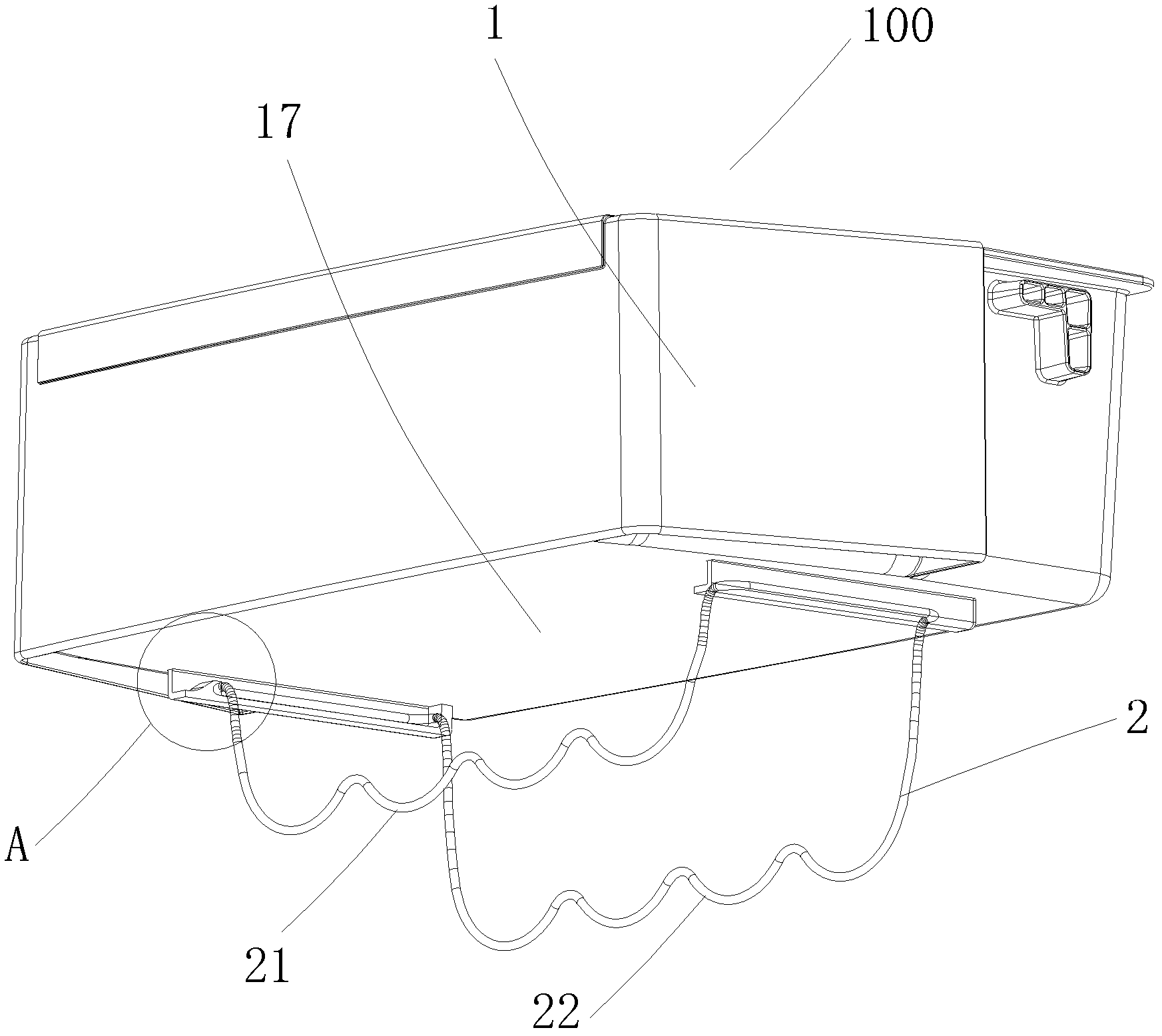

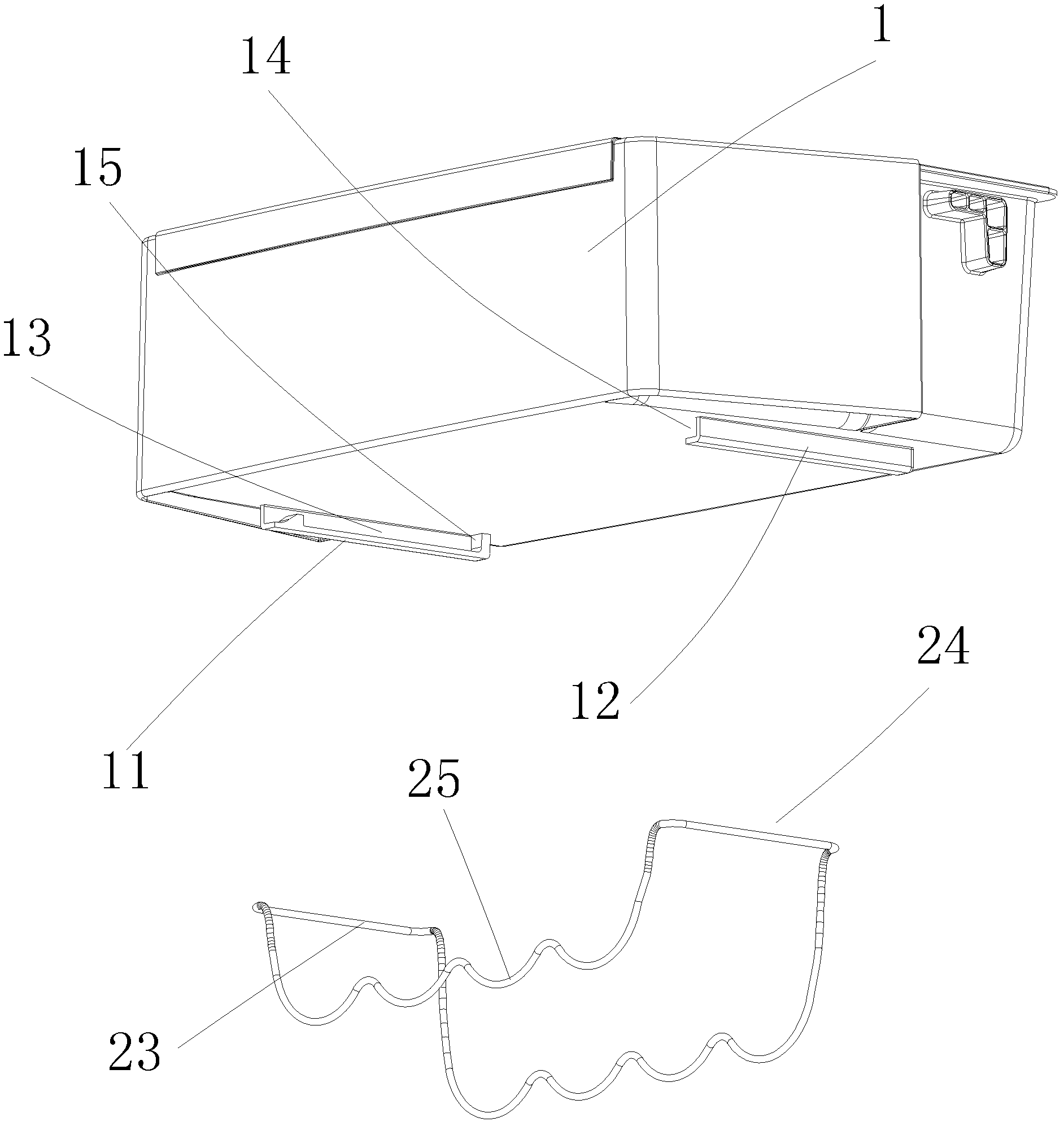

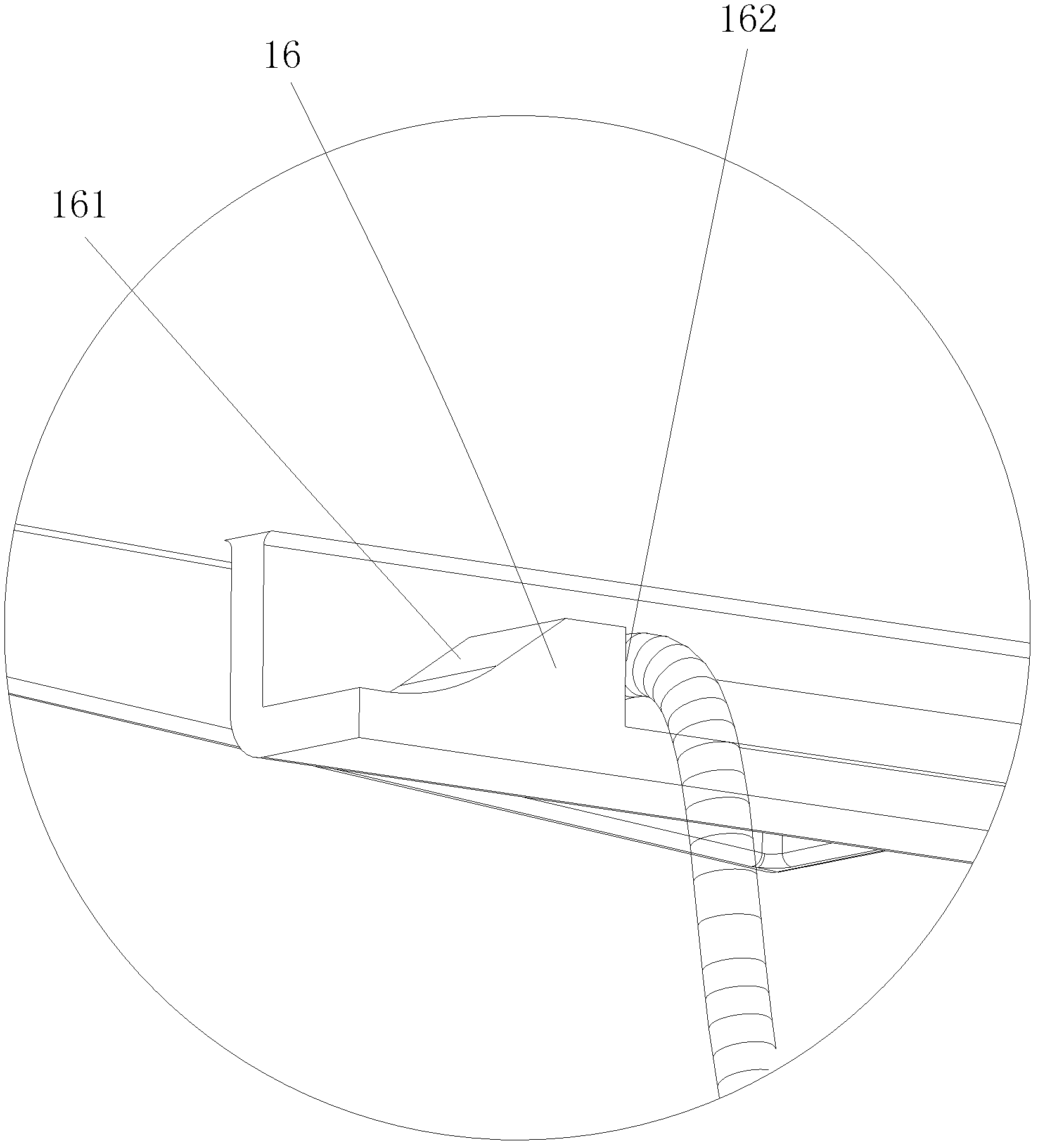

Bottle support and refrigerator provided with bottle support

ActiveCN102506556AMake full use of spaceEasy accessLighting and heating apparatusCooling fluid circulationEngineeringBottle

The invention provides a bottle support and a refrigerator provided with the bottle support. The bottle support includes a bottle support main body and a beverage holder, wherein the bottle support main body is provided with a space for accommodating articles; and the beverage holder is connected with the bottle support main body and arranged below the bottle support main body. Through the adoption of the bottom support, on one hand, as the added beverage holder can be used for holding bottles of bottled and tinned beverage, the bottle support is fixedly arranged, is convenient for a user to take down, and is not easy to fall off under external force as produced by opening / closing the refrigerator door body when the beverage holder is mounted on the refrigerator door body; and on the other hand, the space below the bottle support can be sufficiently utilized, and the bottle support becomes more practical.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

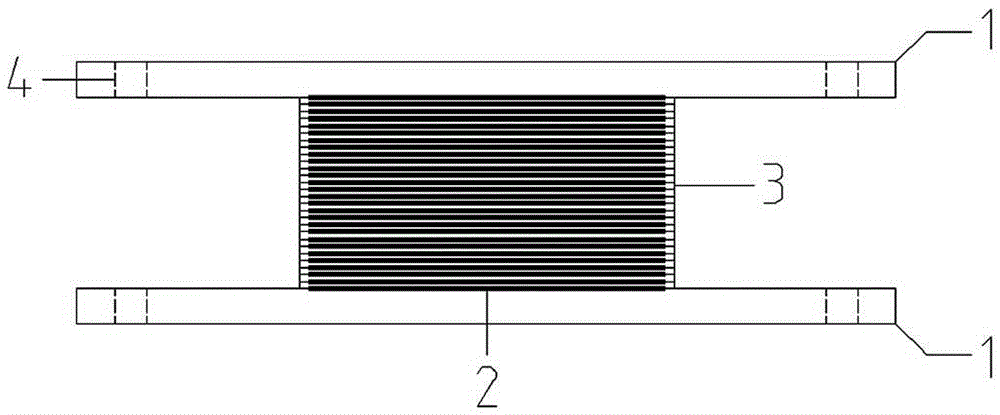

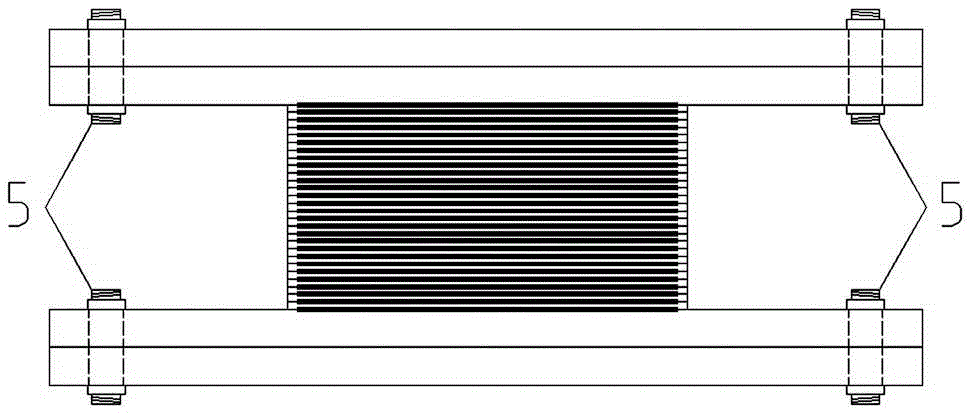

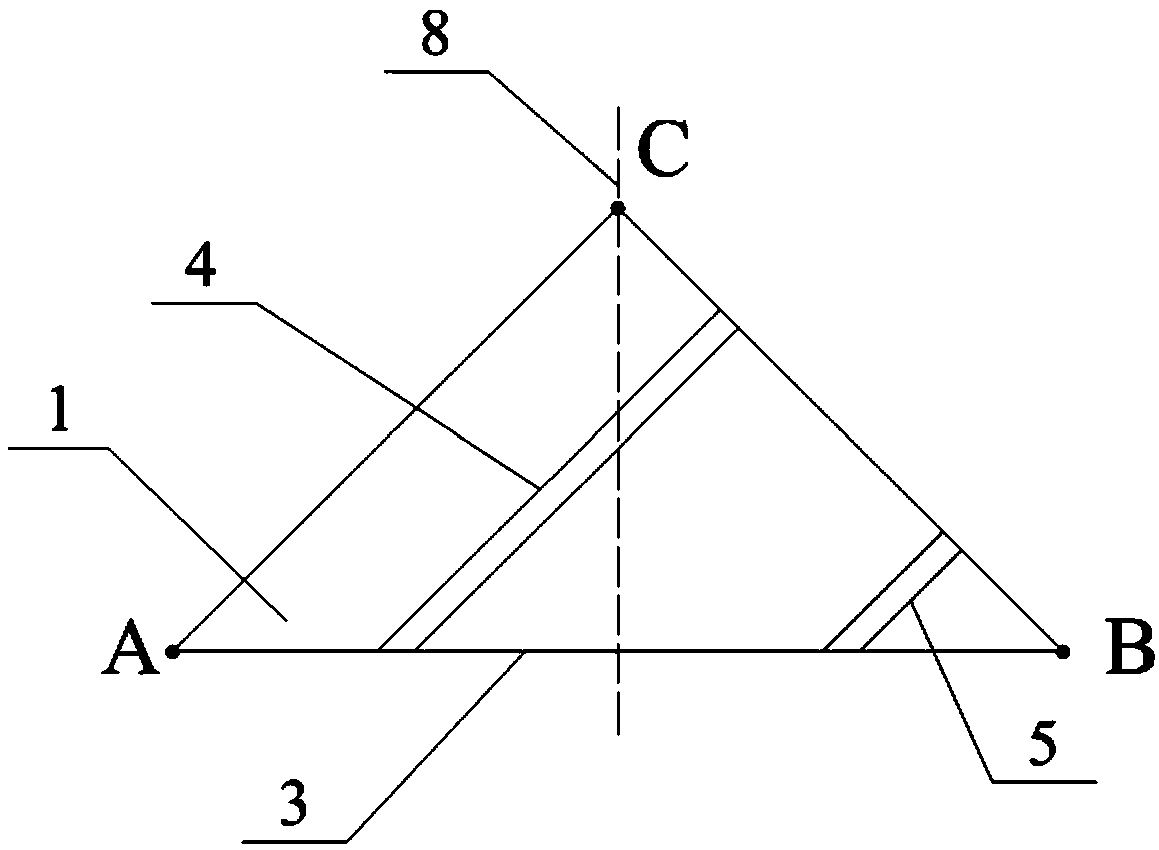

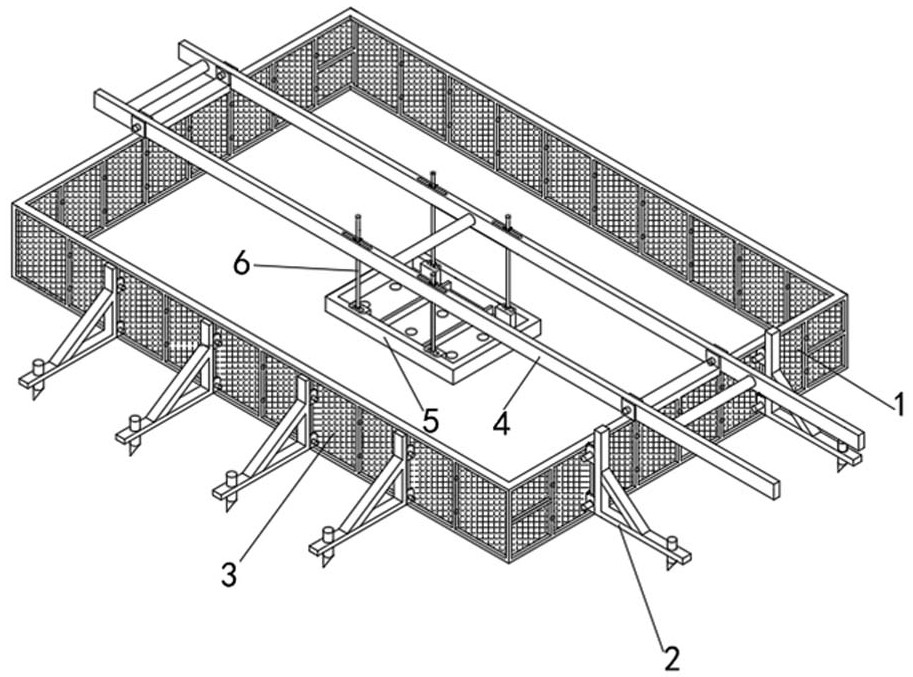

Method for assembling laminated steel-lead support adopting lead plates formed by in-situ pouring and cooling

InactiveCN105178465AIncrease vertical stiffnessSimple structureProtective buildings/sheltersShock proofingSteel platesSheet steel

The invention relates to a method for assembling a laminated steel-lead support adopting lead plates formed by in-situ pouring and cooling, and belongs to the technical field of seismic isolation. The laminated steel-lead support mainly comprises an upper cover plate, a lower cover plate, lead plates and thin steel plates, wherein the lead plates and the thin steel plates are stacked between the upper cover plate and the lower cover plate alternately. When the laminated steel-lead support is assembled, heated lead is poured in gaps among the thin steel plates, the upper cover plate and the lower cover plate after the thin steel plates are inserted in three enclosing plates through an assembly jig, and the cooled lead plates are correspondingly inlaid in first grooves and second grooves of the upper cover plate, the lower cover plate and the thin steel plates. In the method, the steel plates in the laminated lead plates provide a hooping effect for the lead plates so that the radial expansive deformation of the lead plates caused when the lead plates are pressed is limited, and meanwhile by virtue of the excellent plastic property of lead, high energy consumption is provided at the time of horizontal deformation. Horizontal large deformation can be realized easily by increasing the horizontal size and quantity of the laminated lead plates. After being assembled, the support has large vertical bearing capacity and vertical rigidity, and has stable energy consumption capacity and large deformation capacity in the horizontal direction.

Owner:BEIJING UNIV OF TECH

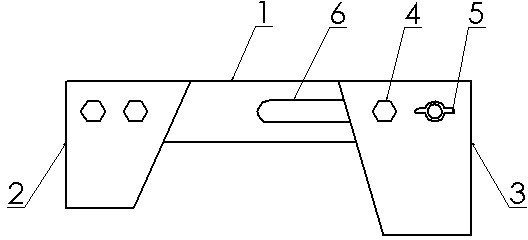

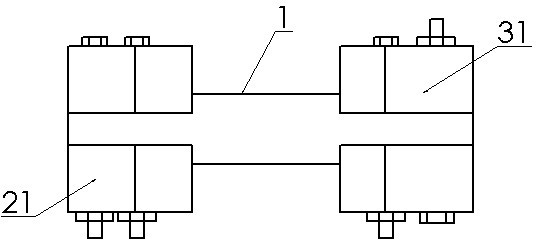

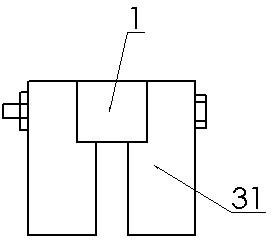

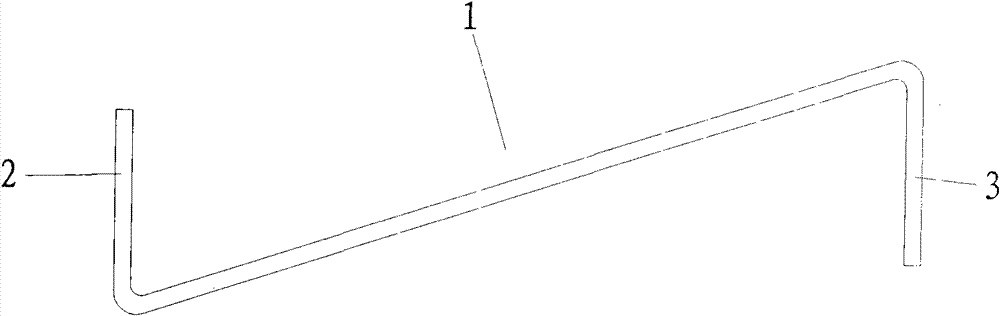

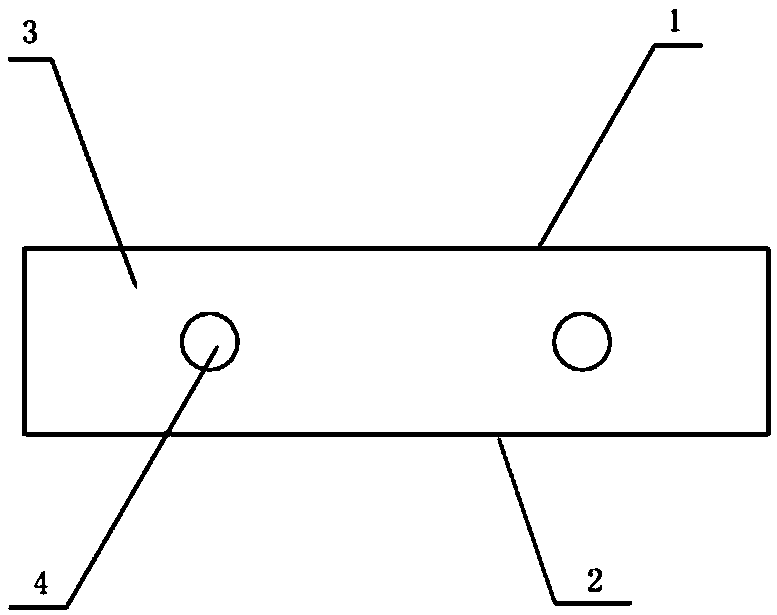

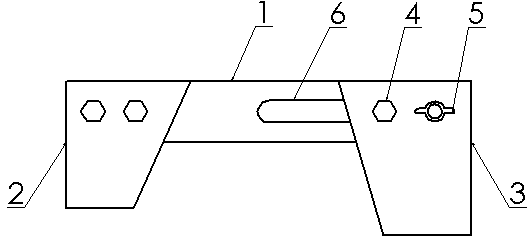

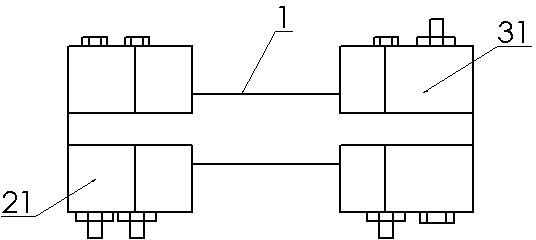

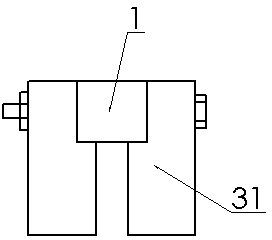

Anti-distortion device for bracing wire

The invention discloses an anti-distortion device for a bracing wire, comprising a supporting plate with a sliding chute at one end. One end of the supporting plate, which is provided with the sliding chute, is movably provided with a live splint for clamping the bracing wire, and the other end of the supporting plate is provided with a retaining clip. The retaining clip consists of two fixed clamping plates fixedly installed at two sides of the supporting plate. The live splint consists of two movable clamping plates installed at two sides of the sliding chute of the supporting plate, and the two movable clamping plates are connected and fixed by bolts passing through the sliding chute. The fixed clamping plates and the movable clamping plates are both in ladder shapes matched with the supporting plate and having two sections of different thickness. Nuts matched with the bolts are butterfly-shaped nuts. By adopting the anti-distortion device, distortion of the bracing wire is effectively avoided, and time and labor are saved. The anti-distortion device for the bracing wire has the advantages of simple structure, attractive shape, low cost, safety, convenience, convenient carrying and strong adaptability.

Owner:STATE GRID CORP OF CHINA +1

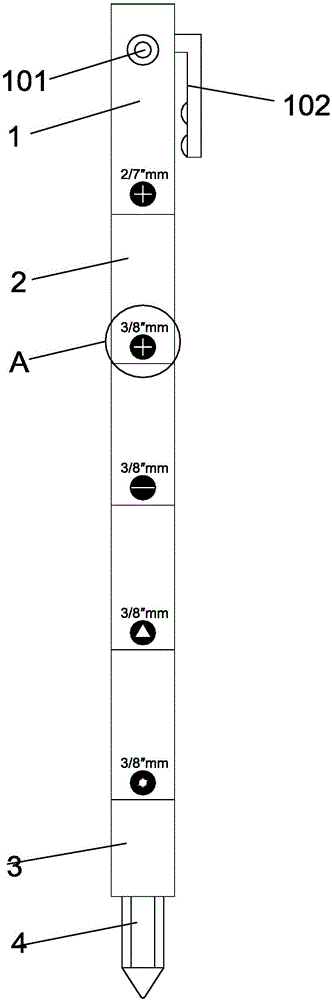

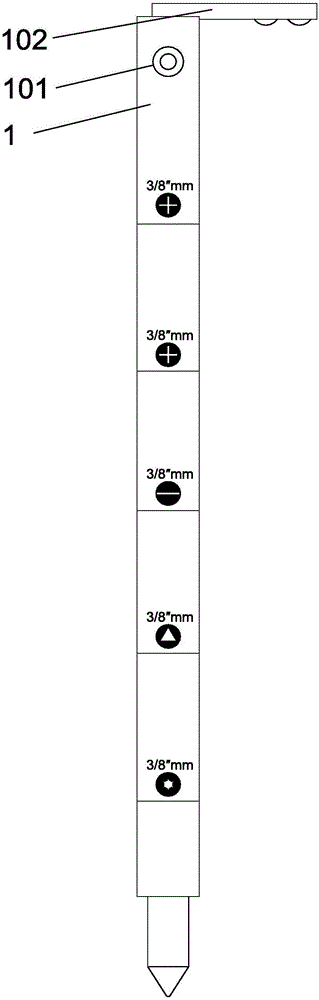

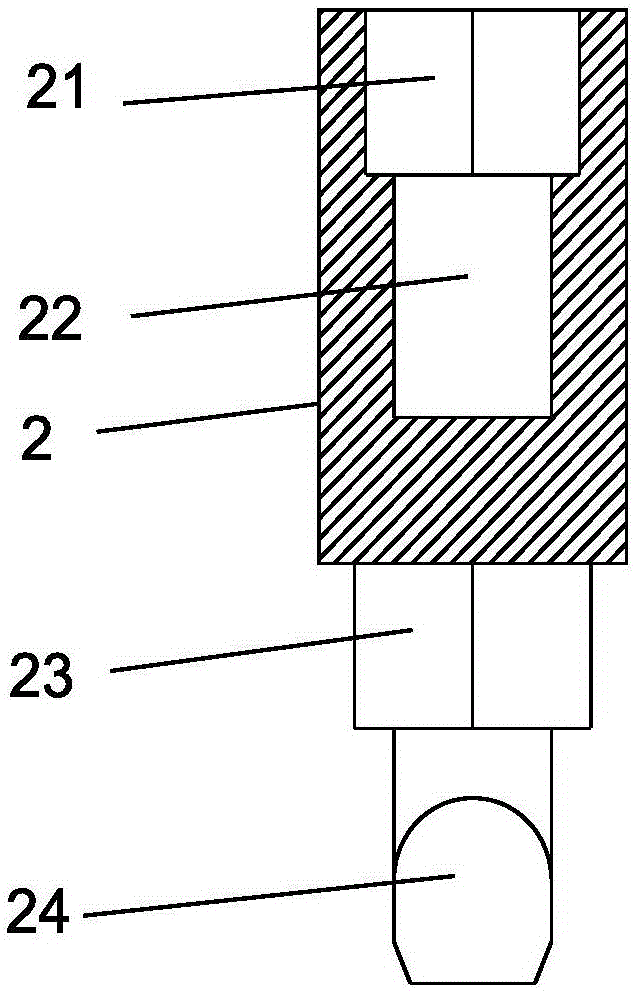

Portable combined screw driver

The invention discloses a portable combined screw driver. The screw driver comprises a handlebar head, a stick and a handlebar bottom. The handlebar bottom is provided with a screw pedestal. The bottom of the pedestal is provided fixedly with blades. The pedestal is a spring steel with square sections. The surface of the pedestal is covered with a layer of NdFeB magnetic iron powder. The top end of the stick is provided with a first empty cavity for containing the pedestal and a second empty cavity for containing the blades. The depth and the sectional shape of the first empty cavity are identical with the pedestal. The depth of the second empty cavity is roughly the same with the length of the blades. The top end of the handlebar bottom is also provided with a column shape empty cavity where a pencil is fixedly located. The screw driver achieves the random dismantling and assembling of different sticks, and directly uses the sticks to form an integral handlebar. The screw driver has the advantages of being small in size, being an eye-candy, easy to carry, and not prone to the blade losses.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

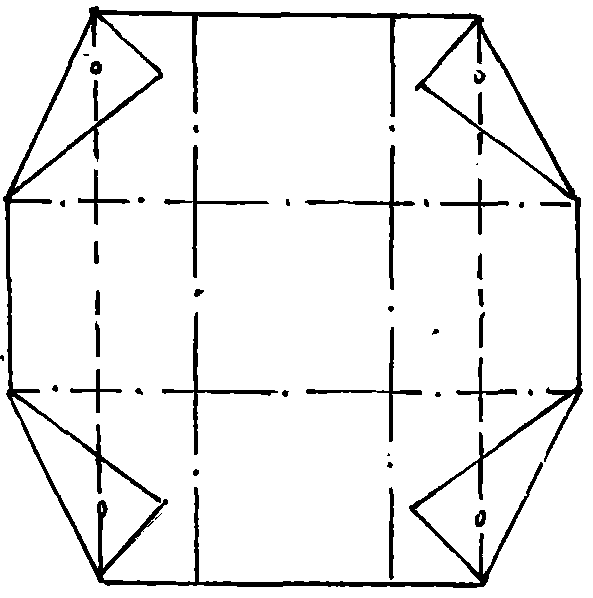

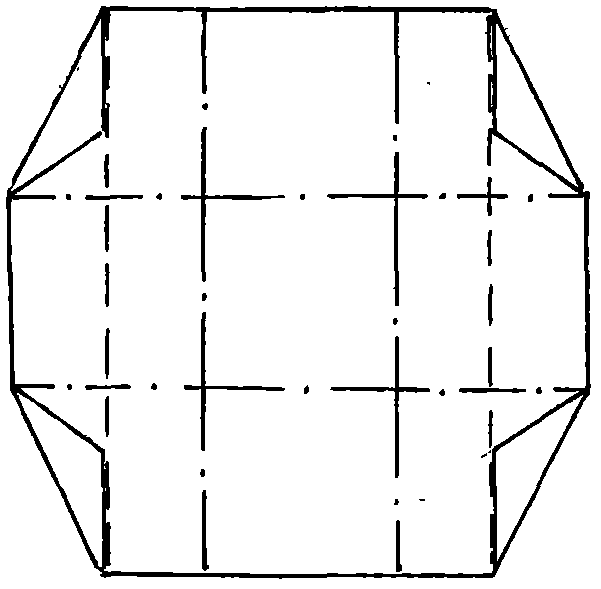

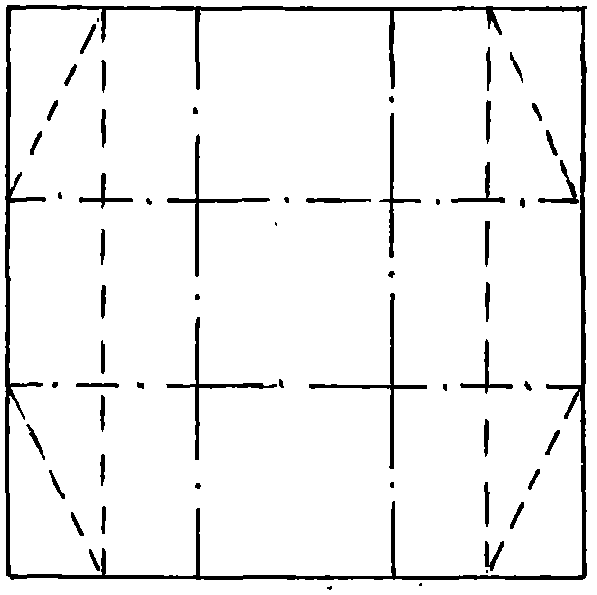

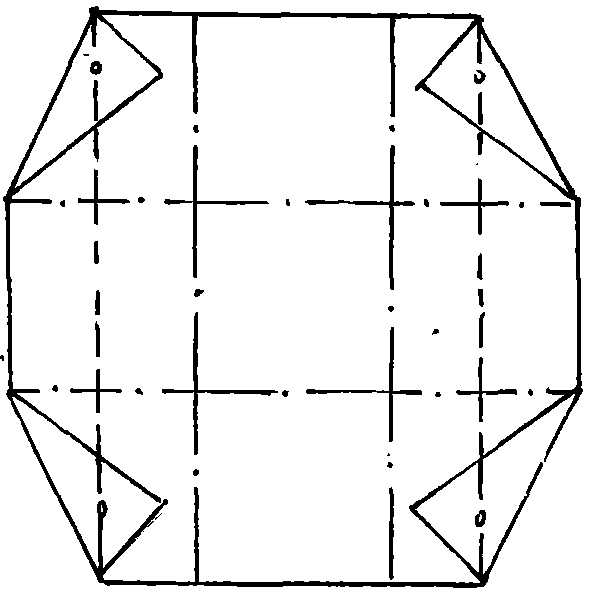

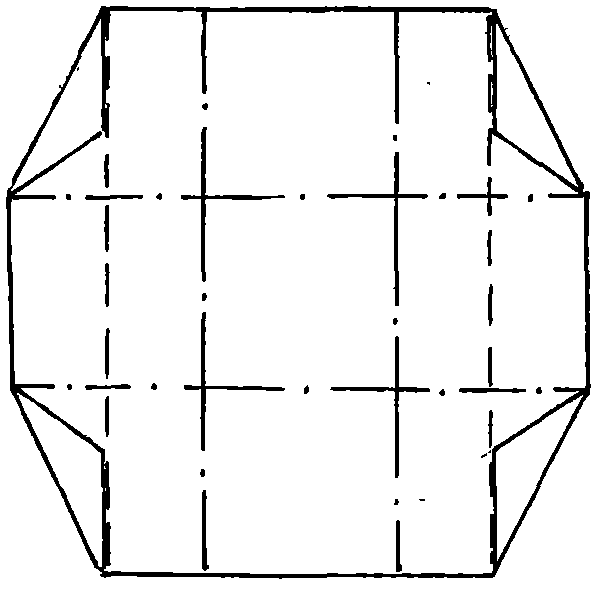

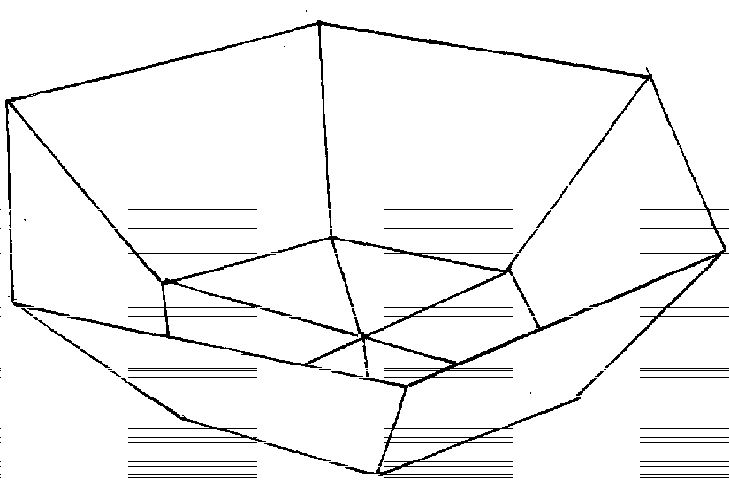

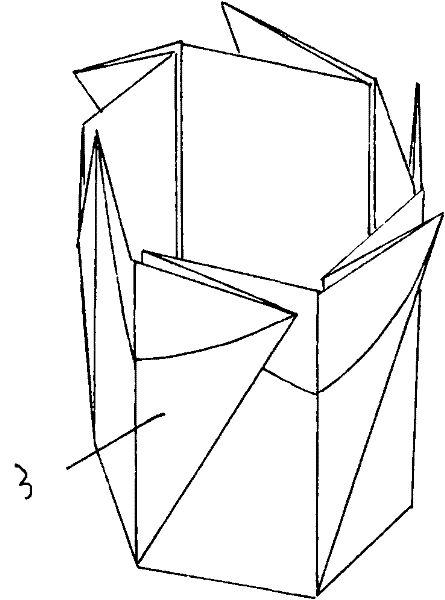

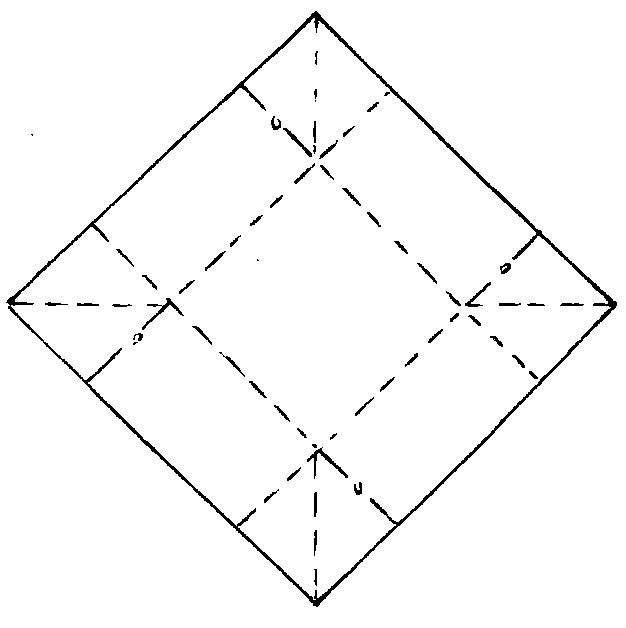

Framework three-dimensional shape

InactiveCN104647808AEasy to combineEasy to plug inPaper/cardboard articlesPolygonal lineThree dimensional shape

The invention provides a framework three-dimensional shape, and relates to a geometry manufacturing method. The framework three-dimensional shape is formed by combining six identical components; first square paper and second square paper are taken, and are stacked for forming a regular octagon shape; four corners of the first square paper are folded and pasted, and an overlapped square is formed; four long reverse fold lines are made and are crossed, and a small square is formed in the middle part; the edge length of the small square is 1 / 5 of the edge length of the first square paper; the folding for 90 degrees is carried out according to the long reverse fold lines; the folding for 90 degrees is carried out according to the positive fold lines of the vertical lines; a paper corner part of the second square paper is an inserting part; a connecting part of the inserting part and the second square paper is an inserted opening; the inserting part of the first component is inserted into the inserted opening of the second component, and three components are inserted and connected to form a triangular framework; through the inserting connection in such a way, the six components are inserted and connected to form the framework three-dimensional shape with eight connected triangular frameworks. The design is ingenious, the component combination is simple, the inserting connection between the components is easy, the geometrical stereoscopic sensation of the modeling is obvious, and the form is attractive.

Owner:李平

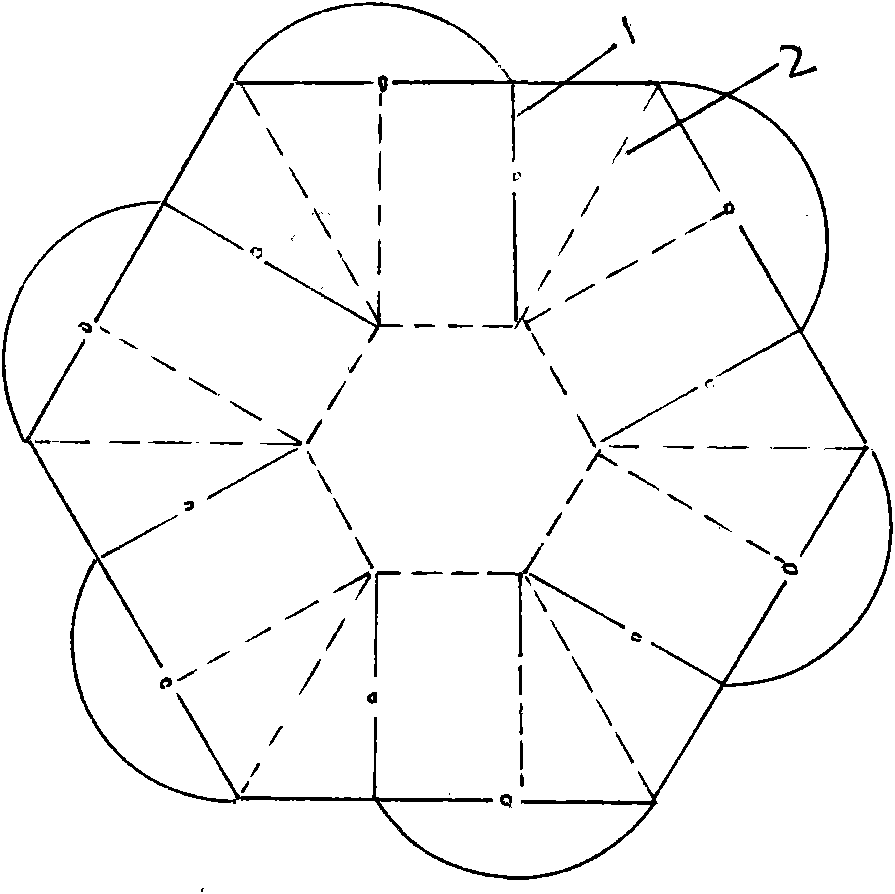

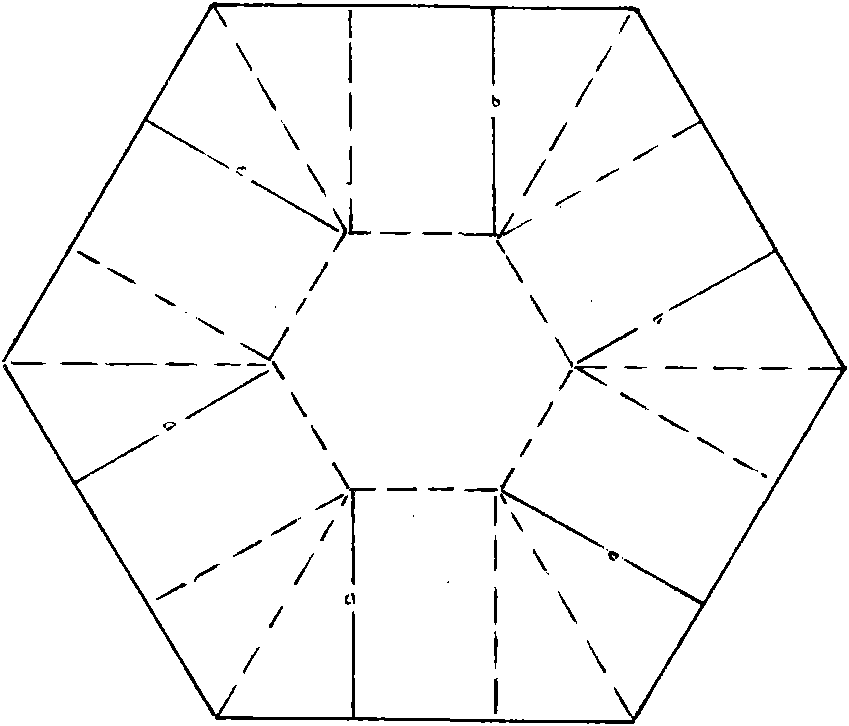

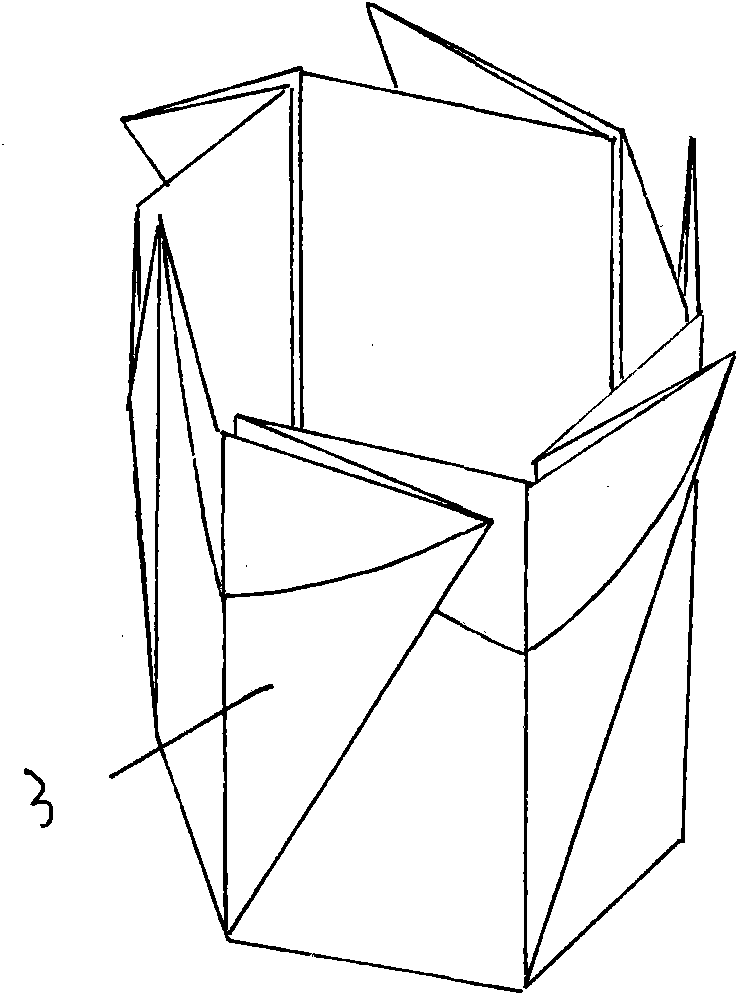

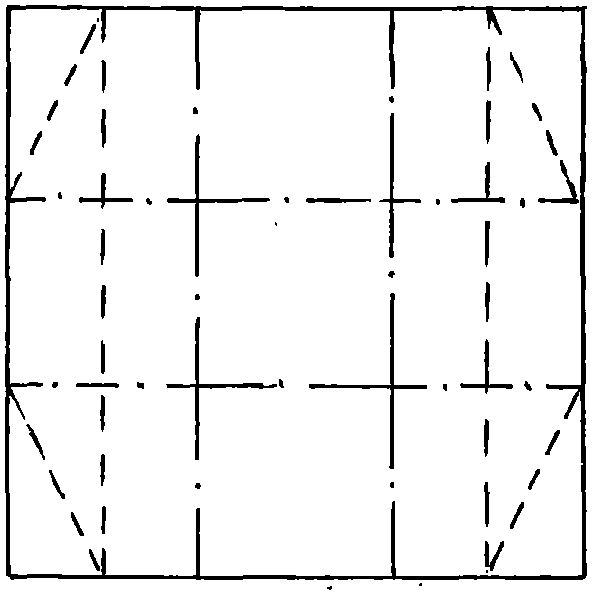

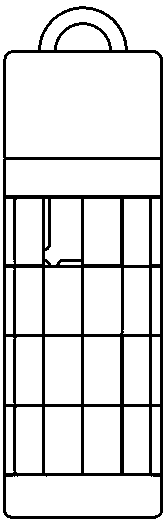

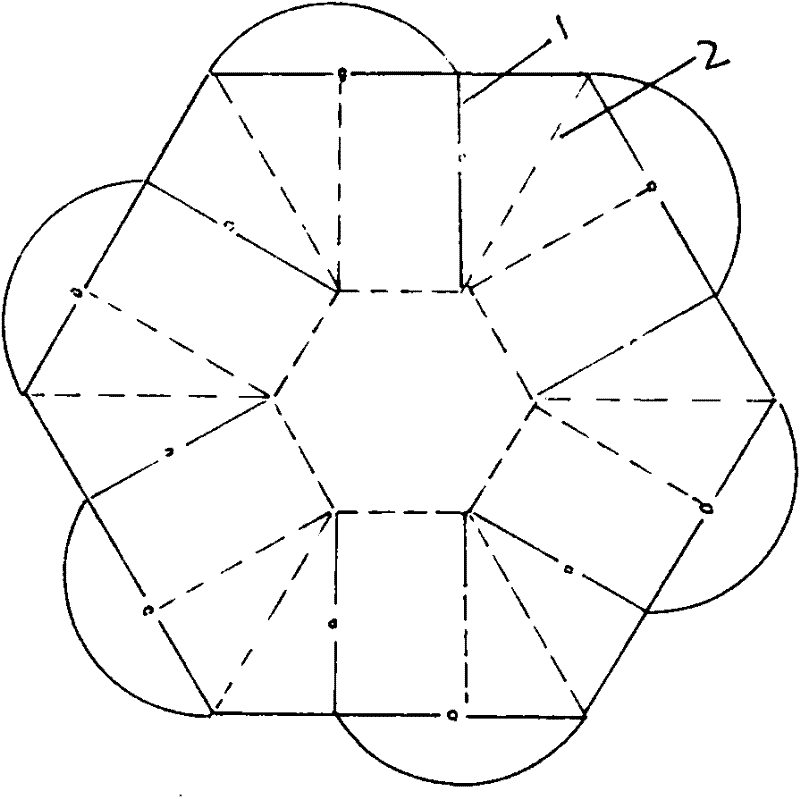

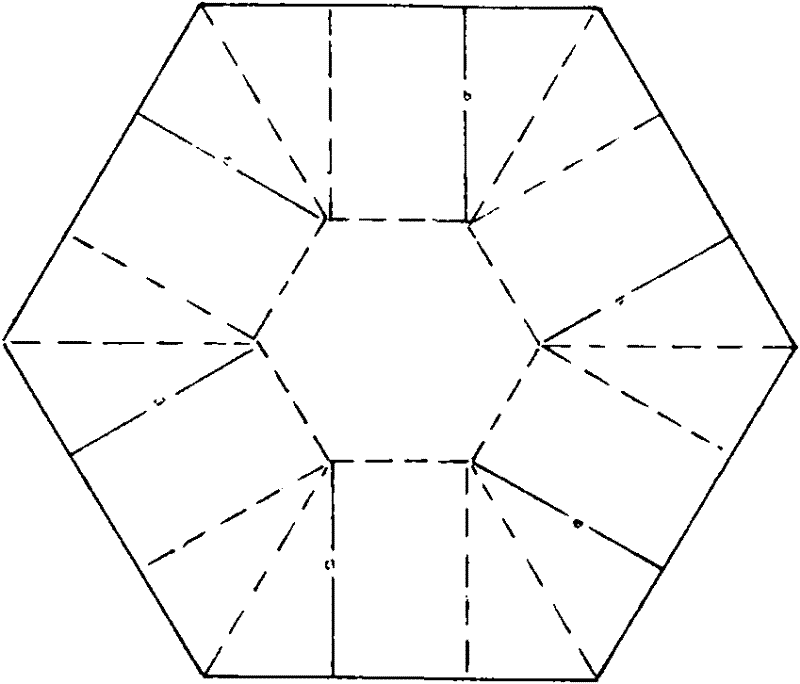

Paper tube

The invention discloses a paper tube. A big regular hexagon is drawn on a piece of paper and a small regular hexagon is drawn in the middle of the big regular hexagon; the corresponding edges of the big and small regular hexagons are parallel; the edge length of the big regular hexagon is three times that of the small regular hexagon; 12 vertical lines 1 are drawn from the angles of the small regular hexagon to the nearest edges of the big regular hexagon; 6 connecting lines 2 are drawn from the angles of the small regular hexagon to the nearest angles of the big regular hexagon; 6 arc lines are drawn outside the big regular hexagon by using the total of each middle section of the big regular hexagon and a section in an anticlockwise direction as a chord length, and the chord height is one third of the length of the vertical lines 1; 6 arcs are folded to form a regular hexagon; a cylindrical base shape is formed by folding along the folding lines, and the folded triangular parts 4 are attached onto the outside of a cylinder; and folded triangular parts 3 are inserted into the arcs which are attached onto the outside of the cylinder, and the paper tube is formed. In the invention, only folding rather than adhering by an adhesive and binding is performed, so the manufacturing is simple; the inserted connection is tight and firm; the shape is unique and elegant; and both ornamental and practice value are achieved.

Owner:李平

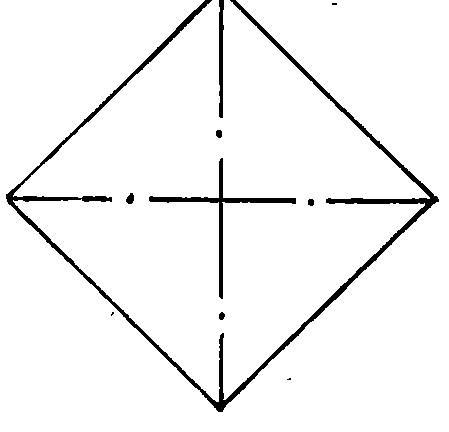

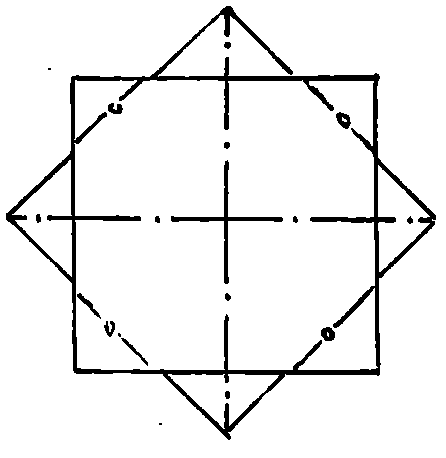

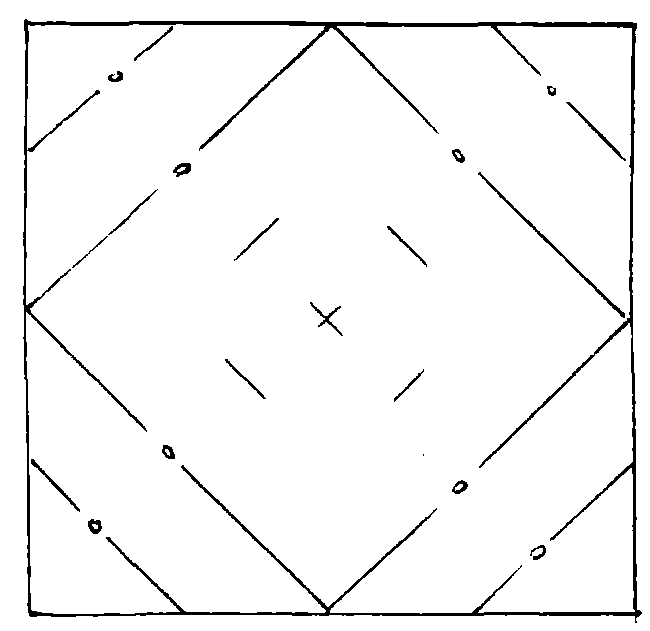

Method for making square box

InactiveCN104787419AInnovative designEasy to manufactureRigid containersIsosceles trapezoidSurface layer

The invention provides a method for making a square box and relates to paper box making methods. A piece of square paper is gotten, and two transverse indicative lines and two longitudinal indicative lines are made; first paper corner triangles, second paper corner triangles and isosceles trapezoids are folded, and the square paper becomes a longitudinal rectangle; the longitudinal rectangle is turned over by 180 degrees to form a turned longitudinal rectangle, oblique line positive broken lines are made, folding is conducted, and the turned longitudinal rectangle becomes a hexagon composed of an upper right trapezoid and a lower right trapezoid which share the same lower bottom; folding and attaching are conducted according to overlapping transverse positive broken lines, short positive broken lines, short negative broken lines and intersection positive broken lines, and meanwhile folded portions are folded into interlayer openings, so that a double-trapezoid hexagon composed of two isosceles trapezoids sharing the same lower bottom is formed; the surface layer is propped open from inside to outside at the lower bottom of the trapezoids of the double-trapezoid hexagon, 90-degree folding is conducted according to connecting line negative broken lines, the lateral sides of the isosceles trapezoids are unfolded into planes accordingly, and therefore the square box is obtained. The square box is novel in design, easy to make, simple in model, firm, stiff, attractive in appearance, and practical.

Owner:王金花

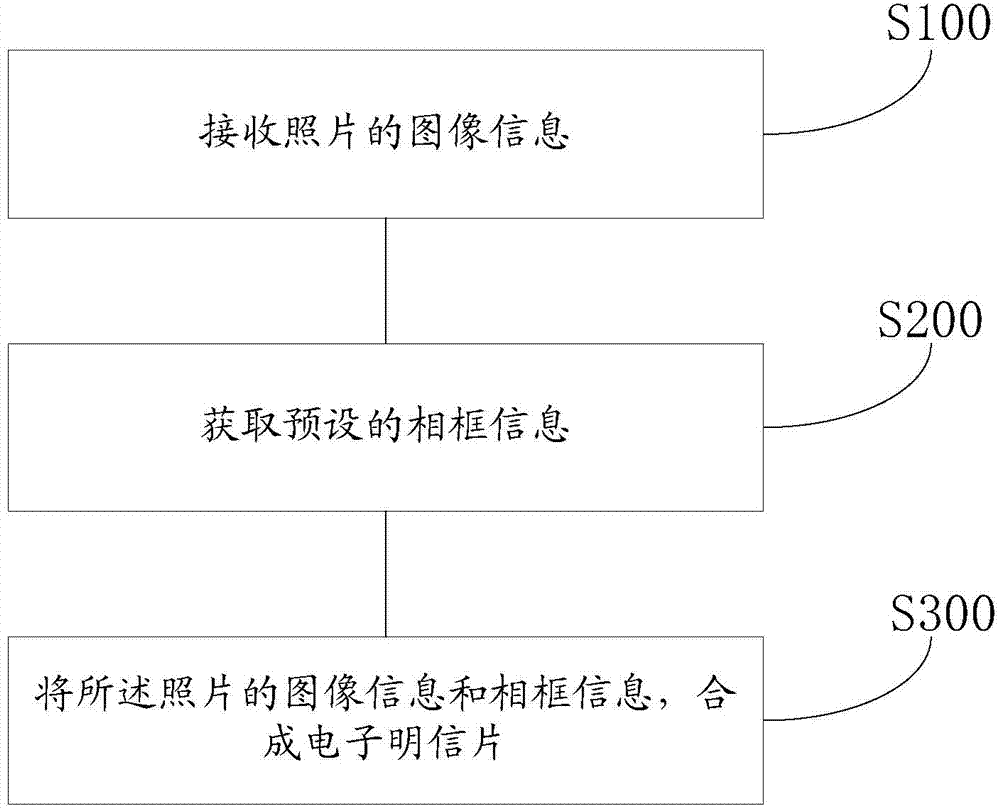

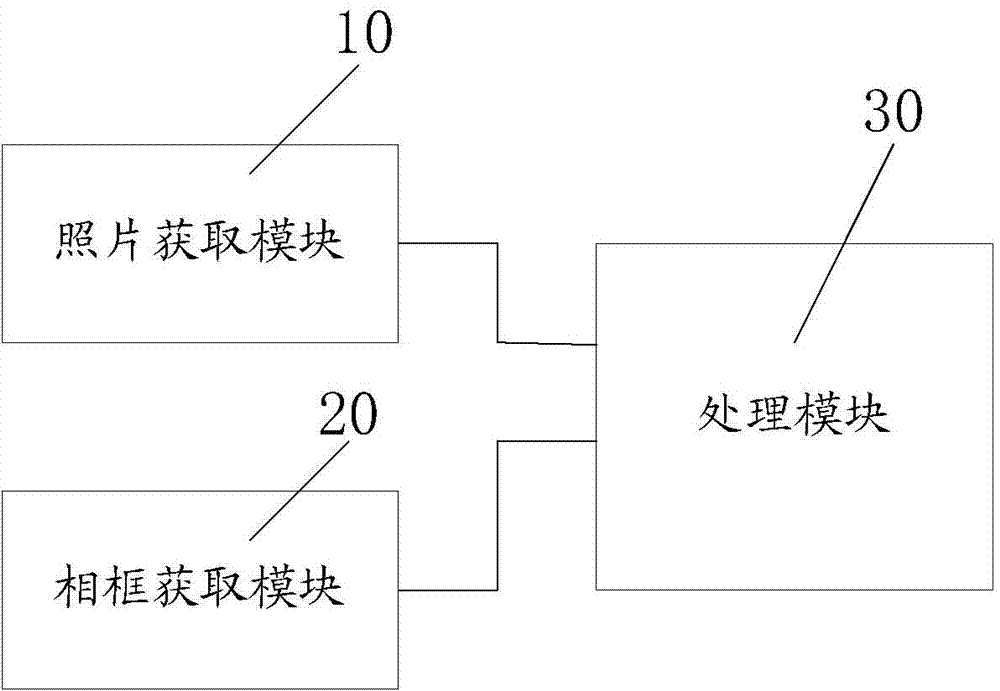

Method and device for generating electronic postcard

InactiveCN104504741AEasy and fast format generationIncrease content2D-image generationComputer visionElectronic information

The invention discloses a method for generating an electronic postcard. The method is used for enriching contents transmitted by electronic information and comprises the steps: receiving image information of a photo; acquiring preset photo frame information; forming the electronic postcard according to the image information of the photo and the photo frame information. The invention further discloses a device for generating the electronic postcard. According to the method and the device which are disclosed by the invention, the photo frames with various formats are provided for the image information by acquiring the image information in real time, so that the format of the electronic postcard can be generated more simply and quickly, the contents are richer, and the form is more attractive; the electronic information sent on the network is enriched, and communication contents among people are richer.

Owner:TVM BEIJING TECH

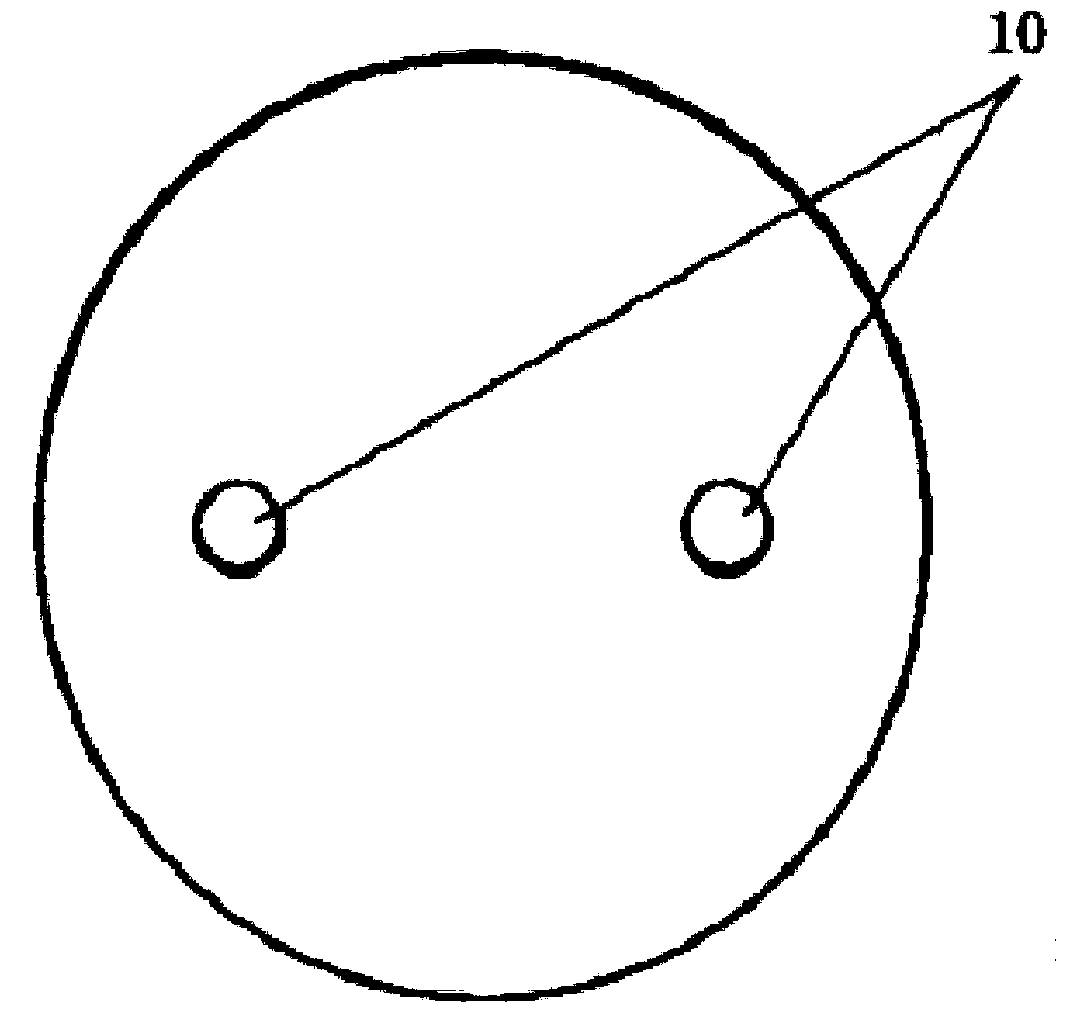

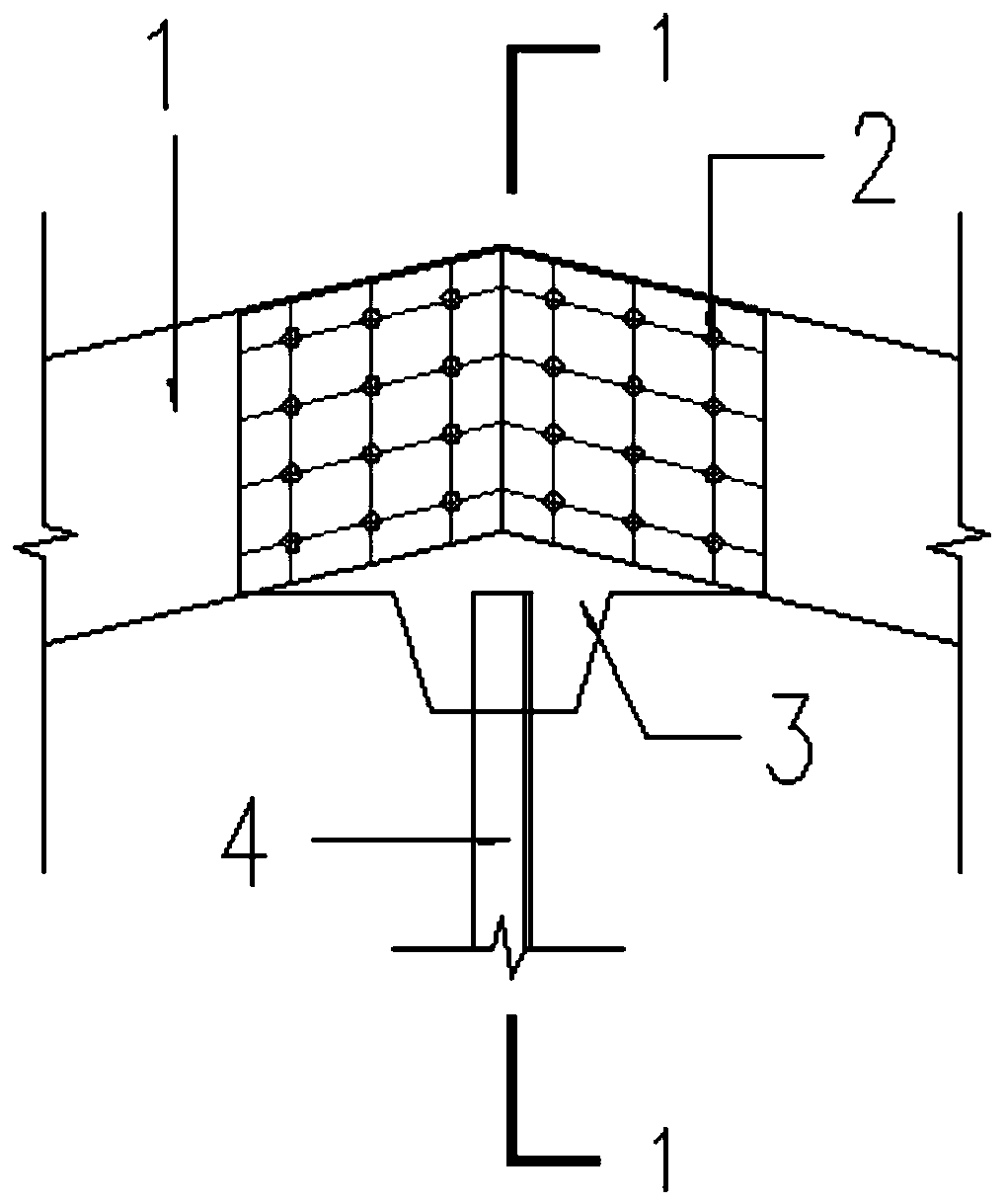

Angle-adjustable bi-direction cable rod panel point

The invention relates to an angle-adjustable bi-direction cable rod panel point. The angle-adjustable bi-direction cable rod panel point plays a role of connection at an intersection position of inhaul cables at two directions, and can be adjusted to meet requirements for forming any angle of the inhaul cables at the two directions. The panel point comprises four layers of circular clamping plates, bolts, lug plates and rigid support rods. The clamping plates are designed into a circular shape so that the cable rod panel point can keep beauty when the clamping plates rotate a certain angle. The clamping plates comprises four layers, the lug plates are placed on a first layer of clamping plates, the first layer of clamping plates are connected with the rigid support rod through bolts, an inner layer of cable is clamped by the first layer of clamping plates and a second layer of clamping plates through bolts, and an outer layer of cable is clamped by a third layer of clamping plates and a fourth layer of clamping plates through bolts. A toothed circular groove is formed in the second layer of clamping plate, a toothed protrusion is placed on the third layer of clamping plates, and the toothed protrusion can be embedded in the toothed circular groove so as to play a role of adjusting angles and uplifting the panel point. The angle-adjustable bi-direction cable rod panel point is reasonable in load carrying capability, easy to manufacture, convenient to install and attractive in form. The inhaul cables at the two directions are allowed to form any angles to meet scheme requirements of suspension structures with various forms, and the angle-adjustable bi-direction cable rod panel point has high practical value.

Owner:BEIJING UNIV OF TECH

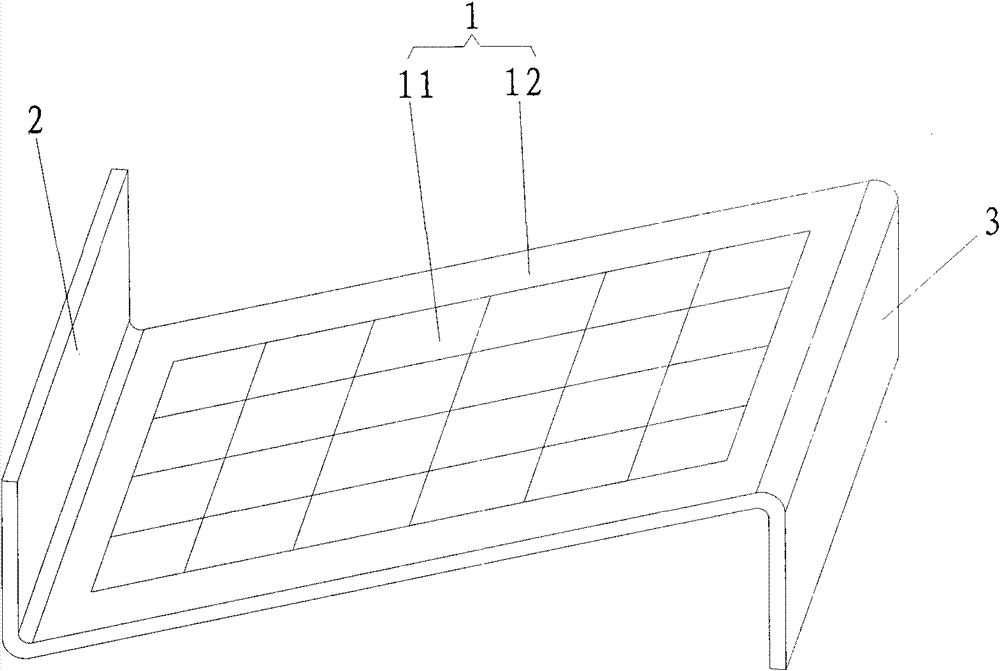

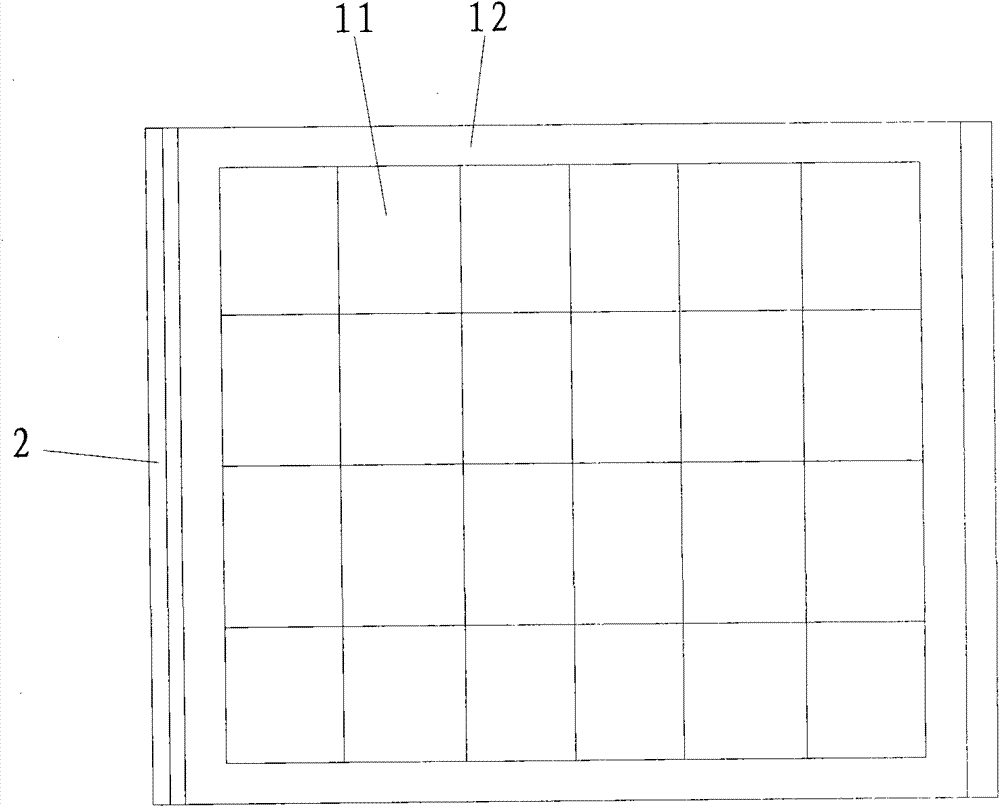

Wind structure of solar photovoltaic panel

ActiveCN101888198BChange the airflow fieldEnsure safetyPhotovoltaicsPhotovoltaic energy generationEngineeringJet stream

Owner:HUAQIAO UNIVERSITY

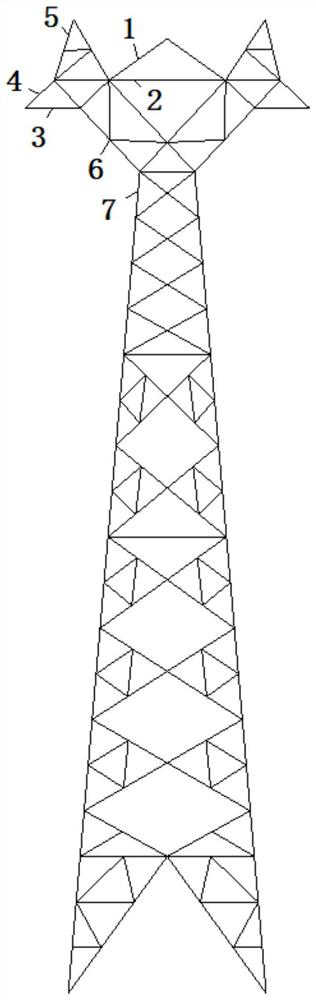

110 kV cathead type composite cross arm tower

PendingCN111852155ASimplify the superstructureShout downTowersPower transmissionMechanical engineering

The invention discloses a 110 kV cathead type composite cross arm tower comprising a set of middle-phase composite cross arms, two sets of edge-phase composite cross arms, tower window support arms, two sets of steel ground wire supports and an angle steel tower body. Specifically, the middle-phase composite cross arms are fixed to the inner sides of the two tower window support arms through towerframe end connection pieces, the edge-phase composite cross arms are arranged on the outer sides of the two tower window support arms, and the ground wire supports are fixed to the upper sides of thetwo tower window support arms. Except the middle-phase and edge-phase composite cross arm structures, all the other structures are angle steel or steel connection pieces. On the basis of a traditional angle steel power transmission tower, the main body form of the tower body is not changed, and the upper structure of a tower head is improved. The specific performance is that original angle steelcross arms are replaced with the FRP composite cross arms, the tower head is improved according to unique insulation characteristics of the composite cross arms, the rigidity deficiency of materials is made up through structure design, and the composite cross arms and the angle steel tower main body are combined reasonably.

Owner:ECONOMIC RES INST OF STATE GRID GANSU ELECTRIC POWER +2

A stainless steel lamp post system and its manufacturing method

ActiveCN108105653BBeautiful formEasy to choose sizeLight fasteningsFixed installationEngineeringMaterials science

The invention provides a stainless steel lamp pole system and a manufacturing method thereof. The stainless steel lamp pole system comprises a lamp pole body, lamp pole cover plates and a lamp pole bottom plate, wherein the lamp pole body is integrally in a long-strip shape, the cross section of the lamp pole body is in a U shape, an opening of the U-shaped part is bent inwards so that mounting sheets can be formed, the lamp pole cover plates cover the upper end and the lower end of the lamp pole body and are provided with lamp mounting holes for installing a spotlight, and the lam pole bottomplate is provided with an interlocking insertion structure. According to the stainless steel lamp pole system and the manufacturing method thereof, by arranging the lamp pole body, the lamp pole cover plates and the lamp pole bottom plate, the lamp pole is more attractive, and the size is easily selected in the manufacturing process.

Owner:中建八局装饰工程有限公司

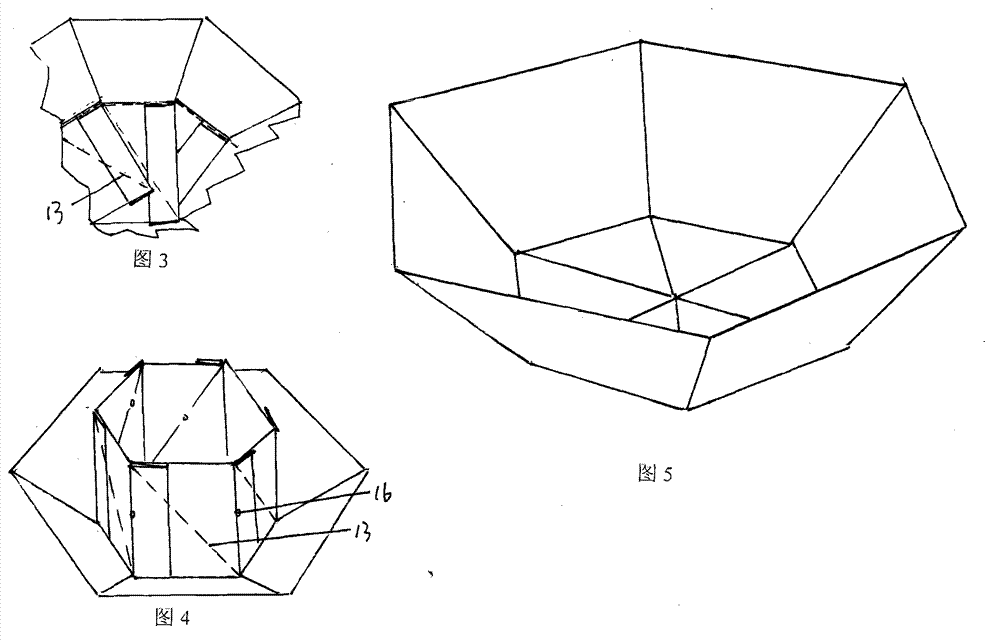

Folding method of hexagonal paper bowl

InactiveCN103086035AControllable tilt angleMaking rulesRigid containersPolygonal linePulp and paper industry

Owner:肖艳光

Cup with jigsaw slide blocks

InactiveCN108433483AHelp intellectual developmentBeautiful formDrinking vesselsEngineeringMechanical engineering

Owner:MAANSHAN XIANGYU MACHINERY AUTOMATION SCI & TECH

The practice of square box

InactiveCN104787419BInnovative designEasy to manufactureRigid containersIsosceles trapezoidPolygonal line

A method for making a square box relates to a method for making a paper box. The method comprises: obtaining a piece of square paper, and making two horizontal indicative lines and two vertical indicative lines on the piece of square paper; folding a first paper corner into a triangle, folding a second paper corner into a triangle, and folding an isosceles trapezoid, resulting in the square paper folded into a vertical rectangle; turning over the vertical square by 180 degrees to form a turnover vertical rectangle, making a valley fold along a diagonal fold line on the turnover vertical rectangle to make a hexagon having an upper and an lower right trapezoids sharing a lower bottom; folding according to an overlapping horizontal valley-folding line, a short valley-folding line, a short mountain-folding line and an intersection valley-folding line, and folding and tucking a folded part into an opening of a pocket to form a double-trapezoid hexagon having two isosceles trapezoids sharing a lower bottom; at the lower bottom of the double-trapezoid hexagon, opening up a surface layer from inside to outside, and making a mountain fold by 90 degrees according to a connection line, such that legs of the isosceles trapezoid are opened up as a plane, thereby forming the square box. The design is novel, simple to produce, simple in structure, solid in construction, and aesthetic and practical.

Owner:王金花

Folding method of hexagonal paper bowl

InactiveCN103086035BControllable tilt angleMaking rulesRigid containersPulp and paper industryOblique angle

Owner:肖艳光

Diagonal tensile protection slope

The invention relates to a diagonal tensile protection slope. In order to solve the problem that an existing protection slope has higher requirements for the production processing and transportation process, has a single formation mode, and difficultly adapts to diversified demands of the environment, the diagonal tensile protection slope is proposed. The diagonal tensile protection slope comprises multiple building block units and multiple ropes, each building block unit is composed of at least one building block, the ropes connect the building block units into protection slope columns, and the protection slope columns are distributed in sequence to form the protection slope. The diagonal tensile protection slope is applied to soil prevention and sand fixation of river embankments. The diagonal tensile protection slope has the advantages that the structure is simple, the placement is simple, easy, convenient and efficient, and the application is wide.

Owner:西安景兴祥环境科技有限公司

Paper tube

The invention discloses a paper tube. A big regular hexagon is drawn on a piece of paper and a small regular hexagon is drawn in the middle of the big regular hexagon; the corresponding edges of the big and small regular hexagons are parallel; the edge length of the big regular hexagon is three times that of the small regular hexagon; 12 vertical lines 1 are drawn from the angles of the small regular hexagon to the nearest edges of the big regular hexagon; 6 connecting lines 2 are drawn from the angles of the small regular hexagon to the nearest angles of the big regular hexagon; 6 arc lines are drawn outside the big regular hexagon by using the total of each middle section of the big regular hexagon and a section in an anticlockwise direction as a chord length, and the chord height is one third of the length of the vertical lines 1; 6 arcs are folded to form a regular hexagon; a cylindrical base shape is formed by folding along the folding lines, and the folded triangular parts 4 areattached onto the outside of a cylinder; and folded triangular parts 3 are inserted into the arcs which are attached onto the outside of the cylinder, and the paper tube is formed. In the invention, only folding rather than adhering by an adhesive and binding is performed, so the manufacturing is simple; the inserted connection is tight and firm; the shape is unique and elegant; and both ornamental and practice value are achieved.

Owner:李平

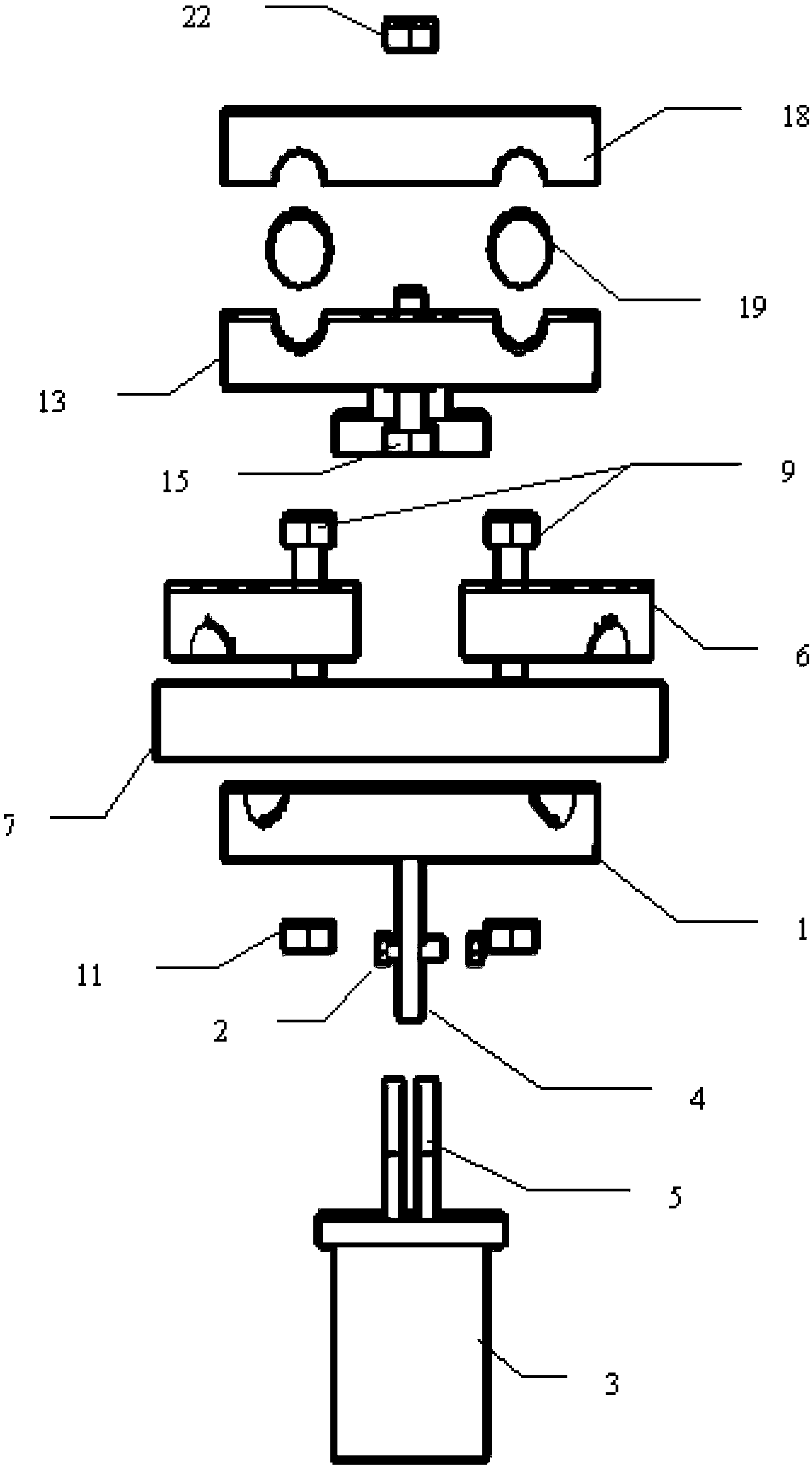

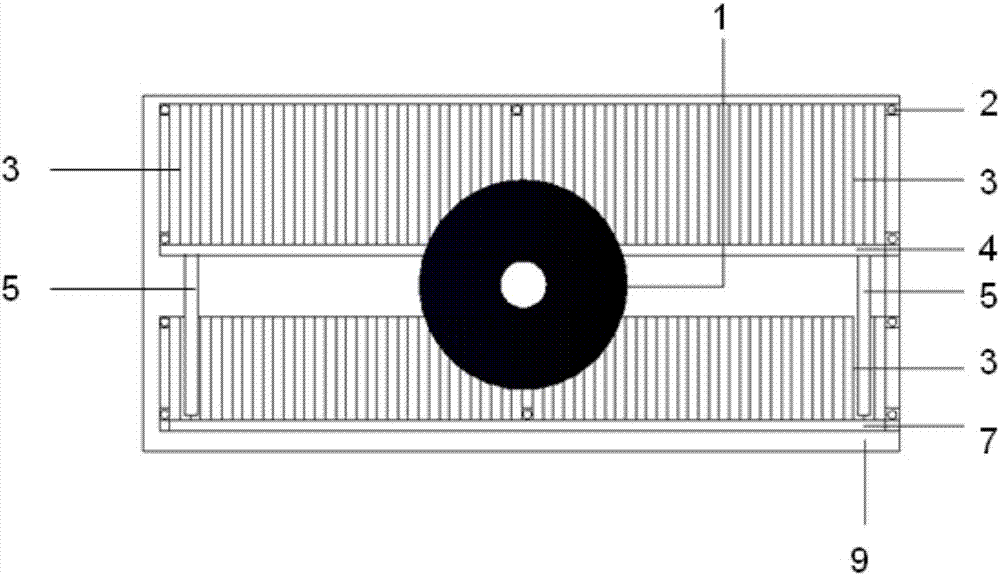

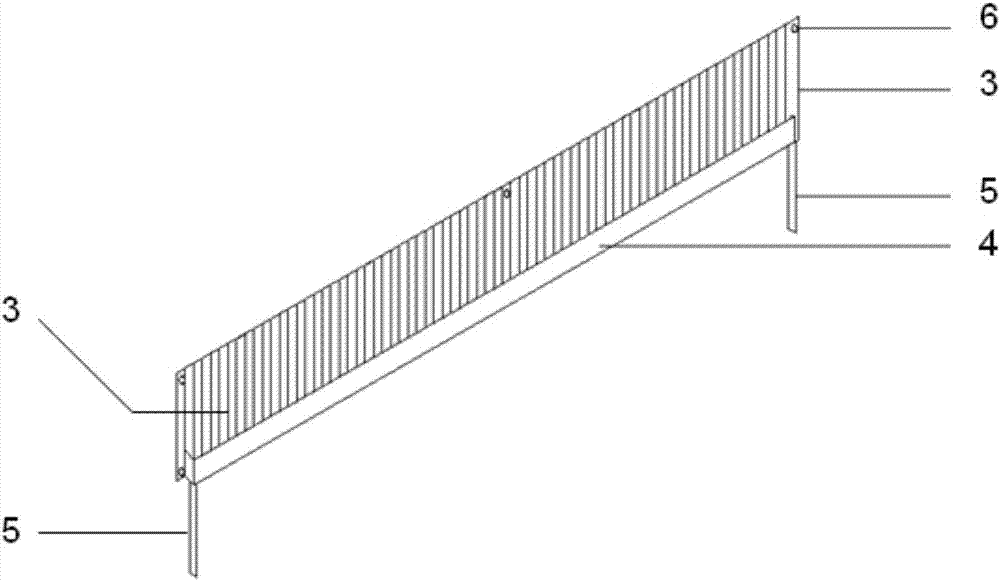

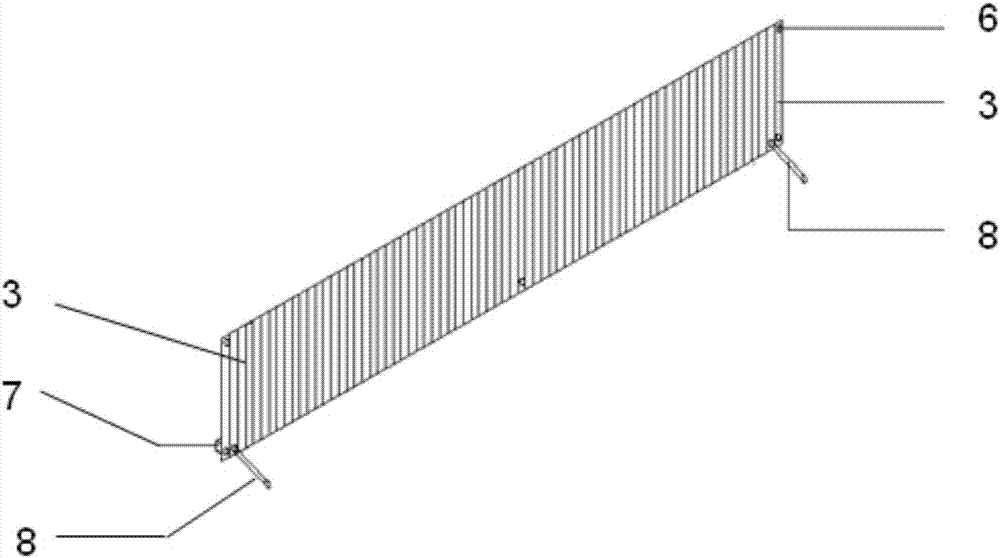

Improved stone grinder waterproof cover

PendingCN107498469AEasy to usePrevent water splashGrinding/polishing safety devicesWater pipeEngineering

The invention discloses an improved stone grinder waterproof cover. The improved stone grinder waterproof cover is characterized in that the improved stone grinder waterproof cover comprises a stone grinder rotary disc 1, organ covers 3 with reserved holes, fastening screws 2, stone grinder outer cover reserved screw holes 6, a stone grinder outer cover 9, PVC water pipes 5, a plastic water collection trough 4 with holes in the bottoms of the two ends of the upper portion, a plastic water collection trough 7 with holes in the tails of the two ends of the lower portion and end water guide pipes 8; the organ covers with the reserved holes are fixedly connected into the stone grinder outer cover reserved screw holes in the stone grinder outer cover through the fastening screws; the plastic water collection trough with the holes in the bottoms of the two ends of the upper portion and the plastic water collection trough with the holes in the tails of the two ends of the lower portion are bonded to the organ covers with the reserved holes on the upper side and the lower side correspondingly and bonded to the inner walls of the organ covers with the reserved holes; and the PVC water pipes are connected with the plastic water collection trough with the holes in the bottoms of the two ends of the upper portion and guide accumulated water into the plastic water collection trough with the holes in the tails of the two ends of the lower portion. According to the improved stone grinder waterproof cover, water can be prevented from being splashed to a motor, operation is convenient, the form is attractive, the accumulated water is drained, and meanwhile the use effect of a stone grinder is guaranteed.

Owner:ANHUI UNIV OF SCI & TECH

Anti-distortion device for bracing wire

The invention discloses an anti-distortion device for a bracing wire, comprising a supporting plate with a sliding chute at one end. One end of the supporting plate, which is provided with the sliding chute, is movably provided with a live splint for clamping the bracing wire, and the other end of the supporting plate is provided with a retaining clip. The retaining clip consists of two fixed clamping plates fixedly installed at two sides of the supporting plate. The live splint consists of two movable clamping plates installed at two sides of the sliding chute of the supporting plate, and the two movable clamping plates are connected and fixed by bolts passing through the sliding chute. The fixed clamping plates and the movable clamping plates are both in ladder shapes matched with the supporting plate and having two sections of different thickness. Nuts matched with the bolts are butterfly-shaped nuts. By adopting the anti-distortion device, distortion of the bracing wire is effectively avoided, and time and labor are saved. The anti-distortion device for the bracing wire has the advantages of simple structure, attractive shape, low cost, safety, convenience, convenient carrying and strong adaptability.

Owner:STATE GRID CORP OF CHINA +1

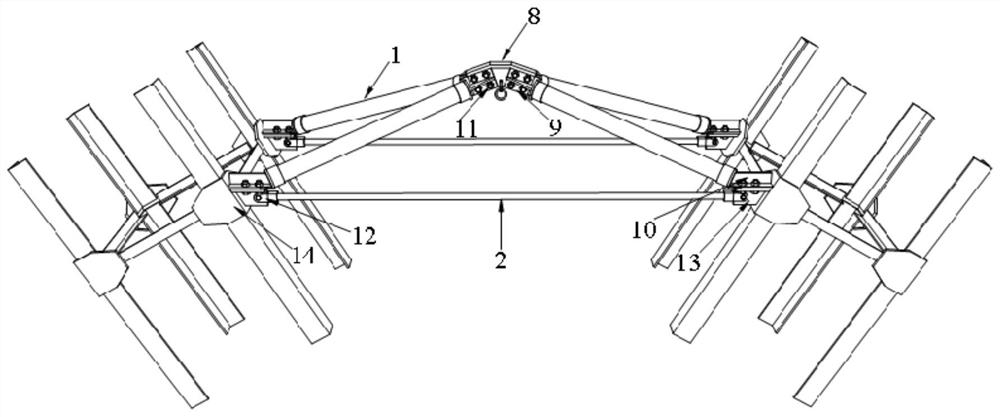

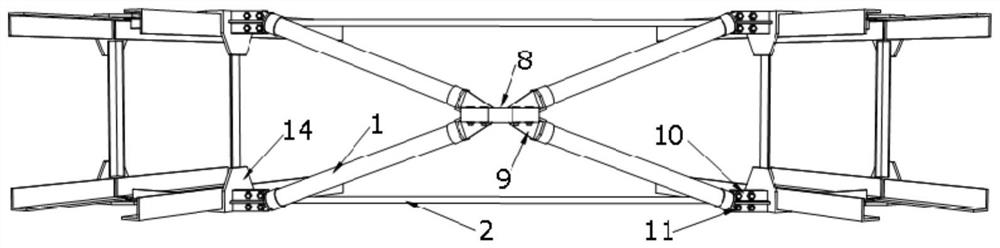

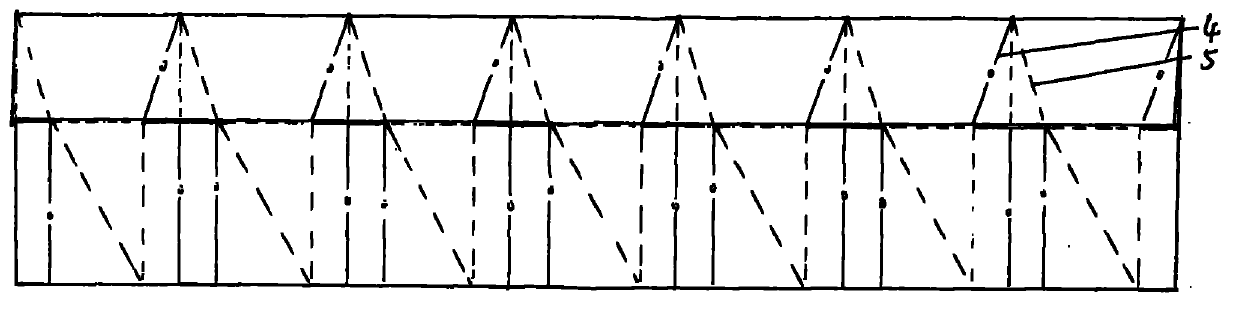

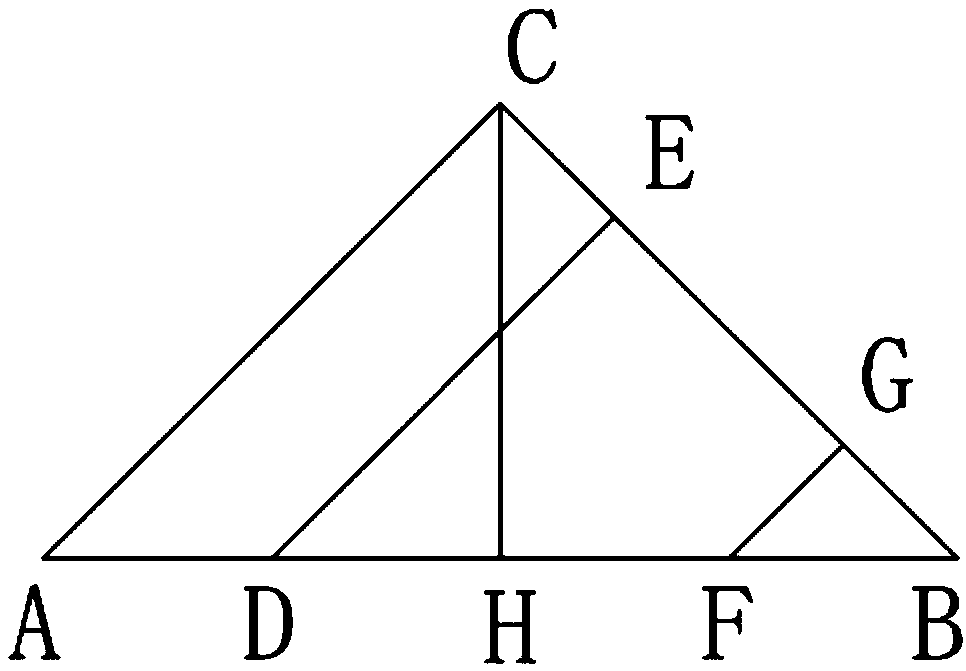

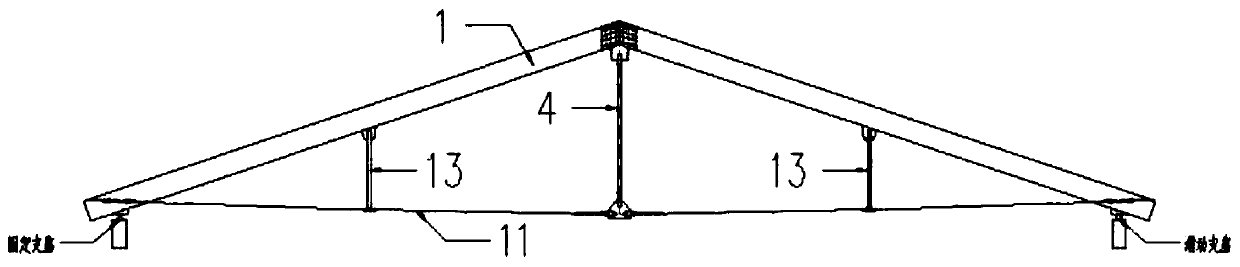

A composite roof truss with frp cables for the lower chord

ActiveCN106930467BEasy to installTake advantage of compressive stabilityGirdersJoistsPre stressArchitectural engineering

Owner:NANJING TECH UNIV

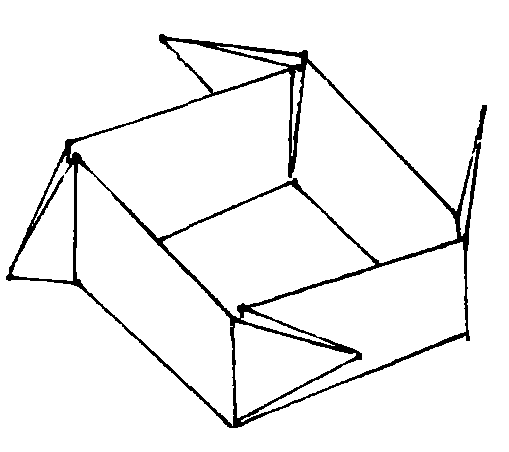

Box-in-box folding method

The invention discloses a box-in-box folding method and relates to a manufacturing method of paper utensils. A box-in-box utensil comprises an inner box component and an outer box component. The inner box component is a square box body, and a box outer triangle is arranged outside each of four box corners. The outer box component is a square box body which is formed by inserting of four single parts. The inner box component is placed in the outer box component. Four box corner outer triangles of the inner box component are respectively inserted into inserted part interlayers on the box inner side of the outer box component, and the box-in-box utensil is formed. A box is in another box, a concept is unique, an inner small square box and an outer big square box are in geometric modeling which is novel and unique, the outer box and the inner box are firmly combined, and the form of the box-in-box utensil is attractive.

Owner:SHANDONG YINGCAI UNIV

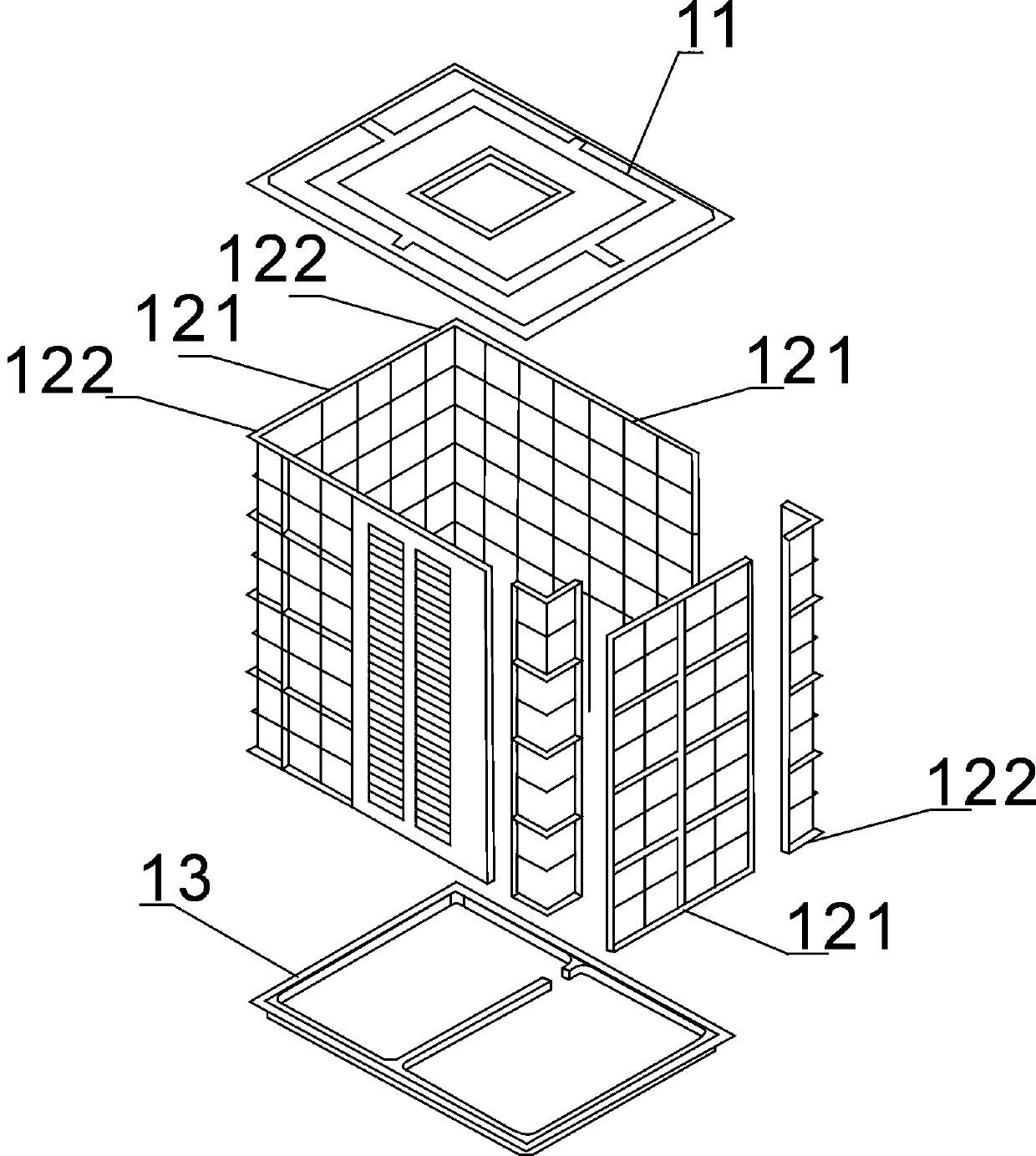

Integrated bathroom or kitchen made of composite material, and assembly method thereof

InactiveCN107724711AGuaranteed stabilityGuaranteed practicalitySpecial buildingBuilding constructionsEngineeringMetal

The invention relates to an integrated bathroom or a kitchen made of a composite material, and an assembly method thereof. The integrated bathroom or kitchen comprises a plurality of wallboards, a topboard, and a bottom board. The integrated bathroom or kitchen is characterized by also comprising a first frame structure, and after welding the first frame structure, a frame shape with an upper opening and a lower opening is formed. In the first frame structure, metal pipes are used to weld a plurality of rectangular frame structures, vertical metal pipes are double metal pipes, that is, aftertwo metal pipes are riveted by screws and nuts, the metal pipes are welded with a horizontal metal pipe, and the horizontal metal pipe is a single metal pipe structure. A cross section of a connectingpiece is in a Z shape, and corners are right angles. Beneficial effects of the integrated bathroom or kitchen are that compared with a conventional bathroom, a frame structure form is used, a connection method is screw and nut connection, providing convenience for secondary dismounting and repeated use, and preventing unnecessary waste in a decoration process.

Owner:CHENGDU ANJIE YIKANG ENVIRONMENTAL PROTECTION TECH CO LTD

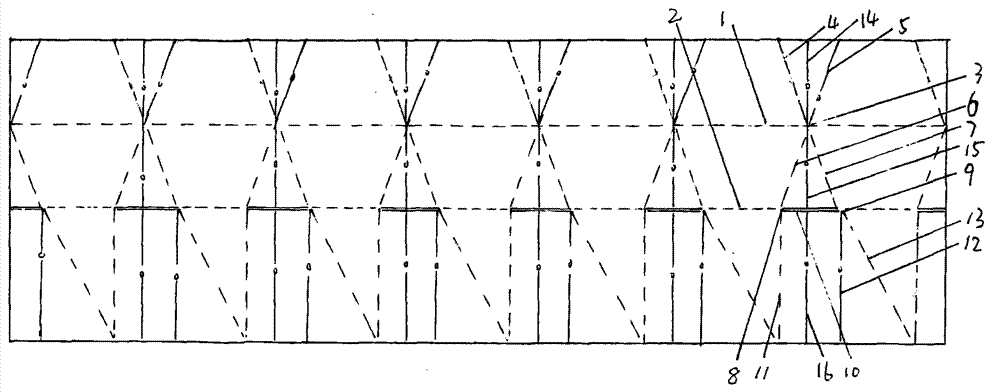

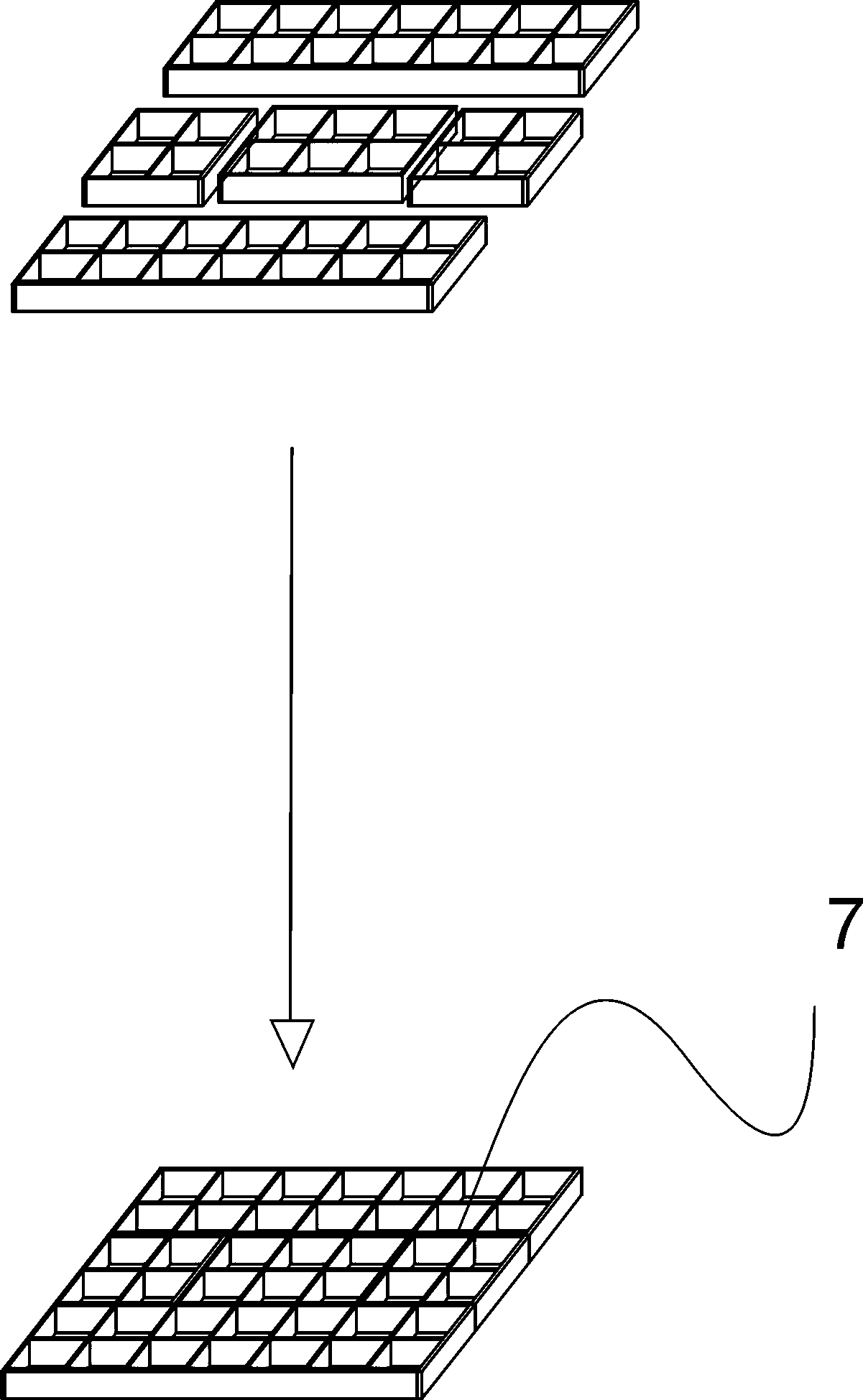

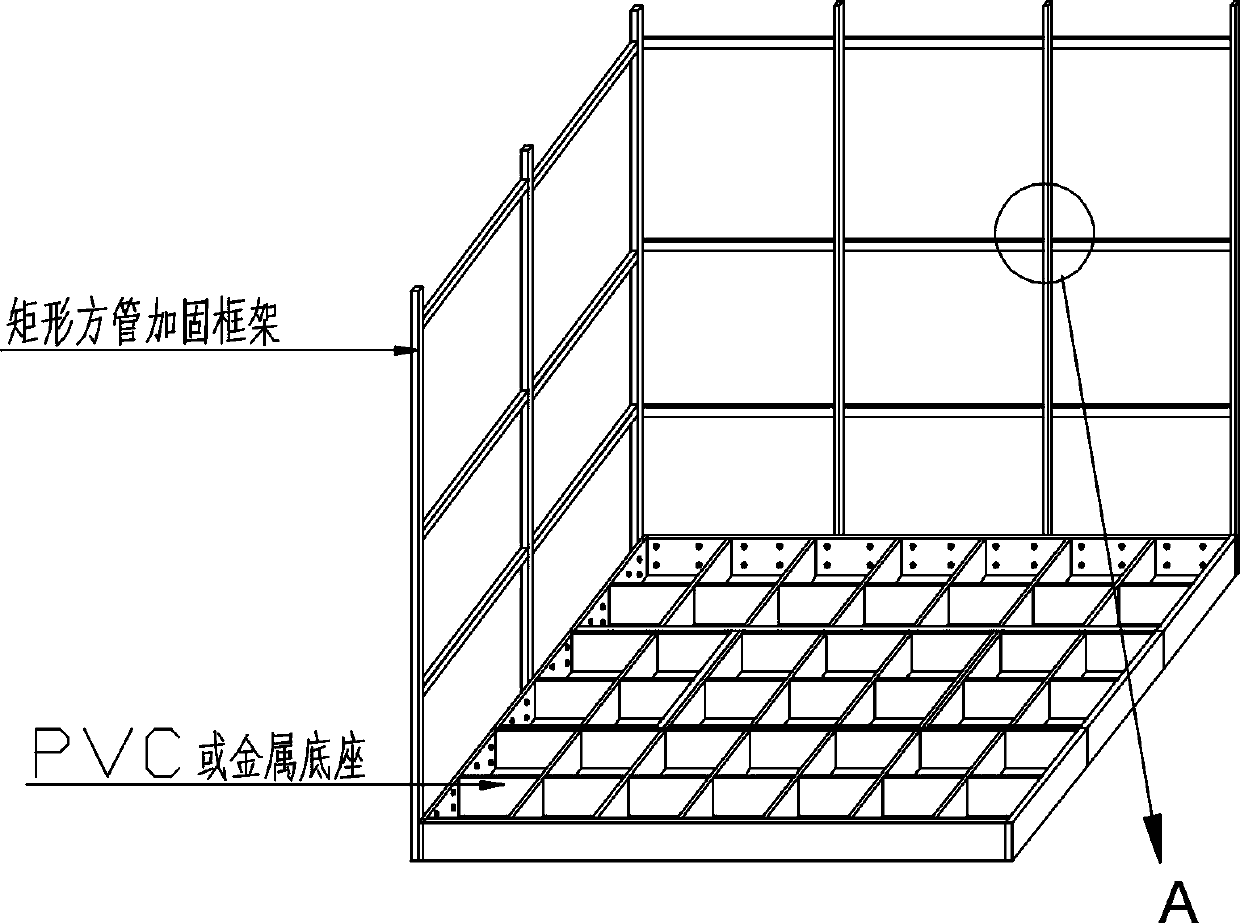

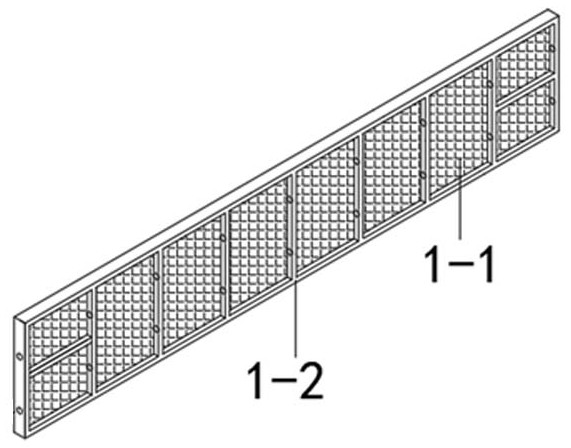

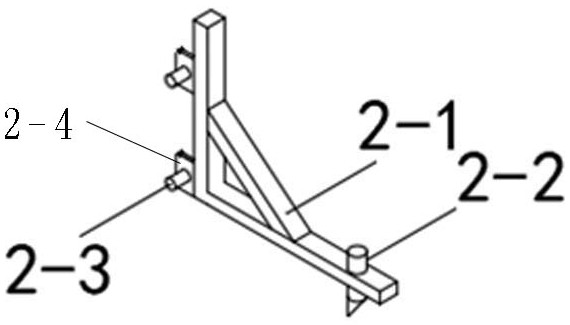

Systematic template for high-speed rail base adopting glass fiber panel

PendingCN112941986AAdjustable weightReduce weightBallastwayRailway track constructionGlass fiberBolt connection

The invention discloses a systematic formwork for a high-speed rail base adopting a glass fiber panel. The systematic formwork comprises formwork side formworks, fixing device frames, plugging plates, bearing beams, groove formworks and T-shaped bolts. The number of the formwork side formworks is two, the number of the plugging plates is two, a rectangle is defined by the formwork side formworks and the plugging plates, the groove formwork is rectangular and arranged in the center of the rectangle, and four T-shaped bolts are perpendicularly connected to the groove formwork. The formwork side formworks are connected with the fixing device frame, and the formwork side formworks are vertically fixed to the ground through the fixing device frame. The plugging plates are connected with the fixing device frame, and the plugging plates are vertically fixed to the ground through the fixing device frame. The bearing beam is arranged above the formwork side formworks, the two ends of the bearing beam are connected with the formwork side formworks through bolts, and the middle of the bearing beam is connected with the T-shaped bolts. The device is high in assembly degree, convenient to construct and install, higher in cast-in-place concrete construction speed, lower in man-hour cost, capable of being recycled for multiple times, good in forming effect and easy to operate and demould.

Owner:SHENYANG JIANZHU UNIVERSITY

A large-capacity well-type solar heat collection-heat storage device

InactiveCN103629827BSimple structureIncrease volumeSolar heating energySolar heat devicesCold airTransfer system

The invention relates to the field of solar heat collection and storage technologies and discloses a high-temperature large-capacity well type solar heat collection-storage device. A primary reflector of the large-capacity well type solar heat collection-storage device is a concave mirror reflector, and a plurality of the primary reflectors are fixed on the ground to form a reflector array; a secondary reflector is mounted in the air and is a convex mirror reflector which is opposite to the primary reflectors, a conical solar well is arranged below the secondary reflector, and a heat absorbing body is arranged at the bottom of the solar well; a heat storage tank body is a hollow tank body, the middle of the heat storage tank body is the solar well, a part of the heat storage tank body is buried underground and is filled with a heat storage medium; a hot air pipe and a cold air pipe penetrate through the heat storage tank body, are immersed into the heat storage medium and are communicated with the air above the solar well and the heat storage tank body; pipe mouths, which are located on the sidewall of the solar well, of the hot air pipe and the cold air pipe are respectively located above and below the heat absorbing body. The large-capacity well type solar heat collection-storage device integrates advantages of point focus heat collection and fuse salt heat storage, does not need a specific heat transfer system, and has the advantages of simple structure, low maintenance cost, large heat storage capacity, small floor space and more artistic form.

Owner:QINGHAI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com