Method for assembling laminated steel-lead support adopting lead plates formed by in-situ pouring and cooling

A technology of cooling forming and assembling method, applied in building types, building components, shockproof and other directions, can solve the problems of inconvenient assembly and inability to meet large deformation, and achieve the effect of convenient design and construction, simple structure and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

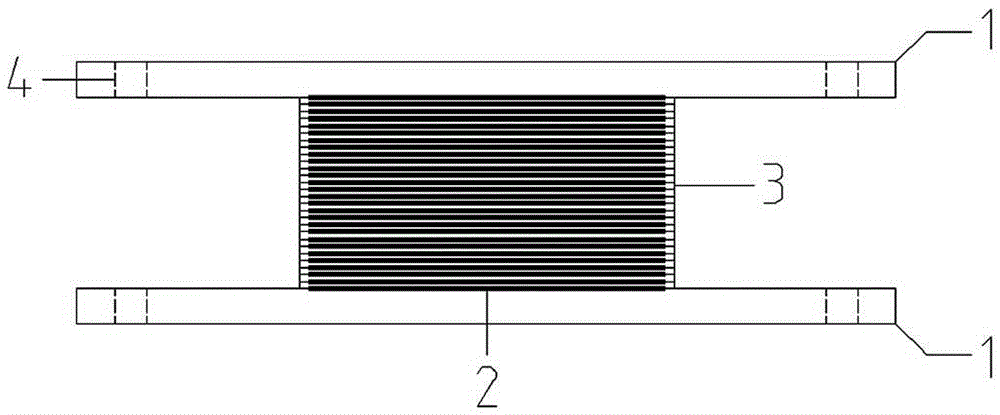

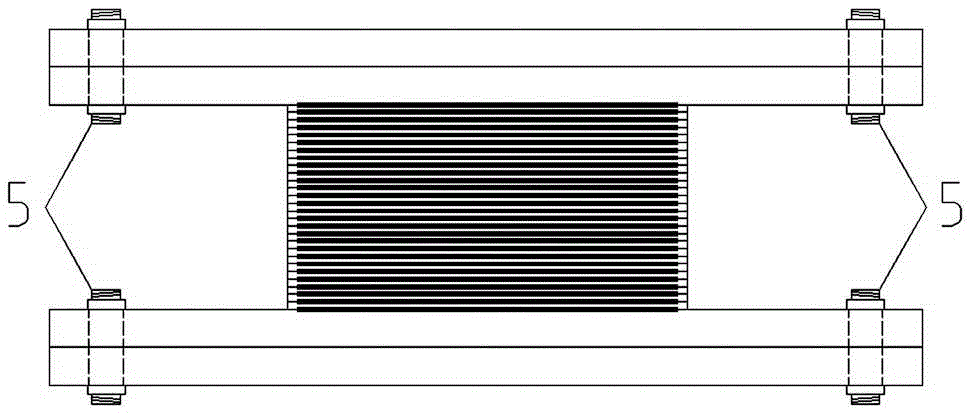

[0042] The following is attached Figure 1-13 The present invention will be described in detail.

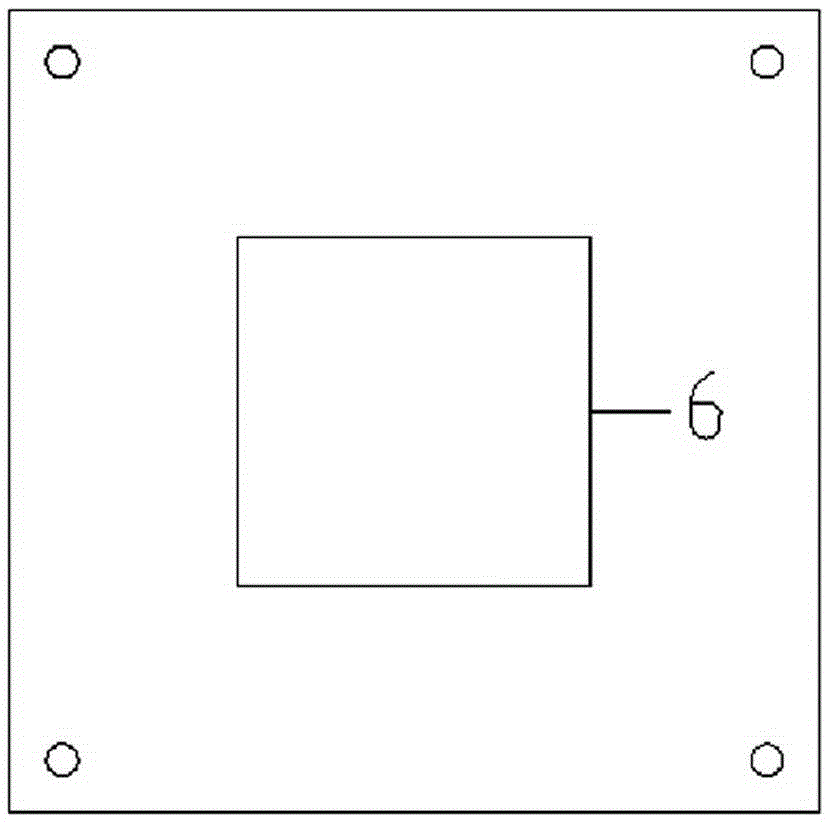

[0043] Such as figure 1 As mentioned above, a laminated steel-lead support of the present invention includes upper and lower cover plates 1 and thin steel plates 3, and it also includes lead plates 2, and the lead plates 2 and thin steel plates 3 are stacked at intervals on the upper and lower sides. Between the cover plates 1, and next to the inside of the upper and lower cover plates 1 is the lead plate 2; the plane size of the lead plate 2 is smaller than the plane size of the upper and lower cover plates 1 and the thin steel plate 3, see Figure 3-8 As shown, the upper and lower cover plates 1 and the thin steel plates 3 that are in contact with the lead plate 2 are respectively provided with a first groove 6 and a second groove 7 according to the plane size of the lead plate 2, and the lead plate 2 is completely embedded in the upper and lower parts. In the cover plate 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com