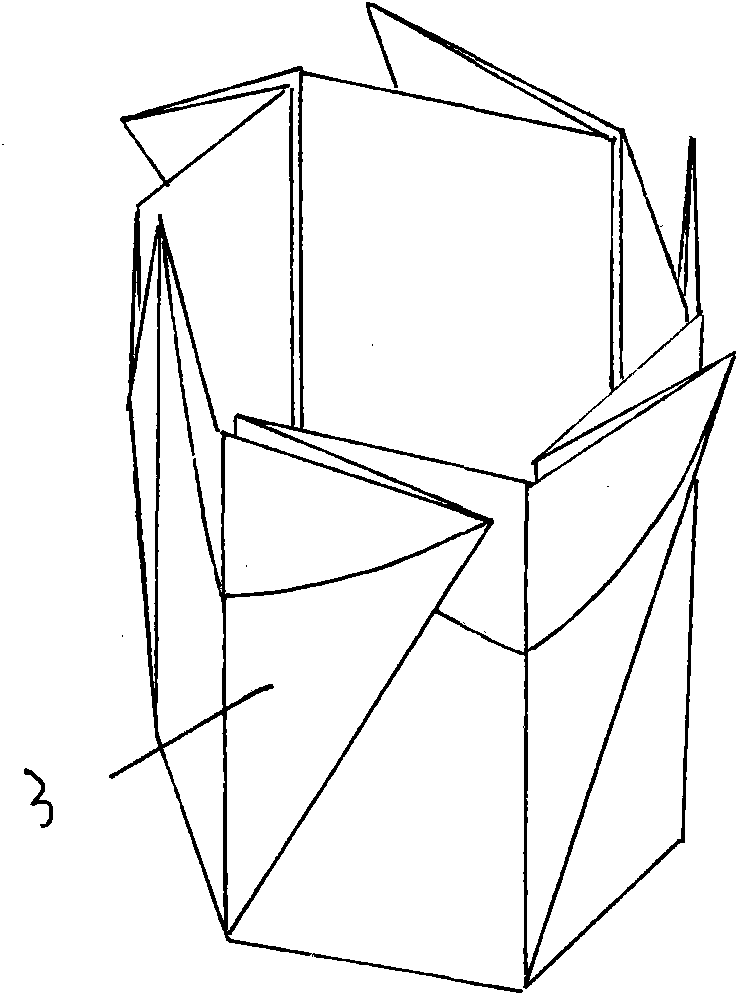

Paper tube

A technology of paper tubes and regular hexagons, which is applied in the field of container production, can solve the problems of time-consuming and labor-intensive, limited aesthetics, etc., and achieve the effect of unique form, simple production, and tight insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

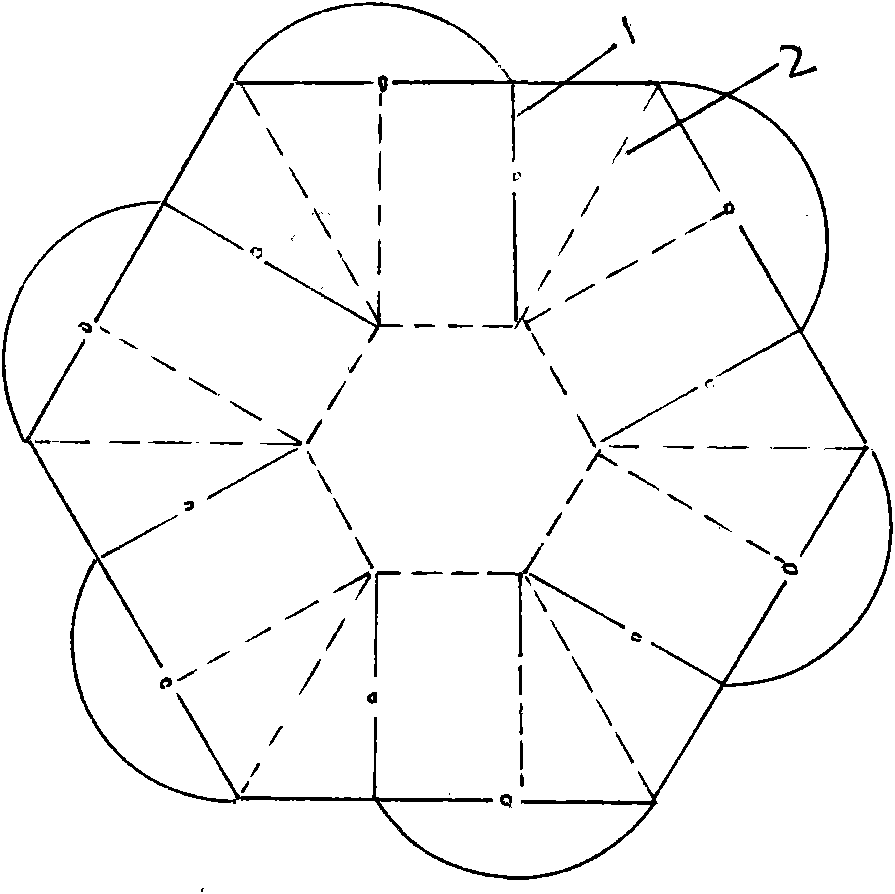

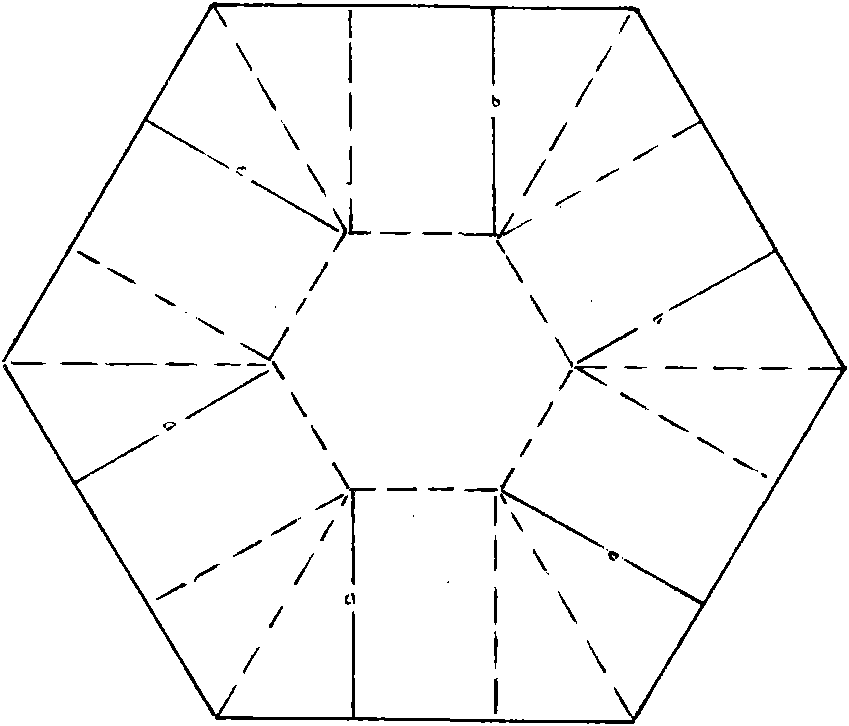

[0015] Draw a large regular hexagon on paper, the middle part of the large regular hexagon is a small regular hexagon; the corresponding side lengths of the big and small regular hexagons are parallel; the side length of the big regular hexagon is three times the side length of the small regular hexagon times; draw 12 vertical lines 1 perpendicular to the large regular hexagon from the six corners of the small regular hexagon to the nearest six sides of the big regular hexagon, and the 12 vertical lines 1 are equal in length; the six sides of the big regular hexagon are respectively Intersect with two vertical lines 1, so that each side of the large regular hexagon is divided into three equal-length line segments; draw six connecting lines 2 from each angle of the small regular hexagon to the corner of the nearest large regular hexagon; 2 / 3 of the side length of the hexagon, that is, the length of the middle section and the section in the counterclockwise direction is the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com