Fire monitoring system for a re-baking room

A technology for fire monitoring and rebaking room, which is applied to fire alarms that rely on radiation, fire alarms and fire alarms that rely on smoke/gas effects, etc. It can solve problems such as low monitoring efficiency and waste of human resources. , to achieve the effect of improving monitoring efficiency and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

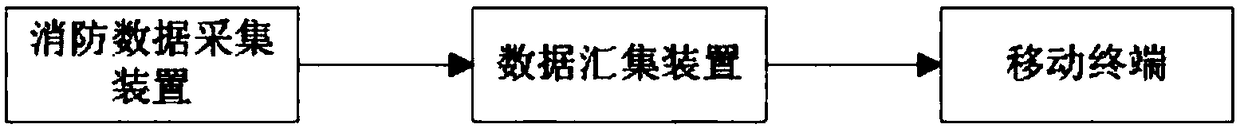

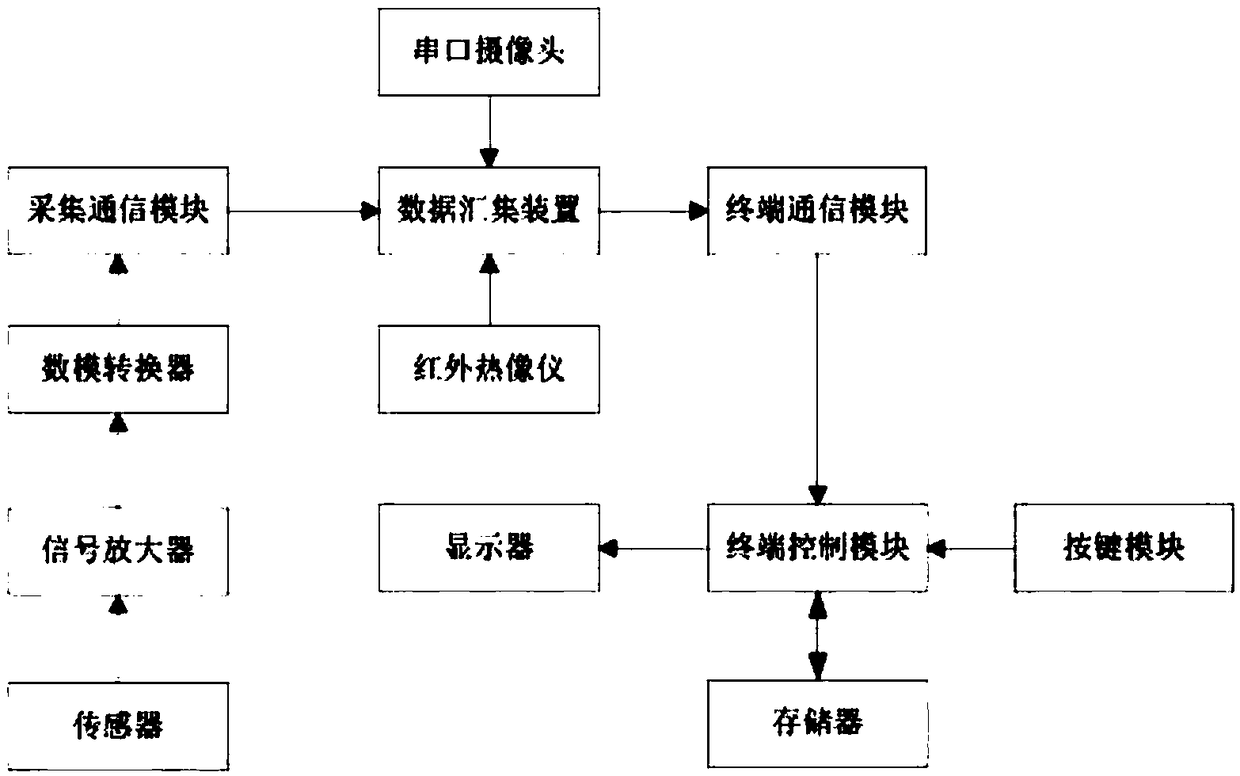

[0025] Such as figure 1 As shown, the fire monitoring system includes a mobile terminal, a data collection device and one or more fire data collection devices installed in the rebaking room, and the mobile terminal is connected to the fire data collection device through the data collection device. The mobile terminal may preferably be a smart phone or a tablet computer.

[0026] In the above solution, the fire data collection device collects fire data in the rebaking room (such as smoke data or open fire data) and transmits the fire data to the data collection device, and the data collection device collects the fire data and then sends the fire data to the mobile Terminal, the user can realize real-time monitoring of the fire situation in the rebaking room through the mobile terminal. During specific implementation, the user can realize real-time monitoring of multiple rebaking rooms through a mobile terminal, so the monitoring system provided by the present invention can imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com