Battery acid circulation inner formation device and method used for electro-hybrid bicycle

An electric moped, internalization technology, applied in the direction of batteries, secondary batteries, lead-acid batteries, etc., can solve the problems of short internalization time, long internalization time, poor conversion effect, etc., and achieve short chemicalization time and reduce manufacturing costs. , good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

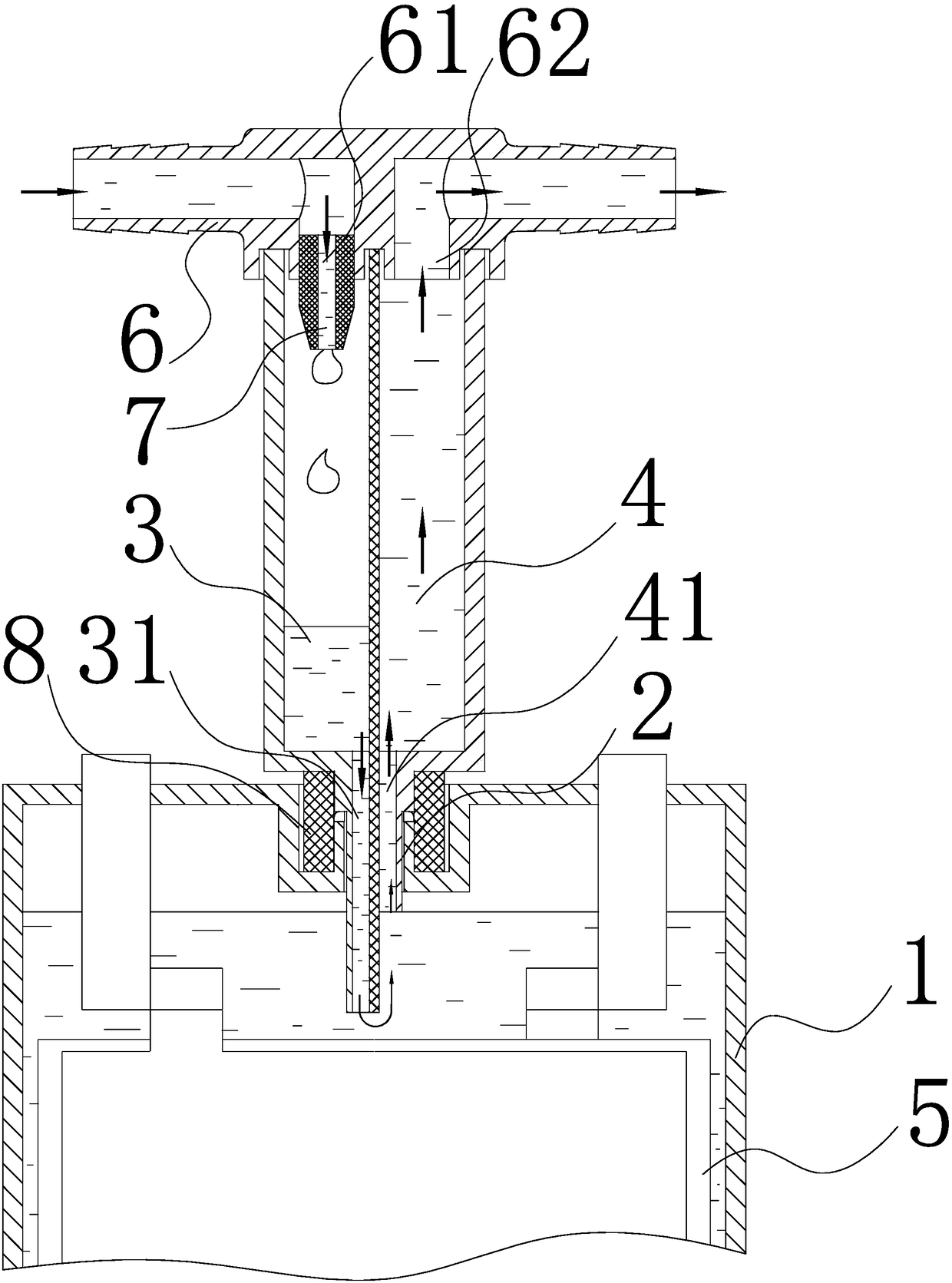

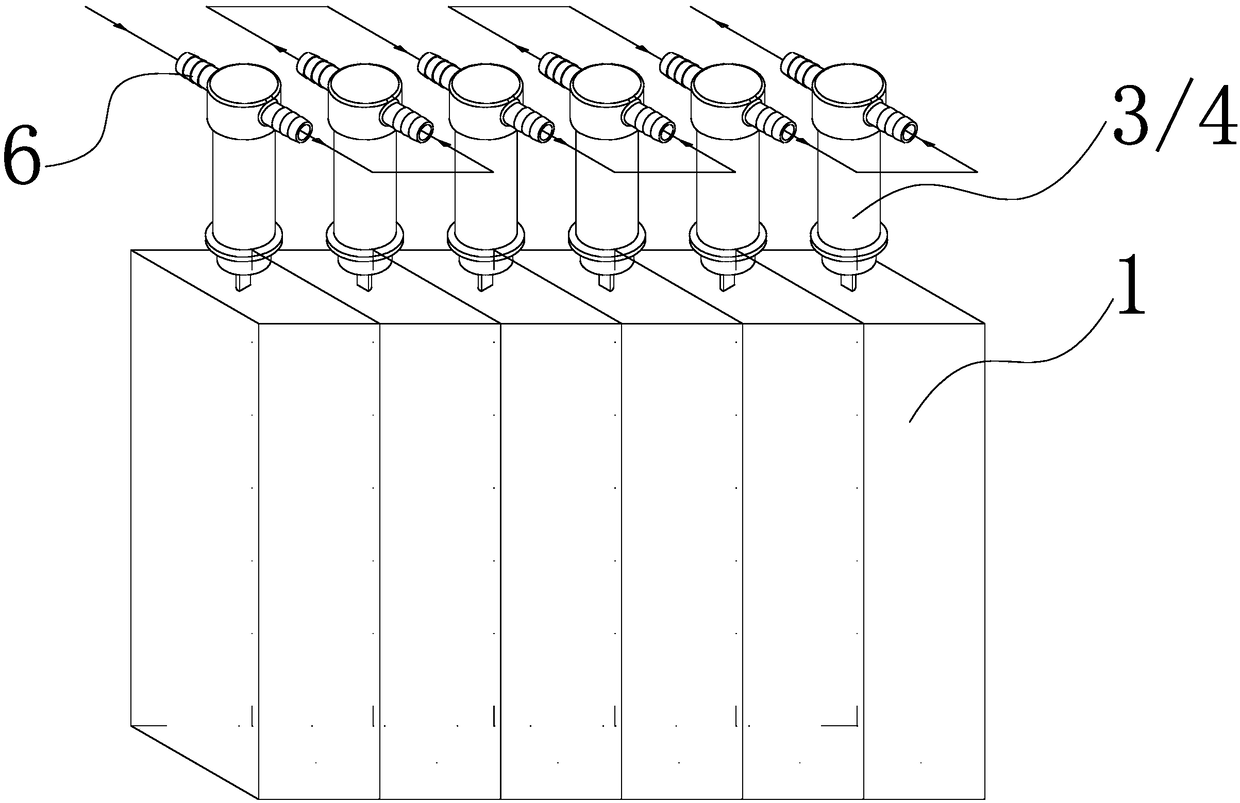

[0027] Such as figure 1 and figure 2 As shown, a battery acid circulation internal formation device for an electric bicycle of the present invention includes a battery assembly composed of six battery cells 1, and liquid filling holes 2 are respectively opened in the middle of the top surface of the battery cells 1. A liquid inlet pipe 3 and a liquid discharge pipe 4 are plugged into the liquid holes 2 at the same time, wherein the liquid inlet pipe 3 and the liquid discharge pipe 4 are integrally formed, and correspond to the lower ends of the liquid inlet pipe 3 and the liquid discharge pipe 4. Extending downwards and inwards corresponds to the integrally formed liquid inlet needle tube 31 and liquid discharge needle tube 41, and the liquid inlet needle tube 31 and the liquid discharge needle tube 41 are interfitted and plugged into the filling hole 2, and the corresponding inlet needle tube outside the liquid filling hole 2 The liquid pipe 3 and the liquid discharge pipe ...

Embodiment 2

[0039] A method for internalizing battery acid circulation for electric mopeds, comprising the following sequential steps:

[0040] 1) Correspondingly insert six pairs of liquid inlet pipes 3 and liquid discharge pipes 4 into the liquid filling holes 2 of the six battery units 1 of the battery assembly;

[0041] 2) Take six circulation conduits 6, and the upper ports of the liquid inlet pipe 3 and the discharge pipe 4 of each battery unit 1 are connected to the corresponding circulation conduits 6, and the six circulation conduits 6 are connected in series through the pipeline;

[0042] 3) Input the low-density formed electrolyte from the inlet end of the circulation conduit 6, pass through each battery unit 1 in turn, and export it from the outlet end of the circulation conduit 6;

[0043] 4) Adjust the input pressure and flow rate of the formed electrolyte at the inlet end of the circulation conduit 6, so that the formed electrolyte in the circulation conduit 6 drips into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com