Cleaning method of materials, cleaning device of materials and cooking utensil

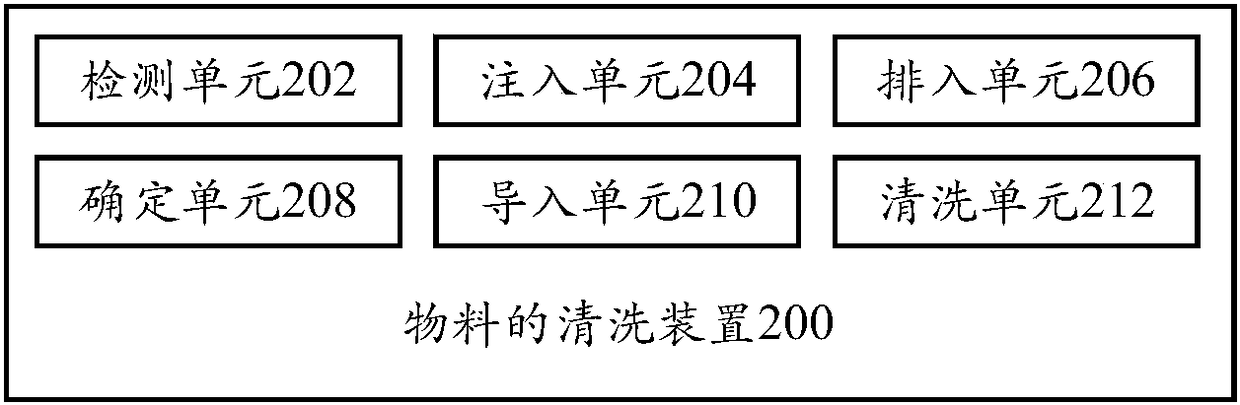

A technology for cleaning devices and cooking utensils, which is applied to cleaning methods and utensils, cleaning methods using liquids, steam cooking utensils, etc., which can solve the problems of insufficient cleaning of rice grains and limited volume of rice washing containers, and reduce the residue of materials hanging on the wall probability, prevent secondary flushing, and improve flushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

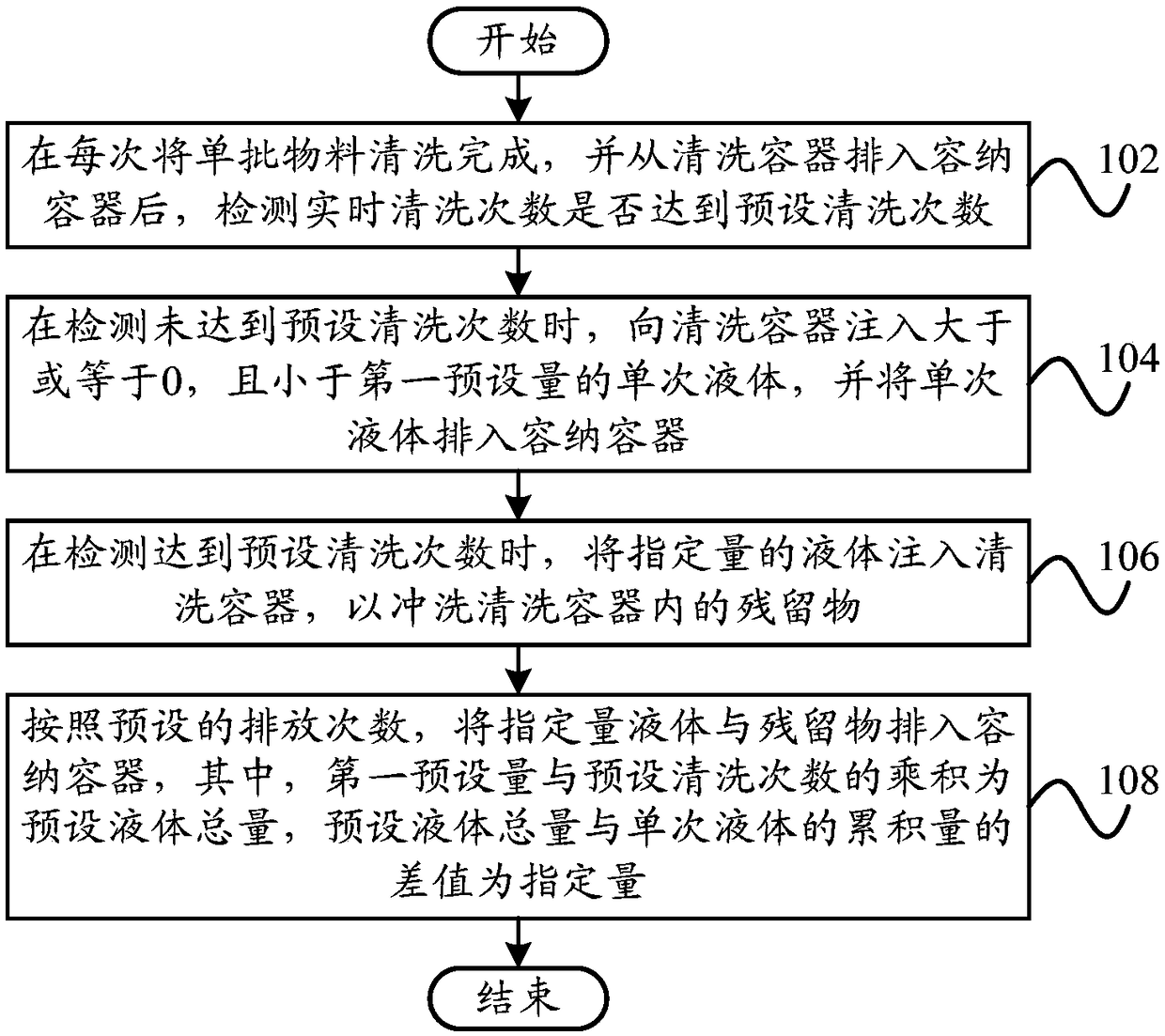

Method used

Image

Examples

Embodiment 1

[0073] In any of the above technical solutions, preferably, when it is detected that the preset number of times of cleaning has not been reached, a single liquid greater than or equal to 0 and less than the first preset amount is injected into the cleaning container, and the single liquid is discharged into the The containing container specifically includes the following steps: when it is detected that the preset number of times of cleaning has not been reached, injecting a single liquid greater than 0 but less than the first preset amount into the cleaning container to perform a flushing operation; and discharging the single liquid into the containing container.

[0074] In this technical solution, when the detection does not reach the preset number of times of cleaning, a single liquid greater than 0 and less than the first preset amount is injected into the cleaning container to perform the flushing operation, and after the flushing operation is completed, the A single liqui...

Embodiment 2

[0079] In addition, it is also possible to inject less than the first preset amount of liquid only after the specified several times of material cleaning in the first N-1 times, for example, after the even number of material cleaning is completed, inject liquid for flushing operation, and for example , only in the last few times of liquid injection for flushing operations, etc., compared with the scheme of injecting less than the first preset amount of liquid after each material cleaning in the first N-1 times, the Nth material cleaning operation When finished, fill the wash container with the specified amount of liquid more for a one-time flush.

[0080] It is also possible to set a comparison threshold, and when it is detected that the value of the specified amount is less than the comparison threshold, after the flushing operation is completed, it is discharged into the holding container at one time.

Embodiment 3

[0082] It is also possible to inject less than the first preset amount of liquid only after the specified number of material cleanings in the first N-1 times, for example, after the even number of material cleanings, inject liquid for flushing operation, and for another example, only In the last few times of injecting liquid for flushing operations, etc., compared with the solution of injecting less than the first preset amount of liquid after the completion of the first N-1 times of material cleaning, after the completion of the N material cleaning operation , inject the specified amount of liquid into the cleaning container for one-time flushing and more.

[0083] It is also possible to set a comparison threshold, and when it is detected that the value of the specified amount is greater than or equal to the comparison threshold, after the flushing operation is completed, it is divided into multiple discharges into the holding container.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap