Printing control apparatus, printing control method, and medium storing printing control program

一种印刷控制、介质的技术,应用在印刷等方向,能够解决无法表现出浓度、输出数据增补效果消失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

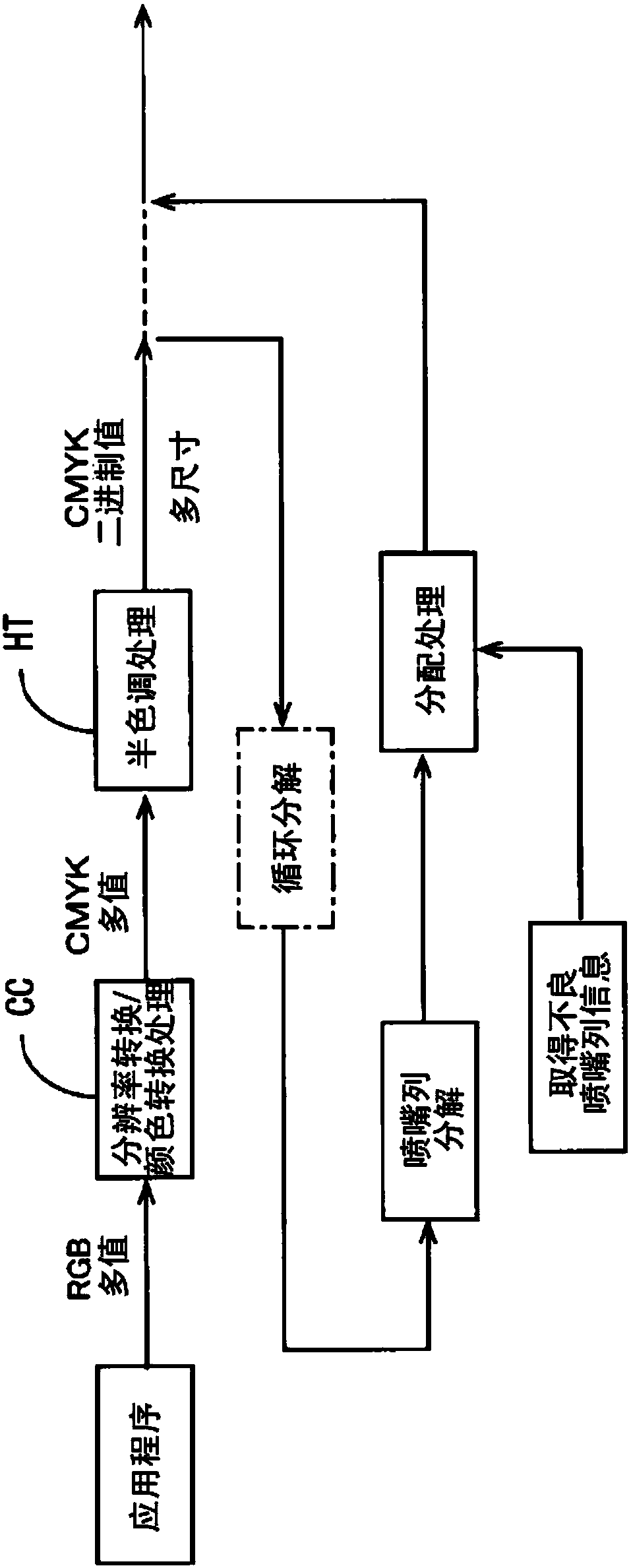

[0027] Embodiments of the present invention will be described below with reference to the drawings.

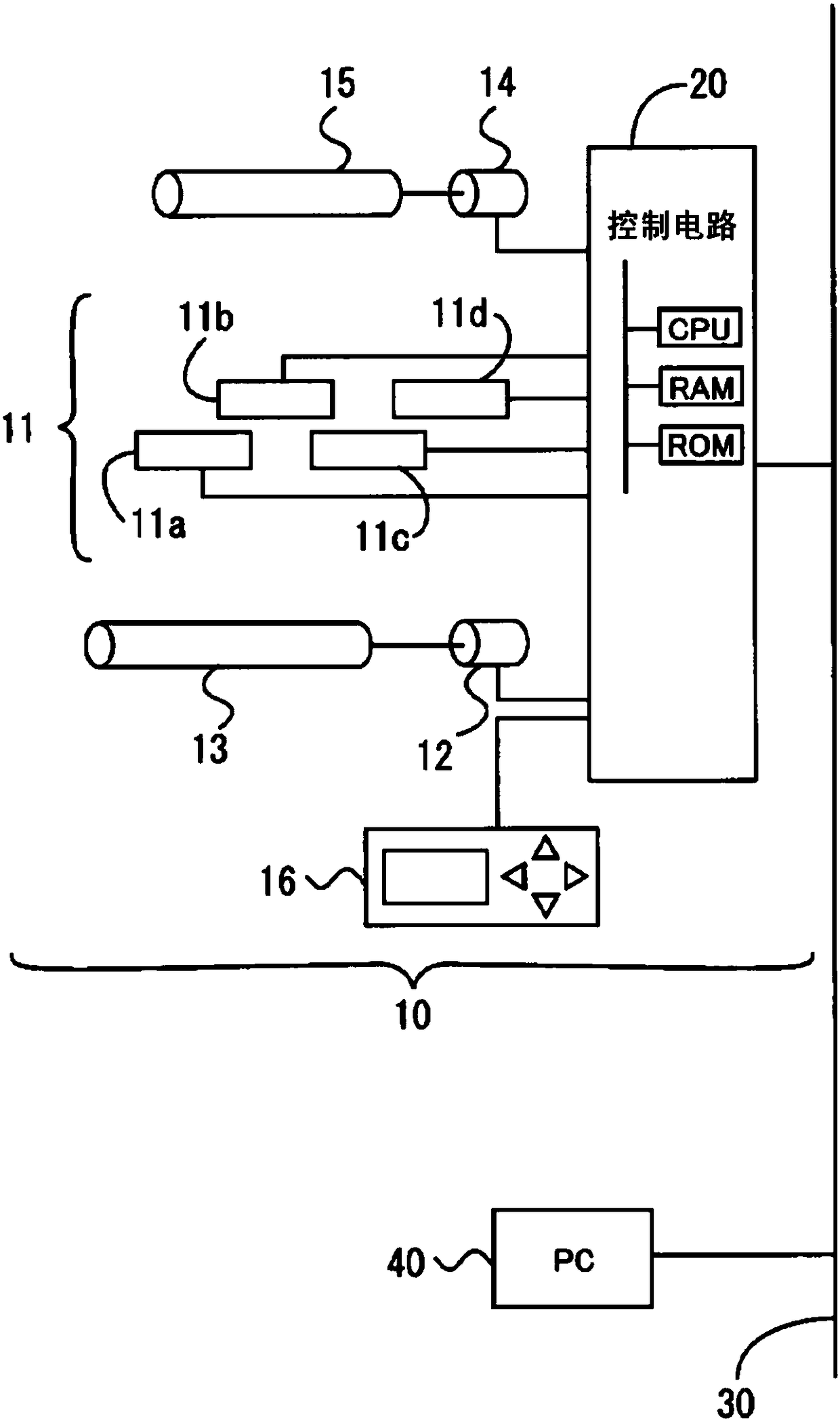

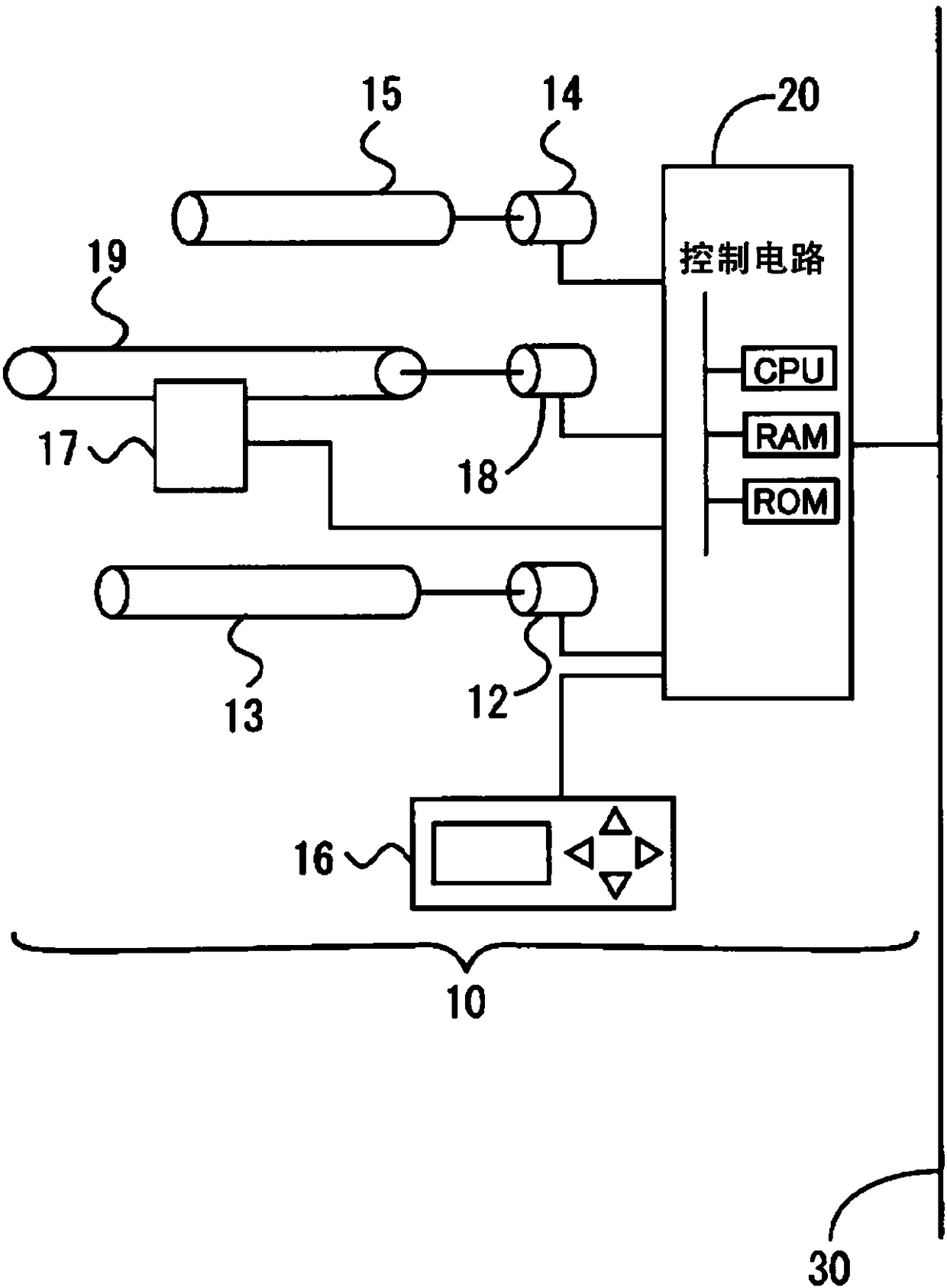

[0028] figure 1 It is a block diagram of a printing system to which the present invention is applied.

[0029] In this figure, a printing head 11 of a printer (droplet discharge device) 10 discharges four or six color inks supplied from ink tanks from nozzles. The printing heads 11a to 11d are fixed at predetermined positions, and the platen 12 is rotationally driven by the platen motor 13 so that the paper is conveyed so as to cross the printing heads 11a to 11d. The print heads 11a to 11d are arranged zigzag in a zigzag shape toward the longitudinal direction, and the nozzles face the paper so as to span the entire width of the paper in the width direction. Accordingly, it can be said that the printing heads 11a to 11d relatively move on the paper.

[0030] The feed motor 14 drives a paper feed roller 15 that feeds paper stored in a predetermined paper stacker. A printer...

no. 2 approach

[0159] In the previous first embodiment, the processed ink shortage amount and the carried-over ink amount were calculated for each pixel. Although the insufficient amount of density can be accurately calculated, the amount of processing increases due to calculation. In addition, there is also a viewpoint that it is impossible to reliably and uniformly determine whether the corrected value of the density obtained by distributing the amount of ink to adjacent dot positions is a correct value based on the ink amount data obtained by calculation. . In particular, if the relationship between the dot value and the ink amount is not proportional, it cannot be said that the calculation result based on the dot value is the correct value for the insufficient ink amount.

[0160] Figure 9 is a diagram showing the contents of the substitution table.

[0161] In this embodiment, using Figure 9 In the replacement table shown, the value of the insufficient ink amount to be allocated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com