Bucket wheel machine electric control system based on PLC

An electrical control system and bucket wheel technology, applied in the field of machinery, can solve problems such as connection complexity, and achieve the effects of ensuring application effects, improving operating efficiency, operating reliability and economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

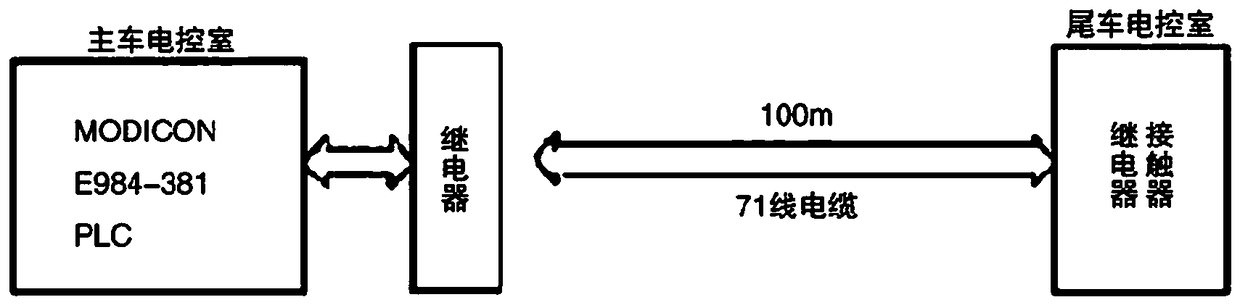

[0010] Such as figure 1 , The two bucket wheel machine main vehicles, the cantilever, the driver's cab and other components are connected as a whole. In practical applications, the cantilever can swing left and right, and can also move up and down. During the process of stacking and reclaiming, the cantilever can be rotated by 135°, and it can be rotated in both forward and reverse directions. At the same time, it can also move up and down, and the movement angle is 130°. In this bucket wheel machine, the main connection method of the ground belt is a fixed connection method. In this way, the tail car and the ground belt are connected reasonably and effectively, so that Make the tail car run along the track set by the ground belt. The control cables used to connect the main car and the tail car of the bucket wheel machine are arranged in the center of the drop hopper,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com