System for monitoring and managing plastic pipe welding Internet-of-things

A management system and Internet of Things technology, applied in the field of plastic pipe welding Internet of Things monitoring and management system, can solve the problem that the production data and completion progress of equipment cannot be effectively monitored in real time, the progress of project completion is difficult to view, and the specific location of equipment cannot be monitored. and other problems, to achieve the effect of improving maintenance efficiency, reducing maintenance costs, and fast and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

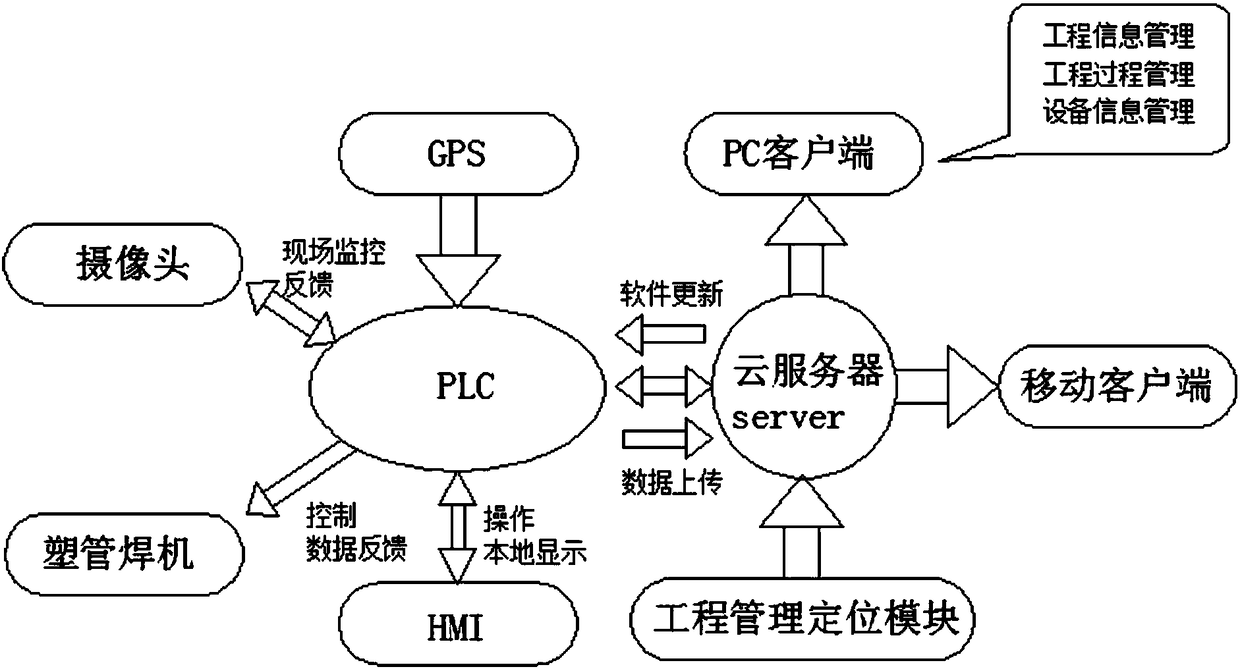

[0020] A plastic pipe welding Internet of Things monitoring and management system, including:

[0021] Management system, it comprises cloud server and PLC, and described cloud server signal is connected with PLC, and described cloud server signal is connected with control terminal;

[0022] The camera is wirelessly connected to the PLC of the management system through the Internet, and the camera enables the manager to observe and monitor online video through the control terminal at any time;

[0023] A positioning device, which includes a project management positioning module and a project map labeling module;

[0024] The engineering management positioning module, whose signal is connected to the cloud server, is used to locate the position of the equipment on the system map, which is convenient for knowing the progress of the project and the scheduling of the equipment, and the engineering management positioning module can accurately record the position of the weld Locati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com