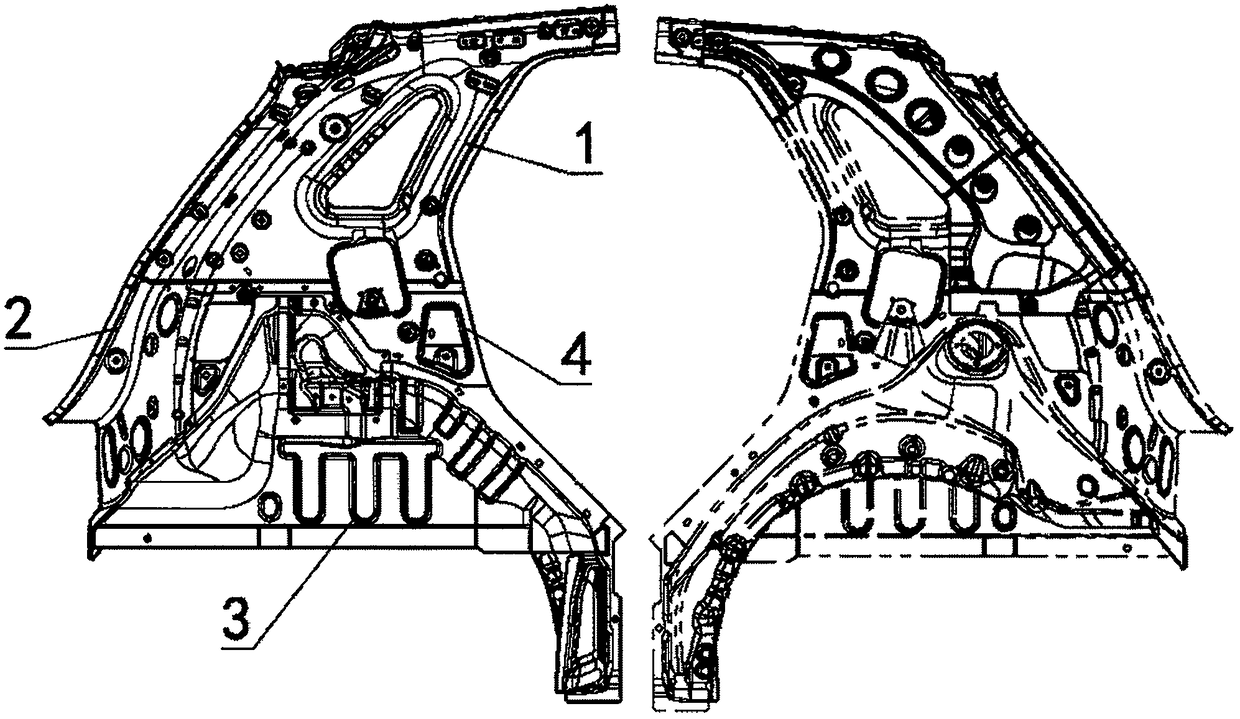

Rear side wall inner plate assembly structure

A technology of assembly structure and assembly, which is applied in the directions of superstructure, subassembly of superstructure, transportation and packaging, etc., can solve the problems of no increase in torsional rigidity of body-in-white, difficulty in deepening, and increase in weight, so as to improve the first-order torsion. Modal, optimized stamping manufacturability, the effect of improving torsional stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

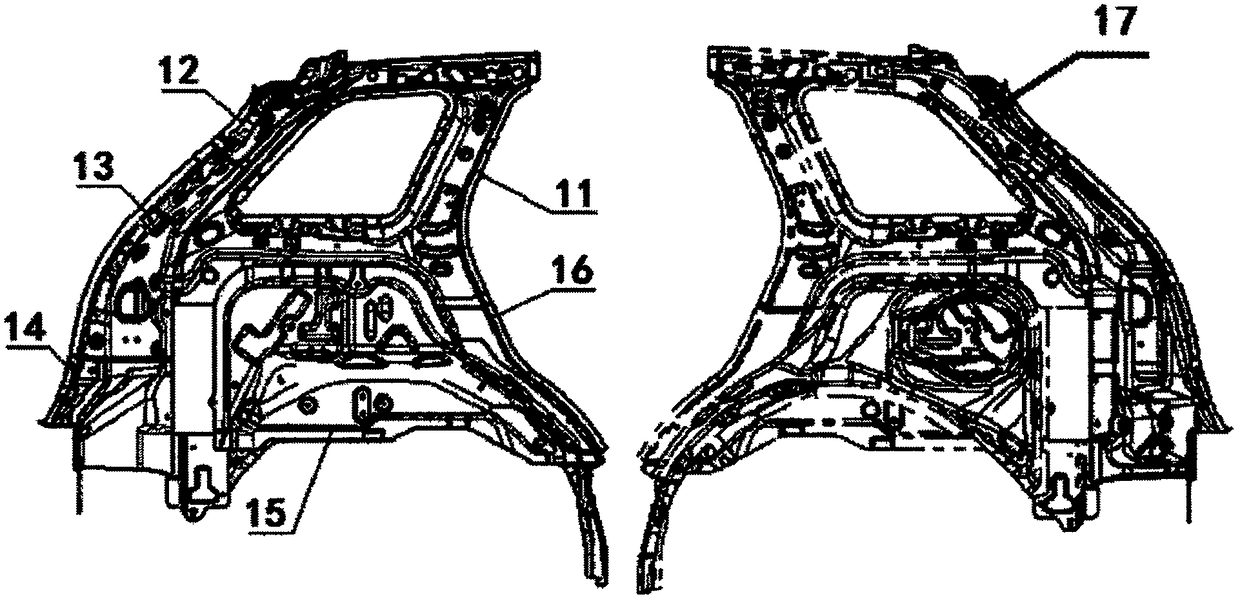

Embodiment 1

[0021] like figure 2 As shown, the rear side wall inner panel assembly structure of this embodiment includes a rear side wall inner panel 11, a D-pillar upper inner panel 12, a D-pillar inner panel 13, a D-pillar lower inner panel 14, and a rear wheel house inner panel 15. , rear wheel house outer panel 16 and D pillar reinforcing plate. The D-pillar upper inner panel 12, D-pillar inner panel 13, and D-pillar lower inner panel 14 are sequentially welded to form the D-pillar inner panel assembly, and the lower corner of the D-pillar inner panel assembly is welded to the rear wheelhouse inner panel 15, The rear wheel house outer plate 16 is welded with the rear wheel house inner plate 15 and the rear side wall inner plate 11 respectively.

[0022] The assembly structure of this embodiment is beneficial to optimize the punching and shaping process of the inner panel of the rear side wall, and reduces the mold cost. In this embodiment, the D-pillar inner panel is divided into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com