Working method of four-way industrial thermostat with tube heater

A technology of tubular heaters and working methods, applied in instruments, temperature control, mechanical equipment, etc., can solve problems such as damage, failure of hydraulic system components, low temperature of hydraulic system oil, etc., to extend service life and ensure stability Operational, highly reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

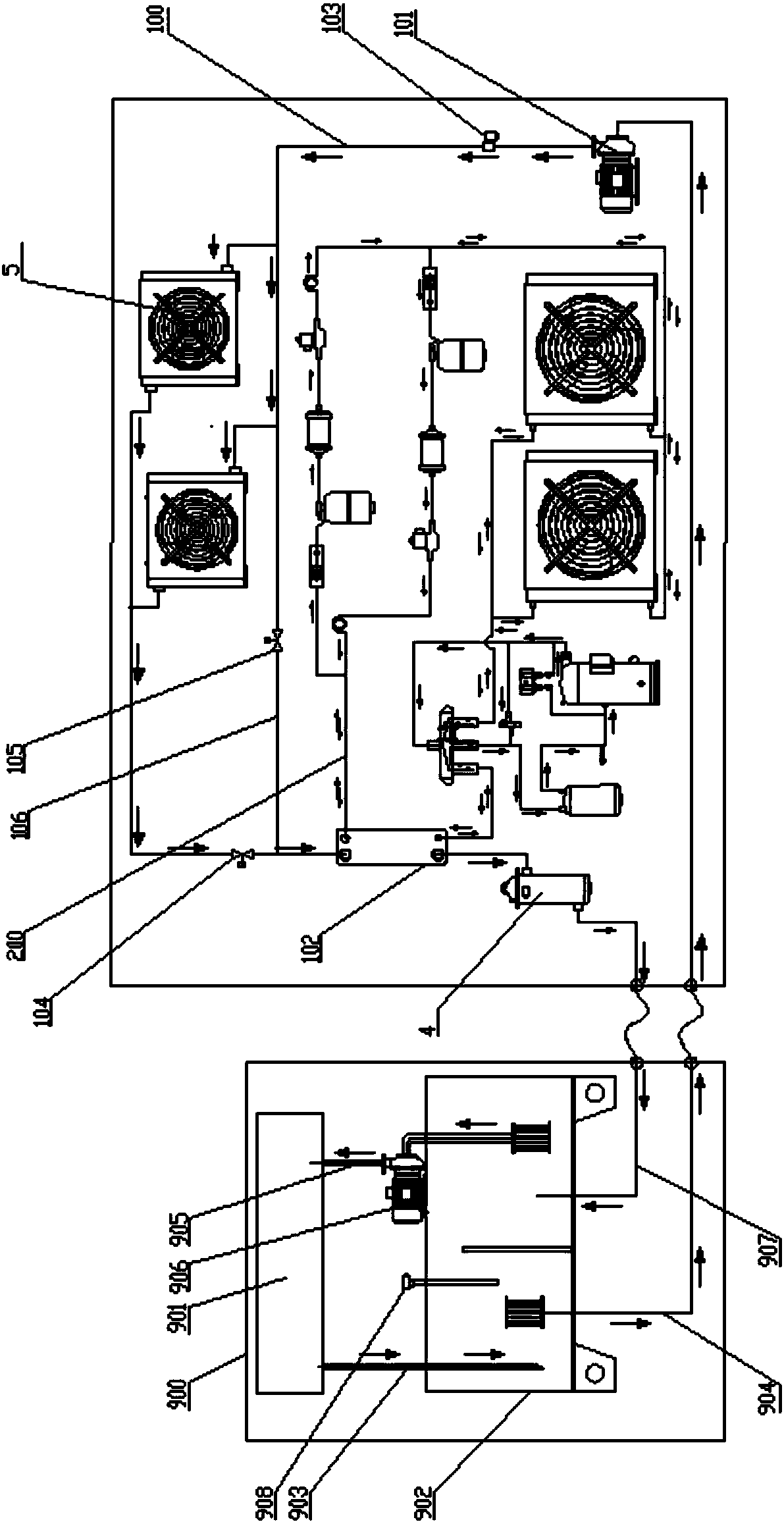

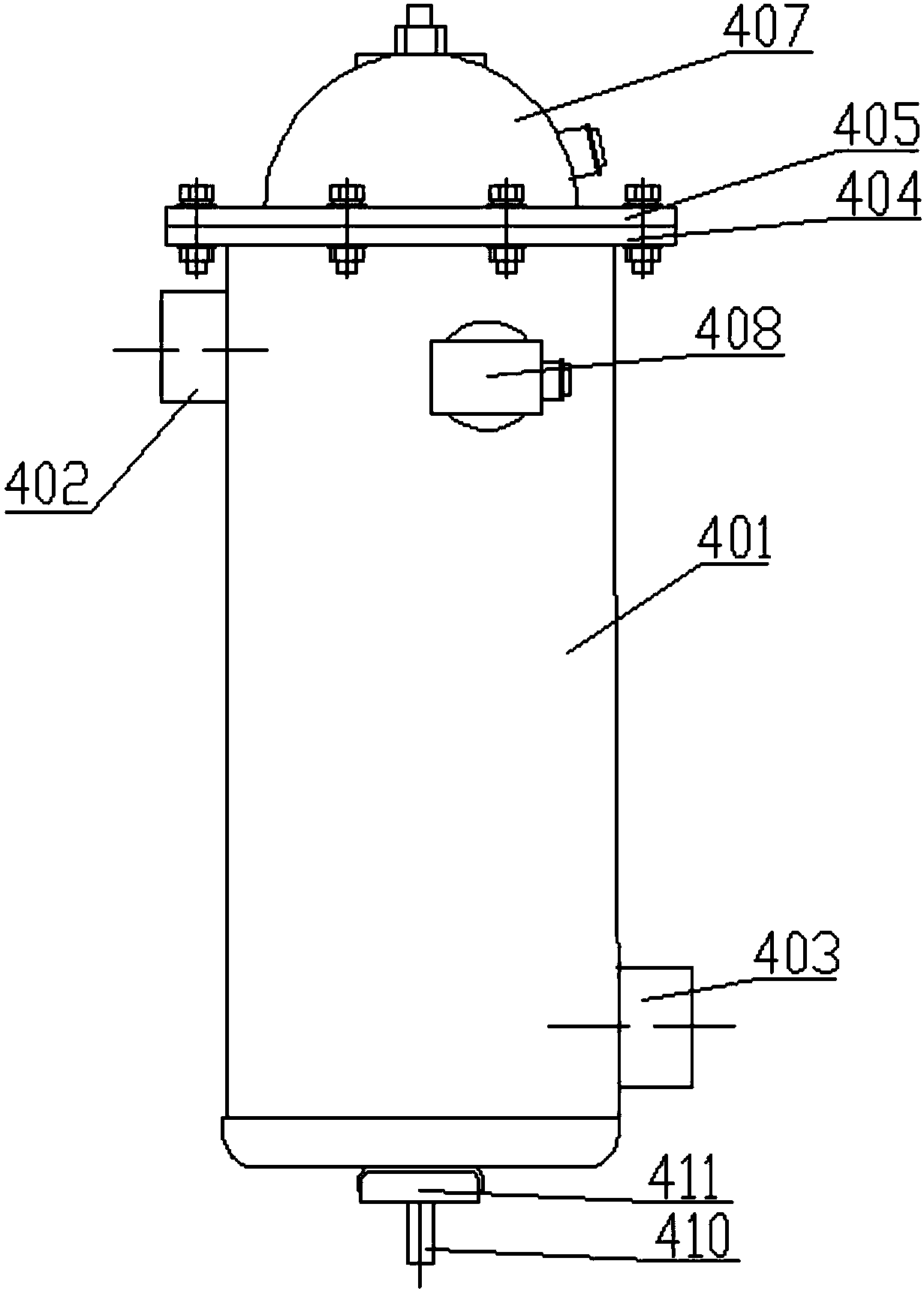

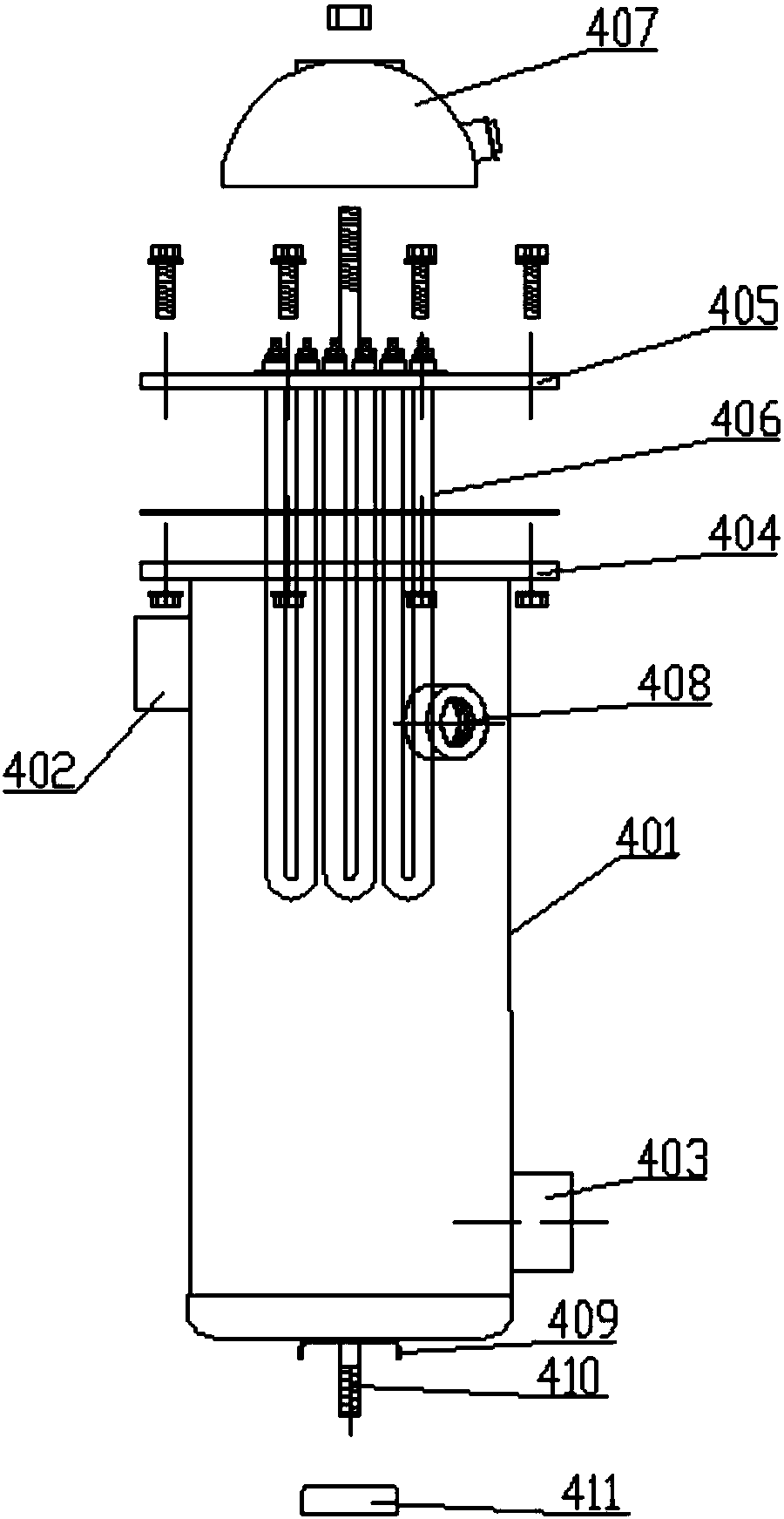

[0052] see Figure 1 to Figure 9 , the present invention relates to a four-way industrial constant temperature machine with a tube heater, which includes a hydraulic oil delivery pipeline 100, and the hydraulic oil delivery pipeline 100 is connected from the hydraulic oil inlet to the hydraulic oil outlet. A hydraulic oil delivery pipeline delivery pump 101, a radiator 5, a heat exchange device and a tubular heater are arranged in sequence between the ports, a cooling fan is arranged on one side of the radiator 5, and a piston is arranged in parallel on the oil circuit at both ends of the radiator 5. pressure relief valve 6,

[0053] Wherein the hydraulic oil delivery pipeline 100 in front of the radiator 5 is also provided with a hydraulic oil delivery pipeline temperature sensor 103, and the hydraulic oil delivery pipeline 100 between the radiator 5 and the heat exchange device 102 is provided with a hydraulic oil delivery pipeline The first solenoid valve 104, the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com