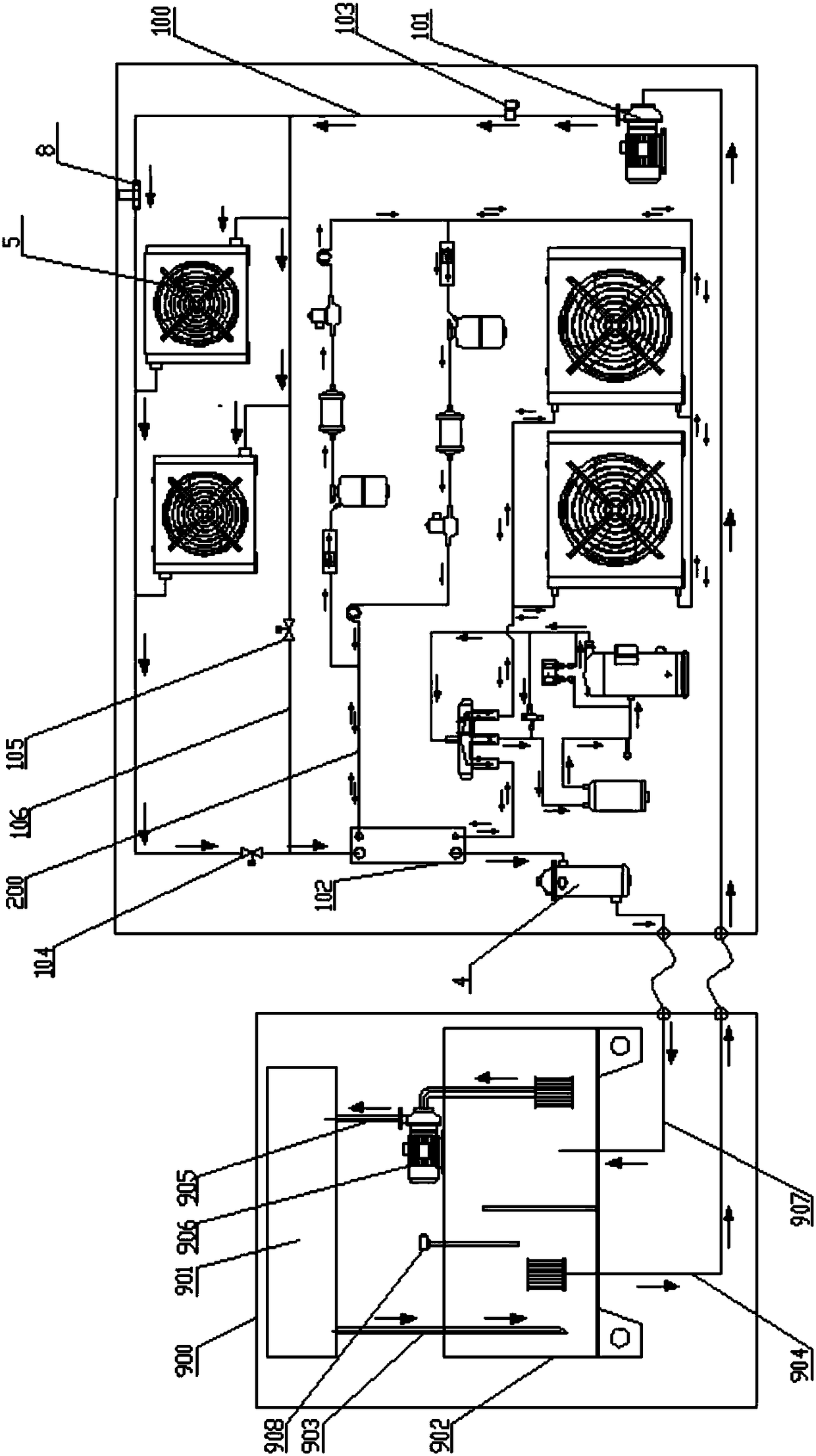

Working method of temperature control industrial thermostat for hydraulic bypass with spherical pressure relief valves

A working method and technology of pressure relief valve, applied in the direction of temperature control, mechanical equipment, servo meter circuit, etc., can solve the problems of easy damage of radiators, scrapping, unbalanced flow, exceeding the radiator, etc., to prolong the service life and guarantee The effect of stable operation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

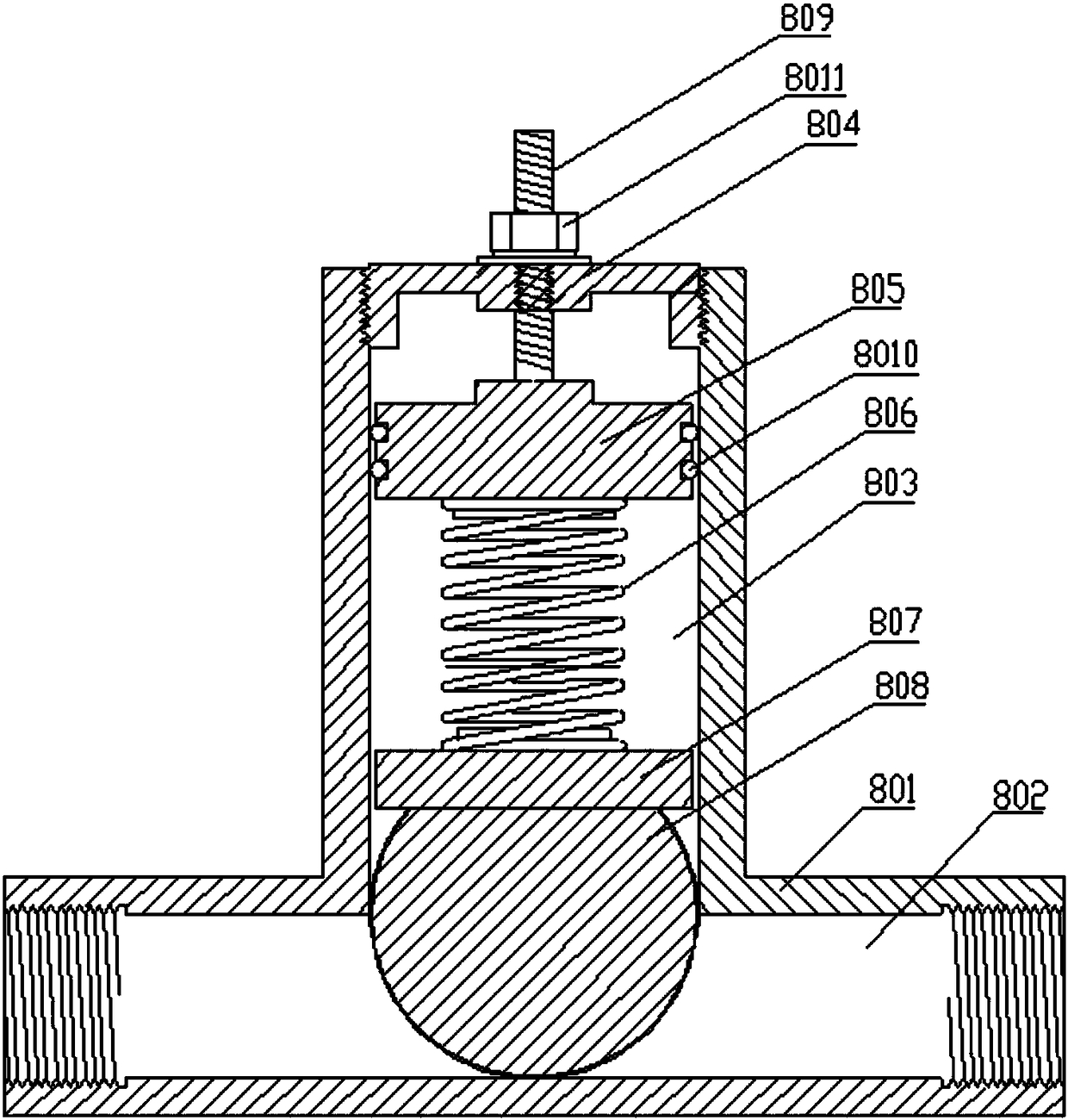

[0078] Example 1. When the liquid flows from left to right and the main hydraulic circuit is blocked, the pressure at the left end of the ball pressure relief valve is greater than the pressure at the right end, because the pressure in the fluid channel on the left side of the ball is greater than the pressure in the fluid channel on the right side of the ball Pressure, the fluid pushes the ball upwards, the bottom of the ball forms a space for the fluid to move, the fluid moves from left to right in the fluid channel, so as to achieve the purpose of pressure relief, until the pressure on the left and right sides of the ball is equal, the ball returns to its original position position, the main hydraulic circuit returns unobstructed.

Embodiment 2

[0079] Example 2. When the liquid flows from left to right and the hydraulic main road is blocked, the pressure at the right end of the ball relief valve is greater than the pressure at the left end, because the pressure in the fluid channel on the right side of the ball is greater than the pressure in the fluid channel on the left side of the ball Pressure, the fluid pushes the ball upwards, the bottom of the ball forms a space for the fluid to move, the fluid moves from right to left in the fluid channel, so as to achieve the purpose of pressure relief, until the pressure on the left and right sides of the ball is equal, the ball returns to its original position position, the main hydraulic circuit returns unobstructed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com